You now see the automotive industry pushing boundaries in 2025, demanding lighter, faster, and more efficient race cars. Teams rely on dry carbon fiber in racing cars to achieve this edge. The latest industry data shows a 25% reduction in weight and up to 15% better lap times, reshaping performance benchmarks:

|

Metric |

Statistic / Projection for 2025 |

Description |

|---|---|---|

|

Weight Reduction |

Estimated 25% |

Use of advanced materials like carbon nanotubes to reduce vehicle weight by about 25%, enhancing speed without compromising safety. |

|

Performance Improvement |

15% better braking and lap times |

Advanced technologies expected to improve braking distance and lap times by 15% compared to combustion engines. |

You benefit from carbon fiber’s unmatched strength and heat resistance, whether in F1, GT3, or rally. Dry carbon fiber sets a new standard for structural integrity, driver safety, and efficiency on every circuit.

Key Takeaways

-

Dry carbon fiber cuts racing car weight by about 25%, boosting speed and handling without losing strength.

-

Its high strength-to-weight ratio makes cars faster, safer, and more efficient on the track.

-

The precise manufacturing process creates stronger, lighter parts that improve durability and performance.

-

Dry carbon fiber resists heat and wear, keeping cars reliable during intense races and harsh conditions.

-

Using dry carbon fiber helps reduce fuel use and emissions, supporting greener and more sustainable racing.

Demands in Racing Cars

Weight and Speed

In racing, every gram matters. You need materials that reduce weight without compromising strength. Dry carbon fiber excels in this area, offering the highest strength-to-weight ratio among modern materials. Its lightweight nature lowers the center of gravity, enhancing stability and handling during high-speed cornering. Components like chassis, suspension systems, and brake rotors made from carbon fiber reduce unsprung mass, allowing faster suspension response and better tire contact.

|

Material Type |

Strength-to-Weight Ratio (kN·m/kg) |

Impact on Racing Performance |

|---|---|---|

|

Carbon Fiber Reinforced Polymer |

175 ± 25 |

Enables lighter, stronger components that improve acceleration and handling |

|

Aluminum |

27.5 ± 2.5 |

Heavier and less efficient for racing applications |

|

Steel |

15 ± 5 |

Lowest ratio, unsuitable for high-speed racing |

Weight reduction also improves fuel efficiency and lap times. Racing teams in F1 and GT3 leverage carbon fiber to optimize aerodynamic shapes, increasing downforce and reducing drag. These advancements directly translate to quicker acceleration and better cornering performance, giving you the competitive edge.

Durability

Durability is non-negotiable in motorsports. Racing cars endure extreme mechanical stresses, from high G-forces to intense vibrations. Dry carbon fiber provides unmatched stiffness and fatigue resistance, ensuring structural integrity under dynamic loads. Its minimal thermal expansion prevents warping, even during prolonged races.

-

Key durability metrics:

-

High stiffness and tensile strength maintain performance under stress.

-

Superior wear resistance ensures longevity in critical components like suspension arms and brake discs.

-

Lightweight properties reduce strain on other parts, extending overall vehicle lifespan.

-

Carbon fiber’s durability makes it ideal for endurance racing, where reliability is as crucial as speed. For example, rally cars equipped with carbon fiber components withstand harsh terrains and extreme conditions, proving their resilience in real-world applications.

Heat Resistance

Heat management is vital in racing. Engines, brakes, and other components generate extreme temperatures during competition. Dry carbon fiber’s thermal stability ensures it performs reliably under these conditions. Pistons in high-performance engines often exceed 300°C, requiring materials that maintain integrity. Carbon fiber’s ability to dissipate heat efficiently prevents overheating and mechanical failure.

-

Thermal testing replicates extreme temperature fluctuations to evaluate material behavior.

-

Wheel force transducers measure dynamic forces during races, complementing thermal tests to optimize performance.

-

Advanced synthetic fibers like Nomex® in racing suits protect drivers from temperatures up to 300°C, ensuring safety and comfort.

Dry carbon fiber’s heat resistance extends to chassis frames and suspension systems, enabling consistent performance in endurance races like the 24 Hours of Le Mans. Its ability to handle thermal stress while remaining lightweight makes it indispensable in modern racing car design.

