Using a uv resistant clear coat for carbon fiber gives you the most reliable defense against sun damage. You can choose from several proven options, including 2K polyurethane, ceramic coatings, and advanced acrylic-based formulas. Recent studies show that acrylic polyol resin-based clear coats with Eversorb CP1 additive provide superior UV protection and durability for carbon fiber parts:

|

Feature |

Detail |

|---|---|

|

Durability |

32% higher than standard UV absorbers |

|

Adhesion |

Superior retention after UV exposure |

|

Industry Use |

Preferred in automotive and aerospace for weather resistance |

Selecting a high-quality uv resistant clear coat for carbon fiber ensures your components retain their strength and appearance over time.

Key Takeaways

-

UV rays damage the resin in carbon fiber, causing cracks, fading, and weakening the parts over time.

-

Using a high-quality UV resistant clear coat protects carbon fiber from sun damage and keeps it strong and shiny.

-

Choose clear coats like 2K polyurethane, ceramic coatings, or acrylic formulas based on your needs for durability and finish.

-

Apply clear coats in thin layers with proper surface prep to ensure long-lasting protection and avoid common mistakes.

-

Regular cleaning, waxing, and inspections help maintain the clear coat’s effectiveness and extend the life of your carbon fiber parts.

UV Protection

Why Carbon Fiber Needs It

You invest in carbon fiber parts for their strength, lightweight properties, and modern appearance. However, these benefits depend on the integrity of the resin matrix that holds the fibers together. When exposed to sunlight, especially ultraviolet (UV) rays, the resin matrix faces several threats:

-

UV radiation breaks covalent bonds in the resin, causing the formation of small molecular fragments. These fragments create microcracks that weaken the surface.

-

The difference in how the resin and carbon fibers expand under UV-induced heat generates thermal stresses. These stresses can cause the fiber-matrix interface to debond and cracks to spread.

-

UV exposure oxidizes chemical groups in the resin, producing free radicals. These free radicals further degrade the polymer chains, leading to resin peeling and mass loss.

-

Over time, you may notice the disappearance of certain chemical bonds within the resin, which signals oxidation and chain breakage.

The carbon fibers themselves resist UV damage, but the surrounding resin and the bond between fiber and matrix remain vulnerable. Without protection, your carbon fiber parts lose mechanical strength and visual appeal.

Effects of Sun Damage

Sunlight does more than fade the surface of carbon fiber parts. UV damage leads to both visible and hidden problems:

-

You may see surface discoloration, microcracking, and a dull finish. These changes often signal deeper issues.

-

The epoxy matrix can depolymerize, causing the interface to shrink and become brittle.

-

Hydrolysis at the interface softens the matrix, making it more likely to fail under stress.

-

A hardened “skin” layer may form on the surface, trapping residual stresses beneath.

-

Structural damage includes interface debonding, modulus deterioration, and even delamination near the surface.

-

Surface oxidation and outgassing of volatiles create mechanical stresses that propagate cracks and voids deeper into the material.

-

Microcracks and internal damage often escape notice without advanced imaging, making regular inspection essential.

Oxidized carbon fiber loses its original strength and can develop hidden weaknesses. Protecting your investment with a UV resistant clear coat helps you avoid these costly issues and keeps your carbon fiber parts performing at their best.

