CarbonXtreme Post

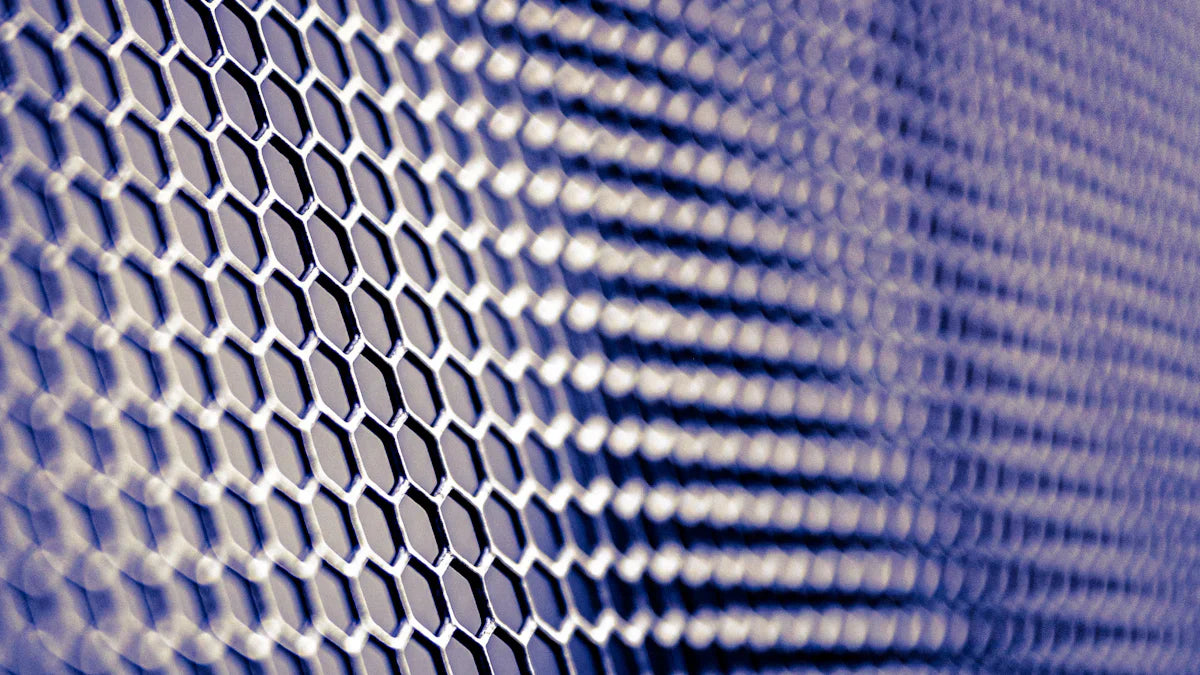

What is Triaxial Carbon Fiber and How is it Used

Triaxial carbon fiber is a high-performance composite woven in three directions, giving it exceptional strength, stability, and even stress distribution. Lightweight yet durable, it resists deformation under heavy loads and excels in demanding industries like aerospace, automotive, marine, sports equipment, medical devices, and military gear. Compared to unidirectional and bidirectional carbon fiber, its three-directional weave offers superior versatility and reliability. While it enables innovative, high-strength, and lightweight designs, challenges remain in high production costs, manufacturing complexity, and recyclability. Future developments are expected to expand its use in renewable energy, robotics, advanced prosthetics, and next-generation defense applications.

Best Silver Carbon Fiber Accessories for Cars and Homes in 2025

Silver carbon fiber has become a major design and functional trend in 2025, appearing in automotive interiors, home décor, and personal accessories. Known for its lightweight durability and sleek metallic finish, it blends modern aesthetics with practical benefits. In cars, it’s used for steering wheel covers, gear shift knobs, dashboard trims, license plate frames, and key covers—offering improved grip, durability, and style. At home, it enhances wall panels, furniture accents, light switch covers, coasters, table mats, and decorative vases, adding a futuristic vibe while resisting wear and tear. Products vary in price, making it possible to start small with items like coasters or key covers before investing in larger upgrades. Regular cleaning and polishing keep the finish looking fresh, ensuring long-lasting appeal.

