The autoclave carbon fiber process uses a combination of heat, pressure, and vacuum to create high-strength composite materials. You follow eight precise steps, from lay-up to post-curing, to ensure your carbon fibre parts reach aerospace-grade quality. Each phase—especially holding temperature—directly affects the degree of cure and residual stress, as shown in the table below:

|

Parameter |

Quality Impact |

|---|---|

|

Holding Temperature |

High (affects cure) |

|

Fiber Volume Fraction |

Moderate |

|

Heating/Cooling Rate |

Low |

Careful control at every stage minimizes defects and maximizes part performance.

Key Takeaways

-

The autoclave process uses heat, pressure, and vacuum to cure carbon fiber parts, producing strong, lightweight composites with minimal defects.

-

Careful prepreg placement and mold preparation set the foundation for high-quality parts by preventing wrinkles, gaps, and weak spots.

-

Vacuum bagging removes trapped air and volatiles, reducing voids and improving the strength and durability of the final composite.

-

Controlling temperature and pressure ramp-up, hold time, and cooling rates ensures even curing, prevents defects, and maintains part shape and strength.

-

The autoclave process delivers superior quality composites widely used in aerospace and automotive industries, but out-of-autoclave methods offer cost-effective alternatives for some applications.

Overview of the Autoclave Carbon Fiber Process

The autoclave carbon fiber process stands as a cornerstone in composite manufacturing. You use this method to produce composite materials with exceptional strength, low weight, and minimal defects. In industries like aerospace and automotive, you need reliable processes that deliver consistent results. The autoclave process gives you that reliability by combining heat, pressure, and vacuum to cure carbon fibre parts to the highest standards.

Key Principles

You start the autoclave carbon fiber process by sealing carbon fibre prepreg in a vacuum bag and placing it inside the autoclave. The autoclave then applies controlled heat and pressure, which cures the resin and bonds the fibers. This approach ensures uniform temperature and pressure throughout the part, which is critical for high-quality composite materials. You rely on specialized equipment, including molds made from aluminum or steel, and consumables like vacuum films and sealing tapes, to maintain quality control.

-

The autoclave process minimizes porosity by controlling resin pressure and curing parameters.

-

You manage deformation by selecting the right layer design, curing temperature, and mold material.

-

Integrated molding techniques, such as co-curing and co-bonding, help you reduce part count and improve structural integrity.

Note: Technical advancements in autoclave design, such as improved sealing and heating systems, have made the process more stable and efficient.

Why Use an Autoclave?

You choose the autoclave process because it consistently delivers superior composite manufacturing results. Compared to other methods, autoclave curing achieves the highest fiber volume fraction and the lowest porosity, which translates to better mechanical strength. For example, autoclave curing produces composite materials with a fiber volume fraction above 58% and porosity as low as 0.5%. In contrast, oven curing and hot pressing result in lower fiber volume and higher porosity, which can weaken the final product.

|

Curing Method |

Fiber Volume Fraction (%) |

Porosity (%) |

Mechanical Strength (MPa) |

|---|---|---|---|

|

Autoclave Curing |

>58 |

0.5 |

675–775 |

|

Oven Curing |

51 |

>4 |

Lower than autoclave |

|

Hot Pressing |

52 |

1.3 |

Lower than autoclave |

You see the autoclave carbon fiber process widely used in aerospace, military, and automotive manufacturing because it produces composite materials with unmatched quality and performance.

Lay-Up

The lay-up stage forms the foundation of the autoclave carbon fiber process. You set the tone for the entire composite part by how you handle prepreg placement and mold preparation. Precision and attention to detail at this stage directly influence the final quality and performance of your carbon fiber component.

Prepreg Placement

You begin by carefully placing sheets of carbon fiber prepreg onto the mold. Each layer must align with the specified fiber orientation. This alignment ensures the part meets strength and stiffness requirements. You avoid wrinkles, gaps, or overlaps, as these can introduce weak points. Consistency in prepreg placement reduces the risk of defects such as fiber misalignment, voids, and delamination. These issues can compromise mechanical properties and structural integrity.