Choosing a UV Resistant Clear Coat for Carbon Fiber

Key Features to Look For

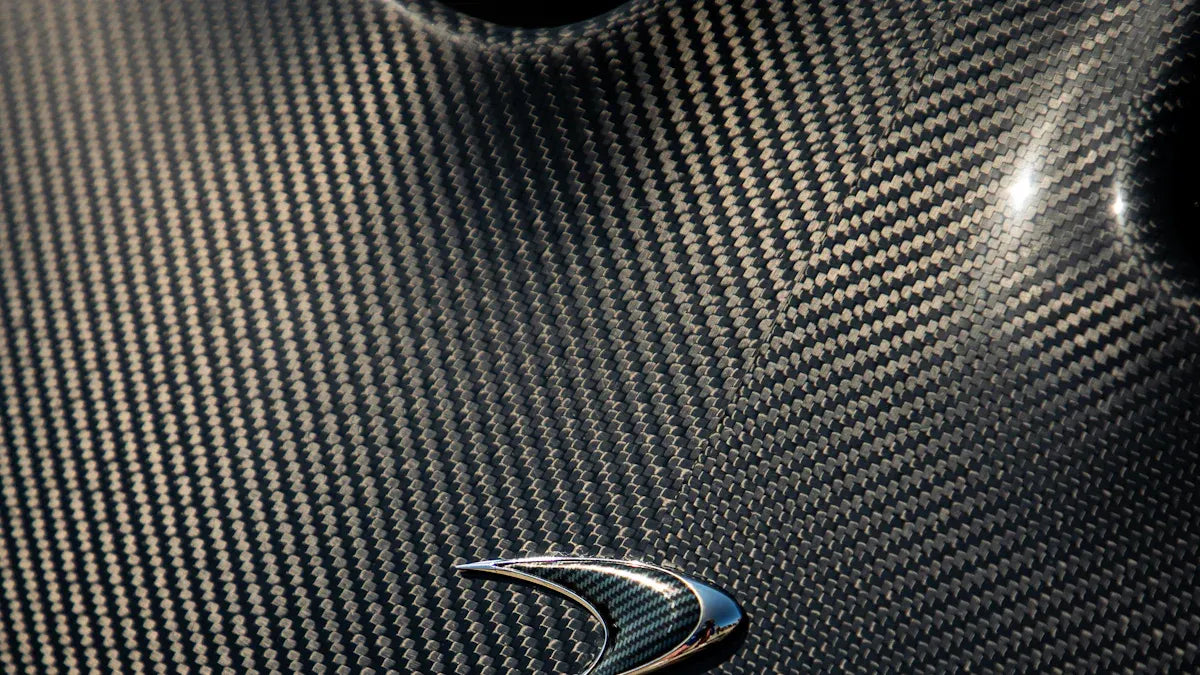

When you select a uv resistant clear coat for carbon fiber, you want to focus on features that guarantee both protection and appearance. Clear coats act as transparent shields for your carbon fiber parts. They defend against scratches, weather, and environmental hazards. You also get a boost in visual depth, making the carbon fiber weave stand out.

-

Look for clear coats that contain advanced UV inhibitors. These additives absorb or block ultraviolet rays, stopping them from breaking down the epoxy resin. This keeps your carbon fiber from yellowing, fading, or cracking.

-

Choose between gloss and matte finishes based on your needs. Glossy clear coats highlight the weave pattern and provide excellent UV protection. Matte finishes offer easier maintenance and hide micro scratches, but both types deliver solid durability.

-

Consider a 2K uv resistant polyurethane based paint or a ceramic coating for the highest level of protection. These options resist chemicals, fuel, and abrasion, making them ideal for automotive and aerospace applications.

-

Make sure the clear coat is compatible with high performance epoxy resins. Epoxy gives carbon fiber its strength, but it needs extra UV protection to prevent yellowing and surface damage.

-

Select a product that fills pinholes and microporosity. This ensures a smooth, even finish and prevents moisture from reaching the carbon fiber.

Tip: Always check if the clear coat is rated as an automotive-grade clear coat. These products meet strict industry standards for weather resistance and longevity.

Benefits of a High-Quality Clear Coat

A high-quality clear coat does more than just protect. It extends the life of your carbon fiber parts and keeps them looking new for years. You get several key benefits:

-

Enhanced longevity: The clear coat acts as a barrier against UV radiation, which can otherwise cause discoloration and weaken the structure.

-

Superior paint protection: Advanced coatings, such as ceramic coating or paint protection film, shield against scratches, chips, and environmental damage.

-

Self-healing properties: Some protective clear coat films repair minor scratches when exposed to heat, reducing the need for frequent maintenance.

-

Lasting appearance: The clear coat preserves the deep, glossy finish of carbon fiber, preventing dullness and fading.

-

Easy maintenance: Regular cleaning with pH-neutral soap and a microfiber cloth, along with occasional polishing, keeps the surface in top condition.

