Carbon fiber weave types describe the distinct patterns created when manufacturers interlace strands of carbon fiber. These patterns play a crucial role in determining the performance and appearance of finished products. Statistical studies show that certain types of carbon fiber, such as plain and leno weaves, significantly enhance power output and efficiency in technical applications by optimizing porosity, electrical resistance, and mechanical stability. The characteristics of each weave type influence not only strength but also how well the material handles stress and supports specialized uses. Understanding the differences between types of carbon fiber helps engineers and designers select the best option for their unique requirements.

Key Takeaways

-

Carbon fiber weave types like plain, twill, and satin affect strength, flexibility, and appearance of products.

-

Plain weave offers high durability and stability, ideal for flat surfaces and technical uses.

-

Twill weave provides better flexibility and a stylish look, fitting curved parts and sports equipment.

-

Satin weave delivers a glossy finish and great drapability but is less durable, suited for luxury and complex shapes.

-

Choosing the right weave depends on balancing strength, flexibility, and appearance to match your specific needs.

Carbon Fiber Weave Types

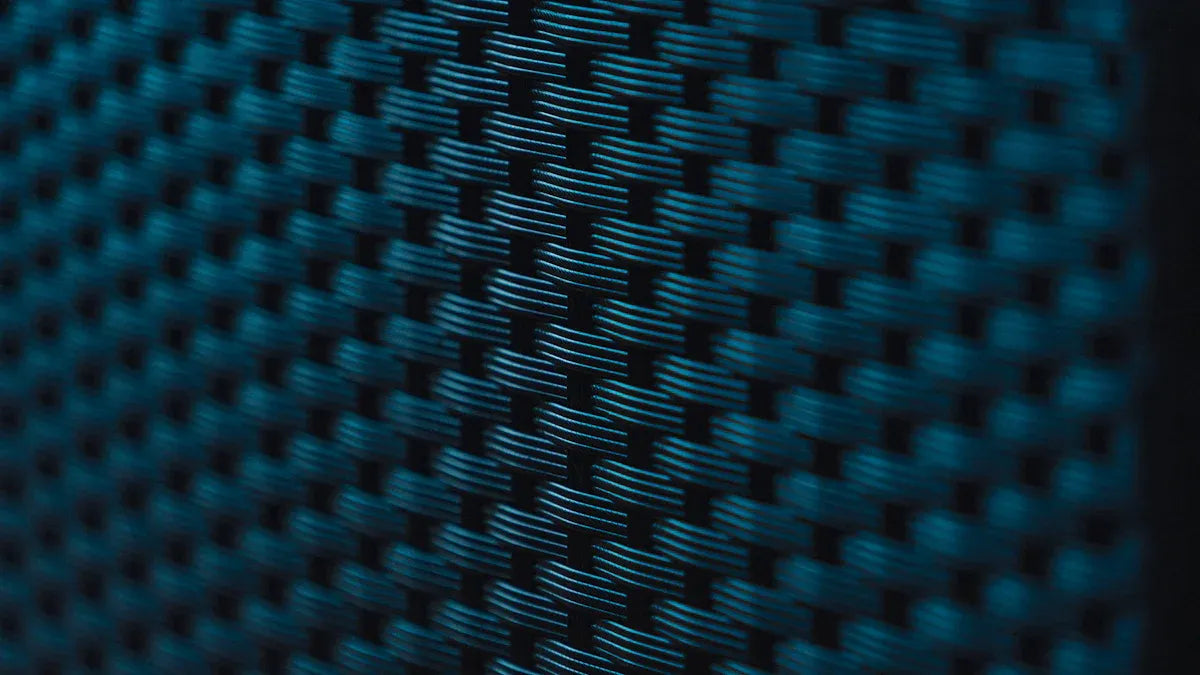

Carbon fiber weave types define the way individual strands of carbon fiber are interlaced to form a fabric. The three most common types of carbon fiber weave patterns—plain weave, twill weave, and satin weave—each offer unique structural and visual characteristics. Understanding these patterns helps engineers and designers select the right material for specific applications.

