Transparent carbon fiber combines strength, durability, and optical clarity in a single material. Unlike traditional carbon fiber, it offers a unique balance of being both lightweight and transparent. This innovation opens doors to exciting possibilities across industries. For example, it can enhance sporting goods like bicycles and tennis rackets, improve medical tools such as prosthetics, and create durable yet visually appealing components for electronics like smartphones and laptops. Its ability to reinforce bridges, pipelines, and wind turbines further showcases its versatility. Transparent carbon fiber has the potential to transform how you think about materials in design and engineering.

Key Takeaways

-

Transparent carbon fiber is strong and clear, perfect for cool designs in many industries.

-

It is light but tough, making it great for cars and planes.

-

Its x-ray see-through ability helps doctors during scans without moving patients.

-

This material looks nice and works well, so it’s used in fancy products and gadgets.

-

Making transparent carbon fiber is hard and expensive, but new ideas are making it easier and greener.

Understanding Transparent Carbon Fiber

What Is Transparent Carbon Fiber?

Transparent carbon fiber is a cutting-edge material that combines the strength and durability of traditional carbon fiber with optical clarity. Unlike its opaque counterpart, this high-tech material allows light to pass through while maintaining its structural integrity. You can think of it as a unique blend of aesthetics and functionality. Transparent carbon fiber opens up possibilities for creating lightweight, strong, and visually appealing products in industries like automotive, aerospace, and consumer electronics.

Composition and Manufacturing Process

The process of creating transparent carbon fiber involves several precise steps. Manufacturers start with a plastic fiber made of ultra-thin filaments. These fibers undergo chemical conversion to form chains of carbon atoms. Next, the fibers are oxidized at high temperatures, which rearranges their atomic structure and makes them heat-resistant.

In the carbonization stage, the fibers are heated in an oxygen-free environment, expelling non-carbon atoms and forming tightly bonded crystals. Afterward, the fibers go through surface treatment to improve resin absorption. A light resin coating strengthens the bond between the fibers and the molding resin. Finally, the fibers are spooled or formed into pre-preg sheets, ready for use in composite materials. This meticulous process ensures the material retains its strength while achieving transparency.

Key Properties of Carbon Fiber

Carbon fiber materials stand out due to their remarkable properties. These include a high strength-to-weight ratio, making them both strong and lightweight. They are also corrosion-resistant, electrically conductive, and exhibit low thermal expansion. This means they remain stable under temperature changes, which is crucial for precision applications. Additionally, carbon fiber reinforced polymer offers excellent fatigue resistance, ensuring durability over time.

|

Property |

Description |

|---|---|

|

High Strength-to-Weight Ratio |

Extremely strong and light, suitable for various applications. |

|

Electrically Conductive |

Useful for lightning strike protection. |

|

Corrosion-resistant |

Resistant to deterioration, though epoxy may need UV protection. |

|

Rigid or Stiff |

Over four times stiffer than glass-reinforced plastic. |

|

Fatigue Resistance |

Better fatigue resistance than fiberglass. |

|

Tensile Strength |

Can bear significant stress when stretched. |

|

Low Thermal Expansion |

Minimal dimensional changes with temperature variations. |

|

Non Poisonous |

Suitable for medical applications, allowing X-rays to pass through. |

|

Non Flammable |

Can be used in firefighting protective clothing. |

These properties make carbon fiber composites a versatile choice for high-performance applications. Whether you need a lightweight structure or a durable material, carbon fiber delivers exceptional results.

Unique Properties of Transparent Carbon Fiber

Optical Clarity and Transparency

Transparent carbon fiber stands out because of its ability to combine strength with optical clarity. Unlike traditional carbon fiber, which is opaque, this material allows light to pass through. This unique property makes it ideal for applications where both aesthetics and functionality matter. For example, you might see it used in luxury goods or architectural designs where transparency enhances the visual appeal.

The optical clarity of transparent carbon fiber doesn’t compromise its performance. It retains the high tensile strength and durability of traditional carbon fiber while offering a sleek, modern appearance. This combination of features opens up new possibilities in industries like consumer electronics, where transparent materials can create innovative designs for smartphones and wearables.

