Precision drives success in engineering, especially when working with advanced materials. Engineers rely on both carbon fiber and metals to achieve strict design requirements. These materials challenge teams to balance dimensional accuracy and functional performance. Carbon fiber part tolerance and fitment QA often reveals unique engineering hurdles. Specialists must understand how materials respond to each step of the process. Both design and engineering teams need to evaluate how materials interact to ensure reliable assemblies.

Key Takeaways

-

Tolerance defines the allowed size variation in parts to ensure they fit and work properly, with tighter tolerances requiring more precise manufacturing.

-

Carbon fiber parts pose unique challenges due to their fiber orientation and curing process, needing special controls to maintain fit and dimensional stability.

-

Metal parts offer more predictable machining and tighter tolerances, making them easier to fit accurately in assemblies.

-

Advanced inspection methods like coordinate measuring machines and non-destructive testing help detect defects and ensure quality in both carbon fiber and metal parts.

-

Managing variability, warping, and inspection difficulties requires careful process control, monitoring, and use of modern technologies to achieve reliable fit and performance.

Tolerance and Fitment QA Basics

Tolerance Defined

Tolerance plays a critical role in manufacturing, especially for aerospace applications where high levels of accuracy and precision are essential. Engineers define tolerance as the permissible limits of dimensional variation from a specified nominal value. In practice, tolerance ensures that parts will fit together and function as intended, even when small deviations occur during production.

-

Tolerance in industrial manufacturing refers to the allowable margin of error or deviation from specified measurements.

-

Numerical tolerances are set as upper and lower limits, creating a tolerance band.

-

Tight tolerances, such as ±0.005″ (0.127 mm), are common in aerospace and high-performance industries.

-

Advanced CNC machines and metrology equipment, like coordinate measuring machines (CMMs), help achieve and verify these tolerances.

-

Tolerances depend on application requirements, including pressure, temperature, and mechanical stresses.

|

Aspect |

Description |

|---|---|

|

Definition of Tolerance |

Permissible limits of dimensional variation from a specified nominal value. |

|

Tolerance Specification |

Upper and lower limits, allowable deviations (e.g., ±0.0001″), and tolerance bands. |

|

ISO 2768 Classes |

Fine (f), Medium (m), Coarse (c), Very Coarse (v) tolerance grades based on precision needs. |

|

Typical CNC Tolerances |

Standard CNC machining: ±0.005″ (0.127 mm); Precision machining: ±0.001″ or better. |

|

Importance of Tolerances |

Ensures part compatibility, performance consistency, quality control, and cost management. |

|

Tolerance Band |

Range between upper and lower limits; tighter bands require more precise manufacturing. |

|

Impact of Decimal Precision |

More decimal places mean stricter tolerances, increasing manufacturing difficulty and cost. |

Fitment QA Explained

Fitment QA ensures that manufactured parts will fit together as designed, which is vital for aerospace assemblies and other high-stakes applications. Quality assurance standards, such as ISO 9000, guide the process by setting clear expectations for fit and finish.

-

ISO 9000 standards provide a framework for quality management and fitment verification.

-

Acceptance Sampling checks random samples to determine if batches meet fitment criteria.

-

Six Sigma targets only 3.4 defects per million opportunities, supporting tight tolerances and reliable fit.

-

Statistical Process Control (SPC) uses data to monitor and control fitment during production.

-

Total Quality Management (TQM) involves every employee in maintaining fitment quality.

Quality management systems integrate these methods to ensure that every part meets fitment requirements. In aerospace, even minor deviations in fit can lead to performance issues or safety risks, so QA processes must maintain high levels of accuracy.

Carbon Fiber vs. Metal Overview

Both carbon fiber and metal materials serve critical roles in aerospace and other industries, but their tolerance and fitment characteristics differ. Metals, such as aluminum and titanium, offer predictable behavior under machining, making it easier to achieve tight tolerances and consistent fit. Carbon fiber, however, presents unique challenges due to its anisotropic properties and curing process.

|

ISO 2768 Tolerance Class |

Description |

Application Example |

|---|---|---|

|

Fine (f) |

High precision tolerance for intricate components |

Parts requiring tight dimensional control |

|

Medium (m) |

Moderate tolerance for general components |

Components where extreme precision is not critical |

|

Coarse (c) |

Looser tolerance for less critical parts |

Larger parts with less stringent requirements |

|

Very Coarse (v) |

Largest tolerance range for rough manufacturing |

Non-critical, large-scale components |

Aerospace engineers often select materials based on the required tolerance and fit. Carbon fiber can achieve high levels of accuracy with specialized tooling and process controls, but metals remain the standard for applications demanding the tightest tolerances. Understanding the differences in how these materials respond to manufacturing processes helps teams choose the right approach for each project.

