CarbonXtreme Post

Strength-to-Weight Showdown: Carbon Fiber, Steel, and Aluminum Compared

The strength-to-weight ratio is a crucial metric when selecting materials for high-performance applications. Carbon fiber stands out for its exceptional strength-to-weight ratio, making it the preferred choice in industries like aerospace, automotive, and renewable energy. While carbon fiber offers superior performance in terms of lightness and strength, it comes at a higher cost compared to materials like steel and aluminum. Steel is durable and cost-effective but heavier, while aluminum offers a balance of lightness and moderate strength. Engineers must consider the specific needs of their projects—whether it’s maximizing strength, reducing weight, or balancing cost—when choosing between these materials.

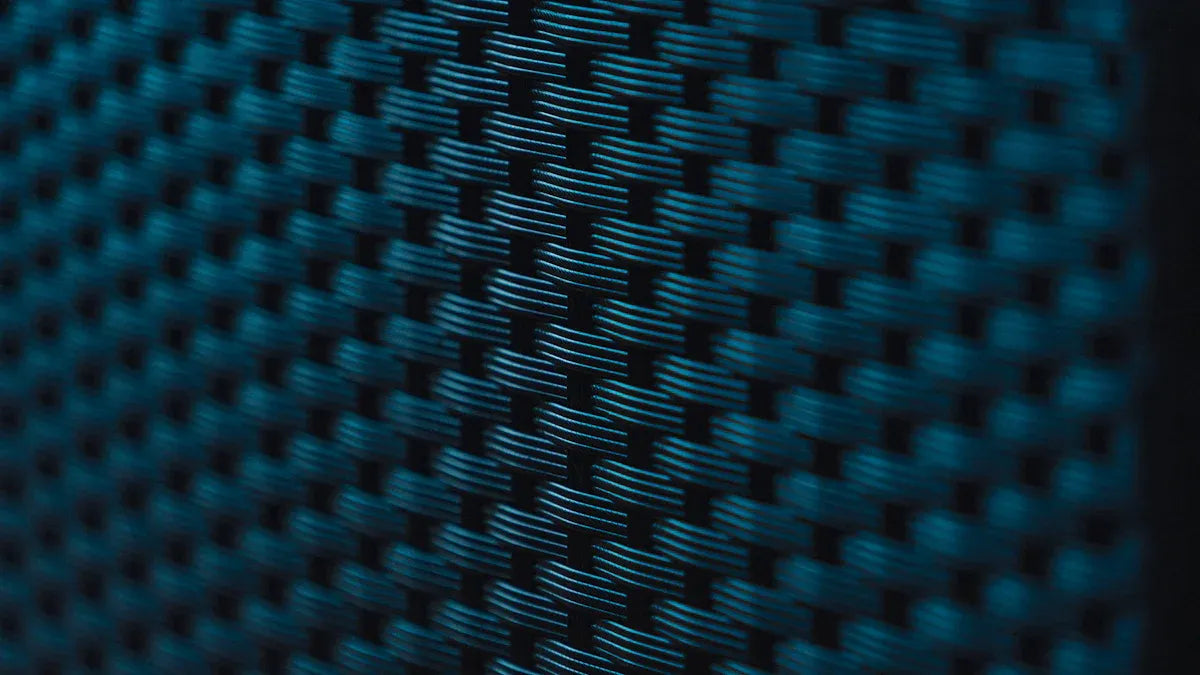

2×2 Twill vs Plain Weave Carbon Fiber: Key Differences and Best Uses

When deciding between 2×2 twill and plain weave carbon fiber, it's essential to consider the specific needs of your project. Plain weave offers superior strength and stability, making it ideal for flat, load-bearing components. Its tightly woven structure provides high durability, especially in high-wear environments. In contrast, 2×2 twill weave offers enhanced flexibility, a visually appealing diagonal pattern, and better adaptability to complex shapes, making it great for curved parts or those that need a premium finish. Understanding the differences between these weaves allows engineers and designers to select the optimal material for performance, aesthetic, and cost requirements.

What You Need to Know About Carbon Fiber Weave Types

In 2025, carbon fiber weave types play a critical role in enhancing the performance, durability, and aesthetics of products across industries, particularly in automotive, sports, and medical applications. The three main weave types—plain, twill, and satin—each offer distinct advantages depending on the requirements. Plain weave provides high strength and durability for technical parts, while twill weave balances flexibility with strength, ideal for curved components. Satin weave, with its glossy appearance, excels in luxury and complex shapes but is less durable. Engineers must carefully select the right weave type for specific applications, taking into account strength, flexibility, and aesthetics.