High Strength-to-Weight Ratio

One of the most impressive features of transparent carbon fiber is its high strength-to-weight ratio. This property makes it incredibly strong while remaining lightweight. You can rely on it to provide the same level of strength as traditional carbon fiber but with added transparency.

This high strength-to-weight ratio is crucial in industries like aerospace and automotive. Engineers use it to design components that reduce overall weight without sacrificing safety or performance. For example, lightweight properties in aircraft parts improve fuel efficiency, while strong yet lightweight car panels enhance speed and handling.

Durability and Thermal Properties

Transparent carbon fiber excels in durability, thanks to its advanced thermal properties. These include thermal conductivity and a low coefficient of thermal expansion (CTE). High thermal conductivity ensures the material can efficiently transfer heat, making it suitable for high-temperature environments.

The low CTE helps maintain dimensional stability, even when exposed to temperature changes. This stability reduces mechanical stresses, ensuring the material lasts longer under demanding conditions. You’ll find these properties especially valuable in aerospace and automotive applications, where materials must withstand extreme heat and pressure.

Additionally, the high thermal conductivity of transparent carbon fiber enhances its performance in electronics. It helps dissipate heat in devices like laptops and smartphones, improving their reliability and lifespan.

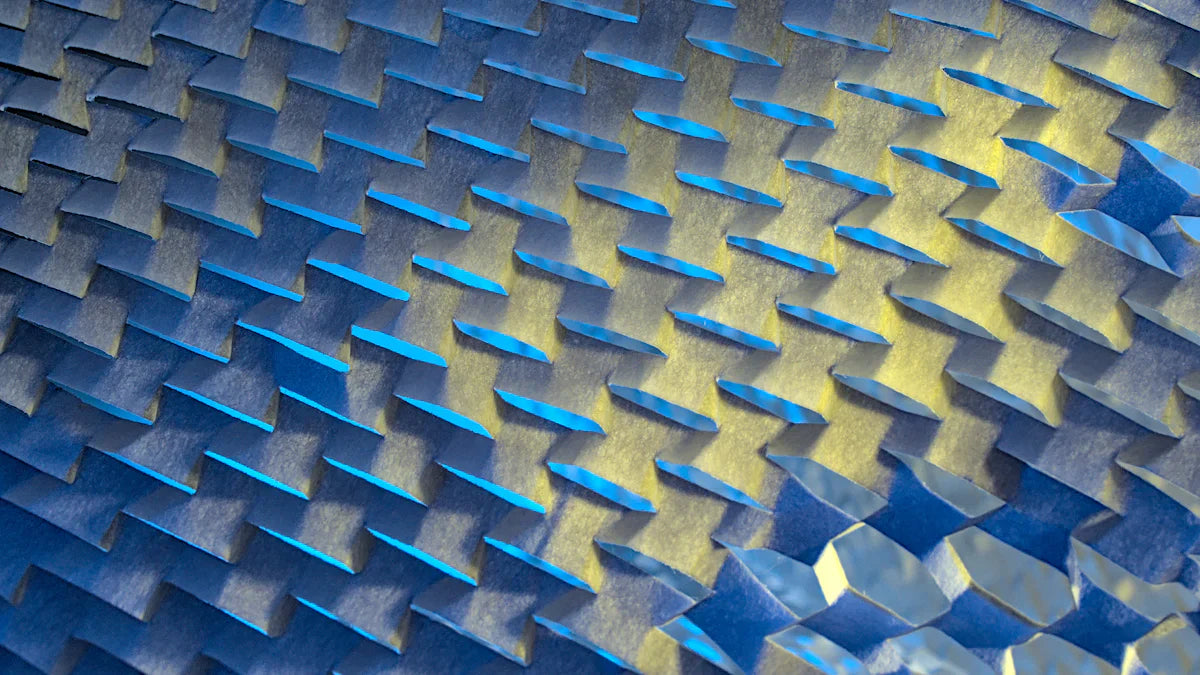

Aesthetic and Functional Benefits

Transparent carbon fiber offers a unique combination of aesthetic appeal and functional advantages. Its instantly recognizable look, featuring an aggressive shark-tooth pattern, makes it stand out in any application. The material’s depth and light-catching properties enhance its visual appeal, creating a bold and striking appearance. You might notice this in luxury goods, where the sleek and modern design elevates the product’s overall value.

