Selecting optimal carbon fiber weave patterns requires you to match both mechanical and visual properties to your project’s needs. You must evaluate key factors to consider, such as part geometry, strength, flexibility, appearance, and cost. For example, plain, twill, and satin weaves each offer unique benefits. Complex shapes often need higher drapability, while flat surfaces benefit from stability. By understanding optimal carbon fiber weave patterns, you ensure your finished part delivers both performance and visual appeal.

Key Takeaways

-

Match the carbon fiber weave pattern to your part’s shape and performance needs for best results.

-

Plain weave works best for flat, stable parts; twill and satin weaves suit complex curves and offer better flexibility.

-

Consider appearance and cost when choosing a weave; twill and satin provide premium looks but cost more than plain weave.

-

High-performance projects need careful weave selection to balance strength, flexibility, and load direction.

-

Avoid mismatching weave patterns with project needs to prevent poor performance, higher costs, or manufacturing issues.

Quick Comparison Table

Carbon Fiber Weave Patterns

When you select carbon fiber weave patterns, you need to understand how each weave impacts your project’s performance and appearance. The four most common carbon fiber weave types—plain weave, twill weave, satin weave, and unidirectional—each offer unique properties.

|

Weave Pattern |

Strength |

Flexibility |

Drapability |

Appearance |

Cost (per yard) |

|---|---|---|---|---|---|

|

Plain Weave |

Good strength-to-weight ratio; high dimensional stability |

Moderate flexibility |

Moderate drapability; even surface |

Checkerboard, matte |

$29.00 (retail) |

|

Twill Weave |

Superior strength from diagonal stress distribution |

Improved flexibility |

Excellent drapability; conforms well |

Diagonal, glossy/matte |

$27.50 (retail) |

|

Satin Weave |

High strength and impact resistance |

Lightweight flexibility |

High drapability; smooth, shiny |

Glossy, subtle pattern |

Varies |

|

Unidirectional |

Maximum strength and stiffness in one direction |

Low flexibility |

Low drapability |

Linear, technical |

Varies |

Tip: Choose plain weave for flat panels and simple shapes. Twill weave and satin weave work better for complex curves and surfaces.

Key Properties

-

You will find that plain weave provides excellent dimensional stability and a uniform checkerboard look. This carbon fiber weave resists stretching and works best for flat sheets, tubes, and simple 2D curves.

-

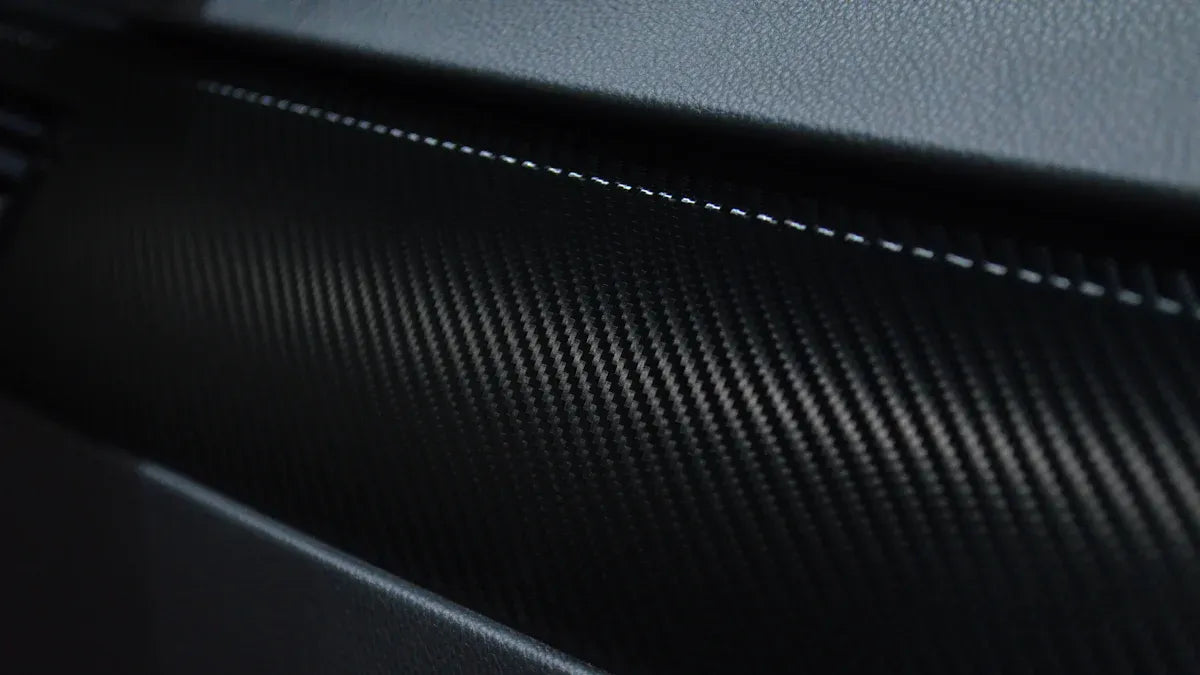

Twill weave stands out for its superior strength, flexibility, and drapability. The diagonal pattern distributes stress evenly, making it ideal for complex shapes and curved surfaces. Twill weave also resists cracking and fraying, and its glossy finish appeals to automotive and sports applications.

