CarbonXtreme Post

Comparing Challenges in Autoclave and Out-of-Autoclave Carbon Fiber Production

The selection between autoclave and out-of-autoclave carbon fiber manufacturing processes impacts cost, quality, scalability, and application suitability. Autoclave curing is the industry standard for high-quality parts, offering precise temperature and pressure control for optimal mechanical properties, but it requires significant investment and limits part size. Out-of-autoclave methods offer flexibility, cost savings, and scalability, making them suitable for large or complex parts, though they require strict process control to maintain quality. Advances in technology are improving the competitiveness of out-of-autoclave curing, making it a viable option for many industries.

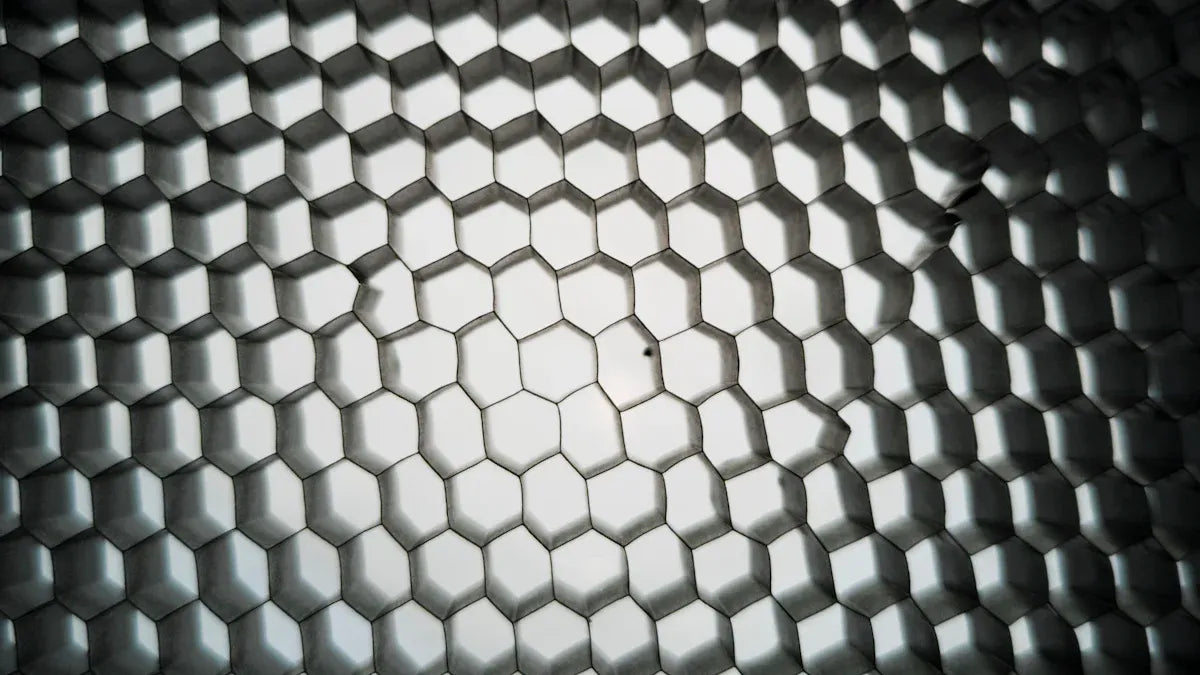

Comparing Carbon Fiber Weave Patterns and Their Impact on Stiffness

Carbon fiber weave impacts the mechanical properties, including stiffness, strength, and flexibility, of your composite. Unidirectional carbon fiber maximizes strength and stiffness along a single axis, making it ideal for structural applications. Biaxial weaves, such as plain or twill, offer better flexibility and strength across multiple directions, which makes them suitable for complex, multi-directional stress environments. Selecting the right weave depends on your project's specific performance needs, balancing mechanical strength, flexibility, and aesthetics.