Comparing Carbon Fiber Tensile Strength to Steel and Aluminum

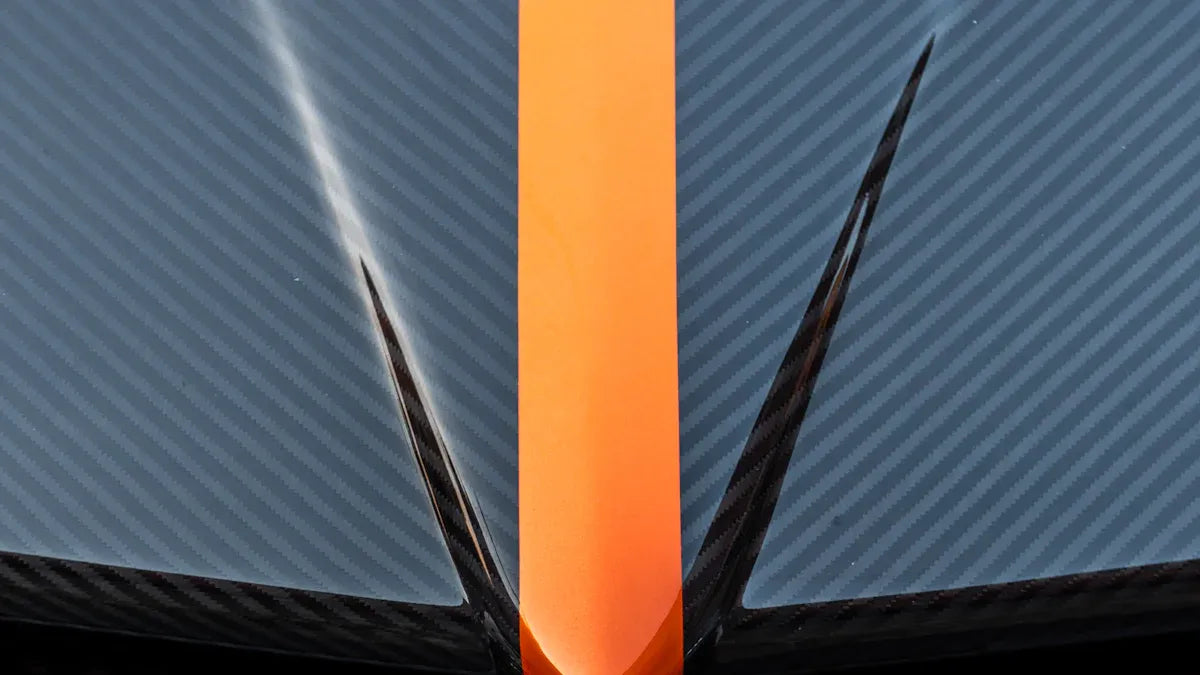

In 2025, carbon fiber continues to lead the way in automotive and aerospace applications, offering significant benefits like reduced weight, improved strength, and enhanced performance. Racing cars, especially in Formula 1, GT3, and rally, utilize carbon fiber for its unmatched strength-to-weight ratio, allowing for faster acceleration, better handling, and superior heat resistance. Aerospace and high-performance vehicles also rely on carbon fiber for structural integrity and fuel efficiency. Although carbon fiber comes with a higher price tag due to its complex manufacturing process, its performance benefits, including fuel savings, longevity, and safety improvements, make it the material of choice for applications where weight and strength are paramount.

Why Dry Carbon Fiber Is Revolutionizing Racing Cars in 2025

In 2025, carbon fiber remains at the forefront of motorsport engineering, delivering performance benefits like reduced weight, enhanced strength, and increased rigidity. Teams in Formula 1, GT3, and rally racing leverage dry carbon fiber to achieve a 25% weight reduction, which translates to faster lap times, improved handling, and better fuel efficiency. With its ability to resist heat, corrosion, and mechanical stress, carbon fiber components—ranging from chassis to aerodynamic parts—help cars perform at the highest levels while reducing environmental impact through sustainable manufacturing practices. The future of racing and high-performance vehicles depends on the continued evolution of carbon fiber technology.

How Carbon Fiber Motorsport Applications Enhance Aerodynamics and Handling

In 2025, carbon fiber continues to dominate motorsport and automotive engineering, enhancing performance, safety, and sustainability. Racing vehicles like Formula 1, GT3, and rally cars use carbon fiber for superior weight savings, rigidity, and aerodynamics, enabling faster lap times and more precise handling. The material’s strength-to-weight ratio is critical in parts such as chassis, front splitters, and suspension arms. While carbon fiber is also increasingly used in street cars, the focus is on balancing cost, durability, and performance. Innovations in manufacturing methods and the use of sustainable materials are driving further adoption, making carbon fiber more accessible and eco-friendly.

Carbon Fiber for Racing vs Street Cars: What the Numbers Show in 2025

In 2025, carbon fiber continues to be a game-changer for both racing and street vehicles, though its application differs significantly between the two. Racing vehicles like Formula 1 and GT3 use carbon fiber for extreme weight savings and rigidity, crucial for performance. These cars benefit from carbon fiber's strength-to-weight ratio, allowing for rapid acceleration, high speeds, and superior handling. Street vehicles, on the other hand, use hybrid carbon fiber constructions that offer a balance between performance, durability, and cost-effectiveness. The growing adoption of carbon fiber in electric vehicles signals its increased use in mass-market applications. While carbon fiber enhances both racing and street car performance, it requires a higher investment and expertise for maintenance, with new technologies and manufacturing methods helping to reduce costs and improve sustainability.

Key Differences Between Autoclave and Oven Curing for Carbon Fiber

The decision between autoclave and out-of-autoclave curing processes in carbon fiber molding depends on performance, cost, and the required quality of the final product. Autoclave curing provides superior quality by applying both high temperature and pressure, reducing voids and enhancing mechanical properties. However, it comes with high costs and size limitations. On the other hand, out-of-autoclave curing is more cost-effective, supports larger parts, and is accessible to smaller manufacturers, but it generally results in higher void content and slightly lower performance. Manufacturers must consider factors like part size, quality demands, and budget when choosing the appropriate process.

Comparing Common Defects in Carbon Fiber Molding with Autoclave and Out-of-Autoclave Methods

Autoclave and out-of-autoclave molding processes each come with distinct benefits and challenges. Autoclave molding ensures high-quality carbon fiber parts with fewer defects, thanks to uniform pressure and temperature control. However, it requires significant investment and limits part size. In contrast, out-of-autoclave molding is more cost-effective, offering flexibility for larger parts, but it tends to introduce more defects, such as porosity, delamination, and fiber misalignment, due to lower pressure and more environmental sensitivity. Manufacturers need to consider factors like part size, performance requirements, cost, and defect control when choosing a method.