CarbonXtreme Post

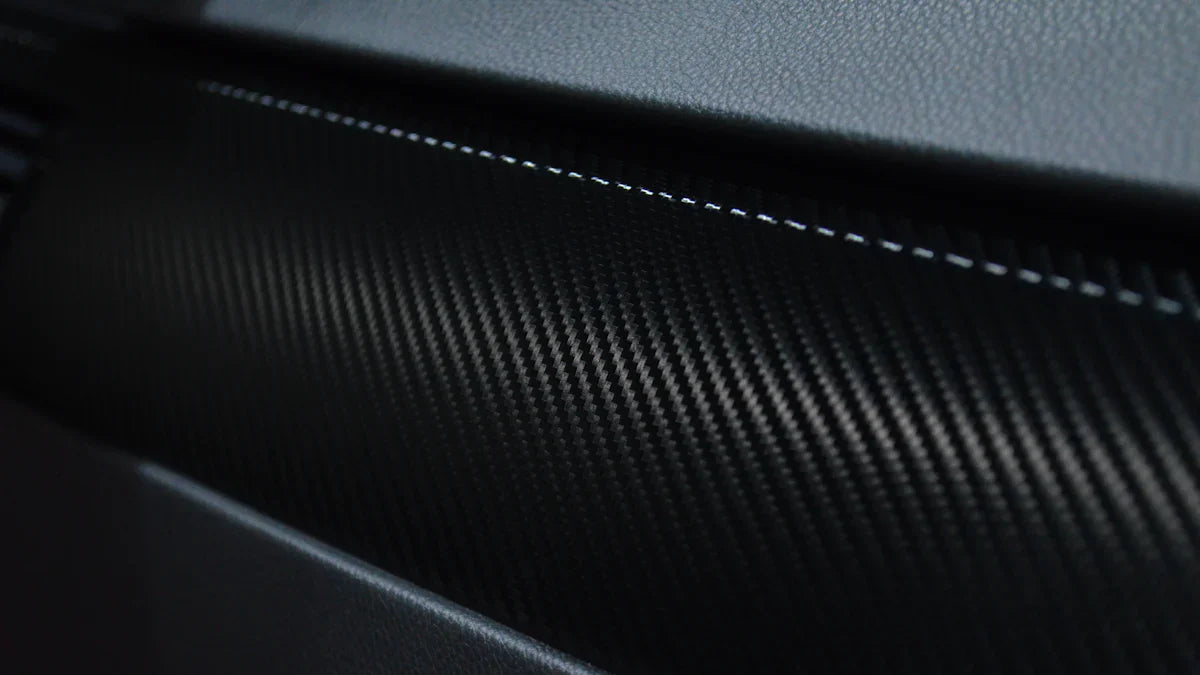

A Guide to Choosing the Right Carbon Fiber Profile for Your Industry

Carbon fiber profiles deliver exceptional strength-to-weight ratios, corrosion resistance, and thermal stability, making them indispensable across aerospace, automotive, construction, and sports industries. Available in forms such as pultruded, woven, unidirectional, and hybrid profiles, they offer tailored performance for specific load patterns, aesthetic needs, and cost constraints. Compared to fiberglass, carbon fiber provides superior stiffness and lighter weight, though at a higher price. Proper selection—considering shape, fiber orientation, environmental exposure, and budget—ensures optimal efficiency, durability, and value in demanding applications.