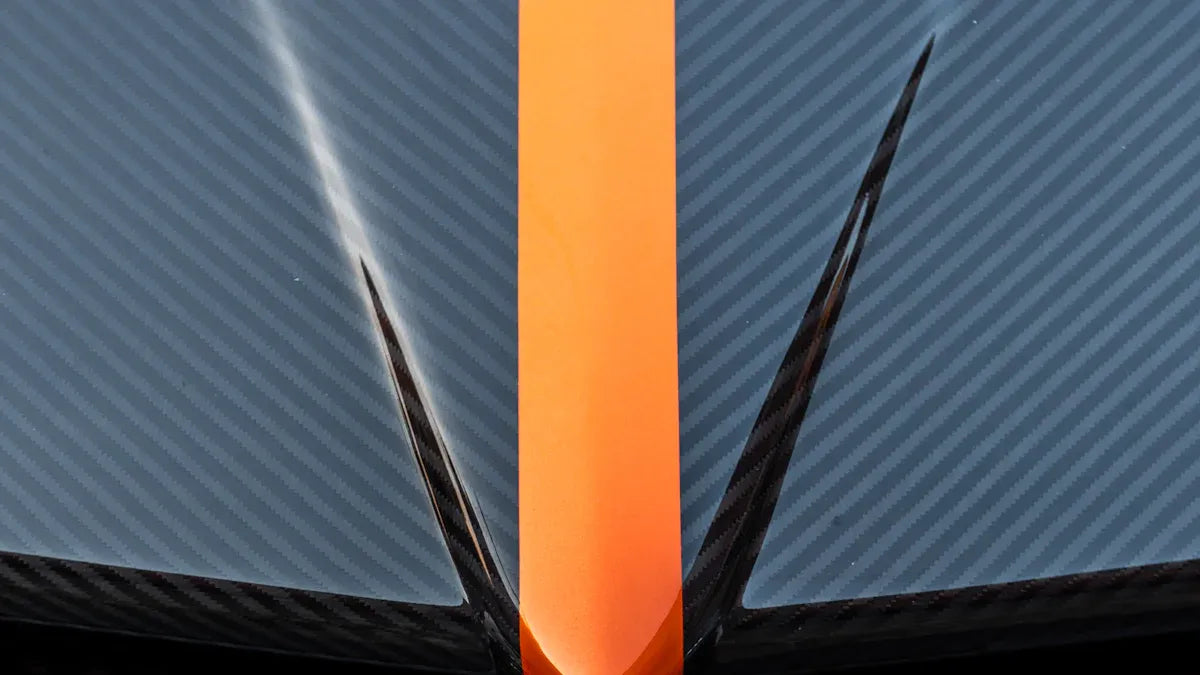

Dry Carbon Fiber in Racing Cars

Manufacturing Process

You see the difference in racing performance start with the manufacturing process. Dry carbon fiber in racing cars uses a pre-preg technique, where carbon fiber cloth is pre-impregnated with a precise amount of resin. This process gives you unmatched control over resin content, which is critical for producing a lightweight composite structure with superior strength.

During production, you place the pre-preg carbon fiber into molds and cure it in an autoclave. The autoclave applies high temperature and pressure, eliminating air pockets and impurities. This step ensures a flawless finish and maximizes the mechanical properties of the final part. Automation, such as Automated Fiber Placement (AFP) systems, further enhances quality. These systems control fiber orientation, compaction, and resin flow with real-time monitoring. You benefit from reduced porosity, minimal thickness variation, and a higher fiber volume fraction. For example, AFP preforms can lower porosity from 2.00% to 0.6% and increase fiber volume fraction from 47.80% to 56.30%. This level of precision means you get stronger, lighter, and more consistent carbon fiber composites compared to traditional wet layup methods.

Tip: The pre-preg and autoclave process in dry carbon fiber manufacturing delivers parts that are both lighter and stronger, giving you a clear advantage on the track.