Biaxial vs Unidirectional Carbon Fiber: Key Differences and Uses

The choice between biaxial and unidirectional carbon fiber comes down to the type of load and application. Biaxial carbon fiber provides balanced strength and shear resistance for multi-directional loads, making it ideal for complex, dynamic stress environments like marine panels, automotive parts, and wind turbine blades. In contrast, unidirectional carbon fiber maximizes strength and stiffness along one axis, making it perfect for applications like aerospace spars, drive shafts, and high-performance sports equipment. Understanding the differences in mechanical properties, cost, and fabrication requirements will help ensure optimal material selection for your project.

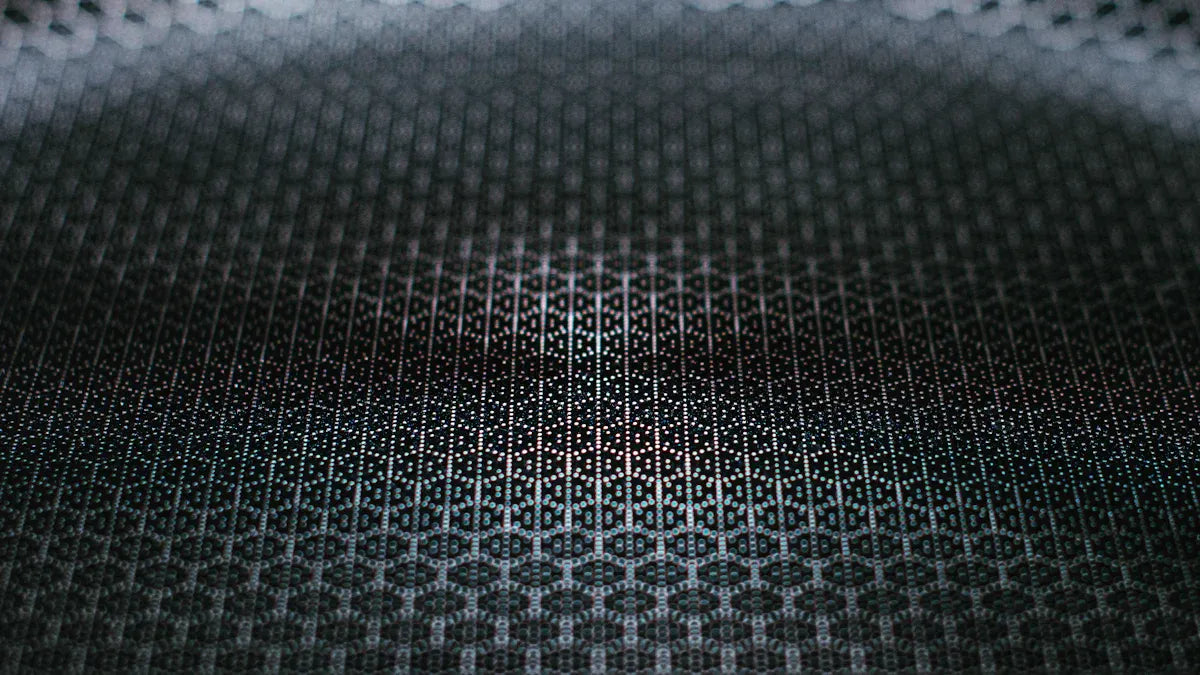

1K vs 3K vs 12K Carbon Fiber Weave: Key Differences and Best Uses

The 'K' number in carbon fiber weaves represents the number of thousands of fibers bundled together in each tow, which directly impacts the strength, flexibility, and weight of the material. A 1K weave offers the lightest, most refined finish for precision parts, while 3K provides a balanced mix of strength, flexibility, and appearance, making it ideal for sports gear and curved surfaces. The 12K weave excels in rigidity and cost efficiency, perfect for structural applications like automotive and aerospace. When choosing between 1K, 3K, or 12K, consider the specific requirements of your project, such as performance, aesthetics, and cost.