Note: The structure of each weave type directly influences the strength, flexibility, and appearance of the final composite. Industry reports confirm that advanced imaging and mechanical testing validate the performance claims for each pattern, ensuring reliability in demanding environments.

|

Feature |

Plain Weave |

Twill Weave |

Satin Weave |

|---|---|---|---|

|

Texture & Feel |

Crisp, firm, clean texture |

Soft, flexible, diagonal rib pattern |

Smooth, shiny, luxurious feel |

|

Durability |

Highly durable, tightly woven |

Extremely durable, strong structure |

Less durable, prone to snagging |

|

Appearance |

Same on both sides, matte finish |

Diagonal lines, distinct front/back |

Glossy, high sheen, elegant look |

|

Common Uses |

Technical panels, flat surfaces |

Automotive, sports, curved parts |

Aerospace, luxury, complex shapes |

|

Maintenance |

Easy to clean and maintain |

Low maintenance, follow instructions |

Requires gentle care to preserve sheen |

Plain Weave

Plain weave carbon fiber pattern stands as the most basic and widely used among all carbon fiber weave types. In this structure, each warp (vertical) strand alternates over and under each weft (horizontal) strand, creating a tight criss-cross pattern. This 1×1 interlacing forms a checkerboard appearance, which remains uniform on both sides of the fabric. The frequent intersections in the plain weave carbon fiber pattern result in a dense, stable fabric with high resistance to fraying and minimal deformation.

The plain weave carbon fiber pattern offers superior stability and mechanical robustness. Scientific studies show that this pattern maintains consistent pore size and resists structural deformation, thanks to the high number of interlacing points. The balanced construction of the plain weave carbon fiber pattern ensures equal weight and density in both directions, making it ideal for flat surfaces and applications requiring durability. This pattern is less pliable than others but excels in providing a clean, matte finish.

Manufacturers often choose the plain weave carbon fiber pattern for technical panels, body armor, and other applications where stability and uniform appearance are critical. The structure supports high energy dissipation and impact resistance, making it a reliable choice for many types of carbon fiber products.

Twill Weave

Twill weave introduces a more complex structure compared to the plain weave carbon fiber pattern. In the 2×2 twill weave carbon fiber pattern, each weft strand passes over two warp strands and then under two, creating a distinctive diagonal rib across the fabric. The 4×4 twill weave carbon fiber pattern follows a similar logic, with the strand passing over and under four strands at a time. This arrangement produces a fabric with fewer interlacing points than the plain weave, resulting in greater flexibility and a softer hand feel.

The twill weave stands out for its diagonal lines and three-dimensional texture. The front and back sides of the fabric differ, with the front displaying a pronounced diagonal pattern. This structure allows the twill weave to conform more easily to complex shapes, making it a popular choice for automotive parts, sports equipment, and curved surfaces. The 2×2 twill weave carbon fiber pattern and 4×4 twill weave carbon fiber pattern both offer a balance between strength and drapability.

Industry testing confirms that twill weave carbon fiber patterns deliver strong mechanical performance while maintaining a visually appealing surface. The pattern resists wrinkles and provides a unique look, which appeals to designers seeking both function and style in carbon fiber weave types.

Satin Weave

Satin weave, also known as harness satin or harness satin weave, features the fewest interlacing points among the common types of carbon fiber pattern. In a harness satin weave, each weft strand floats over several warp strands before passing under one, creating long, uninterrupted fibers on the surface. The most common harness satin patterns include 4-harness satin, 5-harness satin, and 8-harness satin, each defined by the number of strands the weft passes over.

The satin weave produces a glossy, high-sheen finish that stands out in luxury and high-performance applications. The smooth surface of the harness satin weave offers an elegant look but comes with reduced durability compared to plain weave and twill weave. The long floating fibers in the satin weave increase flexibility, allowing the fabric to drape over complex shapes with ease. However, this structure also makes the fabric more susceptible to snagging and wear.