Exploring the Latest Trends in Carbon Fiber Design and Usage

Carbon fiber, renowned for its high strength-to-weight ratio, is experiencing rapid innovation in manufacturing, recycling, and material design. Breakthroughs like plasma-assisted stabilization, microwave curing, and 3D printing improve production speed, efficiency, and design flexibility, while bio-based fibers and hybrid composites enhance sustainability and performance. Global demand is rising sharply, driven by aerospace, automotive, renewable energy, and healthcare applications, from lightweight EV components to wind turbine blades and advanced prosthetics. Recycling methods, closed-loop systems, and renewable-energy-powered facilities are cutting emissions and enabling second-life uses. Future trends include smart carbon fiber with embedded sensors, self-healing composites, and advanced CFRPs, alongside challenges of cost reduction, supply chain stability, and regulatory compliance.

Steps to Join a Car Track Racing Event in 2025

Car track racing in 2025 offers drivers the perfect blend of speed, strategy, and personal growth. To compete, you’ll need a racing license, which involves choosing a category, completing racing school, passing a driving test, and meeting eligibility requirements such as age and medical fitness. Safety is paramount—gear like FIA-certified helmets, fireproof suits, and HANS devices is essential, along with vehicle safety features like roll cages and harnesses. Choosing your racing category, preparing or buying a race-ready car, and deciding between team or independent racing are key early steps. Joining a racing club provides training, networking, and access to exclusive events, while registering for competitions requires meeting deadlines and documentation requirements. On race day, preparation includes pit setup, vehicle scrutineering, driver briefings, practice, qualifying, and the main race. Post-race, drivers review performance, address penalties, maintain their vehicles, and plan future events. With careful preparation, racing becomes not just a sport but an immersive community experience.

Exciting Updates on 2025 Car Racing Events and Championships

The 2025 car racing season promises an unprecedented mix of speed, innovation, and drama. Iconic events such as the Monaco Grand Prix, Daytona 500, and NHRA Summit Racing Series return alongside new additions like the Azerbaijan and Las Vegas Grands Prix. Advances in car design, lightweight components, real-time data systems, and eco-friendly initiatives—such as NASCAR’s goal for net zero emissions by 2035—are reshaping the sport. Star drivers like Lewis Hamilton, Charles Leclerc, and Max Verstappen will battle seasoned rivals and rising talents across Formula 1, NASCAR, FIA WEC, and the Race of Champions. Fans can expect thrilling rivalries, unpredictable outcomes, and enhanced engagement through technology and sustainability.

Best Yellow Carbon Fiber Accessories for 2025

Yellow carbon fiber is a vibrant, lightweight, and durable composite material gaining popularity in 2025 for its blend of style, functionality, and sustainability. Its high visibility makes it ideal for safety gear like helmets, while its strength and low weight suit products from phone cases and wallets to sunglasses, car accessories, and luxury watches. Advancements in recycling further enhance its eco-friendliness. Popular uses include slim protective phone cases, RFID-blocking wallets, heat-resistant car trims, and hybrid fabrics with Kevlar. Yellow carbon fiber stands out for its modern aesthetic, comfort, and long-lasting performance across fashion, automotive, electronics, and industrial applications.

Key Advantages and Limitations of Wet Carbon Fiber

Wet carbon fiber is a cost-effective and versatile composite made by saturating dry carbon cloth with resin in a mold, then curing under heat and vacuum. It offers a glossy “wet-look” finish and flexibility for custom, low-volume projects, making it popular in automotive, marine, and sports industries. Compared to dry carbon fiber, it is heavier, less durable, and has lower precision due to manual resin application. While it requires less specialized equipment and has lower upfront costs, it suffers from longer curing times, greater risk of imperfections, and weaker mechanical properties, making it less suited for high-performance or mass-production applications.

