You create cnc aluminum molds for carbon fiber by designing the mold in CAD software, machining it from 6061 aluminum, and preparing the surface for carbon fiber layup. Precision matters at every step. CNC machining delivers tolerances as tight as ±0.001″ and surface finishes as smooth as 0.8μm Ra, which ensures your mold produces carbon fiber parts with excellent accuracy and finish. You benefit from efficiency, repeatability, and the ability to produce complex shapes. Quality checks using tools like CMMs and profilometers help confirm each mold meets your specifications.

Key Takeaways

-

Use 6061 aluminum and CNC machining to create strong, precise molds that last for many production cycles.

-

Design your mold carefully in CAD, following standards for holes, edges, and draft angles to ensure easy machining and demolding.

-

Finish the mold surface smoothly with polishing and anodizing to improve carbon fiber part quality and reduce post-processing.

-

Apply the right mold release agent evenly to prevent sticking and extend mold life during repeated use.

-

Maintain your mold regularly by cleaning, inspecting, and repairing to avoid defects and keep producing high-quality parts.

CNC Aluminum Molds for Carbon Fiber

Why Choose CNC Aluminum

You gain several advantages when you select CNC aluminum molds for carbon fiber projects. CNC machining delivers high accuracy, repeatability, and tight tolerances, which are essential for producing carbon fiber molds that meet strict performance standards. Aluminum stands out for its strength, corrosion resistance, and ability to withstand thermal cycling. These properties allow a mold to produce over one million parts without significant wear. Advances in welding and repair techniques also help maintain the mold’s integrity over time. You can rely on CNC aluminum molds for carbon fiber to handle complex geometries and deliver a smooth surface finish, which reduces post-processing and improves part quality.

Tip: CNC machining enables rapid design changes and prototyping, making it ideal for both low-volume and high-performance applications.

Mold Types and Applications

You will find several types of molds used in carbon fiber manufacturing, each suited to specific needs. Hand lay-up molds offer a cost-effective solution for custom or low-volume parts, but they lack the precision of CNC aluminum molds for carbon fiber. CNC-machined molds, whether aluminum or steel, provide the highest accuracy and surface finish, making them the top choice for aerospace and automotive components. Open molds work well for simple shapes, while two-piece molds allow you to create more complex parts with detailed features.

|

Mold Type |

Best Use Case |

Precision Level |

|---|---|---|

|

Hand Lay-Up |

Custom, low-volume |

Moderate |

|

CNC Machined |

High-performance, complex |

High |

|

3D Printed |

Prototyping, small batch |

Variable |

|

Injection Molding |

High-volume, industrial |

High |

You should consider factors like draft angles, surface finish, and venting when designing your mold. Mold release systems and advanced techniques such as vacuum-assisted molding help prevent sticking and improve part quality. By choosing the right mold type and optimizing your process, you can avoid common issues like warping or surface defects and extend the life of your carbon fiber molds.

Materials and Tools

Aluminum Selection (6061)

You should always start with the right base material when making CNC aluminum molds for carbon fiber parts. 6061 aluminum stands out as the industry standard due to its excellent machinability, high strength, and resistance to corrosion. These qualities ensure your mold maintains dimensional stability and durability through repeated use. The following table highlights the key properties that make 6061 aluminum ideal for mold fabrication:

|

Property |

Value |

|---|---|

|

Tensile Strength |

310 MPa |

|

Yield Strength |

276 MPa |

|

Fatigue Strength |

96.5 MPa |

|

Shear Strength |

207 MPa |

|

Modulus of Elasticity |

68.9 GPa |

|

Density |

2.73 g/cm³ |

|

Corrosion Resistance |

Natural, high |

|

Machinability |

Excellent |

|

Toughness and Stability |

High, no deformation after processing |

|

Processing Performance |

Excellent welding, electroplating, polishing, oxidation |

6061 aluminum’s combination of strength and machinability means you can achieve tight tolerances and a smooth finish, both critical for high-quality carbon fiber parts.