-

Satin weave offers high drapability and a smooth, shiny surface. You can use satin weave for parts with intricate curves or where a glossy appearance is important. Satin weave is common in high-end sports equipment and decorative panels.

-

Unidirectional carbon fiber weave maximizes strength and stiffness in one direction. Use this weave when you need directional strength, such as in aerospace spars or racing components. However, it lacks flexibility and does not conform well to complex shapes.

Summary of Use Cases:

-

Plain weave: Best for flat, stable parts where stiffness matters.

-

Twill weave: Best for complex shapes, curved surfaces, and when you want a balance of strength and flexibility.

-

Satin weave: Best for highly curved or decorative parts needing a glossy finish.

-

Unidirectional: Best for parts needing maximum strength in one direction.

For most projects, you should match the weave pattern to your part’s geometry and performance needs. Twill weave and satin weave excel on complex shapes, while plain weave remains the top choice for flat, stable panels.

Understanding Weave Patterns

Carbon Fiber Fabric Types

You encounter several carbon fiber fabric types when selecting materials for your project. Each weave pattern offers unique characteristics that affect both performance and appearance. The most common carbon cloth fabric types include plain weave, twill weave, satin weave, unidirectional, and forged carbon fiber. The table below summarizes their defining features:

|

Weave Pattern |

Defining Characteristics |

|---|---|

|

Plain Weave |

Checkerboard look, over-under interlacing, high stability, limited flexibility, many crimps, best for flat/simple shapes |

|

Twill Weave |

Diagonal pattern, longer floats, fewer crimps, excellent drapability, visually appealing, suits complex shapes |

|

Satin Weave |

Few intersections, long floats, very smooth surface, high drapability, lower stability, glossy finish, prone to fraying |

|

Unidirectional |

Fibers aligned in one direction, maximum strength along fiber axis, weak perpendicular strength, technical appearance |

|

Forged Carbon Fiber |

Randomly oriented chopped fibers, isotropic strength, marbled look, strong, used in aerospace and rockets |

You often see plain weave and twill weave in carbon fiber fabric for automotive and sports applications. Satin weave and forged carbon fiber fabric appear in high-end or specialized projects.

Weave Characteristics

When you choose carbon cloth fabric, you must consider how weave patterns affect stability, drapability, and appearance. Plain weave provides high stability and a balanced strength profile, making it ideal for flat panels and simple shapes. Twill weave offers better drapability and flexibility, so you can easily wrap it around complex curves. Satin weave delivers the smoothest finish and highest drapability, but it may fray more easily and lacks the stability of plain weave.

Unidirectional carbon fiber fabric maximizes strength in one direction, which is critical for structural parts that require high strength carbon fibers along a single axis. Forged carbon fiber fabric stands out for its isotropic properties, giving you equal strength in all directions and a unique marbled appearance.

You also need to understand the difference between 3K and 12K carbon cloth fabric. 3K carbon fiber fabric uses three thousand filaments per tow, resulting in lighter, more flexible carbon fiber materials. This type works well for high-performance sports equipment and aerospace parts. 12K carbon fiber fabric contains twelve thousand filaments per tow, making it heavier and stronger, but less flexible. You often use 12K carbon fiber materials in military and high-end aerospace applications.

Tight weaves in carbon fiber fabric increase stability and surface smoothness, while loose weaves improve drapability for complex shapes. By matching the weave pattern and fiber count to your project’s geometry and performance needs, you ensure your carbon fiber composites deliver optimal results.

Choosing a Weave

Project Requirements

You must start by identifying the key factors to consider for your project. Every application demands a unique balance of strength, stiffness, flexibility, weight, and quality. The optimal weave pattern depends on how you prioritize these needs. For example, if your project requires a high strength-to-weight ratio, you should focus on carbon fiber materials that deliver both superior strength and low mass.

|

Weave Pattern |

Stability (Shape Retention) |

Drapability (Flexibility) |

Appearance |

Crimp (Fiber Waviness) |

|---|---|---|---|---|

|

Plain Weave |

High |

Moderate |

Checkerboard look |

High |

|

Twill Weave |

Moderate |

Good |

Diagonal pattern |

Medium |

|

Satin Weave |

Low |

Excellent |

Glossy, smooth |

Low |

Plain weave offers high stability and is easy to handle, making it a reliable choice for projects where shape retention and straightforward manufacturing matter. Twill weave provides balanced performance, with good drapability and a sporty appearance. Satin weave excels in flexibility and aesthetics, but it may fray more easily and lacks the stability of plain weave. When you need enhanced flexibility or a specific visual effect, custom weave patterns can help you achieve your goals.