-

Specification compliance, first pass yield, and process consistency serve as key quality benchmarks during lay-up.

-

Manual lay-up often leads to inconsistencies due to operator skill variability, which can increase defect rates and material waste.

-

Quality assurance systems monitor key performance indicators (KPIs) and process controls to maintain high standards.

Tip: Use templates or laser guides to help you achieve precise fiber orientation and layer placement. This step minimizes human error and supports repeatable results.

Mold Preparation

You must prepare the mold before placing any prepreg. Clean the mold surface thoroughly to remove dust, oils, or residues. Apply a release agent to prevent the cured part from sticking. The mold material—often aluminum or steel—must withstand autoclave temperatures and pressures without deforming.

A well-prepared mold ensures the composite part takes on the correct shape and surface finish. You also reduce the risk of defects and material waste. Consistent mold preparation supports process repeatability and helps you achieve high first pass yield. Quality control at this stage sets the stage for a successful cure and a defect-free final product.

Vacuum Bagging

Vacuum bagging stands as a crucial step in producing high-quality carbon fiber composites. You use this method to remove trapped air and volatile substances from the lay-up before curing. This process helps you achieve a dense, void-free laminate, which directly improves the mechanical properties and durability of your final part.

Air Removal

You begin by placing the prepared lay-up inside a flexible vacuum bag. Once sealed, you connect the bag to a vacuum source. The vacuum draws out air and volatiles from within the laminate and around the mold. Removing these trapped gases is essential. If you leave air pockets or moisture inside, they can form voids during curing, which weaken the composite and reduce its lifespan.

Recent studies have shown that air removal during vacuum bagging happens through two main mechanisms: diffusion through the thickness of the laminate and interlayer flow toward the edges. For thin laminates, diffusion dominates, while for thicker parts, maintaining interlayer permeability becomes more important. Researchers have also used real-time visualization to observe air evacuation, confirming that the process effectively reduces entrapped air and improves laminate quality.

Surface porosity often results from air trapped at the tool-prepreg interface. By optimizing vacuum hold time and ensuring good vacuum quality, you can reduce surface porosity by up to 99%. This significant reduction in voids leads to better mechanical performance and less moisture absorption over time.

Sealing Process

You must ensure a complete and airtight seal around the vacuum bag. Use specialized sealing tapes to secure the bag to the mold. Any leaks can compromise the vacuum, allowing air to re-enter and create defects. After sealing, check the system for leaks using a vacuum gauge or by listening for hissing sounds.

A well-sealed vacuum bag maintains consistent pressure across the entire lay-up. This uniform pressure compacts the layers, optimizes the fiber-to-resin ratio, and further reduces the risk of voids. While vacuum bagging alone limits compaction to atmospheric pressure, it remains highly effective for removing air and volatiles, setting the stage for a strong, defect-free composite part.

Loading into Composite Autoclave

When you reach the loading stage, you prepare your composite lay-up for the critical curing process. This step demands precision and attention to detail. The composite autoclave provides a controlled environment where you can apply uniform heat and pressure, which are essential for producing defect-free carbon fiber parts.

Setup

You start by carefully placing the vacuum-bagged lay-up onto the autoclave loading rack. Make sure the part sits securely and does not touch the chamber walls. Proper spacing allows for even airflow and heat distribution. You connect all necessary thermocouples and pressure sensors to monitor the process in real time. The composite autoclave’s advanced control systems help you maintain strict process parameters throughout the cycle.

A controlled environment inside the composite autoclave ensures that every part receives the same temperature and pressure profile. This consistency leads to high-quality, repeatable results. The equipment’s design supports uniform pressure application, which compacts the laminate and eliminates voids.

Tip: Always double-check sensor placement and bag integrity before closing the autoclave door. Small errors at this stage can lead to costly defects.