Experimental studies on harness satin weave composites reveal that these patterns provide excellent flexibility and a premium appearance, but they may not match the mechanical strength of plain weave or twill weave. Manufacturers often select harness satin weave for aerospace components, luxury automotive interiors, and other applications where aesthetics and formability take priority over maximum strength.

Tip: When selecting among carbon fiber weave types, consider the trade-off between appearance, flexibility, and durability. Satin weave excels in visual appeal and drapability, while plain weave and twill weave offer superior strength and stability.

Carbon Fiber Patterns and Structure

Weave Construction

Manufacturers create different carbon fiber patterns by interlacing carbon fibre tows in specific ways. The construction method directly affects the fabric’s mechanical properties and appearance. For example, plain weave uses a simple crisscross pattern, which provides balanced performance but slightly lower impact resistance. Twill weave features diagonal interlacing, which increases adaptability and impact resistance, offering about 15% higher stiffness than plain weave. Satin weave uses long float yarns, maximizing fiber interlocking for improved strength and stiffness, though it requires more complex manufacturing. Specialized carbon fiber patterns, such as non-crimp fabrics, further expand the range of properties by altering the arrangement of the tows. Technical studies show that woven carbon fiber fabrics generally have higher damage resistance, while non-crimp patterns offer better damage tolerance. The weaving process requires precise control of warp tension to prevent defects and ensure uniformity, which is critical for high-performance carbon fiber fabric.

Tow Size and Filament Count

Tow size refers to the number of filaments bundled together in a carbon fibre tow. Common sizes include 3K, 6K, and 12K, with larger tows containing up to 320,000 filaments. The tow size impacts both strength and flexibility of the fabric. Smaller tows, such as 3K, provide higher tensile strength and more uniform properties, making them suitable for applications requiring precision. Larger tows are more cost-effective but may show greater variability in strength and stiffness due to processing challenges. Mechanical tests reveal that increasing tow width can reduce tensile strength and flexibility because of fiber breakage and abrasion. The unidirectional carbon fiber pattern, which aligns all tows in one direction, relies heavily on tow size to achieve optimal performance. Specialized carbon fiber patterns often use specific tow sizes to balance strength, flexibility, and cost.

Visual Appearance

Different carbon fiber patterns create distinct visual effects. Traditional woven carbon fiber displays a uniform, glossy weave pattern, while forged carbon fiber has a random, marble-like texture. Hand-laid carbon fiber fabric offers flawless, precise weave aesthetics, and machine-pressed fabric may show minor imperfections. Glossy finishes enhance the three-dimensional effect of the weave, creating a deep shine, while matte finishes provide a subtle, non-reflective look. The unidirectional carbon fiber pattern appears as straight, parallel lines, emphasizing directionality and technical appeal. Specialized carbon fiber patterns, such as those used in luxury or high-performance products, often combine unique visual characteristics with advanced mechanical properties. Designers select different carbon fiber patterns not only for performance but also for the desired appearance in the final product.

Note: The choice of carbon fiber weave patterns and fabric construction influences both the technical performance and the visual impact of the finished component.

Carbon Fiber Weaves Comparison

Strength and Flexibility

Different carbon fibre weaves display distinct mechanical properties. The structure of each weave determines how it handles force and adapts to shape. Plain weave offers the highest tensile strength and stiffness due to its tight interlacement. Twill weave, with fewer interlacing points, provides greater tearing strength and flexibility, making it suitable for parts that require draping over curves. The following table summarizes key mechanical properties:

|

Property |

Plain Weave |

2/1 Twill Weave |

2/2 Twill Weave |

|---|---|---|---|

|

Tearing Strength |

~13 N (lowest) |

~19 N (medium) |

~30 N (highest) |

|

Tensile Strength |

Higher |

Lower |

Lower |

|

Stiffness (Bending Length) |

Highest (2.3 cm warp) |

Medium (~2.0 cm warp) |

Lowest (~1.7 cm warp) |

|

Abrasion Resistance |

Higher |

Lower |

Lower |

|

Pilling Resistance |

Rating: 4 (Slight) |

Rating: 2-3 (Moderate) |

Rating: 2-3 (Moderate) |

Statistical analysis confirms that both production methods and material composition significantly affect strength and flexibility. Plain weave excels in applications demanding high tensile strength, while twill weave adapts better to complex shapes.

