CarbonXtreme Post

How ultrasonic testing is used to inspect carbon fiber layers

Ultrasonic testing (UT) is a vital non-destructive testing (NDT) technique for carbon fiber composites, helping detect internal flaws like delaminations, cracks, and voids without causing damage. Using high-frequency sound waves, phased array ultrasonic testing (PAUT) provides detailed 2D and 3D images, enhancing defect detection and inspection speed. The method offers superior performance over other NDT methods like thermography and visual testing, making it essential for industries like aerospace and automotive. Future advancements, including automation and AI, will improve inspection efficiency, making UT even more effective for carbon fiber layer inspection.

What Are Matched Die Molds for High-Volume Carbon Fiber Parts

Matched die molds for high-volume carbon parts offer precise, repeatable shapes with superior surface finishes and dimensional accuracy, making them ideal for large-scale, high-volume production. These molds ensure tight tolerances, fast cycle times, and strong mechanical properties, critical for industries such as automotive and aerospace. Although tooling costs are high, matched die molds provide significant long-term savings by reducing waste, improving production efficiency, and enhancing part quality. The use of automation, smart molds, and advanced materials will drive further improvements in carbon fiber molding processes.

Reusable vs Disposable Carbon Fiber Molds Never Settle for Less

Choosing between reusable and disposable carbon fiber molds significantly impacts manufacturing outcomes, including cost, quality, and sustainability. Reusable molds offer long-term cost savings, durability, and high-quality results, making them ideal for large-scale, high-volume production. On the other hand, disposable molds are better suited for prototypes or low-volume projects, offering flexibility and speed but generating more waste. Each mold type influences the production process, material use, and environmental impact. Regular maintenance, recycling, and careful mold selection are key to achieving optimal performance while minimizing waste.

Carbon Fiber Mold Release Agents Explained for Easy Projects

Mold release agents are essential in carbon fiber manufacturing to ensure smooth demolding, protect molds, and maintain high-quality finished products. These agents form a protective barrier between the mold and carbon fiber material, preventing sticking and damage. Choosing the right release agent depends on project size, mold material, and ease of use, with options such as wax, PVA, and semi-permanent agents available. Proper mold preparation, application, and maintenance are key to ensuring consistent results and extending the life of your molds. Understanding common mistakes, such as improper application or skipping prep, is crucial for achieving optimal outcomes.

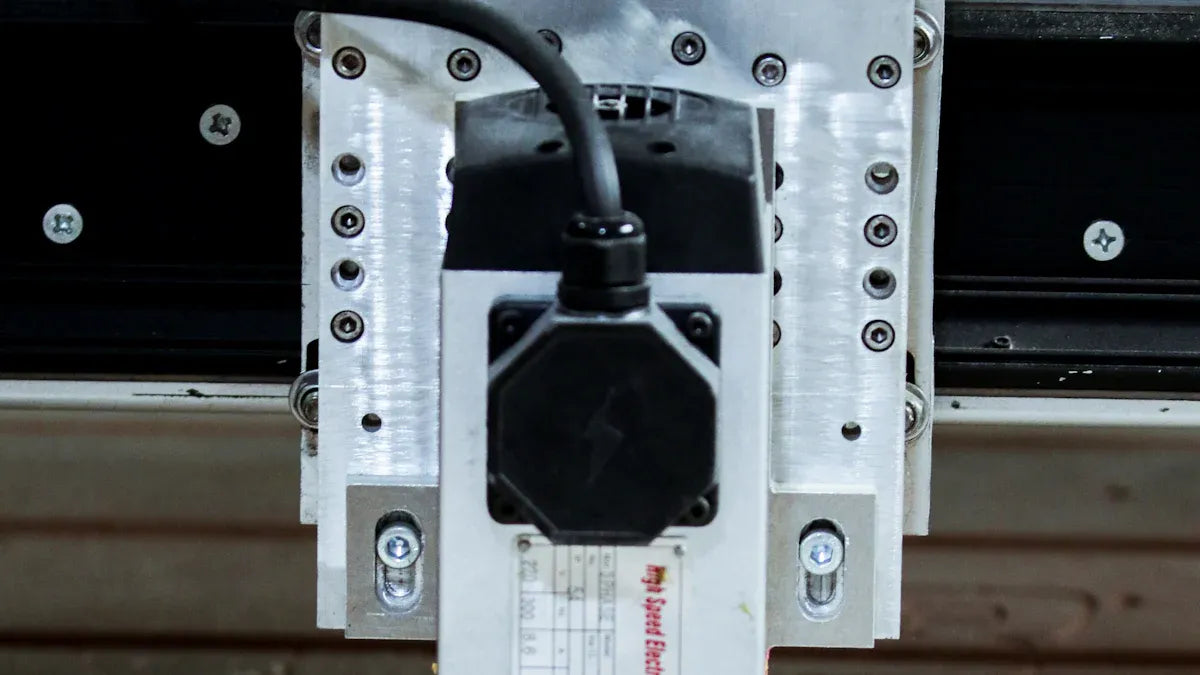

How to Make CNC Aluminum Molds for Carbon Fiber Parts

CNC aluminum molds are essential for producing high-precision carbon fiber parts. By using 6061 aluminum and CNC machining, manufacturers ensure molds meet tight tolerances, smooth finishes, and long-lasting durability. The process begins with careful CAD design, followed by machining, surface finishing, and mold release application. Precision and material selection are crucial to ensure the mold’s longevity and the quality of the final carbon fiber part. Regular maintenance and proper handling prevent defects and maintain mold performance throughout production cycles. For complex, high-performance carbon fiber parts, CNC aluminum molds offer the necessary accuracy and surface quality.

Resin-Rich vs Resin-Starved Carbon Parts: Pros and Cons

The key difference between resin-rich and resin-starved carbon fiber parts lies in the balance of resin and fiber content. Resin-rich parts offer enhanced surface quality, durability, and better resistance to environmental factors but come with higher weight and cost. Conversely, resin-starved parts have a higher strength-to-weight ratio and lower costs, making them suitable for weight-sensitive applications, but may suffer from weaker spots and surface damage due to insufficient resin. Balancing resin content is essential to achieving optimal performance, durability, and cost-effectiveness, and manufacturers use non-destructive inspection methods to detect resin distribution defects and ensure part quality.

Discover the Secret to Long-Lasting Carbon Fiber Prepreg Handling and Storage

Effective handling and storage of carbon fiber prepreg are essential to maintaining its quality, performance, and shelf life. Proper temperature control, humidity management, and sealed packaging are crucial factors in preventing resin degradation and preserving tackiness. The best practice is storing prepreg at -18°C for up to 12 months, with strict monitoring of out-time and environmental conditions. While vacuum bagging can help reduce voids and improve fiber density, mistakes like improper thawing and exposure to high temperatures can lead to defects. Advanced storage solutions and inventory management methods further enhance quality, reduce waste, and maximize material efficiency.

Vacuum Bagging Compared to Compression and Infusion Methods for Carbon Fiber

Choosing the right carbon fiber molding method is essential for optimizing performance, quality, and cost. Vacuum bagging, compression molding, and vacuum infusion each have their distinct advantages. Vacuum bagging improves part quality by reducing voids and increasing fiber density, making it suitable for small to medium production runs. Compression molding offers high-strength and precision for mass production but requires higher investment. Vacuum infusion provides good resin control, ideal for large, complex parts with minimal voids. Manufacturers must weigh factors such as part size, production volume, and budget when selecting the right method.

How to Modify Your Car Suspension for Better Street Performance