Lignin, a natural polymer found in plants, holds the key to creating sustainable carbon fibers. Unlike traditional methods that rely on polyacrylonitrile (PAN), lignin-based production offers a greener and more cost-effective alternative. PAN production consumes significant energy and releases harmful emissions. In contrast, lignin carbon fiber production uses renewable raw materials, reduces toxic by-products, and saves energy.

You also benefit from lower costs. PAN accounts for half the expense of conventional carbon fiber. Lignin, being abundant and affordable, slashes production costs while maintaining quality. This innovation paves the way for a more sustainable future in industries like automotive and aerospace.

Key Takeaways

-

Lignin is a natural material that can replace regular carbon fiber. It helps the environment and costs less to make.

-

To make strong carbon fibers, lignin must be cleaned and taken from plants.

-

Carbon fibers made from lignin are strong and long-lasting. They are great for cars and airplanes.

-

Using lignin saves money and helps the planet by using renewable materials.

-

New ways to process lignin are making better fibers. This means a good future for eco-friendly materials.

What Is Lignin?

Lignin’s Role in Nature

Lignin is a vital component of plant cell walls. It provides structural support and helps plants maintain their stiffness. Without lignin, trees and other plants would struggle to stand upright. This biopolymer also plays a key role in water transport. Its hydrophobic nature ensures that water moves efficiently through plant vessels without leaking.

You’ll find lignin in vessels and fibers, where it binds with hemicellulose and cellulose microfibrils. This binding strengthens the plant’s overall structure. Lignin also acts as a natural defense mechanism. When plants face pathogens like fungi or bacteria, lignin thickens the cell walls. This coarsening process blocks harmful enzymes and prevents the spread of infection.

Interestingly, lignin’s composition varies across plant species. Factors like tissue type, cell location, and environmental conditions influence its structure. It contains functional groups such as hydroxyl, methoxy, carbonyl, and carboxylic groups. These groups, along with its complex structure, make lignin a versatile and valuable material.

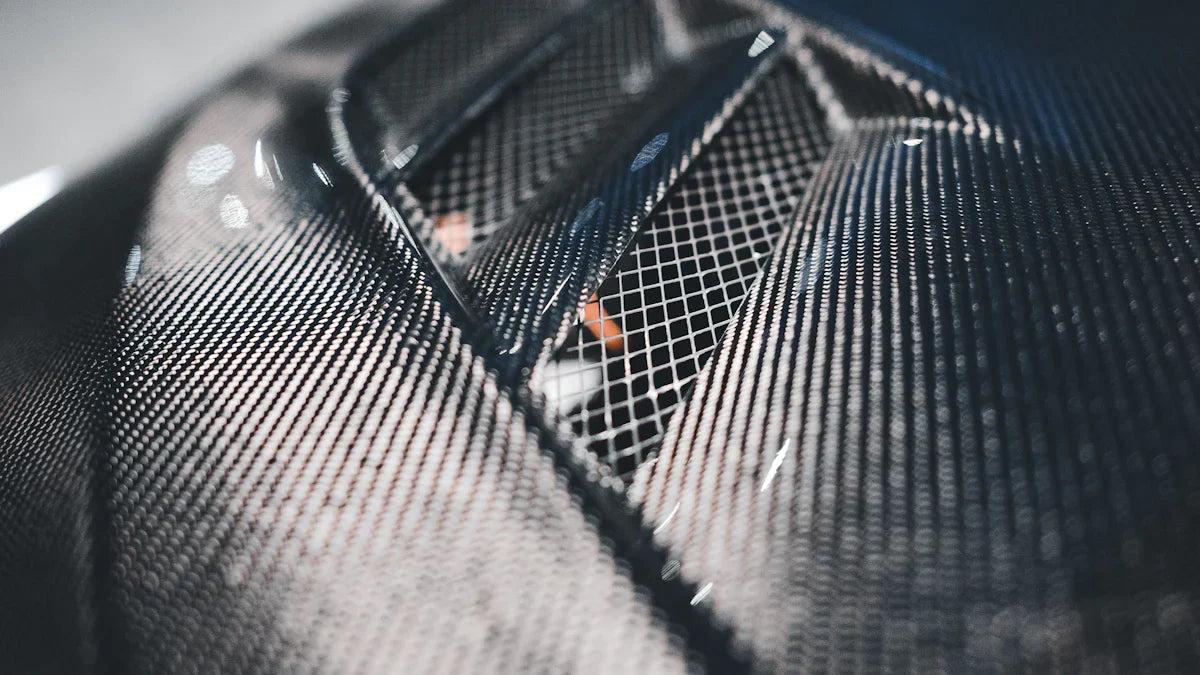

Why Lignin Is Ideal for Carbon Fiber

Lignin stands out as a promising precursor for carbon fiber production. Its polyaromatic structure, rich in functional groups, makes it suitable for creating high-performance materials. Unlike traditional precursors, lignin is abundant and renewable. This makes it an eco-friendly choice for industries seeking sustainable solutions.