The aesthetic benefits go hand in hand with its functional strengths. Transparent carbon fiber retains high tensile strength and stiffness due to its microscopic strands of bonded carbon. This strength rivals that of steel but at a fraction of the weight. Its non-isotropic strength allows engineers to tailor the material’s performance based on specific load scenarios. For example, you could see it used in architectural designs where both beauty and structural integrity are essential.

In addition to its visual and structural qualities, transparent carbon fiber provides versatility across industries. Its lightweight nature makes it ideal for applications requiring mobility, such as sports equipment or wearable technology. The material’s transparency adds a futuristic touch, making it perfect for innovative designs in consumer electronics.

Whether you’re looking for a material that enhances the aesthetics of a product or one that delivers unmatched strength and functionality, transparent carbon fiber excels in both areas. Its ability to combine beauty with performance ensures it remains a top choice for cutting-edge designs and applications.

Transparent Carbon Fiber vs. Traditional Carbon Fiber

Differences in Strength and Performance

When comparing transparent carbon fiber to its traditional counterpart, you’ll notice differences in strength and performance. Traditional carbon fiber is known for its exceptional tensile strength, making it ideal for heavy-duty applications like aerospace and automotive components. Transparent carbon fiber, while still strong, may not match the same level of tensile strength due to the modifications required to achieve transparency. However, it still provides enough durability for most applications where aesthetics and functionality are equally important.

You can rely on transparent carbon fiber for applications that demand a balance between strength and visual appeal. For example, it works well in consumer electronics or luxury goods where performance and design matter equally. Traditional carbon fiber, on the other hand, remains the go-to choice for projects requiring maximum strength without concern for transparency.

Weight and Flexibility Comparison

Both types of carbon fiber share a key advantage: being lightweight. This property makes them ideal for industries where reducing weight improves efficiency, such as in vehicles or aircraft. Transparent carbon fiber retains this lightweight nature while offering additional design possibilities.

In terms of flexibility, traditional carbon fiber tends to be more rigid. Transparent carbon fiber, depending on its resin composition, may offer slightly more flexibility. This can be an advantage in applications where some degree of pliability is beneficial, such as in wearable technology or curved architectural designs.

Transparency vs. Opaque Appearance

The most obvious difference lies in appearance. Traditional carbon fiber has a dark, opaque finish with a recognizable woven pattern. Transparent carbon fiber, on the other hand, allows light to pass through, creating a sleek and modern look.

You’ll find transparent carbon fiber particularly useful in applications where aesthetics play a significant role. For instance, it can enhance the visual appeal of luxury goods, architectural elements, or even sports equipment. Traditional carbon fiber, with its opaque appearance, remains better suited for applications where functionality outweighs the need for visual transparency.

Cost and Manufacturing Challenges

Transparent carbon fiber offers exciting possibilities, but its production comes with significant challenges. You might notice that the cost of manufacturing this material is higher than traditional carbon fiber. This happens because the process requires advanced techniques and specialized equipment to achieve transparency without compromising strength. Manufacturers must carefully balance the resin composition and fiber arrangement, which adds complexity to the production process.

The raw materials used in transparent carbon fiber also contribute to its high cost. High-quality resins and carbon filaments are essential to maintain both clarity and durability. These materials often come at a premium price, making the final product more expensive. If you’re considering using transparent carbon fiber in a project, you’ll need to account for these additional expenses.

Another challenge lies in scaling up production. Transparent carbon fiber is still a relatively new material, so manufacturers face difficulties in producing it on a large scale. The precision required during the manufacturing process limits the speed at which it can be made. This limitation affects its availability and increases its price further.

You might also encounter challenges related to quality control. Ensuring consistent transparency and strength across batches requires rigorous testing and monitoring. Any slight variation in the manufacturing process can lead to defects, which increases waste and production costs.

Despite these challenges, advancements in technology are helping to reduce costs over time. Researchers are exploring new methods to streamline production and make transparent carbon fiber more accessible. As demand grows, you can expect improvements in efficiency and affordability, making this innovative material a more viable option for various applications.

