CarbonXtreme Post

How Carbon Fiber Stacks Up Against Steel and Aluminum in Performance Cars

Carbon fiber has become the material of choice for high-performance road cars due to its exceptional strength-to-weight ratio, offering significant improvements in handling, acceleration, and overall performance. However, its high cost and repair challenges can influence material selection for different parts of a vehicle. Steel and aluminum remain popular alternatives, with steel providing durability at a low cost, and aluminum offering a balance between weight savings and cost efficiency. As the automotive industry continues to innovate, carbon fiber's role in electric vehicles and sustainable manufacturing is expected to grow.

How Curing Time and Method Affect Carbon Fiber Performance

The curing process is essential for ensuring the strength, durability, and reliability of carbon fiber composites, particularly in industries like aerospace. Proper curing time and method, such as autoclave curing, play a crucial role in achieving optimal resin bonding and preventing defects. Under-curing weakens bonding, while over-curing leads to brittleness. Strict control of curing parameters, including temperature, pressure, and humidity, is vital for producing high-quality carbon fiber parts. Advanced simulation and testing methods help engineers optimize curing cycles for specific applications.

Best Mold Materials for Carbon Fiber Production: What Works and Why

When selecting the best mold materials for carbon fiber production, you must consider factors like strength, heat resistance, surface finish, and cost. Aluminum and steel provide durability and precision, ideal for high-volume or complex parts. Fiberglass and composites offer lightweight, cost-effective solutions for prototypes and custom shapes. Silicone, epoxy boards, and 3D-printed molds offer flexibility and ease of shaping for small runs or intricate parts. Matching mold materials to your project's needs ensures optimal results for both quality and cost-effectiveness.

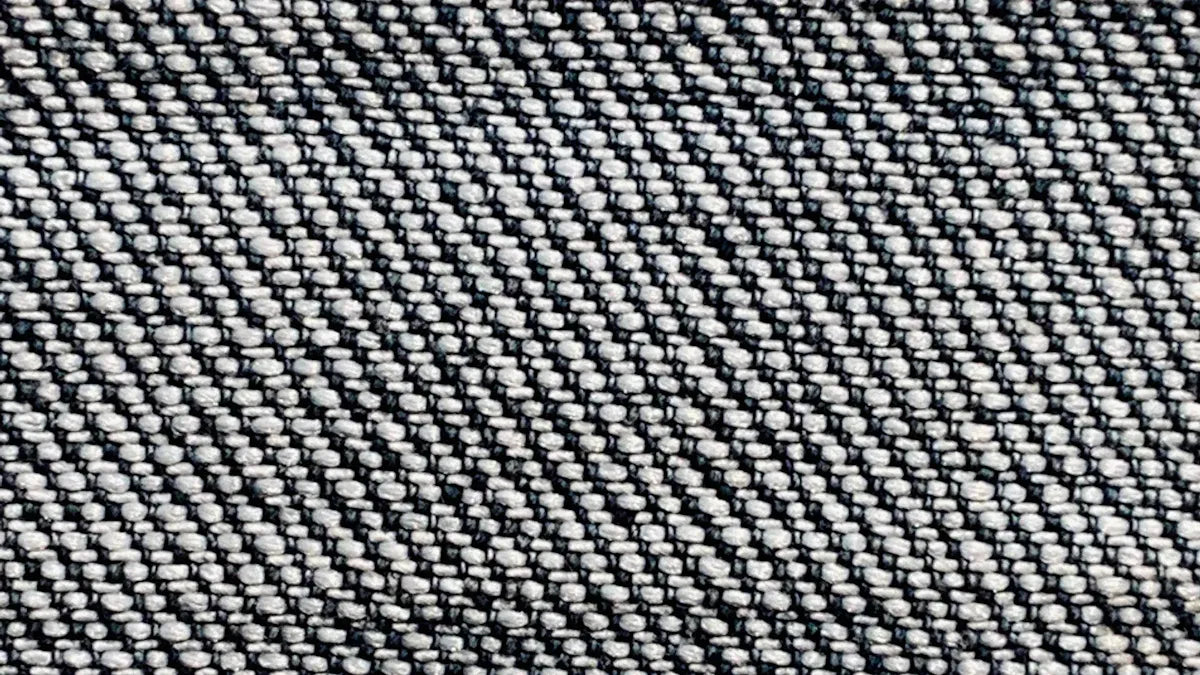

Understanding Carbon Fiber Weave Patterns and Their Key Differences

Choosing the right carbon fiber weave pattern—plain, twill, or satin—depends on the specific requirements of your application. Plain weave offers stability and strength, making it ideal for flat panels and structural components, while twill weave provides flexibility and a modern appearance, suitable for molded parts. Satin weave delivers superior drapability and a glossy finish, making it perfect for intricate designs and luxury applications. Engineers tailor these patterns to achieve the optimal balance of strength, flexibility, and appearance, ensuring the material meets the functional and aesthetic demands of each project.

Carbon Fiber Stiffness vs Flexibility: What Matters Most for Performance?

When choosing between carbon fiber stiffness vs flexibility, it’s essential to understand the specific needs of your application. Carbon fiber excels in performance due to its high stiffness-to-weight ratio, providing excellent rigidity for aerospace, automotive, and racing applications. Flexibility, however, plays a critical role in components requiring controlled movement and shock absorption, such as sports equipment and wearable devices. By adjusting fiber orientation, layering, and resin types, engineers can tailor carbon fiber to meet the precise demands of various applications, ensuring the best balance between strength, weight, and flexibility.