You should know that epoxy alone is not enough for UV protection. Research shows that UV-B and UV-C rays can break down the resin matrix, exposing fibers and causing surface damage. Even high performance epoxy resins will degrade without a proper uv resistant clear coat for carbon fiber. Acrylic resins offer better UV stability, but for most applications, you need a dedicated clear coat with UV inhibitors.

|

Clear Coat Type |

UV Protection |

Durability |

Finish Options |

Maintenance |

|---|---|---|---|---|

|

2K Polyurethane |

Excellent |

High |

Gloss, Matte |

Moderate |

|

Ceramic Coating |

Excellent |

Very High |

Gloss, Satin |

Low |

|

Acrylic Clear Coat |

Good |

Moderate |

Gloss, Matte |

Easy |

Ceramic coating stands out for its long-lasting protection and ease of care. Many professionals and consumers recommend products like FANTOM CLEAR™ CX Carbon Fiber Clearcoat for their strong UV resistance, smooth finish, and compatibility with different resin systems.

Note: Epoxy resin provides strength but needs a uv resistant clear coat for carbon fiber to prevent yellowing and surface breakdown. Always use a protective clear coat designed for outdoor and high-stress environments.

By choosing the right clear coat, you ensure your carbon fiber parts stay strong, glossy, and protected against the elements. This investment pays off in both performance and appearance.

Types of Protective Clear Coat

When you want to protect carbon fiber from UV damage and environmental wear, you have several clear coat options. Each type offers unique benefits and drawbacks. Understanding these differences helps you choose the best solution for your application and maintenance needs.

2K Polyurethane

2K polyurethane stands out as a top choice for a uv resistant clear coat for carbon fiber. This two-component system combines a resin and a hardener, creating a tough, durable finish. You get a smooth, glossy surface that resists yellowing and maintains clarity over time.

Advantages of 2K Polyurethane:

-

Exceptional durability and hardness, which shields carbon fiber from scratches and impacts.

-

Excellent color retention, so your parts stay clear and do not yellow.

-

Fast drying times and easy application, especially with water-based formulas.

-

Lower VOCs and less hazardous solvents, making it safer for you and the environment.

-

Smooth, buttery application with quick leveling and stackable recoats.

Disadvantages:

-

Water-based types can be more susceptible to scratching.

-

You may need multiple coats to achieve a flawless finish.

-

Higher raw material costs can increase the price.

-

Oil-based versions may yellow over time and use flammable, hazardous solvents.

Tip: Water-based 2K polyurethane remains clear and flexible, even with extra coats. This flexibility helps maintain the bond to carbon fiber, especially on parts that flex or vibrate.

If you want a protective clear coat that balances performance, safety, and environmental responsibility, 2K polyurethane is a strong candidate.

Ceramic Coatings

Ceramic coating technology has become a favorite for paint protection on carbon fiber. These coatings use advanced nanotechnology to create a hard, hydrophobic layer that bonds directly to the surface.

Key Benefits:

-

Superior UV resistance compared to waxes and sealants, which often fail within weeks.

-

Long-lasting protection that can outlast traditional clear coats, reducing the need for frequent reapplication.

-

Enhanced resistance to chemicals, water, and environmental contaminants.

-

Maintains a deep, glossy finish that highlights the carbon fiber weave.

You should still wash and wax your carbon fiber parts regularly, even with a ceramic coating. This routine helps maintain the coating’s effectiveness and appearance. Many users report that ceramic coatings provide the best UV protection for carbon fiber, especially in harsh sunlight.

Note: Some paint protection films (PPF) also offer UV resistance and warranties against discoloration, but ceramic coatings generally deliver better long-term results for carbon fiber.

If you want a low-maintenance, high-performance solution, ceramic coating offers unmatched durability and shine.

Acrylic Clear Coats

Acrylic clear coats provide another option for protecting carbon fiber. These coatings use acrylic resins, which offer excellent optical clarity and resist yellowing.