Manufacturing Processes

Carbon Fiber Methods

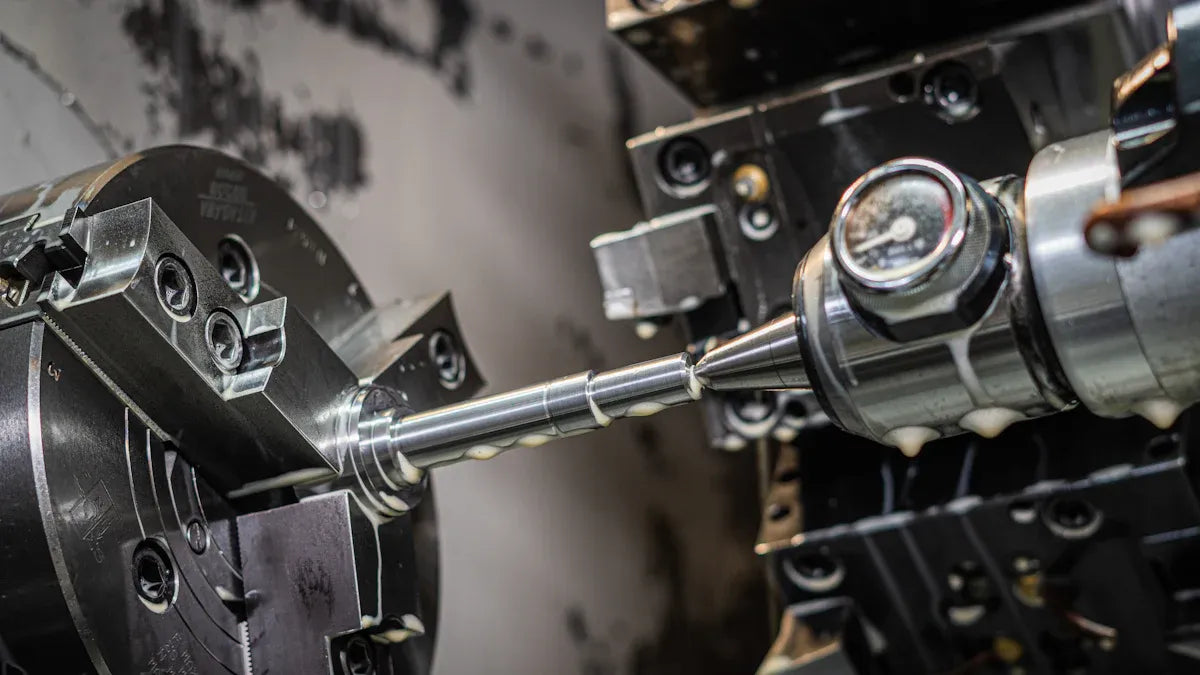

Manufacturers in the aerospace industry use several advanced methods to produce carbon fiber parts with precise tolerance. Common processes include hand layup, resin transfer molding, and autoclave curing. CNC machining of carbon fiber plates allows for defined tolerance ranges, typically between ±0.005 inches and ±0.010 inches. The anisotropic nature of carbon fiber materials, along with fiber orientation, directly influences tolerance outcomes. Machining parameters such as cutting speed, feed rate, and tool selection play a critical role in achieving dimensional accuracy. Specialized cutting tools, like diamond-coated or carbide-tipped bits, help maintain tight tolerance. Environmental factors, including temperature and humidity, also affect the final dimensions of aerospace components. Quality control measures, such as coordinate measuring machines and laser scanning, ensure statistical quality outcomes. Industry standards from organizations like AIA and ISO guide acceptable tolerance levels for aerospace applications. Research on composite structures highlights the need to optimize ply angles and thicknesses, as these factors impact both structural and geometrical functionality. By simulating the effects of discrete tolerance ranges, engineers can design robust aerospace parts that meet strict requirements.

Metal Methods

Traditional metal fabrication in aerospace relies on processes such as CNC machining, laser cutting, waterjet cutting, and welding. CNC machining achieves extremely tight tolerance, sometimes down to micron levels, depending on the equipment. Laser cutting provides precision up to a few hundredths of a millimeter, while waterjet and plasma cutting offer less tight tolerance but greater speed. Welding general fabrication typically maintains a tolerance of about 1/16 inch, though fixtures can improve accuracy. Sheet metal tolerances vary based on part geometry and process sophistication. Numerical standards, such as those for cold-formed steel members, specify crown imperfection tolerances from ±1.59 mm to ±d/100, and bow tolerances as fractions of member length. These standards ensure that aerospace parts meet the necessary tolerance for reliable assembly and performance.