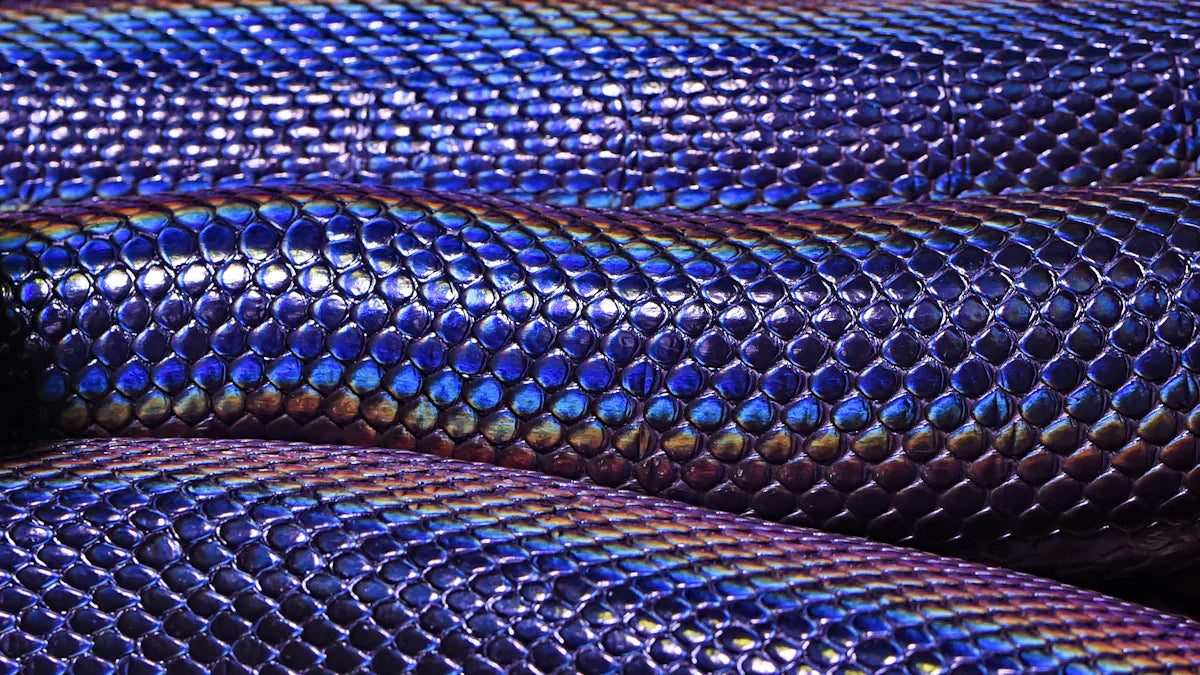

Top Purple Carbon Fiber Picks You’ll Love

Purple carbon fiber combines the high strength, light weight, and durability of carbon fiber with a bold, reflective purple finish, making it both functional and stylish for 2025. Its applications range from automotive and aerospace components to sports gear and consumer products like phone cases and wallets. Top products include the Forged Carbon Fiber Phone Case, Purple Reflections Carbon Fiber Fabric, Universal “Purple Disco” Forged Carbon Fiber Rear Number Plate, 2025 BMW M2 with Twilight Purple Carbon Fiber Accents, and iPhone Purple Flake Real Forged Carbon Fiber Phone Case. Buyers should consider performance vs. aesthetics, budget, durability, and warranties to select the right product. Purple carbon fiber stands out as a premium material that delivers long-lasting performance and distinctive design.

Why Are 12×12 Carbon Fiber Sheets So Popular in Modern Design?

The 12×12 carbon fiber sheet is a compact, high-performance material combining exceptional strength, light weight, and durability. Made from tightly bonded crystalline carbon filaments, it offers superior specific strength and stiffness compared to steel or aluminum while resisting corrosion, temperature extremes, and wear. Its versatility spans aerospace, defense, automotive, sports equipment, medical devices, and consumer products, where it enhances efficiency, performance, and aesthetics. The manageable 12×12 size allows easy handling, customization, and minimal waste, making it suitable for both professional and DIY applications. Despite higher upfront costs, its long service life and low maintenance deliver strong long-term value, with accessibility improving through manufacturing advances.

The Benefits of Using 3D Carbon Fiber in Modern Applications

3D carbon fiber is an advanced material featuring a three-dimensional fiber structure that delivers exceptional strength-to-weight ratio, heat and chemical resistance, and superior durability. Unlike traditional 2D carbon fiber, its interlocked design resists delamination, distributes stress evenly, and enhances flexibility. It supports sustainability through reduced waste, recyclability, and compatibility with efficient manufacturing methods like 3D printing. Applications span aerospace, automotive, medical devices, sports equipment, construction, and industrial tools, where it improves performance, safety, and cost efficiency. Its integration with additive manufacturing enables faster production, complex geometries, and precise, high-strength components.

What is Carbon Fiber Veil and How is it Used

Carbon fiber veil is a lightweight, non-woven material made from fine carbon fibers, valued for improving surface finish, adding strength, and providing corrosion, heat, and chemical resistance. Unlike woven fabrics, it’s primarily used as a surface layer in composites to enhance aesthetics, protect against environmental damage, and improve bonding between layers. Its flexibility allows it to conform to complex shapes without adding weight, making it ideal for aerospace, automotive, construction, marine, and wind energy applications. Benefits include extended service life, reduced maintenance costs, and enhanced visual appeal. Future developments may focus on recycled fiber use and expanded applications in electronics and protective gear.

Choosing the Perfect Resin for Your Carbon Fiber Creations

Selecting the right resin for carbon fiber projects is key to achieving strength, durability, and desired aesthetics. Epoxy resin offers superior bonding, impact resistance, and UV protection, making it ideal for aerospace, automotive, and marine applications, though it’s costly and slower to cure. Polyester resin is budget-friendly, easy to use, and cures quickly, but lacks durability and moisture resistance. Vinyl ester resin strikes a balance, with strong water and impact resistance at a mid-range cost. Choosing the best resin depends on performance requirements, environmental exposure, and budget, with epoxy favored for high-performance, polyester for non-critical or large-scale projects, and vinyl ester for versatile, mid-tier applications.

Why Carbon Fiber Powder is a Game-Changer for Composite Durability

Carbon fiber powder is a finely ground form of carbon fiber that offers high strength-to-weight ratio, corrosion resistance, fatigue resistance, and excellent durability. Its powder form allows uniform dispersion in composites, enhancing mechanical performance without adding bulk. Applications span aerospace, automotive, construction, sports equipment, and consumer goods, where it improves performance, reduces weight, and lowers maintenance costs. Often sourced from recycled fibers, it supports sustainability by reducing waste, energy use, and CO₂ emissions, while also cutting manufacturing and operational expenses.

How to Integrate Milled Carbon Fiber into Polymer Composites

Milled carbon fiber is a short, chopped fiber reinforcement that enhances the strength, stiffness, thermal, and electrical conductivity of polymer composites. Its isotropic reinforcement capability makes it ideal for automotive, aerospace, wind energy, and sporting goods applications. Recycled milled carbon fiber offers 20–40% cost savings and significant CO₂ reduction, supporting sustainable production. Successful integration requires careful polymer and fiber grade selection, uniform dispersion using high-shear mixing, and proper handling/storage. Processing methods like injection or compression molding, plus surface finishing and quality testing, ensure optimal performance. Challenges such as fiber agglomeration and poor fiber–matrix bonding can be addressed with coupling agents, optimized processing parameters, and precise machining techniques.

What is Twill Weave Carbon Fiber and Its Benefits

Twill weave carbon fiber is a high-performance fabric recognized by its diagonal ribbing pattern, offering a balance of strength, flexibility, and refined aesthetics. The weave structure allows it to conform to complex shapes while evenly distributing stress, enhancing durability. Compared to plain weave, it offers greater flexibility and a smoother finish; compared to satin weave, it provides better strength while maintaining visual appeal. Its unique properties make it ideal for aerospace, automotive, sports equipment, marine, medical, and consumer electronics applications, where both performance and style are essential.