Acrylic clear coats excel in UV resistance due to their stable molecular structure. They maintain their appearance and mechanical properties after UV exposure, making them a reliable choice for outdoor applications. You can apply acrylic clear coats over a lightly roughened carbon fiber surface, but proper surface prep is essential for best results.

|

Performance Aspect |

Acrylic Clear Coat (PMMA, Elium-based) |

Epoxy-based CFRP |

|---|---|---|

|

UV Resistance |

Superior, resists yellowing |

Loses strength, fiber exposure |

|

Weathering Resistance |

Maintains integrity, hydrophobic |

Degrades, interface damage |

|

Mechanical Properties |

Slightly lower tensile strength |

Higher initial strength |

|

Surface Damage after UV |

Surface cracks, no fiber exposure |

Fiber exposure, interface damage |

|

Optical Properties |

High transparency, minimal yellowing |

Not specified |

|

Recyclability |

Enhanced (thermoplastic acrylic) |

Limited |

You should know that acrylic clear coats may not match the mechanical strength of epoxy-based systems, but they offer better UV stability and recyclability. They also provide a high-gloss, transparent finish that keeps your carbon fiber looking sharp.

Glossy vs. Matte Finishes

The finish you choose affects both the look and the performance of your carbon fiber parts.

-

Glossy finishes create a shiny, reflective surface that makes the weave pattern pop. This premium look draws attention and often uses UV-protective clear coats to maintain clarity and longevity. However, glossy finishes show fingerprints and scratches more easily and require regular maintenance.

-

Matte finishes offer a soft, non-reflective appearance that hides scratches and fingerprints. They need less upkeep but can make the weave pattern less visible and sometimes appear dull without proper care.

|

Finish Type |

Appearance Characteristics |

UV Protection |

Aesthetic Appeal |

Maintenance and Durability |

|---|---|---|---|---|

|

Glossy |

High reflectivity, polished, premium look |

Often uses UV-protective clear coats |

Eye-catching, luxury feel |

Shows scratches easily; needs polishing |

|

Matte |

Low to medium reflectivity, soft texture |

No explicit UV advantage |

Stealthy, hides scratches |

Easier maintenance; hides wear better |

Both finishes can be equally durable if applied properly. No statistical evidence proves one finish offers better UV protection, but glossy finishes often maintain their shine longer with the right care.

Environmental Considerations

You can also make an environmentally responsible choice by selecting bio-based, waterborne polyurethane coatings. These formulations reduce harmful emissions and toxicity, supporting sustainability. Foaming technology in these coatings creates lightweight, thermally insulating layers that extend the life of your carbon fiber parts and reduce maintenance waste.

Waterborne polyurethane coatings not only provide UV resistance and corrosion protection but also contribute to self-cleaning and aging resistance. This multifunctionality makes them ideal for marine and outdoor applications.

Choosing the Right Protective Clear Coat

When you select a protective clear coat for carbon fiber, consider your performance needs, desired finish, and environmental impact. 2K polyurethane offers a balance of durability and safety. Ceramic coating delivers the best long-term paint protection and UV resistance. Acrylic clear coats provide excellent clarity and recyclability. Glossy finishes enhance aesthetics, while matte finishes simplify maintenance. By understanding these options, you can keep your carbon fiber strong, beautiful, and protected for years.

Application Steps

Surface Prep

Proper surface preparation sets the foundation for a durable, UV-resistant finish. Start by cleaning your carbon fiber part with a gentle, ammonia-free cleaner to remove dust, oils, and contaminants. Avoid harsh chemicals, as they can degrade the clear coat and reduce UV protection. If you notice oxidation or old clear coat damage, wet sand the surface carefully. Use fine-grit sandpaper and avoid sanding into the carbon fiber weave. Fill any chips or fissures with resin and allow it to cure fully. For best results when painting carbon fiber, always use a carbon fiber-safe primer to promote adhesion and prevent future peeling.

Tip: Take your time during prep. Rushing this step can lead to poor adhesion and long-term issues.

Applying Thin Coats

Apply the UV resistant clear coat in multiple thin layers rather than one thick coat. Thin coats dry faster and reduce the risk of runs or sags. The UV blockers in the clear coat concentrate in the top 25% of the coating as it hardens. Maintaining adequate thickness in this upper layer is crucial for long-term UV resistance and durability. If you polish or sand away too much of the clear coat, you risk removing most of the UV protection. Always allow each coat to flash off before applying the next.