Impact on Tolerances

The choice of manufacturing process has a direct impact on tolerance, especially in aerospace applications where precision is critical. Tighter tolerance increases manufacturing difficulty, leading to higher rejection, rework, and scrap rates. Achieving these tolerances often requires advanced machinery, longer processing times, and higher production costs. Allowing larger tolerances can reduce costs and speed up production, but may compromise assembly accuracy and part performance. Advanced measurement technologies, such as 3D scanning and laser measurement, provide precise data for maintaining tolerance. Automation, robotics, and AI optimize quality control by predicting defects and adjusting production parameters in real time. IoT devices enable continuous monitoring, allowing immediate feedback to maintain tolerance. Digital quality control systems support real-time analysis and unified management of quality metrics, enhancing precision control throughout aerospace manufacturing. Manufacturing case studies show that tailored application of precision and hybridization, along with analysis of machine stiffness and heat transfer, directly affect the tolerance achievable in both carbon fiber and metal aerospace parts. By balancing tolerance requirements with process capabilities, engineers ensure that aerospace materials meet design and performance goals.

Carbon Fiber Part Tolerance and Fitment QA

Tolerance Challenges

Engineers face unique challenges when managing carbon fiber part tolerance and fitment QA. The anisotropic nature of carbon fiber means that its strength and press response vary depending on fiber orientation. This property complicates the press for tight tolerances, especially in complex geometries. During manufacturing, sizing and surface treatment protect fibers from damage and improve bonding with resins. However, any inconsistency in these steps can affect the final fit and press the limits of tolerance.

Precise control of fiber tension is essential throughout the press. If tension fluctuates, the resulting part may not fit as designed. Carbonization, which must occur in an oxygen-free environment, introduces shrinkage and weight loss. These changes press the need for tight process control to maintain dimensional tolerances. Variability in fiber properties, often due to differences in sizing chemistry or surface treatments, can lead to inconsistent fit and press the boundaries of quality.

Note: The press for tight tolerances in carbon fiber parts often requires specialized mold design and advanced process controls. Engineers must anticipate fiber movement and resin flow to ensure the final part will fit as intended.

Common tolerance challenges include:

-

Maintaining fiber integrity during handling and press.

-

Achieving uniform sizing application for consistent fit.

-

Controlling chemical and physical changes during high-temperature press.

-

Managing shrinkage and weight loss during carbonization.

-

Customizing surface treatments to match resin and application needs.

-

Ensuring tight tolerances in temperature, dwell time, and atmosphere within furnaces.

These factors press the importance of robust quality control measures and careful design considerations to achieve reliable fit and performance.

QA for Carbon Fiber

Quality assurance for carbon fiber part tolerance and fitment QA requires specialized testing and inspection methods. Standard dimensional inspection techniques, such as coordinate measuring machines, press the need for accuracy in critical dimensions. For carbon fiber plates, CNC machining typically achieves tolerances of ±0.005 inches for critical features. This level of precision supports reliable fit in demanding applications.

Specialized non-destructive testing methods, such as eddy current testing, infrared thermography, and ultrasonic inspection, press the boundaries of quality by detecting internal defects without damaging the part. For example, custom eddy current probes can monitor unidirectional carbon fiber ropes, identifying resin-rich zones and delaminations that could affect fit and press the limits of performance. Deep learning models applied to thermographic images further enhance defect detection, supporting quality control measures and ensuring parts fit as designed.

|

Testing Method |

Description |

Application Example |

Performance Metrics / Notes |

|---|---|---|---|

|

Eddy Current Testing |

Detects internal defects and delaminations |

CFRP ropes, composite structures |

Contactless, fast, tailored for composites |

|

Infrared Thermography |

Identifies surface and subsurface defects |

CFRP panels, automotive parts |

Enhanced by deep learning, high accuracy |

|

Ultrasonic Inspection |

Locates voids and delaminations |

Aerospace composites |

High sensitivity, supports fitment QA |

|

X-ray Imaging |

Reveals inclusions and structural inconsistencies |

Aeronautics composite materials |

Up to 96.8% accuracy |

Quality control measures also include tensile strength, elongation at break, and modulus testing. These tests press the importance of mechanical performance and ensure that parts will fit and function as required. Industry standards, such as ASTM D3531 and ISO 527-4, guide the press for consistent quality and reliable fit.

