You’ve likely encountered carbon fiber sheets in products you use daily, even if you didn’t realize it. The 12×12 carbon fiber sheet stands out for its unique combination of strength, lightness, and adaptability. Industries like aerospace, defense, and automotive rely on these sheets for critical applications. For example, aerospace engineers use them to craft lightweight wings and fuselages, while automakers incorporate them into high-performance car parts to improve fuel efficiency. The table below highlights some key industries and their specific uses for carbon fiber sheets:

|

Industry |

Specific Applications |

|---|---|

|

Aerospace |

Manufacturing components like wings, fuselages, and propellant tanks; used in satellites for reduced launch weight. |

|

Defense |

Body armors, helmets, vehicle reinforcement, and radar-absorbing materials for stealth technology. |

|

Automotive |

High-performance car parts, body panels, and luxury vehicle components for improved fuel efficiency. |

|

Sports Equipment |

Bicycles, tennis rackets, golf clubs, and helmets to enhance performance and provide a competitive edge. |

This versatility makes carbon fiber a go-to material for professionals and hobbyists alike. Its lightweight yet durable nature ensures it meets the demands of modern design.

Key Takeaways

-

12×12 carbon fiber sheets are light but very strong. They are great for industries like airplanes and cars.

-

These sheets last a long time and can handle tough weather. This makes them work well in hard jobs.

-

Carbon fiber can be shaped in many ways. This makes it good for both big projects and small DIY tasks.

-

Using carbon fiber sheets can save money over time. They need little care and work better in many uses.

-

Carbon fiber sheets are now easier to get and cost less. This makes them a smart choice for many projects.

Lightweight Benefits of Carbon Fiber Sheets

Material Composition of Carbon Fiber

Carbon fiber owes its lightweight performance to its unique material composition. It consists of thin, strong crystalline filaments of carbon atoms, which are tightly bonded together. This structure gives it an impressive combination of strength and low weight. To better understand its properties, take a look at the table below:

|

Property |

Value |

|---|---|

|

Specific Strength |

1800 KSI |

|

Specific Stiffness |

200 MSI |

|

Density |

0.050 lb/in³ |

These characteristics make carbon fiber sheets ideal for applications where reducing weight without compromising strength is critical. You’ll find this material in industries that demand high performance, such as aerospace and automotive.

Comparison to Traditional Materials

When compared to traditional materials like steel or aluminum, carbon fiber stands out as a strong and lightweight alternative. Steel, while strong, is significantly heavier. Aluminum is lighter than steel but still cannot match the weight advantage of carbon fiber. The table below highlights this comparison:

|

Material |

Density (g/cm³) |

Weight Comparison |

|---|---|---|

|

Carbon Fiber |

1.6 |

40% to 50% lighter |

|

Aluminum |

2.7 |

Heavier |

This weight difference translates to better fuel efficiency in vehicles and improved handling in sports equipment. By choosing carbon fiber sheets, you can achieve superior performance in your projects.

Applications Leveraging Lightweight Properties

The lightweight nature of carbon fiber sheets has revolutionized multiple industries. In aerospace, they reduce the weight of aircraft components, making flights more fuel-efficient. Automotive manufacturers use them in high-performance car parts and luxury vehicles to enhance speed and efficiency. Sports equipment like bicycles and tennis rackets benefit from their lightweight performance, giving athletes a competitive edge. Even in the medical field, carbon fiber is used to create prosthetic limbs and braces that are both durable and easy to handle. Here’s a breakdown of some key applications:

|

Industry |

Applications |

|---|---|

|

Aerospace |

Aircraft components, spacecraft parts, defense equipment, structural panels, propellant tanks. |