Safety Checks

Before you begin the curing cycle, you must perform thorough safety checks. Inspect the composite autoclave for any signs of wear or damage. Confirm that all safety interlocks and emergency systems function correctly. Review the process parameters and verify that the chamber is sealed.

You rely on precise control of heating and pressure rates to protect both the part and the equipment. The table below highlights key performance statistics that support these controlled conditions:

|

Parameter |

Value/Range |

Significance in Controlled Conditions |

|---|---|---|

|

Heating rate |

2 °C/min |

Ensures uniform temperature increase, minimizing thermal stress |

|

Maximum temperature change |

50 °C |

Limits abrupt temperature variations to protect material |

|

Pressure increase rate |

0.2 barg/min |

Smooth pressure adaptation during heating phase |

|

Maximum pressure variation |

3 barg |

Maintains safety and process stability |

|

Cooling rate |

3 °C/min |

Controlled cooling to prevent internal stresses |

|

Pressure decrease rate |

0.3 barg/min |

Smooth depressurization during cooling |

|

Root Mean Square Error (RMSE) |

1.825 |

Validates numerical model accuracy for process control |

|

Coefficient of determination (R²) |

0.998 |

Confirms high model reliability |

|

Convective heat transfer coeff. |

Up to 8 W/m²K |

Indicates effective heat dissipation and controlled thermal environment |

|

Nusselt number |

Max ~350 |

Reflects efficient convective heat transfer |

The numerical model used to simulate the composite autoclave process shows excellent agreement with experimental data. A low RMSE of 1.825 and a high R² of 0.998 confirm that you can reliably maintain the required temperature and pressure conditions during loading and processing. This accuracy ensures that your carbon fiber parts meet the highest quality standards.

Temperature and Pressure Ramp-Up

As you begin the temperature and pressure ramp-up stage, you set the foundation for a successful curing process. This phase determines how well the resin flows and bonds the carbon fibers. You must control both heat and pressure with precision to avoid defects and ensure optimal part strength.

Heat Application

You start by gradually increasing the temperature inside the composite autoclave. The heating rate must remain steady, usually around 2 °C per minute. This slow ramp-up allows the resin to melt and flow evenly throughout the laminate. If you heat too quickly, you risk creating thermal gradients that can cause uneven curing or internal stresses. You monitor the temperature at multiple points using thermocouples. This real-time feedback helps you maintain uniform heat distribution across the entire part.

Tip: Consistent heat application during the curing process prevents resin-rich or resin-starved areas, which can weaken the final product.

Pressure Control

As the temperature rises, you also increase the pressure inside the autoclave. You typically raise the pressure to between 6 and 7 bar. This pressure compacts the laminate, squeezes out any remaining air, and helps the resin penetrate all fiber layers. You must synchronize the pressure increase with the temperature ramp to avoid trapping volatiles or causing resin bleed. Careful pressure control ensures the curing process produces a dense, void-free composite.

You rely on the composite autoclave’s advanced controls to maintain the correct pressure profile. These systems help you achieve the high fiber volume fraction and low porosity that define autoclave curing. By managing both heat and pressure, you set the stage for a flawless curing process and a high-performance carbon fiber part.

Curing Phase

Hold Time

You reach the critical moment in the curing process when you must maintain both temperature and pressure for a specific period. This hold time allows the resin to fully polymerize and ensures the composite achieves its designed strength. If you shorten this phase, you risk incomplete curing, which can lead to weak spots or early failure. If you extend it too long, you may cause unnecessary energy use or even damage the material.

Researchers have shown that the duration and depth of the curing process directly impact the mechanical properties of composites. Consider these findings:

-

Polymerization time and depth of cure affect the degree of polymerization and hardness.

-

A hardness ratio above 0.8 between the bottom and top surfaces signals adequate polymerization.

-

Some materials show no significant difference in hardness between 20 and 40 seconds of curing, while others do.

-

Increasing polymerization time can improve hardness for certain composites.

-

Light intensity drops as it passes through the composite, reducing curing effectiveness at deeper layers.