The QA process involves:

-

Submitting samples for dimensional inspection and mechanical testing.

-

Using advanced equipment to press for accurate results.

-

Issuing third-party reports to verify quality and fit.

These steps press the need for rigorous quality control measures and support the overall goal of achieving tight tolerances and reliable fit in carbon fiber components.

Dimensional Stability

Dimensional stability plays a critical role in carbon fiber part tolerance and fitment QA. During curing and post-processing, carbon fiber composites can experience changes in shape and size. These changes press the need for careful monitoring and control to ensure the final part will fit as designed.

Thermal cycling, water sorption, and polymerization stress can all press the boundaries of dimensional stability. For example, tensile strength of carbon fiber-reinforced polymers measures 290 MPa at 20 °C but drops to 181 MPa at 100 °C. Elongation at break increases slightly with temperature, pressing the need for design considerations that account for thermal effects. Post-curing at 60 °C optimizes ductility and strength, while excessive temperatures can press the material into brittleness and reduce fit reliability.

Dimensional inspection after curing often reveals minor changes in length, width, or thickness. Engineers use push-rod dilatometers to measure linear thermal expansion and press for stable dimensions. Statistical analysis, such as one-way ANOVA, helps determine if changes are significant and press the need for process adjustments.

Tip: Engineers should always press for thorough dimensional inspection after curing and post-processing. This step ensures that any changes in fit or tolerance are identified before assembly.

Fitment QA standards must account for these dimensional changes. The press for tight tolerances requires that molds and process controls anticipate shrinkage and expansion. By integrating robust quality control measures and continuous dimensional inspection, engineers can press for reliable fit and high performance in carbon fiber assemblies.

Metal Part Tolerances and Quality

Machining and Finishing

Metal part manufacturing relies on precise machining and finishing techniques to achieve high quality and reliable performance. Grinding stands out as a key process, using abrasive wheels to create fine finishes and accurate forms. Modern grinders, equipped with CNC controls, deliver exceptional precision, especially in aerospace and high-volume production. Skilled machinists use calipers to measure dimensions with accuracy up to one-thousandth of an inch, ensuring each part meets strict requirements. Filing, once common for achieving fine tolerances, now serves mainly for deburring. Surface roughness values, such as Ra 32 to 125 microinches for general applications and as low as 4 to 16 microinches for demanding finishes, provide important quality benchmarks.

|

Technique/Tool |

Description |

Precision Benchmark |

|---|---|---|

|

Grinding |

Abrasive wheels for fine finishes and forms |

High precision, CNC controlled |

|

Calipers |

Measures inner/outer diameters |

Up to 0.001″ accuracy |

|

Filing |

Manual deburring and finishing |

Used for detail work |

QA Methods for Metal

Quality assurance in metal part production uses a combination of inspection, calibration, and statistical analysis. Manufacturers inspect parts at multiple stages, including initial, in-process, and final checks. Pin gages, calibrated to tight tolerances, verify small part dimensions. Gage Repeatability and Reproducibility (R&R) studies help identify measurement variation from devices and operators. Sampling plans, such as Acceptable Quality Level (AQL), determine how many parts to inspect from each batch. Zero acceptance sampling ensures that if any defect is found, the entire lot undergoes inspection. Quality control measures include calibration of measuring tools and training personnel to interpret standards. These steps maintain high quality and consistent performance.

-

Real-time inspection uses high-speed cameras and AI to detect defects like corrosion, pits, and cracks.

-

Inspection checkpoints and traceability systems follow ISO 9001:2015 standards.

-

Geometric Dimensioning and Tolerancing (GD&T) in CAD ensures parts fit and function as designed.

Consistency and Stability

Consistency and stability define the long-term quality and performance of metal parts. Manufacturers use documented procedures to monitor equipment capacity, employee competence, and process stability. In-process inspections track tool wear and part dimensions, triggering tool changes before parts fall out of tolerance. Statistical methods, such as process capability ratios (Cp, Cpk) and Monte Carlo Simulation, predict and optimize tolerance outcomes. Quality control measures, including measurement uncertainty analysis, help establish reliable control limits. By maintaining strict standards and continuous monitoring, manufacturers ensure that metal parts deliver stable performance and meet demanding quality requirements.