Surface Finish and Stability

Surface finish and stability play a crucial role in the selection of carbon fiber for visible or high-performance parts. Plain weave provides a balanced, abrasion-resistant surface with moderate drapability. Twill weave delivers a smoother finish and excellent drapability, which enhances resin flow and consistency. Satin weave stands out for its glossy appearance and high surface aesthetics, often used in luxury or aerospace components. The table below compares these traits:

|

Weave Type |

Market Share (2024) |

Surface Finish Characteristics |

Stability / Mechanical Properties |

|---|---|---|---|

|

Plain Weave |

>28% |

Balanced strength, abrasion resistant |

Dimensional stability, moderate drapability |

|

Twill Weave |

~32% |

Smoother finish, excellent drapability |

Better resin flow, strength consistency |

|

Satin Weave |

~18% |

Glossy appearance, minimal crimp |

Enhanced fatigue resistance, high surface aesthetics |

|

Unidirectional Weave |

~22% |

Strength mainly in one direction |

Superior tensile strength and stiffness |

Advanced modeling techniques now predict surface roughness changes with high accuracy, supporting the use of different carbon fiber weaves for specific finish and stability needs.

Durability

Durability testing reveals how carbon fiber performs under harsh conditions. Environmental exposure, such as seawater or thermal cycling, can reduce flexural and tensile strength over time. The chart below illustrates flexural strength reduction after various ageing tests:

Plain weave resists abrasion and pilling better than other weaves, making it ideal for high-wear environments. Twill and satin weaves may offer better fatigue resistance or flexibility but can show greater strength loss after prolonged exposure. Test results highlight the importance of matching the weave type to the expected service conditions for optimal durability.

Tip: Select the weave that aligns with the mechanical, visual, and durability requirements of your application to maximize the benefits of carbon fiber.

Carbon Fiber Applications

Automotive Parts

Automotive manufacturers rely on carbon fibre composites to achieve lightweight, high-strength components. Engineers often select twill weave fabric for body panels and interior trim because it offers a balance of flexibility and visual appeal. Plain weave fabric provides stability and durability, making it suitable for flat surfaces such as underbody shields. Satin weave fabric appears in luxury vehicle interiors, where a glossy finish is desired. A study at the Fraunhofer Project Centre for Composites Research demonstrated that carbon fiber/polyamide 6.6 composites deliver superior stiffness compared to traditional glass fiber alternatives. This improvement in tensile modulus allows designers to reduce part weight, which contributes to better fuel efficiency and lower emissions. The choice of carbon fiber pattern for insoles in automotive pedal covers can also enhance comfort and durability for drivers.

Sports Equipment

Sports equipment manufacturers use carbon fibre composites to improve performance and comfort. Racket frames, bicycle components, and carbon fiber insoles all benefit from the unique properties of woven fabric. For racket-type equipment, specialized weaving and filament winding techniques increase shock absorption and vibration damping, giving athletes better control. In pole vaulting, carbon fibre composites with ultra-high elasticity maximize energy transfer. Board-type equipment, such as skis and surfboards, uses tailored fabric structures for stability and wear resistance. Recent research highlights the use of 3D woven angle-interlock weaves in sports bras and body armor, which optimize fit and support by interlocking yarns in three directions. The main types of carbon fiber patterns used in insoles include plain and twill weaves, which provide both flexibility and support. Carbon fiber insoles offer lightweight reinforcement, reducing fatigue during athletic activity. Manufacturers select the carbon fiber pattern for insoles based on the required balance of stiffness and comfort.

