The best precision molds for carbon fiber depend on several factors. Engineers must consider production volume, part complexity, and required surface finish. Manufacturers often select autoclave molds, compression molds, closed molds (RTM), or additive manufacturing molds for carbon fiber parts. Each option suits different parts and production needs. Choosing the right molds ensures that carbon fiber parts meet strict requirements for accuracy and consistency. Decision-makers can benefit from understanding how to choose a carbon fiber mold manufacturer when quality and cost matter most.

Key Takeaways

-

Choose mold types based on part complexity, production volume, and quality needs to ensure accuracy and consistency.

-

Autoclave molds offer the highest precision and surface finish, ideal for aerospace and motorsport parts.

-

Compression molds provide fast, cost-effective solutions for high-volume automotive and industrial parts.

-

Additive manufacturing molds enable rapid prototyping and custom parts with lower costs but suit low-volume runs.

-

Optimizing mold materials, process parameters, and maintenance extends mold life and improves production efficiency.

Precision Molds for Carbon Fiber

Key Selection Factors

Selecting the right precision molds for carbon fiber requires careful evaluation of several factors. Engineers must consider the intended application, the complexity of the parts, and the expected production volume. Material choice plays a critical role in the carbon fiber mold manufacturing process. Stainless steel offers durability and corrosion resistance for high-volume manufacturing, while aluminum provides cost-effectiveness and faster machining for smaller runs. Companies like Toray Industries and Hexcel Corporation focus on advanced carbon fiber composites, delivering molds that meet strict industry standards.

Tip: Cycle frequency directly impacts mold lifespan. High production cycles increase wear, so optimizing cycle time and scheduling regular maintenance extends service life.

Recent advancements in the carbon fiber mold manufacturing process include AI-driven mold design, digital twin simulations, and automated molding machines. These methods improve efficiency and consistency. Hybrid molding methods, such as combining prepreg compression molding with over-molding, allow manufacturers to add complex features to parts while maintaining strength. Facilities now use large-scale presses and prepreg lines to support rapid prototyping and validation of automotive parts.

|

Performance Metric / Feature |

Description / Relevance |

|---|---|

|

Mold Efficiency |

Enhanced by vacuum-assisted molding and surface treatments for yield and durability. |

|

Life at High Temperatures |

Improved through advanced materials and treatments. |

|

Precision and Detailing |

Enables intricate component production, especially for female molds. |

|

Durability and Recyclability |

Emphasized by sustainable, cost-efficient molds. |

|

Heat Resistance and Mechanical Stability |

Essential for high-temperature applications. |

Tolerance and Accuracy

Precision molds for carbon fiber must achieve tight tolerances and high accuracy to ensure parts meet demanding specifications. Statistical process control and high-resolution measurement systems help manufacturers maintain precision rates close to 95%. Monte Carlo simulations estimate tolerance stack-up variations, providing a clear picture of dimensional consistency. For example, aerospace components often require tolerance levels as tight as ±0.005 mm.

Key machining performance metrics include cutting forces, tool wear, surface roughness, and defect analysis. Advanced methods such as vibration-assisted and thermal-assisted machining improve tool life and surface finish. Specialized tool materials and coatings, like diamond tools and TiN coatings, further enhance machining outcomes. Lubrication methods—dry, flood, minimum quantity, cryogenic, and high-pressure cooling—optimize the process for carbon fiber composites.

Note: Validation of simulation results against quantitative indicators, such as short shot length and injection pressure profile, ensures reliable prediction of the molding process and supports robust mold design.

Precision molds for carbon fiber enable manufacturers to produce parts with consistent quality, supporting industries from aerospace to automotive. The right combination of methods, processes, and mold design ensures each part meets strict performance and durability requirements.