Strength-to-Weight Ratio

When you choose dry carbon fiber in racing cars, you unlock a high strength-to-weight ratio that outperforms both wet carbon fiber and traditional metals. This property is essential for racing, where every gram counts and every bit of strength matters. Dry carbon fiber can be up to 60% stronger and 60% lighter than wet carbon fiber. Compared to steel, carbon fiber is about ten times stronger by weight, while weighing only a quarter as much. Against aluminum, carbon fiber offers twice the tensile strength at half the weight.

|

Material Comparison |

Strength Improvement |

Weight Improvement |

|---|---|---|

|

Dry Carbon Fiber vs Wet Carbon Fiber |

Up to 60% stronger |

Up to 60% lighter |

|

Carbon Fiber vs Steel |

~10x stronger by weight |

1/4 the weight |

|

Carbon Fiber vs Aluminum |

2x tensile strength |

1/2 the weight |

You see these advantages play out in F1 and GT3, where teams use dry carbon fiber for monocoques, wings, and suspension arms. The result is a car that accelerates faster, brakes harder, and corners with greater precision. The high strength-to-weight ratio also means you can push the limits of design, creating aerodynamic shapes that maximize downforce without adding unnecessary mass.

Structural Rigidity

Structural rigidity defines how well your car responds to the stresses of racing. Dry carbon fiber delivers exceptional stiffness, which translates to sharper handling and improved safety. The tightly controlled resin content and fiber orientation in dry carbon fiber composites ensure that each component resists flexing and deformation under load.

You experience the benefits of this rigidity in every corner and straightaway. In F1, the carbon fiber monocoque protects drivers by absorbing and dissipating crash energy. In rally, the chassis and suspension components made from dry carbon fiber withstand rough terrain and high-impact forces without losing shape. This rigidity also allows engineers to fine-tune suspension geometry, giving you more predictable handling and better tire contact with the road.

-

Key advantages of structural rigidity in dry carbon fiber:

-

Enhanced driver safety through superior crash protection.

-

Improved handling due to reduced chassis flex.

-

Consistent aerodynamic performance, even at high speeds.

-

Dry carbon fiber in racing cars sets a new benchmark for structural integrity. You gain a competitive edge with components that are not only lighter but also more robust and reliable than ever before.

Benefits of Dry Carbon Fiber

Performance Gains

Dry carbon fiber in racing cars delivers measurable performance improvements by significantly reducing vehicle weight. When you replace heavier materials like steel or aluminum with dry carbon fiber, you unlock faster acceleration and better lap times. Weight reduction directly impacts how quickly your car can reach top speeds and respond to driver inputs.

|

Metric |

Before Modification |

After Modification |

Improvement |

|---|---|---|---|

|

Vehicle Weight |

2,685 lbs |

2,060 lbs |

-625 lbs |

|

0-60 mph Acceleration |

8.1 seconds |

6.3 seconds |

1.8 seconds faster |

|

1/4 Mile Acceleration |

15.92 seconds |

14.86 seconds |

1.06 seconds faster |

This table highlights the tangible benefits of weight reduction achieved through dry carbon fiber components. By shedding 625 pounds, you gain nearly two seconds in 0-60 mph acceleration and over a second in quarter-mile times. These improvements translate to faster lap times and a competitive edge on the track.

Dry carbon fiber also enhances aerodynamics. Its lightweight properties allow engineers to design complex shapes that maximize downforce without adding unnecessary mass. You experience quicker cornering and improved stability at high speeds, making dry carbon fiber indispensable for modern racing cars.

Handling and Efficiency

Handling defines how well your car responds to driver inputs, and dry carbon fiber elevates this aspect to new heights. Its structural rigidity minimizes chassis flex, ensuring precise steering and predictable cornering. You feel the difference in every turn, as your car maintains optimal tire contact with the road.

Dry carbon fiber components, such as suspension arms and brake rotors, reduce unsprung mass. This reduction allows your suspension system to react faster to road conditions, improving grip and stability. Whether you’re navigating tight corners in GT3 or tackling rough terrain in rally racing, dry carbon fiber ensures your car performs consistently under pressure.

Efficiency gains extend beyond handling. Weight reduction improves fuel economy, allowing you to complete more laps with less fuel. This advantage is critical in endurance races like the 24 Hours of Le Mans, where every ounce of saved weight contributes to better overall performance. Dry carbon fiber in racing cars optimizes both speed and resource consumption, making it a game-changer for motorsports.