Applications of Transparent Carbon Fiber

Automotive and Aerospace Industries

Transparent carbon fiber has revolutionized both automotive and aerospace applications by combining lightweight properties with exceptional strength. In the automotive sector, you’ll find it in high-end sports cars and racing vehicles. It’s used for body panels, hoods, roofs, and spoilers, helping reduce weight and improve handling. Initially adopted in Formula 1 and Indy cars, this material now appears in production vehicles, offering enhanced fuel efficiency and performance.

In aerospace applications, transparent carbon fiber plays a critical role in constructing airplane wings, fuselages, and interior structures. Its lightweight nature reduces fuel consumption, while its strength ensures safety and durability. You’ll also see it in spacecraft and launch vehicles, where it contributes to structural integrity and performance. This material’s ability to meet demanding aerospace requirements makes it a game-changer for the industry.

Consumer Electronics and Wearables

Transparent carbon fiber is making waves in consumer electronics and wearable technology. Its lightweight and durable properties make it ideal for devices like smartwatches, where strong yet sleek housings are essential. For example, you might see it used in products like the iWatch, enhancing both functionality and design.

In addition, this material is perfect for electronics requiring displays or camera lenses. Its transparency reduces material usage while maintaining strength. Sporting goods also benefit from this innovation, as it enhances the design and performance of equipment like tennis rackets and bicycles. Transparent carbon fiber’s versatility ensures it remains a top choice for cutting-edge consumer products.

|

Application Area |

Description |

|---|---|

|

Wearable Technology |

Potential use in devices like the iWatch, enabling lightweight and strong housings. |

|

Consumer Electronics |

Integration into products that require displays and camera lenses, reducing material usage. |

|

Sporting Goods |

Possible applications in enhancing the functionality and design of sporting equipment. |

Medical Imaging and X-Ray Transparency

Transparent carbon fiber offers unique advantages in medical imaging due to its ability to be transparent to x-rays. This property allows for live imaging of patients without the need to move them, improving the efficiency of medical procedures. For example, operating tables and medical devices made from this material combine the strength of metal with the transparency of plastic, ensuring both durability and functionality.

Its high stability and x-ray transparency also reduce radiation exposure for patients, making it safer for use in navigated surgeries. You’ll find this material particularly valuable in applications requiring precise imaging, as it eliminates the need for repositioning during procedures. Transparent carbon fiber’s strength and clarity make it an essential component in modern medical technology.

Sports Equipment and Luxury Goods

Transparent carbon fiber has become a game-changer in sports equipment and luxury goods. Its lightweight and durable properties make it ideal for high-performance gear. You’ll find it in tennis rackets, where it enhances control and power. It also appears in hockey sticks, improving responsiveness and precision. Cyclists benefit from high-end bicycles with carbon fiber frames, which provide a smoother ride and better handling. Golfers enjoy improved swing accuracy with carbon fiber shafts, while fishing enthusiasts appreciate its use in fishing rods for added strength and flexibility.

In racing sports, transparent carbon fiber elevates performance and safety. Helmets made from this material offer superior protection without adding unnecessary weight. Racing shoes also incorporate it to enhance speed and comfort. These innovations not only improve functionality but also add a sleek, modern aesthetic to the equipment.

Luxury goods have also embraced transparent carbon fiber for its unique combination of beauty and strength. Designers use it to create visually striking products that stand out. For example, you might see it in high-end watches, where its transparency adds a futuristic touch. It’s also used in premium luggage, offering durability and a sophisticated appearance. Whether in sports or luxury items, transparent carbon fiber continues to redefine what’s possible in design and performance.

Architectural and Design Innovations

Transparent carbon fiber is revolutionizing architectural and design applications. Its strength and flexibility make it a valuable material for innovative projects. For instance, Kengo Kuma’s carbon-fiber curtain in a Japanese showroom demonstrates its ability to provide earthquake resistance while maintaining a lightweight structure. This project highlights how carbon fiber can enhance both stability and aesthetics in buildings.

Architects like Peter Testa and Devyn Weiser are exploring new construction methods using carbon fiber. Their designs include a carbon-fiber tower that showcases the material’s potential for creating sustainable and efficient structures. Sheila Kennedy’s firm integrates transparent materials with solid-state technologies in public projects, pushing the boundaries of modern design. In New York City, ferry landings incorporate digitally fabricated carbon-fiber components, proving its practicality in public infrastructure.