Types of Precision Molds

Carbon Fiber Autoclave Molds

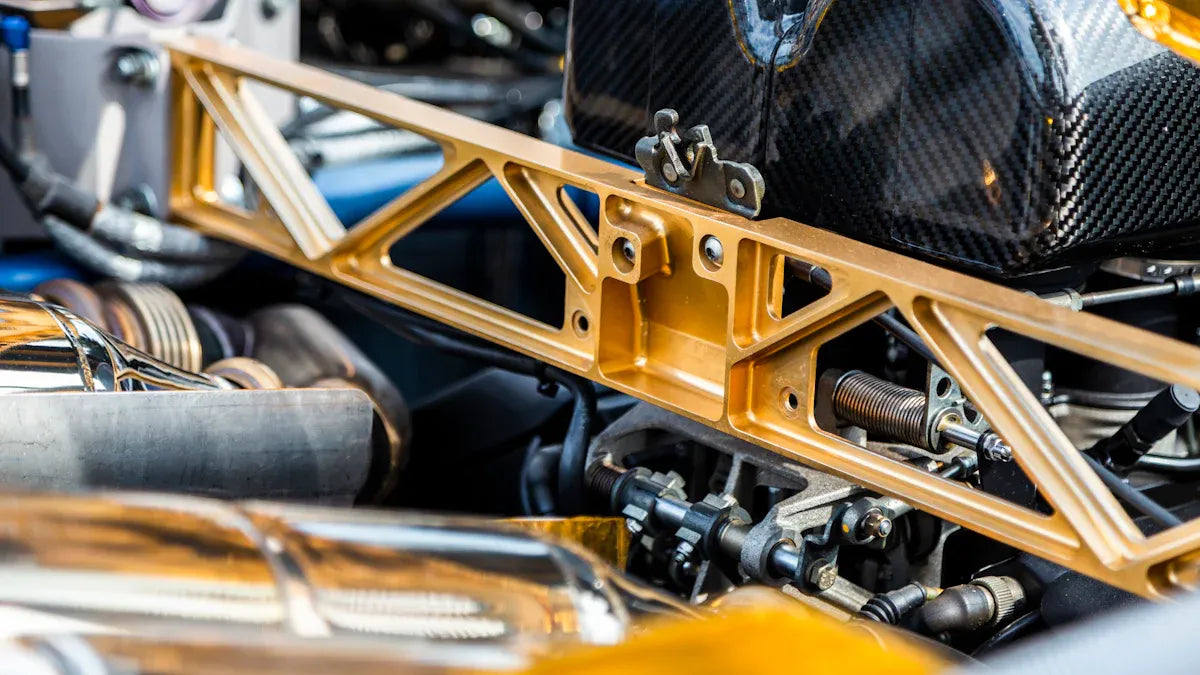

Carbon fiber autoclave molds set the standard for high-performance carbon fiber parts. This process uses controlled heat and pressure inside an autoclave to cure carbon fiber composites. Manufacturers select materials like carbon fiber-reinforced polymers or high-grade metals for these molds. The process ensures excellent dimensional stability and surface finish, making it ideal for aerospace and motorsport parts. Numerical simulations show that autoclave curing uses precise thermal and pressure parameters. For example, the temperature profile heats from room temperature to 180 °C at 3 °C/min, held for 150 minutes. Pressure increases from 1 atm to 0.6 MPa within 10 minutes at 60 °C, then holds steady. These conditions minimize residual strain and warpage, resulting in carbon fiber parts with superior mechanical properties.

|

Parameter |

Value / Range |

Notes / Impact on Mold Performance |

|---|---|---|

|

Temperature profile |

Heating from room temp to 180 °C at 3 °C/min, held for 150 min |

Ensures proper curing of carbon fiber composites |

|

Pressure profile |

Increase from 1 atm to 0.6 MPa within 10 min at 60 °C, maintained during hold |

Maintains consolidation and void reduction during curing |

|

Mold facesheet thickness |

8 to 25 mm |

Influences thermal response and heat distribution |

|

Cooling time |

40 min |

Influences residual stresses and final part quality |

Note: Carbon fiber autoclave molds deliver minimal residual strain after cooling, outperforming aluminum or steel molds in thermal compatibility.

Carbon Fiber Compression Molds

Carbon fiber compression molds offer a fast, cost-effective solution for mass production of carbon fiber parts. The process involves placing carbon fiber composites into a heated mold, then applying high pressure to shape and cure the material. Manufacturers use robust steel or aluminum molds for durability and thermal stability. Recent mass production tests show that carbon fiber compression molds achieve high mechanical performance with optimal parameters: 150 °C compression temperature, 50 MPa pressure, and 20-minute hold time. These settings yield tensile strengths above 780 MPa and bending strengths over 680 MPa. Cycle times can reach as low as two minutes, making this process ideal for automotive and industrial parts.

Tip: Carbon fiber compression molds support sustainable, recyclable materials, combining efficiency with environmental responsibility.