Industrial Uses

Industrial applications demand robust materials that withstand harsh environments. Carbon fibre composites appear in aerospace, robotics, and medical devices. Plain weave fabric offers dimensional stability for structural panels and machine housings. Twill weave fabric adapts to curved surfaces in robotic arms and prosthetics. Satin weave fabric provides a smooth finish for visible components in high-end equipment. In the medical field, carbon fiber insoles support patients who need lightweight, durable orthotic solutions. The fabric structure in these insoles ensures even pressure distribution and long-term comfort. Engineers evaluate the carbon fiber pattern for insoles to match the specific needs of each application, considering factors such as load-bearing capacity and flexibility. The right fabric selection improves product lifespan and user satisfaction.

Tip: Always match the weave type and fabric structure to the performance requirements of your application. For insoles, prioritize comfort, support, and durability by choosing the appropriate carbon fiber pattern for insoles.

Choosing a Carbon Fiber Weave

Key Selection Factors

Selecting the right carbon fiber weave requires careful evaluation of several factors. Strength, flexibility, aesthetics, and fabrication methods all play a role in the decision-making process. Engineers must match the weave’s mechanical properties to the demands of the application. For example, plain weave offers high stability and durability, making it suitable for flat surfaces and technical panels. Twill weave provides greater flexibility and a distinctive appearance, which works well for curved parts and visible components. Satin weave excels in luxury applications where a glossy finish and drapability are essential.

The choice of weave also affects the performance of insoles. Designers must consider the balance between stiffness and comfort. The structure of the weave influences how insoles distribute pressure and resist wear. Technical knowledge about precursor materials and manufacturing processes helps ensure that the selected weave meets the specific needs of insoles. This understanding links material characteristics to application requirements, improving the effectiveness of the selection process.

|

Factor |

Plain Weave |

Twill Weave |

Satin Weave |

|---|---|---|---|

|

Strength |

High |

Moderate |

Moderate |

|

Flexibility |

Low |

High |

Very High |

|

Aesthetics |

Matte, Uniform |

Diagonal, Stylish |

Glossy, Elegant |

|

Best for |

Flat panels, insoles |

Curved parts, insoles |

Luxury insoles, complex shapes |

Practical Tips

When choosing a carbon fiber weave for insoles, users should start by identifying the primary goal. If the focus is on durability and support, plain weave insoles provide a stable foundation. For insoles that must conform to the shape of the foot, twill weave insoles offer better flexibility. Satin weave insoles deliver a premium look and feel, ideal for high-end footwear.

Buyers should also compare real carbon fiber insoles to alternatives like vinyl wrap. Real carbon fiber insoles deliver genuine weight savings, enhanced durability, and superior performance. Vinyl wrap insoles only offer a cosmetic upgrade without functional benefits. Users should weigh performance needs, budget, and installation complexity before making a decision.

Tip: Always consult technical data sheets and seek expert advice when selecting carbon fiber insoles. The right weave can improve comfort, extend product life, and ensure optimal performance.

Carbon fiber weaves offer unique benefits for different applications. Plain weave provides stability for flat shapes, while twill weave balances flexibility and strength. Satin weave suits complex contours but has lower stability. Carbon fiber outperforms metals in strength-to-weight ratio, making it ideal for insoles that demand both support and lightness. When selecting insoles, users should match weave type to comfort, durability, and appearance. The right carbon fiber pattern in insoles ensures long-lasting performance. For best results, always consider both technical needs and visual appeal when choosing insoles.

Choosing the correct weave for insoles maximizes comfort and extends product life.

Share:

Why Carbon Fiber Is the Backbone of Modern F1 Cars

Carbon Fiber for Racing vs Street Cars: What the Numbers Show in 2025