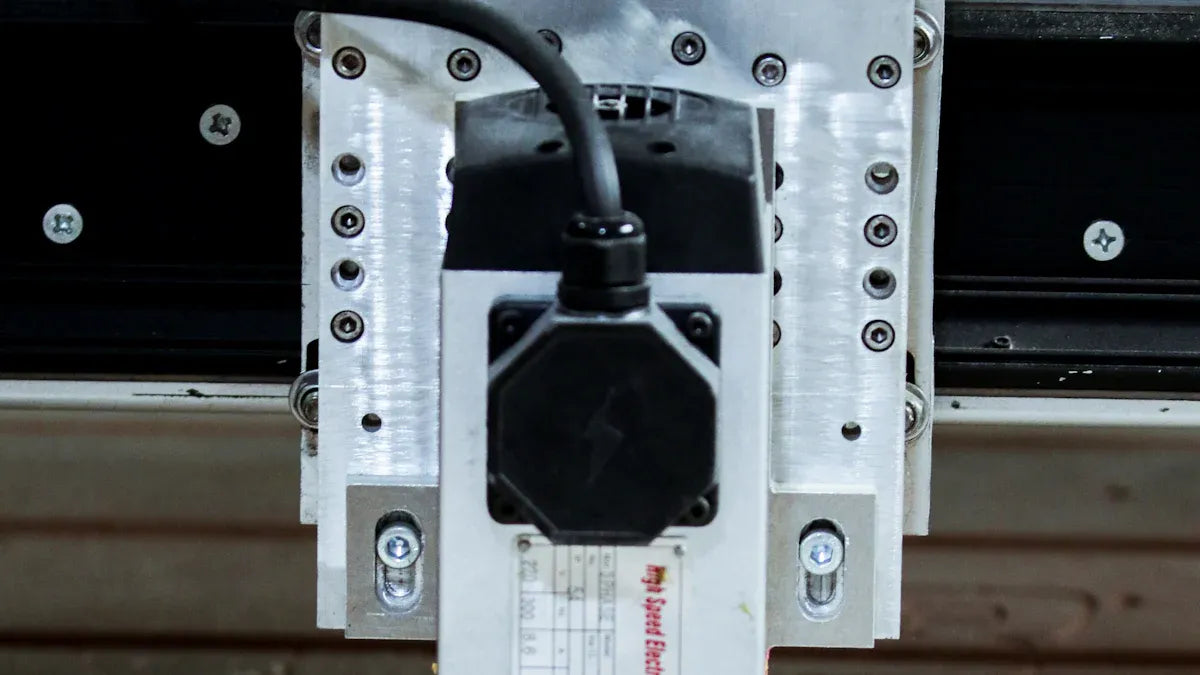

CNC Machines and Accessories

You need a CNC machine with high precision and repeatability to produce molds that meet strict requirements. Modern CNC machines deliver faster production speeds and tighter tolerances than manual methods. Accessories such as high-speed spindles, advanced tooling, and IoT-enabled monitoring systems further enhance efficiency. Consider these performance metrics:

|

Metric |

Manual/Traditional |

CNC Machining |

|---|---|---|

|

Mold Polishing Time Reduction |

N/A |

Up to 50% reduction |

|

Lead Time Reduction |

6–7 weeks total |

9–13 days total (up to 70% reduction) |

|

Surface Roughness (Ra) |

1.8 µm |

0.8 µm |

|

Dimensional Tolerance |

±0.05 mm to ±0.1 mm |

±0.005 mm to ±0.02 mm |

|

Cooling Channel Positional Accuracy |

N/A |

±0.02 mm |

|

Machining Tolerances for Inserts and Slides |

N/A |

±0.005 mm |

|

Average Mold Cycle Time Reduction |

Baseline |

10–20% faster |

|

Defective Product Rate |

3–5% |

Less than 1% |

|

Maintenance Frequency |

High |

Low |

|

Production Downtime |

Moderate |

Minimal |

Tip: Digital twin simulations and smart mold technology now allow you to optimize mold designs virtually, reducing errors and improving durability before you even begin machining.

Other Essentials

You must not overlook safety gear and surface finishing tools. Proper safety equipment—such as gloves, goggles, and respirators—protects you from metal chips, dust, and chemical exposure. Surface finishing tools, including polishing pads, anodizing kits, and laser engravers, help you achieve the required mold quality and longevity. The table below summarizes common finishing methods and their impact:

|

Surface Finishing Method |

Description |

Impact on CNC Aluminum Molds |

|---|---|---|

|

Anodizing Type I (Chromic Acid) |

Thin oxide layer, retains tight tolerances, fatigue resistant |

Prevents stress-corrosion cracking, maintains mold precision and durability |

|

Anodizing Type II (Sulfuric Acid) |

Common anodizing, balances hardness and wear resistance |

Enhances surface hardness and wear resistance, improves mold longevity |

|

Anodizing Type III (Hardcoat) |

Thick, durable oxide layer |

Significantly increases wear and corrosion resistance, ideal for industrial molds |

|

Laser Engraving |

Non-contact thermal marking |

Maintains structural integrity while allowing precise markings for traceability |

|

Heat Treating |

Alters microstructure to improve mechanical properties |

Enhances strength, hardness, and wear resistance, contributing to mold durability |

-

Choosing the right maintenance and cleaning tools directly affects the quality and lifespan of your molds.

-

Innovative, solvent-free cleaners and micro welders help you maintain surface integrity and extend mold life.

When you select the best materials for carbon fiber molds and pair them with advanced machining and finishing tools, you set yourself up for success in both performance and efficiency.