You’ll also notice its use in decorative elements, where transparency and strength combine to create visually stunning designs. Transparent carbon fiber allows architects to experiment with light and form, resulting in unique and functional spaces. Its versatility ensures it remains a top choice for cutting-edge architectural innovations.

Advantages and Challenges of Transparent Carbon Fiber

Unique Benefits of Carbon Fiber in Transparent Form

Transparent carbon fiber offers a combination of strength and transparency that no other material can match. It is stronger than steel while remaining completely transparent to X-rays. This unique property enables innovative medical applications, such as operating tables that allow live imaging of patients without repositioning. Doctors and surgeons benefit from this material’s ability to combine the strength of metal with the X-ray transparency of plastic, unlocking new possibilities in medical procedures.

In addition to medical uses, transparent carbon fiber excels in industries requiring lightweight yet durable materials. Its thermal conductivity ensures efficient heat transfer, making it ideal for electronics and aerospace applications. For example, it can dissipate heat in smartphones or enhance the performance of airplane wings. The material’s low thermal expansion also ensures stability under temperature changes, which is crucial for precision engineering. These unique benefits of carbon fiber make it a game-changer across multiple fields.

Current Limitations and Development Hurdles

Despite its advantages, transparent carbon fiber faces several challenges. Manufacturing this material requires advanced techniques and precise control over resin composition. These complexities increase production costs, making it less accessible for widespread use. Additionally, scaling up production remains difficult due to the meticulous processes involved. Manufacturers must ensure consistent transparency and strength, which demands rigorous quality control.

Another limitation lies in the material’s thermal properties. While its thermal conductivity is beneficial, achieving the perfect balance between transparency and heat resistance can be challenging. Researchers are exploring ways to improve these properties without compromising performance. Recycling transparent carbon fiber also presents hurdles, although advancements in this area show promise. By 2026, the market for recycled carbon fiber is expected to grow significantly, offering a more sustainable solution.

Future Innovations and Potential Applications

The future of transparent carbon fiber looks promising, with innovations on the horizon. Researchers are developing sustainable production methods, such as using lignin as a raw material. This approach could reduce costs and environmental impact. Recycling techniques are also advancing, ensuring the material’s long-term viability.

Industries like aerospace, automotive, and infrastructure stand to benefit from these developments. In aerospace, transparent carbon fiber can create lightweight airplane wings with enhanced thermal conductivity. Automotive engineers can use it to design efficient, lightweight vehicles. In infrastructure, it can reinforce bridges and buildings, combining strength with aesthetic appeal.

|

Industry |

Application of Transparent Carbon Fiber |

|---|---|

|

Aerospace |

Building strong, lightweight airplane wings |

|

Automotive |

Reducing weight and improving efficiency in cars and boats |

|

Medical |

X-ray transparent operating tables for easier imaging |

|

Sports |

Manufacturing of bicycles, tennis rackets, and golf clubs |

|

Infrastructure |

Reinforcement of bridges and buildings for structural integrity |

These innovations highlight the material’s potential to transform industries. As technology advances, you can expect transparent carbon fiber to play an even greater role in shaping the future of design and engineering.

Transparent carbon fiber combines strength, lightweight properties, and versatility, making it a revolutionary material. Its unique features, such as x-ray transparency and environmental resistance, open doors to innovative applications across industries. The table below highlights its standout properties:

|

Property |

Description |

|---|---|

|

Strength |

Stronger than steel, providing high durability. |

|

Lightweight |

Offers a lightweight alternative to traditional materials. |

|

Environmental Resistance |

Resistant to various environmental factors, enhancing longevity. |

|

X-Ray Transparency |

Transparent to x-rays, enabling innovative medical applications. |

|

Versatility |

Applicable in various fields, including medical and industrial uses. |

You can expect this material to transform industries like aerospace, medical, and architecture. As advancements continue, transparent carbon fiber will likely redefine design and engineering, paving the way for groundbreaking innovations.

Share:

Steps to Join a Car Track Racing Event in 2025

Ever Wondered How Lignin Becomes Carbon Fiber?