CarbonXtreme Post

Effective BMW M2 CS Brake Upgrade Tips You Need

Upgrading the brake system of your BMW M2 CS enhances both its performance and safety. With improvements in key components like high-performance pads, advanced rotors, and stainless steel brake lines, you can enjoy better stopping power, reduced fade, and enhanced control—whether you’re on the track or commuting. The M2 CS brake upgrade ensures your car handles high-speed maneuvers with confidence and precision. Regular maintenance and tailored upgrades based on driving style ensure long-term performance and reliability.

BMW M2 CS vs M4: Which Model Fits Your Daily Driving Needs?

The 2025 BMW M2 CS and M4 offer distinct driving experiences, each catering to different needs. The M2 CS delivers raw performance and thrilling agility with its track-focused design, powerful turbocharged engine, and precise handling. Its compact size, aggressive stance, and lightweight materials make it ideal for driving enthusiasts who prioritize speed and excitement. On the other hand, the M4 focuses on comfort and practicality, with a more refined design, spacious interior, and smoother ride. It’s a better option for daily driving and long commutes, offering luxury without compromising performance.

Motorsport-grade fasteners keep your race car safe

Motorsport-grade fasteners are essential for securing critical components in race cars. These fasteners are designed to handle extreme stress, heat, and vibration, ensuring that parts like the engine, suspension, and brakes remain intact during high-performance racing. By using materials like titanium, alloy steels, and advanced coatings, these fasteners offer superior strength, reliability, and vibration resistance compared to standard automotive fasteners. Their proper selection and installation prevent costly failures and improve overall performance. When racing at high speeds, you depend on these fasteners to keep your car secure and your performance optimized.

Why car fans choose carbon fiber fuse box covers for style

Upgrading your vehicle with a carbon fiber fuse box cover offers significant benefits in both aesthetics and function. These covers not only enhance the style of your engine bay with their sleek, high-tech look but also provide strong protection against heat, corrosion, and wear. The lightweight nature of carbon fiber contributes to overall vehicle weight reduction, which improves handling and performance. The easy installation process, along with long-term durability and minimal maintenance requirements, makes this a practical upgrade for car enthusiasts. Additionally, the use of high-quality carbon fiber ensures that the cover remains glossy and resistant to UV damage, maintaining its appearance even after prolonged exposure to sunlight.

Best Ways to Boost Your BMW M3 and M4 with Engine Bay Mods in 2025

Upgrading the engine bay of your BMW M3 or M4 (especially the G82 model) with high-performance modifications like carbon fiber strut braces, high-flow air intakes, and custom engine covers can greatly enhance both performance and aesthetics. These modifications reduce weight, improve handling, and boost cooling efficiency, making them essential for track use. The benefits are evident in the increased power output, improved acceleration, and enhanced vehicle balance. However, these parts come at a higher cost, require careful maintenance, and may be challenging to repair if damaged. Weighing the cost, performance goals, and installation complexity is key to making the right choice for your vehicle.

Is Carbon Fiber Under the Hood Worth It for Track Days

Upgrading to underhood carbon fiber parts for track use provides substantial performance benefits, including significant weight savings (up to 70%), improved handling, and enhanced cooling efficiency. These parts help reduce the strain on braking systems and increase overall track performance by lowering the car's weight and improving its balance. While carbon fiber parts are highly durable, they come with a higher cost, complex installation, and maintenance requirements. Damage repair can be difficult and costly due to limited reparability. Carbon fiber is best for frequent track participants who want to maximize performance, but casual racers might find traditional materials more cost-effective.

Proven Methods for Strong and Lightweight Carbon Fiber Parts

Mastering carbon fiber fabrication techniques is essential for achieving high-performance, lightweight, and durable parts in various applications, including motorsports, aerospace, and automotive industries. Dry carbon fiber, with its superior strength-to-weight ratio, is the preferred material for critical components like engine covers and spoilers. Through careful material selection, precision in fabrication, and advanced techniques like prepreg layup, vacuum bagging, and automation, you can create consistent and reliable carbon fiber parts. Prototyping and real-world testing ensure that your designs meet performance standards, while learning from build stories helps refine your approach and achieve optimal results.