Closed Molds (RTM)

Closed molds, especially resin transfer molding (RTM), enable the production of complex carbon fiber parts with high repeatability. In this process, manufacturers inject resin into a closed mold containing dry carbon fiber preforms. The method ensures precise resin distribution, reducing waste and improving surface finish. RTM supports high-volume production, especially in automotive and aerospace industries. High-pressure RTM (HP-RTM) can operate at injection pressures up to 200 bars, cutting cycle times by 50% or more. This efficiency, combined with automation and advanced resins, makes closed molds a cost-effective choice for intricate carbon fiber parts.

Additive Manufacturing Molds

3d printed molds, created with 3d printing technology, bring flexibility and speed to carbon fiber manufacturing. Material extrusion methods like Fused Deposition Modeling (FDM) allow scalable production of custom molds for carbon fiber parts. FDM supports multimaterial printing, enabling complex geometries and improved mechanical properties. However, 3d printed molds may show surface finish limitations and dimensional precision issues, such as layer stair-stepping. Powder Bed Fusion (PBF) methods offer higher resolution and accuracy, suitable for small, detailed molds. Vat Photopolymerization (VPP) delivers excellent surface finish and precision, though with higher costs. 3d printed molds excel in prototyping and low-volume production, supporting rapid design changes and custom carbon fiber parts.

-

FDM and SLS methods have demonstrated scalability and adaptability for producing functional, high-performance carbon fiber parts.

-

3d printed molds enable manufacturers to quickly iterate designs, making them valuable for custom or complex parts.

Advantages of Carbon Fiber Molds

Surface Finish and Consistency

Precision molds for carbon fiber deliver exceptional surface finish and consistency. Manufacturers rely on quantitative quality control metrics to monitor improvements in surface texture. The following table summarizes key parameters used to evaluate surface finish:

|

Parameter |

Description |

Relation to Surface Finish Improvement |

|---|---|---|

|

Ra |

Arithmetic mean roughness |

Lower values indicate smoother surfaces |

|

Rq |

Root mean square roughness |

Reflects overall surface roughness magnitude |

|

Rt |

Total height of the profile |

Measures vertical distance between highest and lowest points on surface |

|

Δa |

Average angle of profile tangents |

Lower Δa means smoother surface and lower friction |

|

Rpk |

Reduced peak height |

Represents surface peaks worn away during running-in |

|

Rvk |

Reduced valley depth |

Represents valleys that retain lubricant |

|

Rsk |

Skewness (asymmetry) |

Negative skewness correlates with smoother surface |

|

Rku |

Kurtosis (peakedness) |

Describes sharpness of surface profile peaks |

Lower Δa and more negative Rsk values signal smoother surfaces and reduced friction. These metrics help ensure that every carbon fiber part meets strict quality standards. Consistent surface finish reduces post-processing and improves product appearance.

Durability and Thermal Stability

The advantages of carbon fiber molds extend to durability and thermal stability. Empirical studies using thermogravimetric analysis and kinetic modeling show that precision molds with carbon fiber composites maintain thermal stability at temperatures up to 400 °C. Only 5% degradation occurs above these temperatures, which supports long service life in demanding environments. Strong adhesion between recycled carbon fiber and thermoplastic matrices, such as PA11 and PA12, preserves or even enhances thermal stability. Plasma surface treatments further improve adhesion and extend mold lifespan. These findings confirm that carbon fiber molds withstand repeated thermal cycling and maintain performance over time.

Note: Manufacturers can expect reliable operation and reduced maintenance when using carbon fiber molds in high-temperature applications.

Cycle Time and Efficiency

The advantages of carbon fiber molds also include reduced cycle times and increased operational efficiency. Using chopped carbon fiber in injection molding eliminates the need for fiber alignment, which speeds up the reinforcement process. The short length of chopped fibers improves material flow, reducing clogging and minimizing downtime. As a result, production lines experience fewer defects and more consistent output. Comparative research shows that copper alloy molds, despite higher initial costs, provide faster cooling, lower energy consumption, and improved product quality compared to stainless steel. At higher production scales, injection molding with precision molds achieves significant long-term cost savings and productivity improvements.

-

Manufacturers benefit from faster production cycles and lower labor requirements.

-

The advantages of carbon fiber molds become more pronounced as production volume increases.

Comparing Mold Types for Carbon Fiber Parts

Accuracy and Surface Quality

Engineers evaluate accuracy and surface quality as top priorities when selecting molds for carbon fiber parts. Autoclave molds deliver the highest precision, producing parts with tight tolerances and smooth finishes. These molds use controlled heat and pressure, which minimizes defects and ensures uniformity. Compression molds also achieve high accuracy, especially for flat or moderately complex parts. However, surface finish may require additional post-processing for intricate shapes.