Lignin-based carbon fibers exhibit impressive mechanical properties. For example, they have a tensile strength of 0.51 GPa and a tensile modulus of 28.6 GPa. These characteristics ensure durability and strength in applications like automotive and aerospace. Additionally, lignin blends enhance fiber spinning and stabilization rates, improving the overall production process.

By using lignin as a precursor, you can reduce costs and environmental impact. This innovation transforms lignin into a valuable resource, paving the way for sustainable advancements in material science.

The Process of Lignin Carbon Fiber Production

Lignin Extraction

The journey of lignin carbon fiber begins with extracting lignin from plant material. This step involves isolating lignin from black liquor, a by-product of the paper-making process. You can follow these key steps:

-

Separation: Lower the pH of black liquor using carbon dioxide. This causes lignin to precipitate, making it easier to filter out.

-

Washing: Wash the crude lignin in a low-pH solution to remove impurities. The purity of the lignin depends on the washing conditions.

This process ensures that the lignin is ready for the next stages of carbon fiber manufacturing. By carefully controlling the extraction process, you can achieve high-quality precursor fibers for carbon fiber production.

Purification

Purifying lignin is essential to improve its uniformity and performance as a precursor material. Recent advancements in fractionation technologies have made this step more efficient.

Researchers have developed a non-solvent strategy called autohydrolysis. This method uses only water to fractionate lignin into water-soluble and water-insoluble fractions. The water-insoluble fraction has a higher molecular weight and increased uniformity. It also enhances the mechanical properties of the resulting carbon fibers.

This innovative approach reduces the need for costly chemicals and materials, making the purification process more sustainable and cost-effective. By using purified lignin, you can create stronger and more reliable carbon fibers.

Stabilization

Stabilization is a critical step in carbon fiber production. During this phase, you heat the precursor fibers in hot air to prepare them for carbonization. Lignin fibers stabilize faster than traditional precursors like PAN. They also require lower temperatures, which saves energy.

The energy savings during stabilization and carbonization can reach up to 50% compared to conventional methods. This efficiency makes lignin-based carbon fiber manufacturing more sustainable and economical. By optimizing the stabilization process, you can produce high-quality carbon fibers while reducing environmental impact.

Carbonization

Carbonization is the stage where lignin fibers undergo a transformation into carbon fibers. This step involves heating the stabilized lignin fibers in a controlled environment to remove non-carbon elements like hydrogen and oxygen. The process enhances the carbon content, creating a material with improved thermal stability and mechanical properties.

During carbonization, you heat the fibers to temperatures ranging from 500 °C to 800 °C under a carbon dioxide atmosphere. As the temperature rises, the mass yield of lignin decreases from 49.2% to 39.8%. This reduction occurs because of chemical reactions such as demethanation, dehydration, and decarboxylation. These reactions restructure the lignin, forming aromatic structures that contribute to the fiber’s strength and durability.

Higher temperatures also increase the carbon content while reducing hydrogen and oxygen levels. This change improves the thermal stability of the fibers, making them suitable for high-performance applications. By carefully controlling the carbonization conditions, you can ensure the successful conversion into carbon fibers with desirable properties.

Final Fiber Formation

The final step in the process involves refining the carbonized fibers to achieve the desired mechanical and thermal properties. At this stage, you may treat the fibers further to enhance their performance or tailor them for specific applications. Lignin-based carbon fibers exhibit impressive characteristics, making them a viable alternative to traditional carbon fibers.

For example, these fibers have a tensile strength of 0.51 GPa and a tensile modulus of 28.6 GPa. When compared to traditional carbon fibers made from polyacrylonitrile (PAN), lignin-based fibers offer competitive performance. The table below highlights the mechanical properties of lignin-based carbon fibers versus PAN-based fibers:

|

Property |

Lignin-based Carbon Fibers |

Traditional Carbon Fibers (PAN) |

|---|---|---|

|

Tensile Strength |

0.51 GPa |

600 MPa |

|

Tensile Modulus |

28.6 GPa |

36 GPa |

These properties demonstrate the potential of lignin-based fibers for applications in industries like automotive and aerospace. Additionally, their thermal properties, evaluated through advanced techniques like thermogravimetric analysis, confirm their suitability for high-performance uses. By completing this final step, you unlock the full potential of lignin’s conversion into carbon fibers.

Advantages of Lignin-Based Carbon Fibres

Sustainability

Lignin-based carbon fibres offer a sustainable alternative to traditional carbon fiber production. You can rely on lignin, a renewable resource, instead of fossil-based polyacrylonitrile (PAN). This shift reduces CO2 emissions and minimizes the environmental impact of manufacturing.