-

A 3-mm thick composite cured for 40 seconds achieves a sufficient hardness ratio for all tested materials.

You must match the hold time to your material and part thickness. This step ensures the entire part cures evenly and achieves the desired performance.

Resin Reaction

During the curing phase, the resin undergoes a chemical transformation. You apply heat and pressure, which trigger the resin to cross-link and form a solid matrix around the carbon fibers. This reaction locks the fibers in place and gives the composite its strength and durability.

The curing process must match the resin’s design. If you use a fast, high-intensity protocol, you may see a lower degree of conversion, reduced hardness, and increased water absorption. For example, some composites cured in just three seconds showed a degree of conversion as low as 38.7%, which is not enough for high-performance parts. The photoinitiator system in the resin also affects how well the reaction proceeds. Improper curing can cause early chain termination, leading to a weaker polymer network.

You achieve the best results when you follow the recommended autoclave curing protocol for your specific resin. This approach ensures the composite reaches its full mechanical potential and remains stable over time.

Cooling

Controlled Cooling

You must manage the cooling phase with precision after the curing process. Controlled cooling ensures that your carbon fiber part maintains its shape and mechanical properties. If you cool the part too quickly, you risk creating internal stresses and uneven shrinkage. These issues can lead to warping or even cracks.

During cooling, the material’s out-of-plane coefficient of thermal expansion (CTE) increases sharply—up to 1247 με/°C during crystallization. This value is about five times higher than before crystallization. Such a dramatic change means the part can shrink rapidly and unevenly if you do not control the temperature drop. The crystallization process also happens within a narrow temperature range. You need precise temperature control to avoid sudden changes that could damage the part.

You should use the autoclave’s programmable controls to set a gradual cooling rate. This approach allows the resin and fibers to contract together, maintaining contact with the mold. Consistent cooling helps you achieve a smooth surface finish and stable dimensions.

Tip: Always monitor the temperature at multiple points on the part. This practice helps you catch any hot spots or rapid drops that could cause defects.

Preventing Defects

Proper cooling plays a key role in preventing defects in your carbon fiber parts. If you allow the material to cool too quickly or unevenly, you may see the laminate lose contact with the tooling. Optical microscopy often reveals these defects, which can form as the part shrinks away from the mold.

Mechanical testing, such as ASTM D3410 compression tests, shows that parts with cooling-induced defects have lower compressive strength than defect-free samples. Dynamic mechanical analysis confirms that thermal shrinkage during cooling causes the material to pull away from the tooling, leading to voids or surface imperfections.

Here is a summary of key metrics that highlight the importance of controlled cooling:

|

Metric / Observation |

Description / Result |

Implication for Controlled Cooling Necessity |

|---|---|---|

|

Out-of-plane CTE during crystallization |

1247 με/°C (about 5× higher than before crystallization) |

Rapid, non-uniform shrinkage if cooling is uncontrolled |

|

Temperature range of crystallization |

Narrow temperature range |

Requires precise temperature control to avoid uneven cooling and shrinkage |

|

Defect identification method |

Optical microscopy |

Reveals defects formed during cooling due to loss of contact with tooling |

|

Mechanical testing standard |

ASTM D3410 |

Compression tests quantify impact of defects on mechanical strength |

|

Effect of defects on compressive strength |

Defective specimens show reduced compressive strength |

Defects degrade mechanical performance, emphasizing controlled cooling |

|

Dynamic mechanical analysis |

Loss of contact between material and tooling surfaces due to thermal shrinkage |

Confirms defect formation mechanism linked to cooling-induced shrinkage |

By following a controlled cooling protocol, you protect your carbon fiber parts from these common defects. This step ensures your finished components meet the highest standards for strength and reliability.

Pressure Release and Unbagging

Pressure Drop

You must manage the pressure release phase with care. When the curing and cooling cycles finish, you cannot simply open the autoclave. A sudden drop in pressure can damage your composite part or even cause safety hazards. You should follow a controlled pressure reduction protocol. Most autoclave systems allow you to program the rate of pressure drop, often around 0.3 barg per minute.