Closed molds, such as those used in resin transfer molding (RTM), offer consistent surface quality for complex geometries. RTM methods distribute resin evenly, reducing voids and improving the appearance of finished carbon fiber parts. Additive manufacturing molds provide flexibility for custom shapes, but surface quality can vary. Layered construction in 3D printing sometimes leads to visible lines or minor imperfections, which may require secondary finishing.

Tip: For aerospace and automotive manufacturing, select molds that consistently achieve surface roughness values below Ra 0.8 µm to meet industry standards.

Cost and Production Volume

Cost and production volume play a critical role in mold selection. High tooling costs and long lead times are common with metal molds used in high-pressure methods like injection and compression molding. These investments make sense for moderate to high production volumes or for complex carbon fiber parts that benefit from integrated features and fewer secondary operations.

For low to moderate production volumes and simpler parts, the capital required for metal tooling and presses often outweighs the benefits. Manufacturers in these cases prefer thermoset composites or metals, which reduce upfront costs. Differential Pressure Molding (DPM) offers a cost-effective alternative for low-to-moderate volume production. DPM reduces complexity, size, weight, and energy requirements, making it suitable for runs from a few hundred to several hundred thousand parts per year. This flexibility supports diverse industry applications of carbon fiber molds, especially in automotive and industrial sectors.

-

The carbon mold market reached 1.2 million metric tons in 2024 and is projected to grow to 1.8 million metric tons by 2028.

-

Automotive manufacturing dominates with a 45% market share, followed by aerospace at 30% and industrial applications at 25%.

-

Growth in the carbon mold market comes from the demand for lightweight, durable, and precision-engineered carbon fiber parts.

Additive manufacturing molds stand out for prototyping and low-volume runs. These methods require lower initial investment and allow rapid design changes, but may not scale efficiently for mass production.

Application Suitability

Each mold type aligns with specific industry applications of carbon fiber molds and manufacturing needs. Autoclave molds suit aerospace and motorsport sectors, where high accuracy and superior mechanical properties are essential. Compression molds excel in automotive manufacturing and industrial production, where speed and cost-effectiveness matter most.

Closed molds, including RTM, fit applications that demand complex shapes and high repeatability. These methods support both automotive and aerospace sectors, providing reliable performance for structural and aesthetic parts. Additive manufacturing molds enable rapid prototyping and custom part development. They serve industries that require frequent design changes or low-volume, specialized carbon fiber parts.

The table below summarizes the main differences among mold types for carbon fiber parts:

|

Mold Type |

Accuracy & Surface Quality |

Cost & Production Volume |

Application Suitability |

|---|---|---|---|

|

Autoclave |

Excellent |

High cost, high volume |

Aerospace, motorsport, high-performance parts |

|

Compression |

High |

Moderate cost, high volume |

Automotive, industrial, flat/moderate parts |

|

Closed (RTM) |

High, complex shapes |

Moderate cost, moderate-high volume |

Automotive, aerospace, complex geometries |

|

Additive Manufacturing |

Variable, custom shapes |

Low cost, low volume |

Prototyping, custom, low-volume parts |

Note: Manufacturers should match mold type to the complexity, volume, and quality requirements of their carbon fiber parts to maximize efficiency and value.

Matching Mold Type to Manufacturing Needs

Prototyping and Custom Parts

Engineers often select additive manufacturing molds for prototyping and custom carbon fiber parts. This approach enables rapid iteration and cost-effective production of unique geometries. Fused Deposition Modeling (FDM) and other 3D printing techniques allow the creation of molds with integrated cooling channels and optimized lattice structures. These features improve thermal management and reduce cycle times, especially in vacuum-assisted resin transfer molding for carbon fiber reinforced plastics.

A case study involving a racing motorbike fuel tap protection illustrates the effectiveness of precision molds produced by FDM 3D printing. The team used CAD modeling and optimized printing parameters to achieve a high surface finish suitable for continuous fiber-reinforced carbon fiber parts. Traditional mold manufacturing methods often require significant investment and time, but 3D printed molds reduce both costs and lead times for prototypes and limited series. Chemical smoothing further enhances the surface quality, making these molds ideal for custom applications.