Tip: Investing in dry carbon fiber components not only enhances handling but also reduces long-term maintenance costs due to their durability and wear resistance.

Environmental Impact

Dry carbon fiber offers significant environmental benefits by reducing manufacturing waste and energy consumption. Life cycle assessment studies show that carbon fiber composites save approximately 20% in weight compared to metals like aluminum. This weight savings leads to lower fossil fuel consumption and reduced CO2 emissions over the product’s life cycle.

Although manufacturing dry carbon fiber is energy-intensive, advancements in production methods are minimizing its environmental footprint. For example, alternative approaches to carbon fiber production reduce energy-intensive steps, lowering overall impacts. By choosing dry carbon fiber, you contribute to a more sustainable racing industry while benefiting from superior performance.

Dry carbon fiber also generates less waste during manufacturing. Precise resin control in the pre-preg process ensures minimal material loss, unlike traditional wet layup methods. This efficiency reduces the environmental burden and aligns with the motorsport industry’s push for greener technologies.

Note: While dry carbon fiber manufacturing requires significant energy, its long-term benefits in fuel savings and reduced emissions outweigh initial production costs.

Carbon Fiber vs. Traditional Materials

Steel and Aluminum

You often see steel and aluminum in traditional racing car construction. These metals offer reliability and ease of manufacturing. However, they add significant weight to your vehicle. Steel provides strength but lacks the lightweight advantage you need for top-tier racing. Aluminum reduces weight compared to steel, but it cannot match the performance of carbon fiber composites. When you use dry carbon fiber, you achieve a dramatic reduction in mass while maintaining superior strength. This shift allows you to design cars that accelerate faster and handle better. In automotive applications, dry carbon fiber also resists corrosion, which extends the lifespan of critical components.

|

Material |

Density (g/cm³) |

Tensile Strength (MPa) |

Application Benefit |

|---|---|---|---|

|

Steel |

7.85 |

400–550 |

Strong but heavy |

|

Aluminum |

2.70 |

200–550 |

Lighter, less rigid |

|

Dry Carbon Fiber |

1.60 |

3,500+ |

Lightest, strongest option |

Dry carbon fiber gives you the best balance of weight and strength for racing.

Wet Carbon Fiber

Wet carbon fiber uses a hand layup process that introduces more resin and air pockets. This method creates heavier and less consistent parts. When you choose dry carbon fiber, you benefit from precise resin control and fewer voids. The result is a lighter, stiffer, and more reliable component. Dry carbon fiber composites outperform wet carbon fiber in every critical racing metric. You notice improved lap times, better heat resistance, and greater durability. Teams that switch to dry carbon fiber see immediate gains in both performance and safety.

Real-World Racing Use

You witness the impact of dry carbon fiber across the world’s top racing series. Formula 1 teams rely on dry carbon fiber for monocoques, wings, and suspension arms. In GT3, engineers use carbon fiber composites to optimize aerodynamics and reduce unsprung mass. The World Endurance Championship (WEC) features cars built almost entirely from dry carbon fiber, allowing for unmatched speed and resilience during long-distance events. Rally teams also trust dry carbon fiber to withstand harsh impacts and extreme conditions. These real-world examples prove that dry carbon fiber is not just a material upgrade—it is a revolution in racing car engineering.

You now see carbon fiber redefining what is possible in racing car engineering for 2025. Teams in F1, GT3, and rally rely on carbon fiber for unmatched weight reduction, structural integrity, and heat resistance. You benefit from cars that accelerate faster, handle better, and offer superior safety.

-

Market projections show carbon fiber wheel hub caps growing at a 15% CAGR through 2033, driven by lightweighting and customization trends.

-

Advancements in recycled carbon fiber and eco-friendly manufacturing support sustainability goals.

-

The automotive market for carbon fiber is expected to reach $9.12 billion by 2033, fueled by demand for high-performance vehicles.

You can expect carbon fiber to remain at the forefront of motorsport innovation, shaping the next generation of racing excellence.

Share:

Why Carbon Fiber Is the Backbone of Modern F1 Cars

Carbon Fiber for Racing vs Street Cars: What the Numbers Show in 2025