CarbonXtreme Post

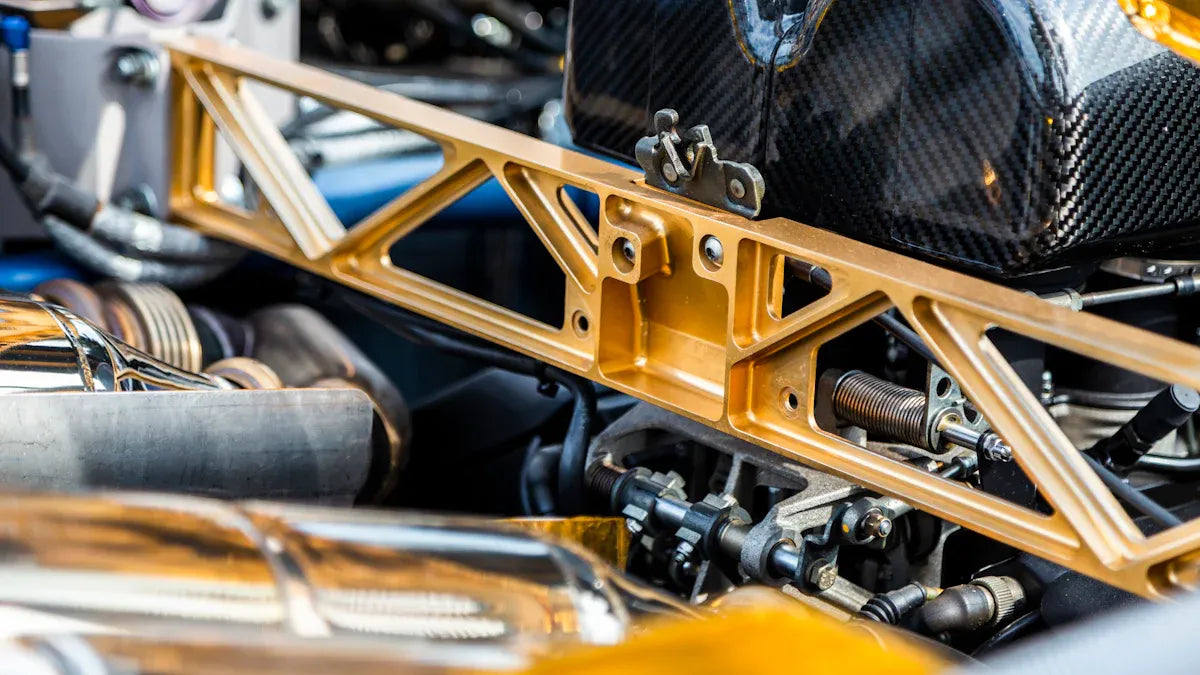

Why Carbon Fiber Is the Backbone of Modern F1 Cars

Carbon fiber has revolutionized Formula 1 (F1) engineering, providing a perfect balance of strength, lightness, and crash safety. The use of carbon fiber in F1 cars began with McLaren’s MP4/1 in 1981, introducing a full carbon fiber monocoque chassis that set new performance and safety standards. Today, carbon fiber remains essential for creating lightweight, rigid, and high-performing F1 cars. In addition, advances in sustainable carbon fiber technology, such as recycled fibers, are shaping the future of F1, aligning with environmental goals and maintaining the sport’s rigorous safety standards.

A Step-by-Step Guide to Carbon Fiber Quality Control in 2025

In 2025, ensuring the quality of carbon fiber products is crucial for safety, durability, and peak performance across industries such as aerospace, automotive, and consumer goods. Engineers and manufacturers must prioritize raw material selection, environmental control, and advanced monitoring systems to detect defects early. AI-driven insights, non-destructive testing, and strict quality control standards help maintain consistent product quality and reduce waste. By employing these methods, companies can improve manufacturing efficiency, reduce costs, and ensure the reliability of their carbon fiber parts.

Choosing the Best Precision Mold for Carbon Fiber Manufacturing

In 2025, precision carbon fiber molds are crucial for high-quality, efficient manufacturing across industries such as aerospace, automotive, and consumer goods. The selection of mold types—autoclave, compression, closed molds (RTM), or additive manufacturing—depends on production volume, part complexity, and desired surface finish. Autoclave molds offer the highest precision and surface finish, ideal for aerospace and motorsport parts, while compression molds are more cost-effective for high-volume automotive production. Additive manufacturing molds provide flexibility for prototyping and custom parts but may not be suitable for mass production. Understanding these factors ensures the optimal mold choice for carbon fiber parts, balancing cost, efficiency, and performance.

Forged Carbon vs Layered Carbon: Which Is Better for Your Project in 2025

In 2025, the choice between forged carbon and layered carbon remains pivotal for high-performance applications across industries. Forged carbon fiber excels in projects requiring complex shapes, unique marbled aesthetics, and strong impact resistance, making it ideal for luxury vehicles, sports equipment, and decorative parts. Layered carbon fiber, on the other hand, offers maximum strength, minimal weight, and a classic weave appearance, making it perfect for structural, load-bearing applications like aerospace and automotive components. The carbon fiber market is growing rapidly, and both materials are critical in pushing the boundaries of design and performance.

What Are the Main Types of Carbon Fiber Molds and Their Uses

Carbon fiber molds—male, female, and matched—are integral to the production of high-strength, lightweight parts used across industries like aerospace and automotive. The male mold shapes the external surface, the female mold creates precise finishes and internal features, and matched molds enable the production of net-shape parts with consistency and minimal defects. The choice of mold material—aluminum, steel, or composite—impacts mold durability, cost, and performance. Advanced methods such as vacuum bagging and autoclave curing ensure high-quality, mechanically robust parts. The carbon fiber molding market is projected to grow significantly, driven by demand in automotive, aerospace, and industrial sectors.