|

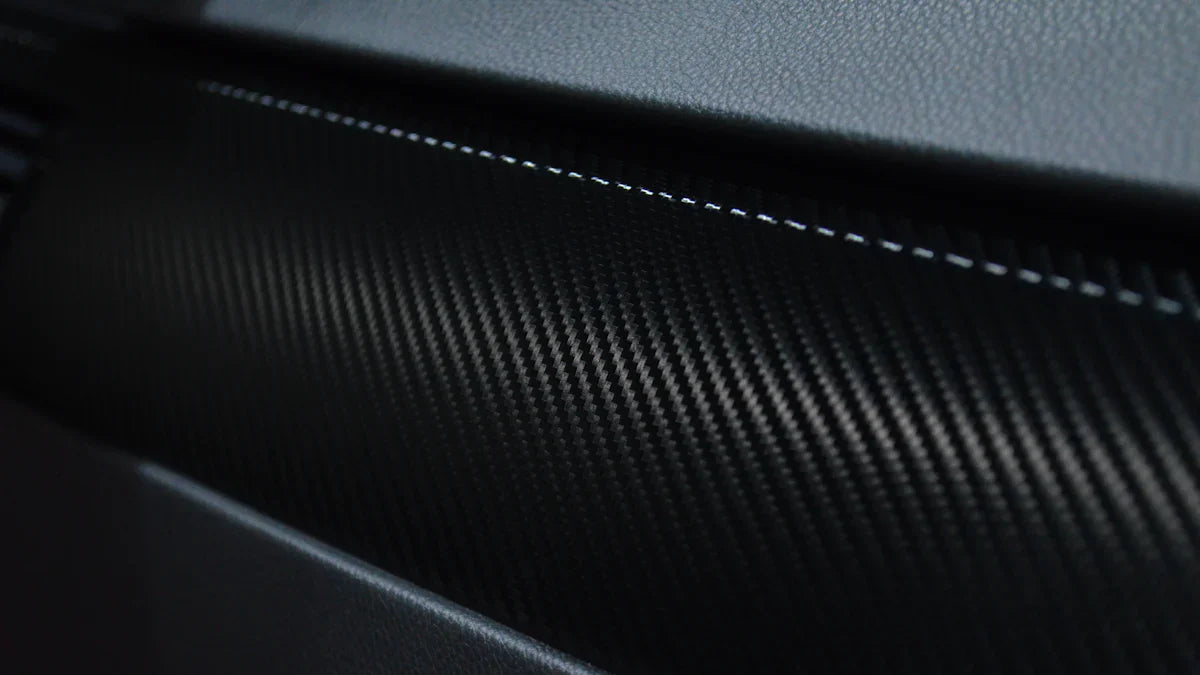

Automotive |

High-performance car parts, body panels, interior trims, luxury vehicle components. |

|

Sports Equipment |

Bicycles, tennis rackets, golf clubs, helmets. |

|

Medical |

Prosthetic limbs, braces, wheelchairs, MRI tables. |

|

Consumer Products |

Luxury watches, wallets, phone cases, furniture. |

By using a 12×12 carbon fiber sheet, you can tap into these benefits for both professional and DIY projects. Its versatility and lightweight properties make it a favorite among designers and engineers alike.

Durability and Strength of 12×12 Carbon Fiber Sheets

High Strength-to-Weight Ratio

The high strength-to-weight ratio of carbon fiber sheets makes them a standout material in modern design. You’ll find that carbon fiber combines exceptional strength with minimal weight, outperforming traditional materials like aluminum and steel. This unique property allows it to deliver high performance in demanding applications. The table below highlights how carbon fiber compares to other materials:

|

Material |

Specific Stiffness |

Specific Strength |

|---|---|---|

|

Carbon Fiber |

200 MSI |

1800 KSI |

|

6061 Aluminum |

100 MSI |

350 KSI |

|

4130 Steel |

100 MSI |

417 KSI |

This data shows that carbon fiber offers twice the stiffness and significantly higher strength than aluminum or steel. These qualities make 12×12 carbon fiber sheets ideal for projects requiring a strong and lightweight material.

Resistance to Environmental Factors

Carbon fiber sheets excel in harsh environments. Their resistance to extreme temperatures and low thermal expansion ensure stability under fluctuating conditions. Unlike metals, carbon fiber does not corrode, making it suitable for outdoor or marine applications. You can rely on its high durability to maintain performance even in challenging settings. For example, aerospace engineers use carbon fiber in aircraft components exposed to high altitudes and temperature variations. This resilience ensures consistent strength and reliability over time.

Longevity in Demanding Applications

The longevity of carbon fiber sheets is unmatched in industries like aerospace and automotive. These sheets withstand fatigue and maintain their structural integrity under repeated stress. They also resist wear and tear, ensuring long-term performance. For instance:

-

Aerospace applications include wings and fuselages, where carbon fiber enhances fuel efficiency and payload capacity.

-

Automotive manufacturers use it for body panels and interior trims, benefiting from its high tensile strength and lightweight nature.

-

Its corrosion resistance further extends its lifespan, reducing maintenance costs over time.

By choosing a 12×12 carbon fiber sheet, you gain access to a material that combines high durability, strength, and long-lasting performance.

