CarbonXtreme Post

Why Carbon Fiber Outshines Steel in Modern Applications

Carbon fiber, five times lighter than steel yet capable of tensile strengths up to 6,000 MPa, offers an unmatched strength-to-weight ratio. With a density of just 1.6 g/cm³, it excels in aerospace, automotive, and sports applications where weight reduction and high performance are essential. Unlike steel, it resists corrosion and maintains structural integrity in harsh environments, though its compressive strength is lower. Steel remains dominant in construction, heavy industry, and mass-market goods due to its low cost, scalability, and durability under compression. While carbon fiber’s high production costs limit its widespread use, innovations in low-cost precursors and recycling are making it more accessible. The global carbon fiber market is projected to more than double by 2032, signaling broader adoption in performance-driven industries.

Understanding Carbon Fiber Composition in 2025

Carbon fiber is a high-performance material made of carbon atoms in a crystalline structure, forming thin filaments combined with epoxy resin for exceptional stiffness, strength, and lightness. It is 31% stiffer, 60% stronger, and 42% lighter than aluminum, making it ideal for aerospace, automotive, renewable energy, sports, and medical industries. Manufacturing involves precursor preparation, stabilization, carbonization, surface treatment, sizing, and weaving. Carbon fiber excels in tensile strength, thermal stability, corrosion resistance, and customizable properties, outperforming steel, aluminum, and many composites. Future trends focus on sustainable production, cost reduction, recycling, and expanded applications, with the global market projected to reach $16 billion by 2030.

How to Perform Carbon Fiber Infusion with Vacuum Resin Techniques

Carbon fiber infusion is a composite manufacturing process where resin saturates carbon fiber fabric under vacuum, creating strong, lightweight, and high-quality parts. Vacuum infusion molding ensures even resin distribution, minimizing air pockets and improving durability for aerospace, automotive, and sports applications. The process involves meticulous mold preparation, applying release agents, precise fabric cutting and layering, arranging vacuum bagging consumables, sealing and leak-testing the bag, controlling resin flow under vacuum, and proper curing. Post-processing steps like demolding, trimming, and finishing ensure optimal strength, appearance, and performance. Precision, preparation, and quality control are critical for flawless results.

What You Need to Know About Biaxial Carbon Fiber in 2025

Biaxial carbon fiber, with fibers woven at 90-degree angles, combines exceptional strength, stiffness, and design flexibility. Its high strength-to-weight ratio makes it lighter and more efficient than traditional materials, enhancing fuel economy and reducing emissions in aerospace, automotive, renewable energy, and sports applications. In 2025, advancements in manufacturing, smart material integration, and sustainability have expanded its capabilities, enabling tailored mechanical properties, improved durability, and resistance to fatigue, corrosion, and harsh environments. While high costs, complex production, and recycling challenges remain, innovations in automated weaving, eco-friendly processes, and recycling technologies are driving broader adoption and market growth.