How the Autoclave Carbon Fiber Process Works in 8 Steps

The autoclave carbon fiber process combines heat, pressure, and vacuum to create high-strength, lightweight composite materials with superior quality. This method is widely used in aerospace, automotive, and other high-performance industries. The process involves careful prepreg placement, mold preparation, vacuum bagging, autoclave curing, and post-curing to ensure minimal defects and optimal part performance. Despite its higher cost, the autoclave process delivers consistent, reliable results with excellent mechanical properties, making it ideal for critical applications. Out-of-autoclave methods offer cost-effective alternatives for some applications, but the autoclave process remains the gold standard for quality.

The Real Reasons Carbon Fiber Remains Expensive in 2025

The carbon fiber industry continues to face high costs in 2025 due to expensive raw materials, particularly polyacrylonitrile (PAN), and the energy-intensive manufacturing process. Despite advancements, the material remains a premium choice in sectors like aerospace, automotive, and construction. The global market is projected to grow significantly, driven by demand for lightweight and high-strength materials, but challenges like high production costs, slow progress in cost-reduction technologies, and difficulties with recycling persist. Companies are focusing on innovations, including alternative feedstocks and advanced manufacturing techniques, to lower prices and enhance sustainability.

How the Dry Carbon Manufacturing Process Works Step by Step in 2025

Dry carbon fiber stands out for its exceptional strength-to-weight ratio, making it the material of choice for high-performance applications across industries like aerospace, automotive, and energy. The manufacturing process, which includes advanced steps like prepreg carbon fiber, vacuum bagging, autoclave curing, and meticulous finishing, ensures that dry carbon fiber parts offer unmatched precision, durability, and reliability. As automation and sustainability efforts grow in 2025, dry carbon fiber's role in reducing waste, improving production efficiency, and meeting environmental goals continues to expand, solidifying its place in cutting-edge technologies.

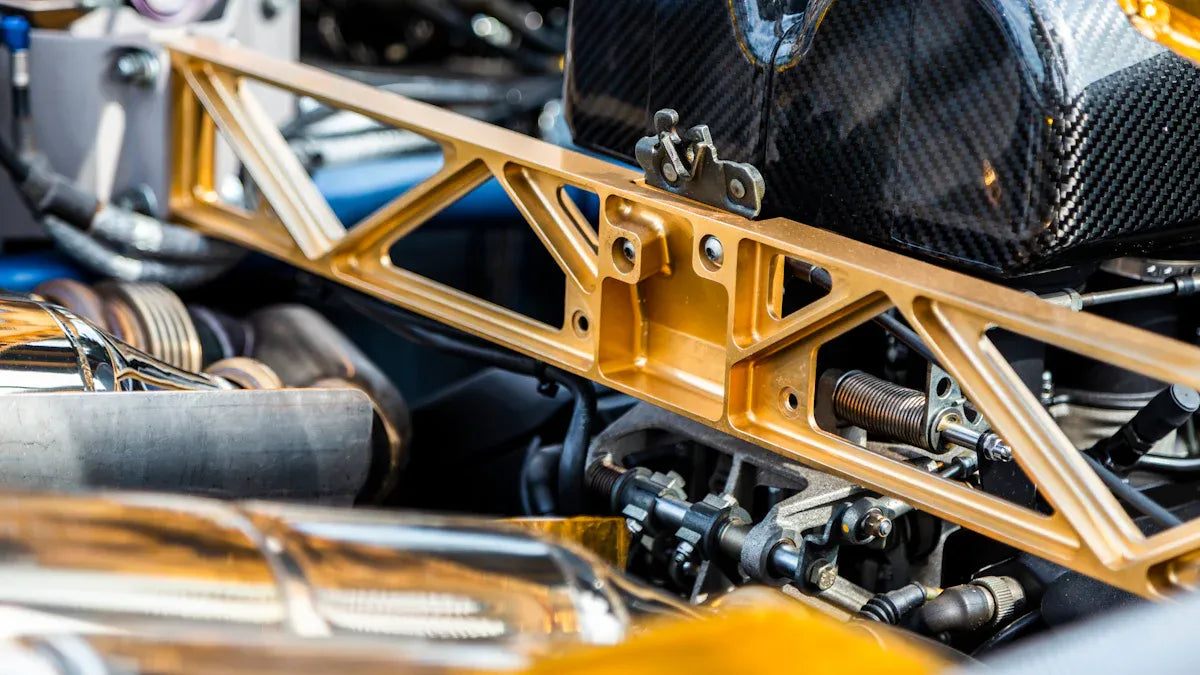

Why Carbon Fiber is Preferred Over Steel in High-Speed Vehicles

Carbon fiber’s exceptional strength-to-weight ratio makes it a crucial material in high-speed vehicles, offering improvements in acceleration, handling, and crash safety. It is significantly lighter than steel (up to 70%) and much stronger, offering up to five times the strength of mild steel. Its use in vehicles leads to weight reductions of up to 50%, improving performance and fuel efficiency. Advanced manufacturing techniques make carbon fiber parts increasingly affordable, and the automotive industry is expanding its use to meet safety, performance, and sustainability goals. Despite its high initial cost, carbon fiber provides long-term benefits through improved fuel economy and reduced emissions.