What Makes Transparent Carbon Fiber Unique

Transparent carbon fiber is an advanced composite that merges the strength, durability, and lightweight benefits of traditional carbon fiber with optical clarity. This unique combination unlocks applications in industries such as aerospace, automotive, medical, consumer electronics, sports equipment, and architecture. It enables x-ray transparent medical tools, lightweight yet durable automotive and aerospace components, and visually striking luxury goods. Despite current production challenges and high costs, ongoing innovations in sustainable manufacturing and recycling promise to expand its accessibility, making it a potential game-changer in future design and engineering.

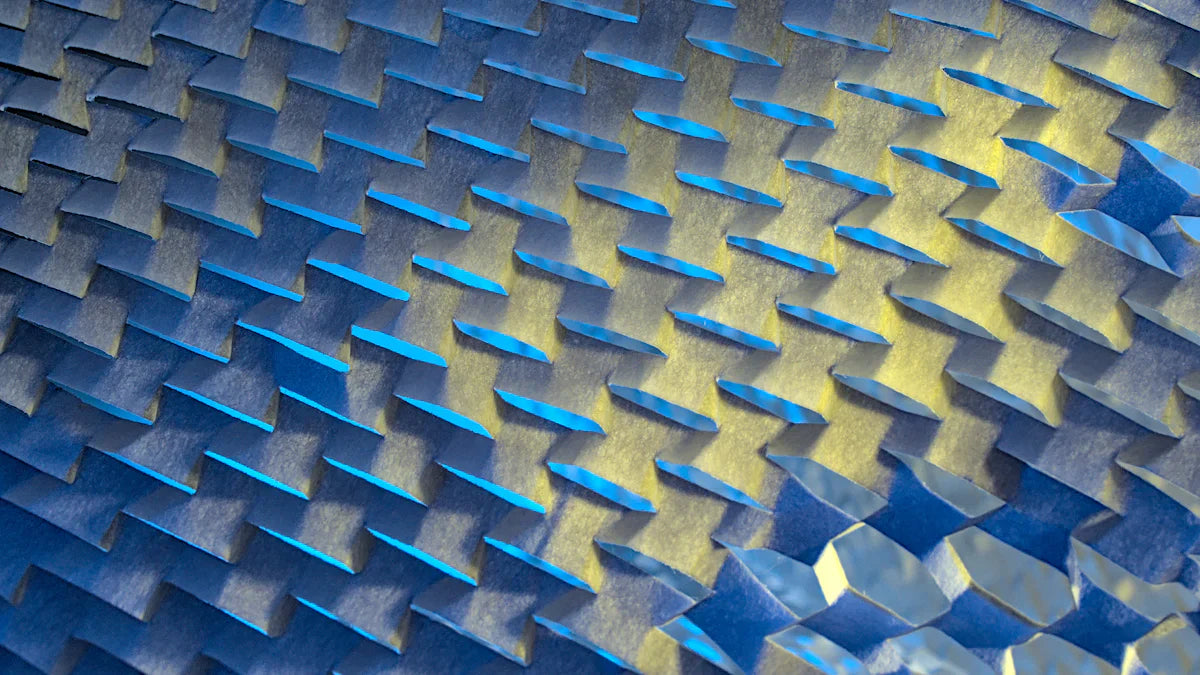

What is Carbon Fiber Satin Weave Fabric and Its Uses

Carbon fiber satin weave fabric offers a unique balance of strength, flexibility, and a smooth, refined finish, making it a preferred choice in industries like aerospace, automotive, marine, and sporting goods. Its satin weave structure—available in 4HS, 5HS, and 8HS patterns—provides superior drapability for complex shapes, while retaining the high strength-to-weight ratio of carbon fiber. This combination allows for lightweight yet durable components with excellent aesthetic appeal, often eliminating the need for additional finishing. From luxury interiors to high-performance engineering applications, its versatility ensures it meets both functional and design demands.