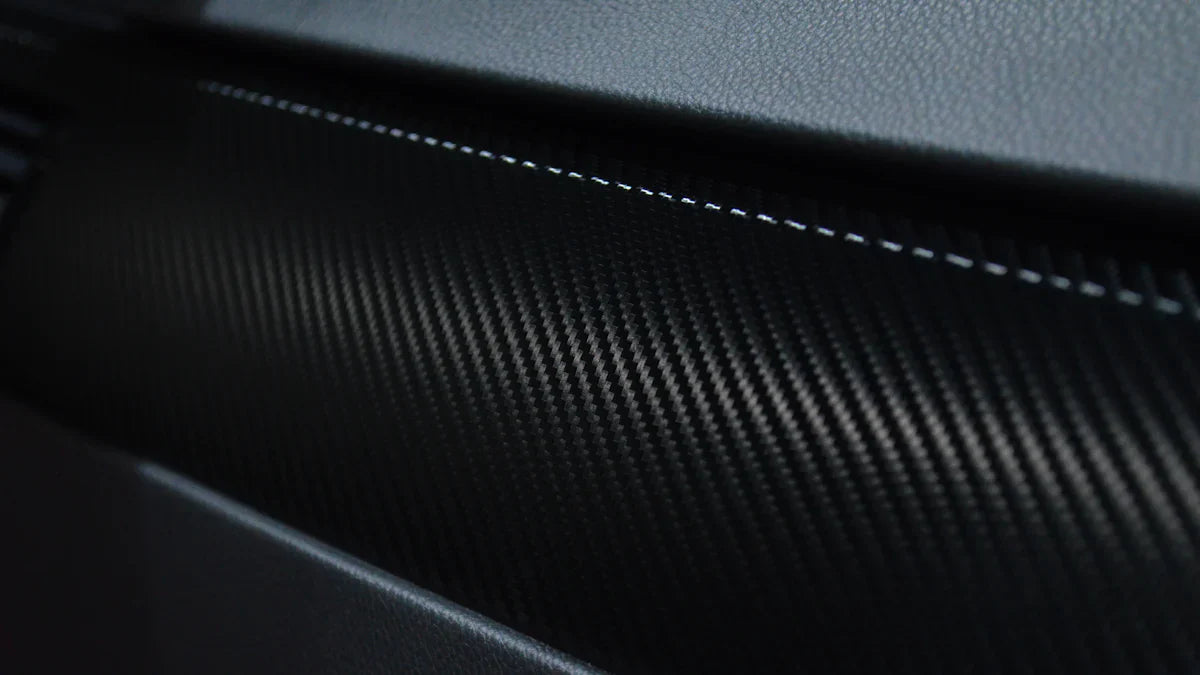

Top Methods to Improve the Surface Finish of Carbon Fiber in 2025

Achieving a flawless carbon fiber finish requires addressing common surface defects like pinholes, voids, fiber print-through, and surface roughness, often caused by manufacturing errors, material limitations, or environmental factors. Manual methods such as wet sanding, polishing, epoxy coatings, and clear coats improve surface quality, while advanced automated techniques like CNC machining, robotic sanding, and laser polishing offer precision and efficiency. Emerging trends for 2025 include self-healing and nano-coatings, eco-friendly materials, AI-driven defect prevention, and automated quality control. Combining manual craftsmanship with automation ensures optimal durability, aesthetics, and performance for carbon fiber parts.

Aramid Fiber vs Carbon Fiber Explained for 2025

Aramid fiber and carbon fiber are both high-performance materials but excel in different areas. Aramid fiber (e.g., Kevlar) offers excellent flexibility, heat resistance, impact absorption, and electrical insulation, making it ideal for protective gear, safety equipment, and applications needing shock absorption. Carbon fiber delivers superior stiffness, strength-to-weight ratio, corrosion resistance, and electrical conductivity, making it the preferred choice for aerospace, automotive, and structural uses. Key differences lie in composition, thermal behavior, weight, and electrical properties. Choosing between them depends on whether flexibility and heat resistance (aramid) or rigidity and high structural performance (carbon) are more important for the project.

Key Differences Between Liquid Carbon Fiber and Traditional Carbon Fiber

Liquid carbon fiber and traditional carbon fiber differ mainly in manufacturing methods, properties, and ideal applications. Liquid carbon fiber uses a wet lay-up process, offering high design flexibility, glossy finishes, and suitability for decorative or intricate shapes, though it is heavier and less strong than traditional types. Traditional carbon fiber uses prepreg sheets and controlled curing, giving it superior strength-to-weight ratio, durability, and environmental resistance—ideal for structural, high-performance uses like aerospace, automotive, and sports equipment. Choosing between them depends on whether design aesthetics or structural performance is the top priority.

Gold carbon fiber for cars or decor: Choose wisely

Gold carbon fiber is a premium composite that merges the lightweight strength of carbon fiber with a luxurious gold finish, offering both performance and visual appeal. In vehicles, it improves efficiency, heat resistance, and durability while adding a high-end look to trims, spoilers, and engine components. In décor, it enhances furniture, wall panels, and accessories with a modern, sophisticated style that lasts. While costly and often requiring professional installation for automotive use, it allows more DIY flexibility in decorative projects. Alternatives like carbon fiber vinyl wrap provide a budget-friendly way to achieve a similar aesthetic.

How to Handle Carbon Fiber Repairs Without Professional Help

Repairing carbon fiber parts at home is possible with the right tools, materials, and patience. The process starts with assessing whether damage is cosmetic or structural, followed by careful cleaning and sanding of the area. Epoxy resin combined with carbon fiber fabric is the preferred method for restoring strength and appearance. Proper curing, surface finishing, and optional layering ensure a durable, seamless repair. Safety measures—like wearing protective gear and working in a ventilated space—are essential. Using high-quality materials, practicing beforehand, and layering strategically can result in professional-quality results while saving time and money compared to professional repairs.