Track-Tested Carbon Fiber vs Aftermarket: Which Performs Better on the Track?

Track-tested carbon fiber delivers superior performance in motorsports and high-performance applications, offering proven strength, lightweight design, and durability. Unlike aftermarket carbon fiber, which may vary in quality and fitment, track-tested carbon fiber undergoes rigorous testing, ensuring reliability under the stresses of racing. It provides measurable performance improvements such as faster acceleration, sharper handling, and reduced energetic cost. Although aftermarket carbon fiber parts can be more affordable, they may compromise durability and performance, making track-tested options the best choice for professional use.

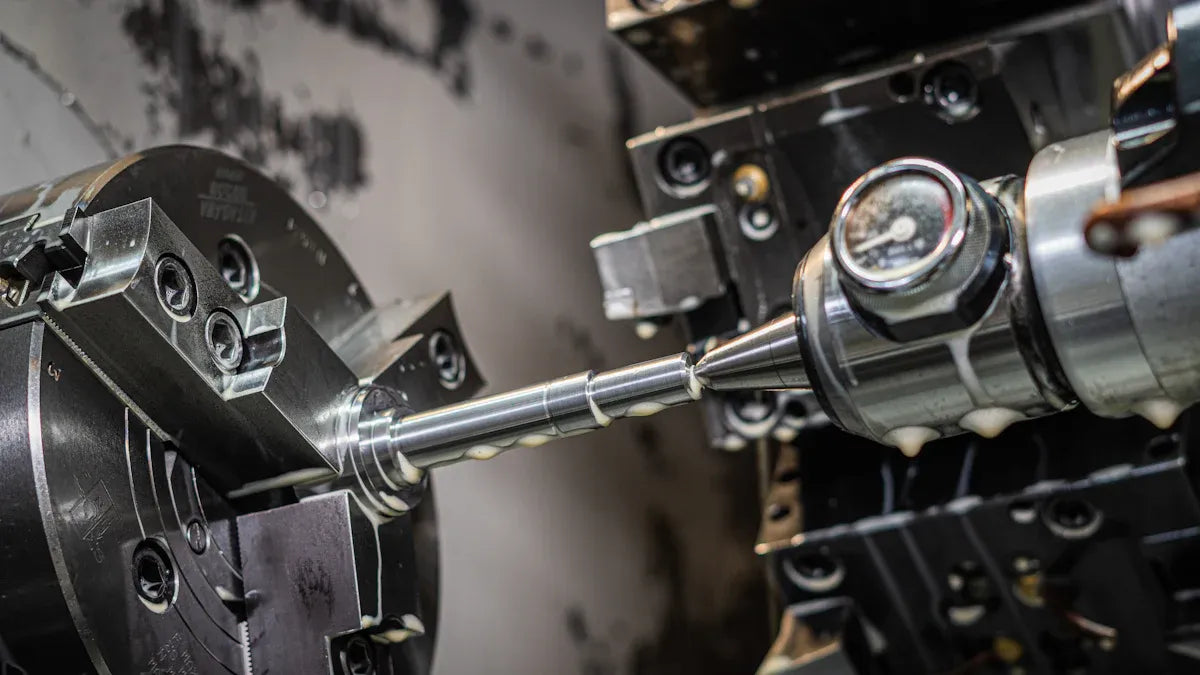

How Carbon Fiber Part Tolerance and Fitment QA Stacks Up Against Metal in Real Life

Precision is essential in engineering, especially when working with advanced materials like carbon fiber and metals. Both materials pose unique challenges for dimensional accuracy and functional performance, particularly in aerospace and automotive applications. Carbon fiber's anisotropic properties and the curing process introduce complexities in tolerance, while metals offer more predictable machining and tighter tolerances. Engineers must employ advanced inspection methods, such as CNC machining, coordinate measuring machines (CMM), and non-destructive testing (NDT), to ensure that parts fit properly and perform reliably. Managing variability, warping, and inspection difficulties requires careful process control, monitoring, and use of modern technologies to achieve precise, high-quality results.

Handmade vs Autoclave Carbon Fiber: Differences Explained

The key difference between handmade and autoclave carbon fiber lies in the curing process. Handmade carbon fiber uses lower temperatures and no high pressure, making it ideal for prototypes, custom shapes, and low-volume projects. Autoclave carbon fiber, on the other hand, uses high heat and pressure, producing stronger, more consistent parts with a smooth finish, perfect for critical applications like aerospace and medical parts. Autoclave curing ensures higher strength, fewer voids, and better performance but comes with higher costs. Handmade methods offer flexibility and cost savings but may not achieve the same level of strength and finish.

How to Spot Delamination in Carbon Fiber Composites

Delamination in carbon fiber composites can significantly weaken components, leading to failure if not detected early. Regular inspections using methods like visual checks, tap tests, and physical checks help identify surface and hidden damage. Non-destructive testing (NDT) techniques such as ultrasonic testing, thermography, and X-ray imaging are crucial for revealing internal defects without damaging the part. Combining multiple inspection techniques enhances detection accuracy and ensures timely repair, preventing costly failures and extending the life of carbon fiber components.