Curing and Drying

Curing times vary by product. Refer to the table below for guidance:

|

Coating Type |

Curing/Drying Time |

Additional Notes |

|---|---|---|

|

DiamondFinish Clear |

Handle after 1 day; full cure at 7 days |

Can polish after 24 hours; apply thin coats |

|

Ceramic Coating |

Minimum 48 hours; hardens over 7 days |

Apply in sections; wipe residue after drying |

|

Wax |

10–15 minutes to haze before wiping |

Use microfiber towel to remove excess |

Keep your workspace at a moderate temperature with low airflow for best results. Avoid touching or exposing the surface to moisture during curing.

Common Mistakes

Many users make avoidable errors during application. Watch out for these pitfalls:

-

Using harsh or ammonia-based cleaners that break down the clear coat.

-

Ignoring chips or scratches, which can spread and cause peeling.

-

Letting water spots sit, leading to mineral etching.

-

Rubbing dust off with a dry cloth, which scratches the surface.

-

Attempting DIY sanding or repairs without proper tools or experience, risking damage to the carbon fiber weave.

Note: Improper sanding or aggressive correction can permanently damage your carbon fiber part and compromise UV protection. When in doubt, consult a professional.

Maintenance Tips

Cleaning and Waxing

Proper cleaning and waxing routines form the foundation of effective maintenance for carbon fiber parts. You should always use pH-neutral car wash soap and a soft microfiber cloth to clean the surface. This approach prevents scratches and chemical damage. Avoid harsh chemicals like acetone or alcohol, as these can weaken the resin matrix and reduce the effectiveness of your UV resistant clear coat.

-

Wash your carbon fiber parts every 1-2 weeks to remove dust and contaminants.

-

Decontaminate the surface with a clay bar and quality clay lubricant before waxing.

-

Apply a ceramic coating or a ceramic-infused wax, such as 3D GLW Series SiO2 Ceramic Wax, for superior protection.

-

Let the wax cure for 10-15 minutes until it hazes, then buff with a clean microfiber towel.

-

Use hydrophobic ceramic detail sprays and pH-neutral ceramic car wash soaps to maintain the protective layer.

Tip: Never wax over dirt or debris. Always clean thoroughly before applying any wax or sealant to avoid scratches.

Inspections and Reapplication

Regular inspections help you catch minor issues before they become major problems. You should visually inspect your carbon fiber parts every 3-6 months. Look for surface scratches, chips, or signs of resin damage. Annual professional inspections ensure structural integrity, especially for high-stress applications.

-

Reapply UV-resistant clear coats every 12-18 months, depending on climate and exposure.

-

Wax your carbon fiber parts with UV-protective waxes every 3-4 months to maintain optimal protection.

-

Consider reapplying ceramic coatings every 1-2 years for long-term durability.

-

Address any surface damage promptly to prevent further degradation.

Consistent maintenance extends the lifespan of your UV resistant clear coat and preserves the appearance of your carbon fiber parts.

Storage and Sun Protection

Proper storage and sun protection play a crucial role in carbon fiber care. Store your carbon fiber parts indoors whenever possible to avoid prolonged sun exposure. Sunlight can degrade even the best UV resistant clear coats over time.

-

Maintain controlled temperature and humidity in storage areas to prevent resin weakening.

-

Use soft, non-abrasive covers to shield your carbon fiber parts from dust and scratches.

-

Avoid abrasive materials and harsh cleaning tools during maintenance.

-

Apply UV-resistant coatings regularly, especially if your carbon fiber parts see frequent outdoor use.

Note: Storing your carbon fiber parts in a cool, dry place and using breathable covers will help you maximize the effectiveness of your maintenance routine.

You protect your investment and preserve the beauty of custom carbon fiber designs by choosing a high-quality UV resistant clear coat. Proper application and regular maintenance prevent yellowing, cracking, and delamination caused by sun exposure. Always wash with gentle soap, avoid harsh chemicals, and store your custom-painted carbon fiber out of direct sunlight. These steps help you avoid premature failure and keep your parts looking sharp for years. Consistent care ensures your carbon fiber remains strong and visually striking.

Share:

How to Choose the Optimal Carbon Fiber Weave Pattern for Any Project

How Does Carbon Fiber Composite Material Deliver Strength and Lightness