Tolerance Ranges in Practice

Industry Standards

The aerospace industry relies on strict tolerance standards to ensure reliable press fit and assembly. ISO 2768 provides numerical references for both carbon fiber and metal components. Engineers use these standards to define tolerance in press fit and tolerance stack-up for critical aerospace assemblies. The table below summarizes key ISO 2768 parts and their applications:

|

ISO 2768 Part |

Scope |

Tolerance Classes |

Application |

|---|---|---|---|

|

Part 1 |

General tolerances for linear and angular dimensions |

Fine (f), Medium (m), Coarse (c), Very Coarse (v) |

Metal components, sheet metal fabrication, linear sizes, radii, chamfers, angular dimensions |

|

Part 2 |

Geometrical tolerances for features |

H, K, L |

Geometrical features on metal parts |

Typical tolerances for flat sheet metal parts reach ±0.3 mm. Simple bends maintain ±0.3 mm across a single bend, with bend radius tolerance at ±1.0°. Multiple bends allow ±0.5 mm, while angularity tolerance is ±2 degrees. These standards guide the aerospace industry in achieving high levels of accuracy and consistent press fit design.

CNC Machining Aerospace Parts

CNC machining aerospace parts demand extremely tight tolerance in press fit and tolerance stack-up. Aerospace engineers achieve tolerances within ±0.002 mm for avionics and structural components. Specialized tooling, such as polycrystalline diamond tools, supports press-fit components and maintains dimensional stability. Cleanroom environments and precise coolant selection prevent defects like delamination or stress cracking during press fit design. Advanced inspection systems verify that each part meets aerospace specifications, ensuring reliable press fit and tolerance in press fit. Heat treatments, including annealing, relieve internal stresses and preserve tolerance during long machining cycles. CNC machining aerospace parts consistently deliver high levels of accuracy, supporting critical press-fit components and assemblies.

Real-World Fitment

Real-world fitment in the aerospace industry and automotive sector highlights the importance of tolerance in press fit and tolerance stack-up. Case studies show that direct observation and employee engagement improve assembly cycle times, reduce defect rates, and lower labor costs. For example, an automotive manufacturer reduced cycle time by 16.7% and production delays by 75% after addressing press fit and assembly bottlenecks. Digital twin technology now enables real-time simulation and control of assembly deviations, achieving over 91% prediction accuracy for out-of-tolerance issues in aerospace assemblies. Data-driven models optimize tolerance press fit, manufacturing cost, and quality loss, identifying key error sources and supporting smart assembly. These advances ensure that press-fit components and assemblies meet the demanding requirements of the aerospace industry, even as tolerance in press fit and tolerance stack-up become more challenging with complex materials like carbon fiber.

Note: Engineers in the aerospace industry must continuously monitor tolerance press fit and assembly parameters to maintain high levels of accuracy and prevent costly rework.

Quality Assurance and Inspection

Non-Destructive Testing

Non-destructive testing (NDT) plays a vital role in inspection routines for both carbon fiber and metal components. Engineers rely on NDT to evaluate internal and surface conditions without damaging the part. Modern inspection methods include ultrasonic inspection, X-ray and CT scanning, eddy current testing, and laser ultrasound. Industrial CT scanning provides high-resolution 3D images, allowing detailed analysis of internal structures. Micro-CT offers even higher resolution for small samples, supporting microstructural inspection. Lock-in thermography, combined with thermal diffusivity measurement, evaluates resin impregnation in carbon fiber reinforced polymers. NASA’s calibration system for automated fiber placement creates known defects to calibrate inspection systems, improving defect detection accuracy. These inspection techniques support quality assurance by identifying flaws early and reducing the risk of failure.

Measurement Techniques

Accurate measurement techniques ensure that inspection data supports high-quality manufacturing. Fiber optic shape sensing, using multi-core optical fibers with embedded fiber Bragg gratings, measures strain, bending, and twisting. This technology provides highly accurate 3D position and shape characterization, surpassing previous methods. Fiber optic sensors also enable real-time cure monitoring and damage detection in composites. In-situ CT scanning allows engineers to observe damage progression during mechanical testing. Integration of multiple NDT methods and advanced data analysis, including machine learning, enhances defect detection accuracy. These measurement techniques represent best practices for maintaining quality and reliability in aerospace and automotive applications.