-

Lignin is a by-product of biorefinery processes, making it an eco-friendly choice.

-

Processing lignin requires less energy, further lowering its carbon footprint.

-

Replacing PAN with lignin decreases reliance on oil and promotes the use of natural materials.

Tip: By choosing lignin carbon fiber, you contribute to a greener future while supporting sustainable practices in material production.

Cost-Effectiveness

Using lignin as a precursor significantly reduces the cost of carbon fiber production. Traditional methods rely on PAN, which accounts for half the total cost. Lignin, however, is abundant and inexpensive, making it a cost-effective alternative.

-

The process avoids solvents and uses natural raw materials, cutting expenses.

-

Energy savings during stabilization and carbonization lower production costs.

-

Lignin’s availability as a waste product from paper production enhances its economic viability.

|

Aspect |

Traditional Method (PAN) |

Lignin Method |

|---|---|---|

|

Cost of Precursor |

50% of total cost |

Significantly reduced |

|

CO2 Emissions |

High |

Reduced |

|

Availability of Raw Material |

Limited |

Abundant and inexpensive |

Switching to lignin-based carbon fibres not only saves money but also supports large-scale industrial applications by reducing production costs.

Versatility in Applications

Lignin-based carbon fibres are transforming industries with their versatility. In the automotive sector, you can find them in carbon fibre composites (CFRPs) used for lightweight vehicle components. These composites reduce vehicle weight by up to 70%, improving fuel efficiency and lowering CO2 emissions.

Note: Lightweight materials like CFRPs are essential for creating energy-efficient vehicles.

Beyond automotive, lignin carbon fiber has potential in aerospace, construction, and renewable energy. Its mechanical properties make it suitable for high-performance applications, while its affordability broadens its use across industries.

By adopting lignin-based carbon fibres, industries can innovate while reducing costs and environmental impact.

Challenges and Innovations in Carbon Fiber Production

Current Challenges

Producing lignin-based carbon fibers comes with several technical hurdles. You may face issues with the mechanical performance of these fibers due to lignin’s heterogeneity. This variability in lignin’s structure can lead to inconsistent fiber quality. Additionally, current fractionation methods, which separate lignin into usable forms, often rely on expensive chemicals. These methods increase production costs and limit scalability.

Another challenge lies in optimizing manufacturing processes. Detailed characterization of lignin as a precursor is essential to address its structural inconsistencies. Without this optimization, achieving the desired mechanical properties for industrial applications becomes difficult.

Note: Overcoming these challenges is crucial for lignin-based carbon fibers to compete with traditional options like polyacrylonitrile (PAN).

Recent Advancements

Recent technological breakthroughs have improved the efficiency of lignin-based carbon fiber production. For instance, researchers have developed a method that uses low-cost ionic liquids as solvents. This approach significantly reduces production costs while maintaining high lignin content in the fibers—over 90%. The process also achieves a carbon yield of more than 50% after pyrolysis, making it highly efficient.

Another advancement involves non-solvent fractionation techniques like autohydrolysis. This method uses only water to separate lignin into fractions with higher molecular weight and uniformity. These improvements enhance the mechanical properties of the resulting fibers. By increasing lignin’s miscibility with PAN, this technique also boosts the overall quality of the carbon fibers.

Tip: Innovations like these make lignin a more viable and resource-efficient renewable carbon fibre precursor.

Future Potential

The future of lignin-based carbon fibers looks promising. Researchers are exploring ways to further enhance the graphitic structure of these fibers, which could improve their strength and thermal stability. Using non-toxic solvents for lignin processing is another area of focus. This innovation could make the production process safer and more sustainable.

You can also expect advancements in fractionation technologies to reduce lignin’s heterogeneity. These improvements will likely lead to better mechanical performance and lower production costs. Additionally, integrating carbon nanomaterials into lignin-based fibers could unlock new applications in high-performance industries like aerospace and renewable energy.

Insight: With continued research, lignin-based carbon fibers could revolutionize material science by offering a sustainable and cost-effective alternative to traditional fibers.

Lignin-based carbon fibers mark a transformative step in sustainable material production. By using lignin, industries can significantly reduce costs and environmental impact. This bio-based alternative replaces fossil-derived precursors, lowering CO2 emissions and energy consumption during production.

-

Lignin enables high-volume production, making it ideal for automotive applications.

-

Its affordability and renewable nature align with the growing demand for eco-friendly materials.

-

Industries like aerospace and automotive can leverage lignin carbon fiber to meet sustainability goals while maintaining performance standards.

Insight: Transitioning to lignin-based carbon fibers supports a greener future and fosters innovation across multiple sectors.

Share:

Steps to Join a Car Track Racing Event in 2025

What Are the Latest Carbon Fiber Products and Uses