CarbonXtreme Post

Thermoplastic vs Thermoset Carbon Fiber Composites Explained

Carbon fiber composites are essential in modern industries for their high strength-to-weight ratio. Thermoset composites, made with cross-linked resins like epoxy, offer superior rigidity, heat resistance, and long-term durability, making them ideal for aerospace, automotive, and industrial applications. However, they are brittle and non-recyclable. Thermoplastic composites, reinforced with resins like PEEK or polycarbonate, provide toughness, impact resistance, and recyclability. They can be reshaped and processed quickly, supporting sustainable, high-volume manufacturing. Thermosets excel in extreme heat and structural stability, while thermoplastics are better for flexible, recyclable, and lightweight designs. Selection depends on performance requirements, environmental conditions, budget, and sustainability goals, with each type serving distinct industry needs.

How Carbon Fiber Reinforcement Enhances Structural Durability

Carbon fiber reinforcement is transforming modern construction and engineering by combining exceptional tensile strength with a lightweight profile. Resistant to corrosion, chemicals, and extreme temperatures, it enhances durability in both new builds and retrofits—particularly in seismic upgrades and aging infrastructure repairs. Applications include reinforcing concrete, steel, bridges, high-rise buildings, and historical structures without adding significant weight. While initial costs are higher than traditional materials, long-term savings come from reduced maintenance, faster installation, and extended lifespan. Its superior strength-to-weight ratio enables innovative designs, improves structural efficiency, and supports sustainability goals across infrastructure, architectural, aerospace, and automotive projects.

Thin Carbon Fiber Sheets for Aerospace, Automotive, and More

Thin carbon fiber sheets are high-performance composites made from materials like PAN, offering exceptional strength-to-weight ratio, corrosion resistance, and thermal/electrical conductivity. They are widely used in aerospace, automotive, renewable energy, sports, and high-end consumer products, enabling up to 60% weight reduction and significant fuel savings. Key advantages include durability in harsh environments, design versatility, and suitability for advanced engineering applications. Challenges involve high production costs, complex manufacturing processes, and recycling difficulties, but innovations such as hybrid materials, nanotube reinforcement, and advanced recycling methods are making them more sustainable. As manufacturing and eco-friendly technologies advance, these sheets are set to expand into more industries, balancing performance with environmental responsibility.

The Surprising Sustainability of Carbon Nanotube Fiber

Carbon nanotube fiber is an advanced, fully recyclable material that combines high strength, durability, and light weight with minimal environmental impact. Its production consumes fewer resources than metals, plastics, or natural fibers, while offering superior mechanical properties and resistance to wear, corrosion, and environmental damage. Exceptional conductivity improves energy efficiency in electronics, renewable energy systems, and transportation. Current recycling methods, such as thermal and chemical processes, preserve fiber quality, while emerging solvent-based and enzyme-assisted techniques promise lower energy use and greater scalability. Compared to traditional materials, carbon nanotube fibers reduce energy consumption in manufacturing, operation, and transport, making them a strong candidate for sustainable, circular-economy applications across aerospace, automotive, construction, and green technologies.

Black Carbon Fiber Essentials for Automotive Enthusiasts

Black carbon fiber is transforming automotive design by combining lightweight strength, modern aesthetics, and performance benefits. Lighter than steel yet stronger, it enhances acceleration, handling, braking, and fuel efficiency while resisting corrosion for long-term durability. On the exterior, components like body kits, splitters, spoilers, and hoods improve aerodynamics and reduce weight. Inside, dashboards, trim pieces, and carbon fiber seats elevate style, comfort, and value. Performance upgrades such as carbon fiber wheels, monocoque structures, and exhaust systems boost agility, rigidity, and engine output. Accessories—mirrors, license plate frames, and key fobs—add subtle style and practicality. Whether for sports cars or daily drivers, black carbon fiber merges function with luxury, making it a top choice for enthusiasts.

Carbon Fiber Market Shifts and Pricing Trends to Watch

The global carbon fiber market is expanding rapidly, with a projected CAGR of over 10%, driven by aerospace, automotive, and renewable energy sectors that demand lightweight, durable materials. Asia leads in production and competitive pricing, while Europe focuses on sustainability and North America on innovation. Pricing trends are influenced by raw material and energy costs, supply chain stability, and regional policies. Technological advances like automation, AI, and recycling are improving efficiency and reducing waste, though eco-friendly production may raise costs. By 2025, regional pricing will vary, with Asia retaining cost advantages, Europe integrating green initiatives, and North America stabilizing through innovation. Emerging applications in construction, consumer electronics, and medical devices, alongside investment in production capacity and technology, present strong growth opportunities despite risks from supply disruptions and global economic shifts.