Tip: Always monitor the pressure gauge and follow your facility’s standard operating procedures during this step.

A gradual pressure drop prevents rapid expansion of any trapped gases inside the laminate. This step protects the structural integrity of your part. You also reduce the risk of delamination or microcracking. Many manufacturers use a checklist to confirm that the pressure has reached atmospheric levels before opening the autoclave door.

Key steps for safe pressure release:

-

Confirm the autoclave has completed its cooling cycle.

-

Set the pressure release rate according to your process specification.

-

Monitor the pressure gauge until it reaches zero.

-

Document the pressure release in your process log.

Part Removal

Once you release the pressure and open the autoclave, you can remove your composite part. Use caution when handling the part, as it may still retain some heat. Wear protective gloves and use appropriate lifting tools to avoid damaging the surface.

You should inspect the vacuum bag and consumables for signs of resin bleed or bag rupture. Carefully peel away the vacuum bagging materials, starting at the edges. Avoid using sharp tools that could scratch the composite surface.

Note: Immediate inspection helps you catch any defects, such as surface imperfections or incomplete cure, before moving to post-processing.

A clean removal process ensures your part remains free from contamination. You set the stage for successful post-curing and final inspection by following these best practices.

Post-Curing and Inspection

Finishing

You move to the finishing stage after removing your carbon fiber part from the autoclave. This step shapes the final appearance and ensures the part meets dimensional requirements. You trim excess material using precision cutting tools. Sanding edges and surfaces helps you achieve a smooth finish. If your part requires holes or cutouts, you drill or machine them at this stage. You must handle the part carefully to avoid introducing new defects.

You often apply a protective coating or paint to enhance durability and appearance. This coating can also provide resistance to UV light, chemicals, or moisture. You inspect the surface for any imperfections, such as pinholes or resin-rich areas. If you find minor flaws, you can repair them with specialized fillers or resins.

Tip: Always use clean gloves and tools during finishing. This practice prevents contamination and keeps your part looking professional.

Quality Check

You ensure your carbon fiber part meets strict quality standards before it enters service. Inspection protocols help you catch defects early and maintain consistency. You start with a pre-inspection of raw materials. This step verifies that your inputs meet quality requirements and prevents defects later in the process.

During production, you perform process inspections at regular intervals. You might inspect every two hours, after every five units, or as your management defines. This approach helps you detect issues before they affect the entire batch. For critical parts, you use a 100% inspection method. You examine every finished product to separate non-conforming units.

You also rely on statistical quality control measures:

-

Acceptance sampling: You test a sample of products against set criteria. This method reduces the chance of defective parts reaching your customers.

-

Process control: You monitor and adjust your production process to keep performance consistent and variation low. You may use batch, continuous, or hybrid control systems.

These combined methods help you detect defects early, maintain high product quality, and take corrective action when needed. By following robust post-curing and inspection protocols, you deliver carbon fiber parts that meet the highest industry standards.

Benefits of the Autoclave Carbon Fiber Process

Strength and Quality

You choose the autoclave process when you want the highest standards for carbon fiber products. This method gives you a low void content—often between 0.25% and 1%—and a high fiber volume fraction. These features help you achieve maximum strength and stiffness, which are essential for high-performance materials. When you use autoclave processing, you can expect consistent results and minimal defects. This reliability makes it a trusted choice for critical applications.

However, recent industry data shows that the strength and stiffness improvements over vacuum bagged methods are modest, usually about 1-3%. For many structural parts, you may find that both autoclave and out-of-autoclave processes deliver similar performance. In some cases, vacuum bagged or oven-cured parts even show better resistance to delamination and damage. You should consider your specific needs before choosing a process.

Note: Autoclave processing remains the gold standard for quality, but advances in out-of-autoclave technology have narrowed the gap.