Carbon Fiber Mold Making Process

CAD Design

You begin carbon fiber mold making by creating a precise CAD model. This digital blueprint defines every detail of your mold, from cavity shape to venting channels. You must follow key considerations in carbon fiber mold design to ensure manufacturability and performance. Use standard drill bit sizes for holes, maintain recommended corner radii, and design cavities with appropriate depth-to-width ratios. The table below summarizes essential CAD standards and precision metrics for CNC aluminum molds for carbon fiber:

|

Design Aspect |

Recommended Standards and Precision Metrics |

|---|---|

|

Holes |

Standard drill sizes; diameters above 1 mm; max depth ~4x diameter; end mills for non-standard sizes; 135° conical floor |

|

Internal Edges |

At least 1/3 cavity depth; larger corner radii for tool paths; T-bone undercuts for sharp corners |

|

Threads |

Minimum M2; M6+ preferred; thread length 1.5–3x diameter; unthreaded length at hole bottom |

|

Cavities/Pockets |

Depth 3–4x width; >6x tool diameter is deep; special tooling for up to 30x tool diameter |

|

Text Marking |

Font size 20+; engraving depth ~5 mm; laser or electrochemical etching preferred |

You should always check your CAD model for undercuts, draft angles, and venting features. These elements help you avoid costly machining errors and ensure easy demolding. By following these standards, you set the foundation for accurate CNC machining and high-quality carbon fiber molds.

Tip: Use digital simulation tools to verify your design before machining. This step helps you catch potential issues early and reduces wasted material.

Machining Steps

Once your CAD model is ready, you move to the CNC machining phase. You select 6061 aluminum for its machinability and stability. Specialized carbide or diamond-coated tools prevent heat buildup and tool wear during the process. You use peck drilling techniques for deep holes and maintain low cutting speeds with high feed rates to minimize damage. These steps are crucial in carbon fiber mold making because they ensure the mold matches your CAD design with tight tolerances.

You should monitor dimensional accuracy throughout machining. Use coordinate measuring machines (CMMs) and profilometers to check critical features. If you find deviations, adjust your tool paths or parameters immediately. This proactive approach helps you achieve the precision required for carbon fiber molds.

-

Always remove chips and debris between passes.

-

Inspect the mold after each major operation.

-

Document any tool changes or parameter adjustments for future reference.

Surface Finishing

After machining, you focus on surface finishing. The surface quality of your mold directly affects the appearance and performance of your carbon fiber parts. You start with precision machining, then move to polishing or even super precision polishing for critical surfaces. The table below shows typical surface roughness (Ra) values for different finishing techniques:

|

Surface Finishing Technique |

Typical Ra Range (μm) |

Surface Condition Description |

Application Examples |

|---|---|---|---|

|

Super Precision Polishing |

0.025 – 0.2 |

Mirror-like, ultra-smooth |

Optical lenses, high-precision bearings |

|

Precision Machining |

0.2 – 0.8 |

Smooth |

Hydraulic valves, sealing surfaces, precision molds |

|

Ordinary Machining |

0.8 – 3.2 |

Semi-smooth |

Gear teeth, shaft parts |

|

Rough Machining |

3.2 – 12.5 |

Obvious tool marks |

Non-mating surfaces, casting blanks |

You should aim for a surface roughness of 0.2–0.8 μm Ra for most carbon fiber mold making projects. Lower Ra values result in smoother parts and easier demolding. Use contact or non-contact measurement tools to verify your finish. If you find rough areas, repeat polishing or apply a finer abrasive.

Note: Surface roughness on the mold transfers directly to your carbon fiber parts. A smoother mold means a better finish and less post-processing.

Mold Release Application

The final step in carbon fiber mold making involves applying a mold release agent. This coating prevents the carbon fiber part from sticking to the mold and protects the mold surface during repeated cycles. You can choose from semi-permanent polymerized coatings, sprayable coatings, gelcoats, or vinyl ester layers. Research shows that advanced polymerized coatings, such as stearyl methacrylate, can improve demoldability by over 90% and maintain performance over many cycles.

-

Apply the release agent evenly across all mold surfaces.

-

Allow the coating to cure fully before starting the layup.

-

Reapply as needed based on the number of cycles and manufacturer recommendations.

Surface coatings not only reduce demolding force but also enhance mold longevity and maintain dimensional accuracy. These treatments help you avoid surface defects and ensure a high-quality finish on your carbon fiber parts.

Tip: Regularly inspect your mold for wear or buildup. Proper maintenance of the release layer extends the life of your molds and improves part consistency.

By following these steps, you ensure that your cnc aluminum molds for carbon fiber deliver consistent, high-quality results. Careful attention to each stage of carbon fiber mold making sets you up for success in both performance and efficiency.