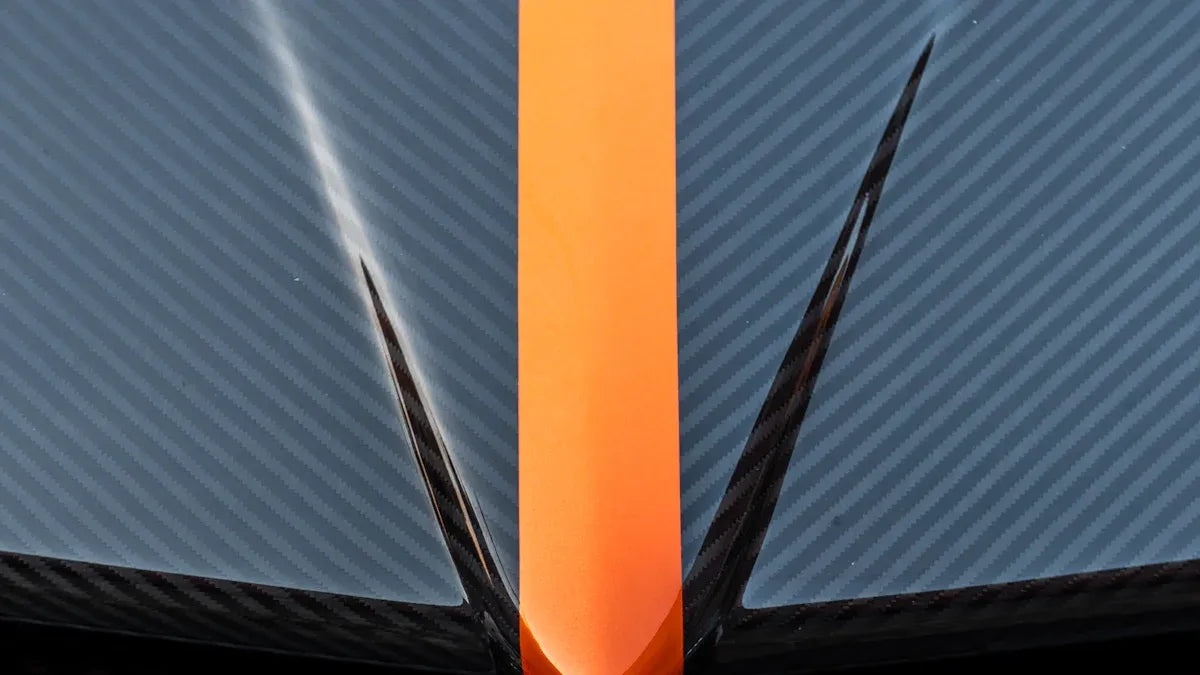

Why Track Drivers Choose Dry Carbon Over Wet Carbon for Motorsports

Track drivers consistently choose dry carbon fiber for its superior strength, lightness, and durability, which are essential for peak performance on the track. Dry carbon’s precise manufacturing process ensures consistency and reliability, which helps drivers gain an edge in acceleration, handling, and overall track performance. While wet carbon is more affordable, it does not offer the same performance benefits, making dry carbon the go-to choice for professional motorsports. Advances in carbon fiber technology, including automation and sustainable practices, further enhance the material’s advantages.

Top Emerging Trends in Dry Carbon Fiber Manufacturing for 2025

The carbon fiber manufacturing industry is evolving rapidly, driven by automation, smart technology, and sustainability efforts. Innovations like automated fiber placement, AI-driven defect detection, and energy-efficient processes such as plasma-assisted stabilization and microwave curing are improving production efficiency and reducing environmental impact. The demand for dry carbon fiber continues to rise, especially in aerospace, automotive, wind energy, and construction sectors. These trends are shaping the future of carbon fiber production, making it more cost-effective, sustainable, and capable of meeting the growing demand for lightweight, durable materials.