How Carbon Fiber Weave Affects Strength in Simple Terms

The selection of carbon fiber weave plays a crucial role in balancing strength, flexibility, and durability for your project. By aligning the fibers correctly, you can optimize performance based on your specific requirements. For instance, plain weave offers rigidity, making it ideal for flat, stable surfaces, while twill and satin weaves provide more flexibility for curved shapes. Unidirectional weaves maximize strength in one direction, ideal for high-performance applications like aerospace. Matching the weave pattern to your project's needs ensures the best possible mechanical performance and durability.

Carbon Fiber Layup Orientation for Strength and Stiffness Made Simple

The orientation of carbon fiber fibers plays a crucial role in maximizing the strength and stiffness of your composite parts. Aligning fibers in the load direction (0°) gives the highest strength and stiffness, while mixed orientations like 0°, 45°, and 90° offer better performance for multi-directional loads. By choosing the right layup pattern and stacking order, you can optimize your carbon fiber parts for durability, impact resistance, and handling. For real-world applications, combining multiple orientations and reinforcement methods ensures the best balance of strength, stiffness, and flexibility.

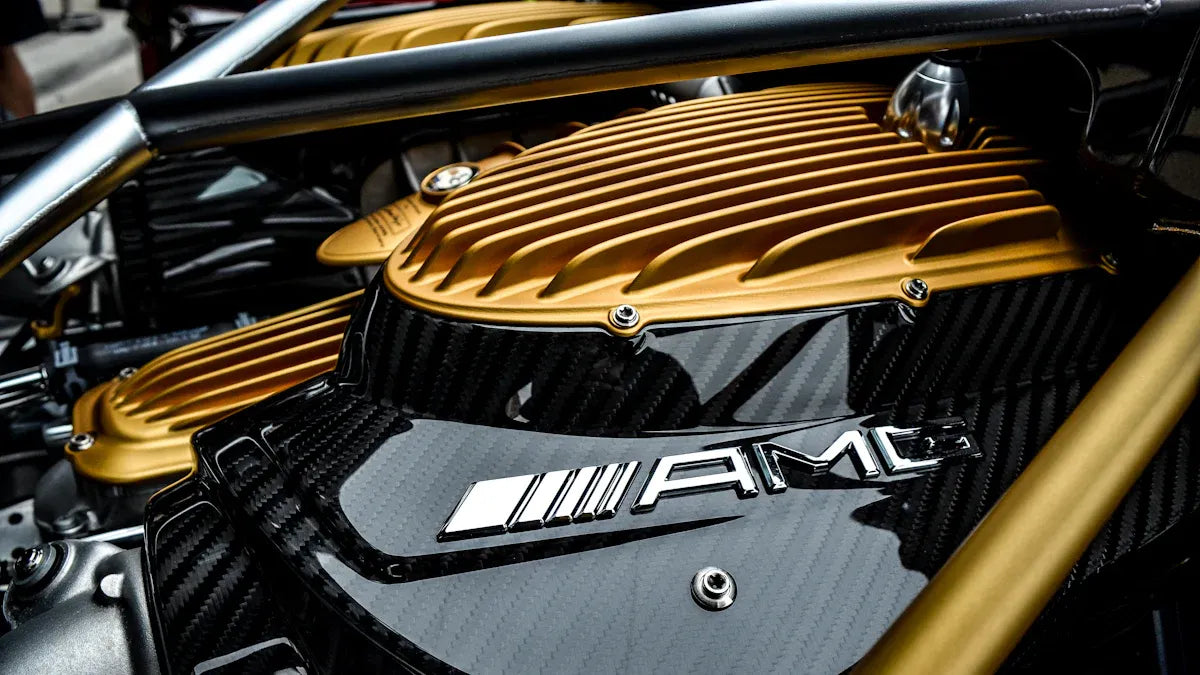

Is Racing Carbon Fiber Different from OEM Carbon Fiber? Discover the Real Answer

Racing carbon fiber is engineered for maximum performance with an emphasis on weight reduction and customization, while OEM carbon fiber is built for durability, safety, and everyday use. Racing carbon fiber typically features advanced materials and manufacturing methods like prepreg and autoclave processes, often customized for specific racing needs. On the other hand, OEM carbon fiber is mass-produced, focusing on long-term reliability and safety. Cost, durability, and intended use should guide your decision to ensure the best performance for your needs.