Industry Applications

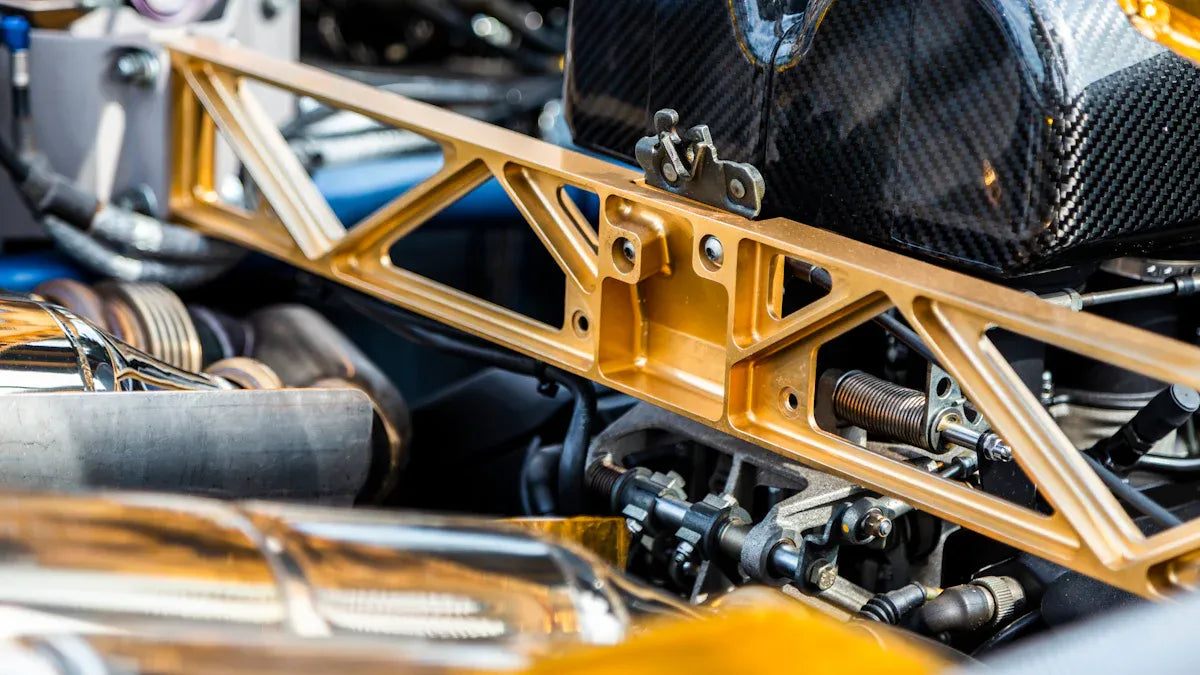

You see autoclave processing most often in aerospace, where every gram counts and reliability is non-negotiable. Aircraft manufacturers rely on this method to produce carbon fiber products with precise tolerances and superior mechanical properties. You also find autoclave-cured parts in motorsports, defense, and medical devices, where high-performance materials are essential.

Today, you notice a shift in the industry. Companies like Boeing and Bristol Aerospace now use out-of-autoclave methods for some aerospace components. These new processes offer similar quality, lower costs, and greater flexibility for large or complex parts. If you work in manufacturing, you may find that out-of-autoclave techniques help you scale production and reduce expenses without sacrificing quality.

-

Autoclave: Best for maximum performance and minimal defects.

-

Out-of-autoclave: Ideal for cost savings, larger parts, and high production volumes.

You should evaluate your project’s requirements and resources to select the best process for your carbon fiber products.

You have seen how the autoclave carbon fiber process delivers high-performance composites through eight precise steps. This method uses uniform heat and pressure to create defect-free parts for aerospace, automotive, and wind energy sectors. You benefit from improved material quality, structural integrity, and consistent results. As industries demand lighter, stronger materials, you can appreciate the advanced control and innovation that make this process a benchmark for quality and sustainability.

Share:

Why Carbon Fiber Is the Backbone of Modern F1 Cars

Carbon Fiber for Racing vs Street Cars: What the Numbers Show in 2025