-

Key measurement techniques for inspection:

-

Fiber optic shape sensing

-

Industrial and micro-CT scanning

-

In-situ CT with mechanical testing

-

Embedded fiber Bragg gratings for real-time monitoring

-

Common Defects

Inspection teams frequently encounter a range of defects in both carbon fiber and metal parts. Common issues include dimensional inaccuracies, surface imperfections, material flaws, assembly errors, and cosmetic defects. Statistical analysis of inspection data helps identify non-random patterns in defect occurrence. Techniques such as the chi-square test compare observed defect rates to expected rates, revealing root causes like mold temperature variations or defective raw materials. Reliability analysis, using models like Weibull, estimates the remaining useful life of components. These insights guide corrective actions and process optimization, supporting best practices in quality management. Automated inspection systems, manual checks, and customer feedback all contribute to comprehensive quality assurance. By prioritizing inspection and data-driven analysis, manufacturers reduce defect rates and improve overall quality.

Tip: Regular inspection and statistical analysis help teams identify critical points and optimize inspection planning, ensuring high-quality results and resource efficiency.

Challenges and Solutions

Variability in Carbon Fiber

Variability in carbon fiber manufacturing presents a significant challenge for engineers who must achieve a reliable fit in every assembly. Each step in the process, from fiber placement to curing, introduces sources of variability that can affect press and final part dimensions. An industry case study in aerospace identified over 60 sources of variability and 130 defect sources in carbon fiber reinforced polymer production. This level of unpredictability often forces engineers to overdesign parts to guarantee a secure fit and robust press during assembly. Overdesign increases weight and cost, which impacts fuel efficiency and environmental outcomes. For example, reducing variability in Boeing 787 manufacturing could save thousands of tons of fuel and prevent tens of thousands of tons of CO2 emissions over the aircraft’s lifetime. Quality management frameworks such as Total Quality Management and Six Sigma help teams manage variability, minimize overdesign, and improve the press for consistent fit. By implementing advanced process controls and continuous monitoring, manufacturers can reduce the need for excessive press and ensure each assembly meets design intent.

Warping and Deformation

Warping and deformation remain persistent issues in carbon fiber part production, directly impacting fit and press during assembly. The behavior of carbon fiber under press depends on factors like shear angle, deformation rate, and temperature. The table below summarizes key observations:

|

Parameter / Observation |

Value / Description |

|---|---|

|

Locking angle (UD CF/PA6 material) |

45° |

|

Validity of Pin-Jointed Net (PJN) idealization |

Up to shear angle of about 30° |

|

Effect of temperature on deformation load |

Load required to deform specimens increases at lower temperatures |

|

Effect of deformation rate on deformation load |

Load required to deform specimens increases at faster deformation rates |

|

Deformation localization |

Highly rate-dependent; more pronounced at lower deformation rates |

|

Shear behavior comparison |

Comparable to woven fabrics for limited deformations |

|

Impact on forming complexity |

Larger maximum in-plane shear deformation allows production of more complex parts without defects |

Engineers must anticipate these factors during design and press planning to ensure each part will fit as intended. Warping can cause misalignment in assembly, requiring additional press or rework to achieve proper fit. By optimizing press parameters and using simulation tools, teams can reduce deformation and improve the reliability of press-fit components.

Inspection Difficulties

Inspection of precision parts in both carbon fiber and metal assemblies requires careful planning and resource allocation. Teams must conduct frequent inspections at critical control points to prevent quality lapses, especially when production rates increase. Inspection methods must adapt to different scales and product types, with larger operations often integrating automated technologies. Engineers use a variety of tools, including calipers, micrometers, coordinate measuring machines, and ultrasonic testing equipment, to verify fit and press accuracy. Environmental factors, tool calibration, and machining parameters all influence inspection outcomes and must be controlled to maintain measurement accuracy. Advanced technologies such as AI, machine learning, and IoT enable real-time monitoring and predictive quality control, helping teams identify potential press or fit issues before they impact assembly. A geometric dimensioning and tolerancing framework supports process calibration and provides quantitative metrics for manufacturing precision, especially in complex assemblies where traditional inspection methods may fall short. By combining skilled inspectors, advanced tools, and robust process controls, manufacturers can overcome inspection challenges and ensure every assembly achieves the required fit and press.

Carbon fiber and metal parts differ in how they achieve precision and maintain fitment. Engineers must consider the anisotropic properties of carbon fiber and the predictable behavior of metals. They should evaluate process controls, inspection methods, and environmental factors. To ensure quality and precision, teams can follow this checklist:

-

Select the right material for the application

-

Use advanced inspection tools

-

Monitor environmental conditions

-

Document all quality checks

Share:

How Curing Time and Method Affect Carbon Fiber Performance

Vacuum Bagging Compared to Compression and Infusion Methods for Carbon Fiber