Versatility of 12×12 Carbon Fiber Sheets in Design

Adaptability Across Industries

You’ll find carbon fiber sheets in a wide range of industries due to their versatility and high-performance characteristics. Aerospace and defense sectors rely on these sheets for crafting lightweight aircraft components and military equipment. Automotive manufacturers use them to create high-performance parts and luxury vehicle components, enhancing both efficiency and durability. In sports, carbon fiber improves the performance of bicycles, tennis rackets, and helmets, giving athletes a competitive edge. Consumer electronics also benefit from carbon fiber’s strength and aesthetic appeal, with devices like laptops and phones incorporating it into their designs. Even in construction and architecture, carbon fiber is used to create strong and lightweight building materials that align with modern trends.

Customization for Specific Projects

The ability to customize carbon fiber sheets makes them ideal for projects with unique requirements. You can tailor these sheets to enhance strength, reduce weight, or improve durability, depending on your needs. For example, in the medical field, carbon fiber manufacturing allows for the creation of lightweight and durable prosthetic limbs. In sports, customized carbon fiber equipment provides a tailored fit, improving performance for athletes. Whether you’re working on structural projects or specialized applications, the flexibility of carbon fiber manufacturing ensures that you can achieve the desired results.

Suitability for Professional and DIY Use

The 12×12 carbon fiber sheet is perfect for both professionals and DIY enthusiasts. Its manageable size and strong and lightweight properties make it easy to handle and versatile for various applications. For instance, hobbyists often use these sheets to build drones, benefiting from their lightweight nature for longer flights and better maneuverability. Robotics projects also leverage carbon fiber sheets for faster movements and energy efficiency. Whether you’re a novice or an expert, the versatility of carbon fiber sheets allows you to explore creative and functional designs with ease.

Practicality and Cost-Effectiveness of 12×12 Carbon Fiber Sheets

Why the 12×12 Size Is Ideal

The 12×12 size offers a practical solution for many projects. Its compact dimensions make it easy to handle, especially for small to medium applications. You can cut or shape it without requiring specialized tools, which simplifies the process for both professionals and hobbyists. This size also minimizes material waste, making it an efficient choice for projects that demand precision. Whether you’re building a drone, crafting a custom car part, or designing a prototype, the 12×12 carbon fiber sheet provides the perfect balance of usability and performance.

Accessibility and Market Availability

Carbon fiber sheets, including the 12×12 size, are becoming more accessible due to advancements in manufacturing. Over the past decade, the cost of carbon fiber has dropped by nearly 50%, making it more affordable for a wider audience. However, prices still range from $50 to $100 per square meter, which can be a barrier for smaller enterprises or hobbyists. Local availability may also be limited, requiring you to source these materials online. Despite these challenges, the growing demand for carbon fiber composite materials is driving innovation, which will likely improve accessibility and reduce costs further in the future.

Cost-Effectiveness for Small to Medium Projects

Carbon fiber sheets offer excellent value for small to medium projects. While the initial cost may seem high compared to materials like fiberglass, the long-term benefits outweigh the expense. For example:

-

Carbon fiber reduces weight, improving fuel efficiency in automotive applications.

-

Its corrosion resistance minimizes maintenance costs, especially in harsh environments.

-

Low maintenance requirements ensure durability and long-lasting performance.

-

Customization options allow you to optimize the material for specific needs, enhancing efficiency.

The table below compares the cost of carbon fiber to other materials, highlighting its affordability for high-performance applications:

|

Material |

Cost per Pound |

Cost per Square Meter |

|---|---|---|

|

Carbon Fiber |

$10 – $20 |

$50 – $100 |

|

Fiberglass |

$2 – $5 |

N/A |

|

Steel |

N/A |

N/A |

|

Aluminum |

N/A |

N/A |

By choosing a high-performance material like carbon fiber composite, you gain a durable, lightweight, and versatile solution that delivers exceptional results for your projects.

You can see why 12×12 carbon fiber sheets have become indispensable in modern design. Their lightweight nature, combined with exceptional durability and versatility, makes them a top choice for professionals and hobbyists. These sheets are practical and cost-effective, offering solutions for projects across industries.

Future trends highlight their growing importance:

-

Aerospace applications enhance fuel efficiency and performance.

-

Automotive designs benefit from improved vehicle efficiency.

-

Sports equipment gains strength and lightweight advantages.

-

Medical devices improve mobility and comfort.

-

Consumer products combine durability with aesthetic appeal.

Advancements in recycling processes also point to a more sustainable future for carbon fiber sheets, ensuring their relevance in design and engineering.

Share:

Top Purple Carbon Fiber Picks You’ll Love

What You Need to Know About Carbon Fiber Sheets and Resin Today