Layup and Curing

Carbon Fiber Layup

You start the layup process by cutting carbon fiber fabric to match your mold’s contours. Place each layer carefully, ensuring fibers align with the load paths for maximum strength. Use gloves and clean tools to avoid contamination. The way you stack and orient the layers—known as the layup configuration—directly affects the structural integrity of your finished part. Research shows that optimized layup techniques, such as interlayer (layer-by-layer) or hybrid fiber architectures, can increase tensile strength by up to 68% and impact strength by 10%. These configurations also help control crack propagation and improve damage tolerance in carbon fiber composites. Always smooth out wrinkles and avoid curved fiber sections, as these areas are prone to delamination.

Tip: Use a vacuum bag to compress the layers and remove air pockets. This step improves fiber volume fraction and reduces voids.

Resin Infusion

Once you finish the layup, you move to resin infusion. This process saturates the carbon fiber with resin, locking the fibers in place. Several infusion methods exist, each with unique benefits. The table below compares common techniques:

|

Infusion Method |

Fiber Volume Fraction |

Void Content |

Mechanical Strength |

Curing Consistency |

Notes |

|---|---|---|---|---|---|

|

VARTM |

Baseline |

Baseline |

Baseline |

Standardized |

Simple, widely used |

|

SCRIMP |

Slightly higher |

Similar |

Baseline |

Standardized |

Uses distribution media |

|

CAPRI |

+5% over SCRIMP |

Reduced |

Improved |

Standardized |

Reduces thickness variation |

|

VAP |

1–3% decrease |

Reduced |

Reduced voids |

Standardized |

Reduces porosity |

|

Pulsed Infusion |

N/A |

N/A |

+9% flexural modulus, +24% flexural strength |

Standardized |

Improves properties |

You should select the method that matches your part’s requirements. CAPRI and pulsed infusion offer higher fiber volume and better mechanical properties, while VARTM provides simplicity and reliability.

Curing and Demolding

After resin infusion, you cure the part to harden the resin and lock the structure. Place the mold in an oven or autoclave and follow the recommended temperature and pressure cycle. Longer curing times reduce residual stress and optimize part quality. Gradually reduce temperature and pressure after curing to prevent damage. Wait until the mold cools below 50°C before demolding. This step avoids deformation or resin cracking. Proper curing and careful demolding help you avoid defects like delamination, porosity, and warping. Adjust curing time and cooling rate as needed to control residual stress and distortion. These practices ensure your carbon fiber part meets high standards for strength and appearance.

Note: Monitoring temperature and pressure throughout curing is critical. Consistent process control leads to reliable, high-quality results.

Troubleshooting Carbon Fiber Molds

Common Issues

You may encounter several challenges when working with a mold for carbon fiber parts. Surface imperfections often appear if you do not maintain a clean environment or if the mold surface has scratches or residue. Air bubbles can form during layup, leading to weak spots in the finished part. Warping sometimes occurs if you do not control the curing temperature or if the mold lacks proper support. Sticking is another frequent problem. This usually happens when you apply an insufficient release agent or use the wrong type for your mold surface.

Dimensional inaccuracies can result from tool wear or improper calibration of your CNC machine. If you notice parts that do not fit or align as expected, check your mold for wear or deformation. Cracking or chipping may develop if you use aggressive demolding techniques or if the mold experiences repeated thermal cycling without proper care.

Tip: Always inspect your mold before each production run. Early detection of issues helps you avoid costly downtime and defective parts.

Maintenance Tips

You can extend the life of your mold and ensure consistent results by following proven maintenance practices. Regular cleaning and inspection using nonabrasive methods prevent residue buildup and help you detect early signs of wear. Proper lubrication and careful use of release agents reduce stress on the mold texture during part ejection. This approach prevents surface damage and preserves fine details.

-

Recondition worn textures with laser etching to restore precision. Avoid overpolishing, as it can remove important surface features.

-

Store your mold in a temperature-controlled environment and apply anticorrosion coatings to protect against rust and oxidation.

-

Implement a preventive maintenance schedule that aligns with your production cycles. This ensures consistent calibration and keeps your molds in optimal alignment.

By following these steps, you maintain the integrity of your carbon fiber molds and achieve reliable, high-quality parts every time. Consistent care and attention to detail help you avoid unexpected failures and maximize your investment in each mold.

You now have a clear roadmap for making CNC aluminum molds for carbon fiber parts:

-

Design your mold in CAD.

-

Machine it from 6061 aluminum.

-

Finish and prepare the surface.

-

Apply a quality mold release.

Precision, material selection, and surface finish drive your results. Always follow best practices to achieve reliable, high-quality parts. For advanced techniques, explore resources on digital simulation, smart mold technology, and composite engineering.

Share:

How Curing Time and Method Affect Carbon Fiber Performance

Vacuum Bagging Compared to Compression and Infusion Methods for Carbon Fiber