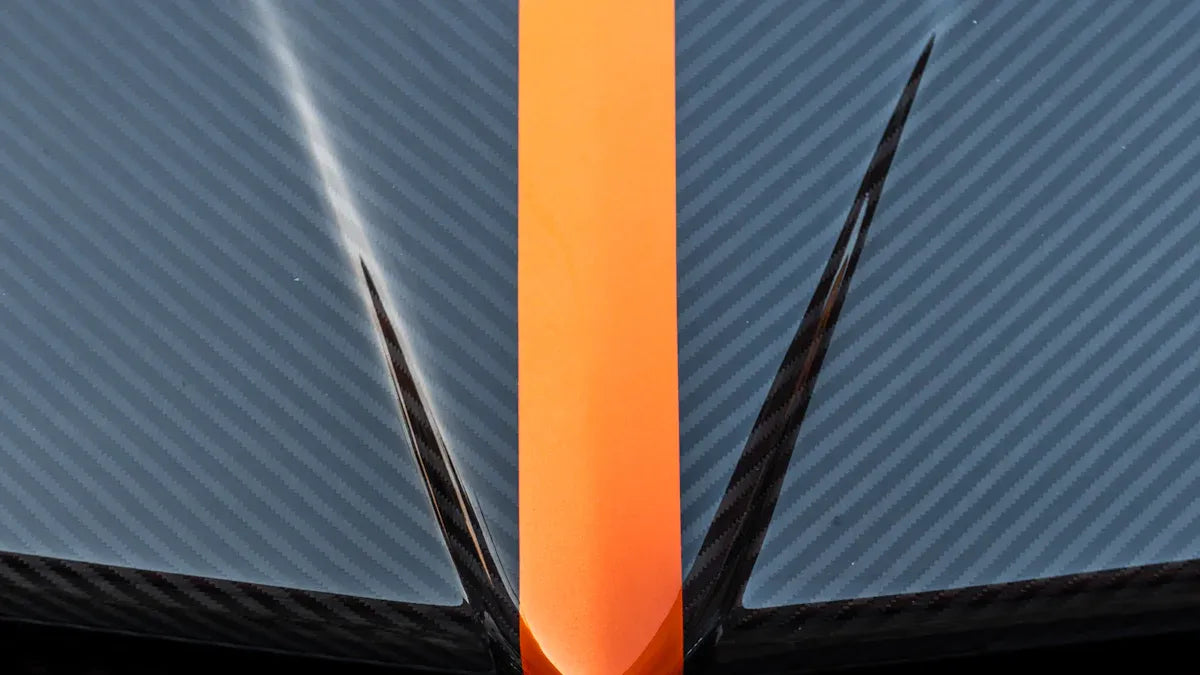

Steel, Aluminum, or Carbon Fiber: Which Is Best for Racing?

When selecting materials for racing, carbon fiber stands out for its unmatched strength-to-weight ratio, providing superior performance in handling, acceleration, and safety. Steel and aluminum, while more affordable, offer durability and ease of repair but sacrifice some performance characteristics compared to carbon fiber. Professionals favor carbon fiber for its performance benefits, while amateurs often choose aluminum or steel for their cost-effectiveness and repairability. Each material offers distinct advantages, and the right choice depends on your racing goals, budget, and repair skills.

Street-Legal Carbon Fiber Parts and Race-Only Options Compared

When upgrading your vehicle with carbon fiber parts, it's essential to choose between street-legal and race-only options based on your needs. Street-legal parts meet safety and emissions standards, ensuring compliance and reliability for daily driving. Race-only parts are designed for maximum performance in closed-course environments but lack the necessary reinforcements and certifications for public road use. Always check for proper certifications such as DOT, SAE, or CARB to avoid fines and insurance issues. Making informed decisions ensures both safety and performance without legal or financial risks.