What You Need to Know About Carbon Fiber Sheets and Resin Today

Carbon fiber sheets combined with resin deliver exceptional strength, lightweight performance, and versatility, revolutionizing industries from aerospace and automotive to sports and construction. With a high strength-to-weight ratio, corrosion resistance, and thermal stability, carbon fiber outperforms metals like steel and aluminum in demanding environments. The choice of resin—epoxy for maximum durability, polyester for cost-effectiveness, or polyurethane for flexibility—directly impacts composite performance. Applications span aircraft components, high-efficiency car parts, infrastructure reinforcement, and advanced sports equipment. While initial costs are higher, long-term savings, improved performance, and sustainability benefits make carbon fiber composites a strategic material choice.

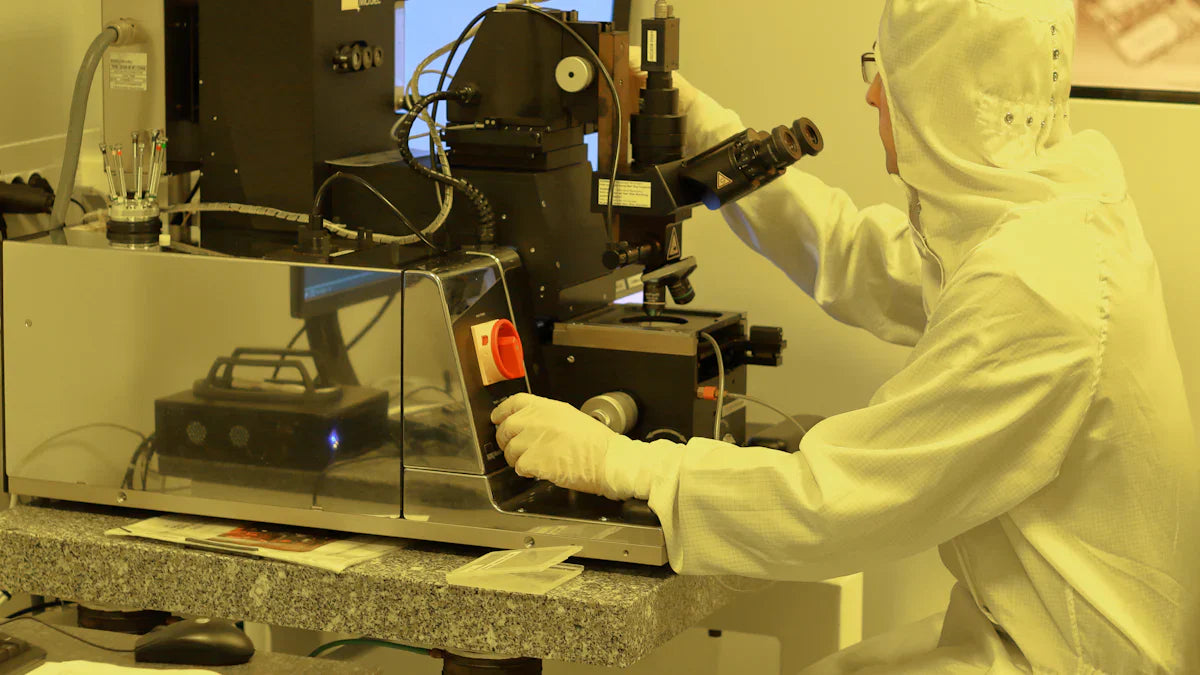

What’s New in Graphene Carbon Fiber Technology Today

In 2025, graphene carbon fiber technology has achieved record-breaking performance and cost efficiency. Adding just 0.075% graphene to PAN precursor fibers has boosted tensile strength by 225% and modulus by 184%, while cutting production costs from $15 to $5 per pound. These advances improve strength-to-weight ratios, thermal/electrical conductivity, and durability, making graphene composites ideal for aerospace, automotive, energy, sports, and medical applications. New semi-automated manufacturing methods enhance scalability and sustainability, while recyclability supports circular economy goals. Ongoing research into multifunctional composites, AI-driven material design, and graphene derivatives promises to expand applications and accelerate adoption across high-performance industries.

Discover the Best Colored Carbon Fiber Products Available

Colored carbon fiber is gaining massive popularity in 2025, with the global market expected to grow from USD 0.5 billion in 2022 to USD 1.2 billion by 2030, at an 11.5% CAGR. It merges the strength, lightness, and durability of traditional carbon fiber with vibrant colors and patterns, enabled by advanced colorization technologies that are both visually striking and eco-friendly. Applications span automotive body kits, sports gear, luxury accessories, and interior trims. Leading brands are innovating with naturally-colored fibers, high-performance wheels, and limited-edition designs. Key benefits include customization flexibility, corrosion and UV resistance, and a high strength-to-weight ratio. This combination of performance and aesthetics is fueling its rapid adoption across industries.