Digital supply chain platforms, such as those used by Honeywell, have accelerated development cycles by up to seven times. These platforms leverage precision manufacturing capabilities to deliver custom carbon fiber parts quickly. The ability to iterate designs rapidly and produce functional prototypes supports innovation and reduces time-to-market. Companies seeking guidance on how to choose a carbon fiber mold manufacturer should prioritize those with advanced additive manufacturing and digital prototyping capabilities.

Tip: For custom or prototype carbon fiber parts, select mold suppliers who offer rapid tooling and digital design integration to maximize flexibility and minimize costs.

Small and Medium Batch Production

Small and medium batch production of carbon fiber parts requires a balance between cost efficiency and output quality. Manufacturers often use compression molds, closed molds, or hybrid additive manufacturing techniques for these runs. Research shows that optimizing precursor materials and processing parameters can significantly reduce costs while maintaining high mechanical performance. For example, melt spinning of PAN precursor yields carbon fibers with tensile strength around 3.6 GPa and modulus near 233 GPa. Alternative precursors, such as lignin and polyethylene, offer further cost reductions, though process optimization remains essential for consistent quality.

Recycled carbon fiber has become increasingly popular in medium-volume production, especially for nonstructural parts. Additive manufacturing methods that incorporate recycled carbon fiber powders enable the production of functional components with reliable structural integrity. These advances support sectors such as UAVs and medical prosthetics, where cost-effective, high-quality output is critical. Recycled carbon fiber also finds use in composite products like construction panels, demonstrating versatility and improved quality in diverse applications.

Manufacturers benefit from selecting mold types that align with their batch size and part complexity. Compression and closed molds provide the repeatability and durability needed for medium runs, while additive manufacturing offers flexibility for custom features or rapid changes.

-

Small batch production: 3D printed molds, CNC machining, and vacuum casting.

-

Medium batch production: Compression molds, closed molds, and recycled carbon fiber integration.

Mass Production

Mass production of carbon fiber parts demands high yield, low defect rates, and consistent quality. Precision molds, such as those used in injection and compression molding, form the backbone of large-scale manufacturing. Traditional injection molding processes often experience defect rates above 20% due to manual parameter adjustments and operator variability. However, the integration of AI-powered visual inspection and machine learning-based process optimization has transformed quality control.

Recent studies demonstrate that machine learning models can reduce defect rates to as low as 1.63%, far outperforming traditional methods. These models enable real-time adaptation to environmental changes, ensuring consistent part quality. Optimizing key process parameters—such as mold temperature, holding pressure, and injection speed—can increase production yield from 38% to 93%. This improvement directly impacts the efficiency and profitability of mass production operations.

|

Statistic/Aspect |

Value/Description |

|---|---|

|

Initial yield rate of micro-injection molded gears |

38% |

|

Improved yield rate after robust parameter design |

93% |

|

Key process parameters affecting quality |

Mold temperature, holding pressure, injection speed |

|

Common issues reducing yield |

Geometric precision, molecular orientation, optical properties |

Manufacturers focused on mass production should invest in precision molds with advanced process control systems. These investments ensure high throughput, minimal waste, and reliable delivery of carbon fiber parts at scale.

Note: Selecting the right mold type and optimizing process parameters are essential for achieving high yield and low defect rates in mass production of carbon fiber parts.

Selecting the best precision mold for carbon fiber in 2025 requires careful consideration of part requirements, production scale, and desired quality. Market trends show small tow carbon fiber dominates automotive applications, while aerospace and Europe lead in advanced mold adoption.

|

Segment Type |

Key Statistic / Trend |

|---|---|

|

Tow Size |

Small tow segment projected to dominate with 78.4% market share in 2025, driven by automotive use. |

|

End User |

Aerospace & Defense expected to hold largest share at 32.7%. |

|

Regional Market |

Europe leads with 32.4% market share; Germany holds 35.4% within Europe. |

|

Growth Projection |

North America projected to have highest CAGR. |

|

Application Insight |

Small tow carbon fiber preferred for precise automotive body panels. |

Industry professionals value detailed market analysis and responsive support, which helps guide strategic decisions. Key performance indicators, such as cutting speeds up to 60 inches per second and tolerances of +0.002″ to -0.001″, support high-quality production. For complex or high-value parts, consulting with mold suppliers or running pilot projects ensures optimal results.

Share:

Why Carbon Fiber Is the Backbone of Modern F1 Cars

Carbon Fiber for Racing vs Street Cars: What the Numbers Show in 2025