Mechanical properties such as crimp also play a role. Less crimp means straighter fibers, which increases tensile strength and durability. You should always match the optimal weave pattern to your project’s required performance, durability, and quality standards.

Shape and Geometry

The geometry of your part directly influences which optimal weave pattern you should select. Flat panels and simple shapes benefit from plain weave, which provides excellent strength and stability. However, complex curves and 3D surfaces require weaves with enhanced flexibility and drapability.

-

Plain weave works best for flat surfaces, offering high shape retention and a uniform appearance.

-

Twill weave adapts well to curved components, providing a balance between strength and flexibility.

-

Satin weave delivers the highest drapability, making it ideal for intricate, curved panels and high-performance carbon fiber parts.

The crimp ratio and yarn geometry affect how the fabric conforms to your mold. Smaller crimp ratios lead to higher elastic modulus and strength, while larger crimp ratios can reduce stiffness and increase the risk of defects. For complex shapes, you should choose a weave with high malleability to avoid fiber misalignment and wrinkling. This ensures your finished part maintains both performance and quality.

Tip: For tubes, shafts, or round parts, braided or spread tow weaves offer multidirectional strength and superior durability.

Appearance Goals

Your project’s visual requirements often guide your choice of optimal carbon fiber weave patterns. Each weave creates a distinct surface finish and texture, which can enhance the perceived quality and style of your product.

|

Weave Pattern / Finish |

Visual Characteristics |

Reflectivity |

Typical Applications |

|---|---|---|---|

|

Plain (1×1) Glossy |

Fine, checkered weave |

High |

Electronics, drone frames, clean designs |

|

Twill (2×2) Glossy |

Diagonal, flowing pattern |

Very High |

Automotive, sporting goods, premium look |

|

Satin Weave |

Smooth, lustrous surface |

High |

Aerospace, luxury interiors |

|

Forged Carbon |

Random, marble-like texture |

Variable |

Luxury, decorative, artistic finishes |

Plain weave offers a clean, professional look, perfect for understated or technical applications. Twill weave stands out with its diagonal, dynamic pattern, popular in automotive and sports equipment for its premium appearance. Satin weave provides a glossy, elegant finish, ideal for luxury or high-end products. Forged carbon fiber delivers a bold, marbled effect, making it a favorite for decorative or statement pieces.

Surface finish also matters. Glossy finishes create depth and highlight the weave, while matte finishes offer a modern, low-glare look that hides scratches and wear. You should select the optimal weave pattern that aligns with your brand image and the desired visual impact of your product.

Budget Factors

Cost plays a significant role in choosing the optimal weave pattern. You must balance material performance, quality, and financial constraints to achieve the best results.

|

Carbon Fiber Form |

Typical Price Range (USD) |

Notes on Cost and Budgeting |

|---|---|---|

|

Raw Carbon Fibers |

$15 to $50 per pound |

Base cost varies with fiber strength and modulus |

|

Woven Carbon Fiber Fabrics |

$20 to $75 per yard |

Plain weave is most cost-effective; twill and satin cost more |

|

Prepreg Carbon Fibers |

$30 to $150 per square meter |

Higher cost due to resin impregnation and processing complexity |

Plain weave remains the most cost-effective option, holding the largest market share due to its versatility and quality. Twill and satin weaves, while more expensive, justify their price with better drapability and performance for complex or high-performance carbon fiber applications. High production costs and raw material price volatility can impact your budget, so you should plan carefully and select the optimal weave pattern that meets both your technical and financial requirements.

Note: Manufacturing constraints, such as the chosen fabrication method and part complexity, may limit your options. Simpler weaves like plain weave are easier to handle and produce, while advanced weaves may require specialized processes and higher labor costs.

By carefully considering project requirements, part geometry, appearance goals, and budget, you can confidently select the optimal carbon fiber weave patterns for any application. This approach ensures your finished product achieves the desired performance, durability, and quality.

Application Guide

High-Performance Carbon Fiber Uses

You encounter the most demanding requirements for carbon cloth fabric in aerospace and motorsports. These industries rely on high-performance carbon fiber for its unmatched strength-to-weight ratio, stiffness, and ability to tailor mechanical properties. When you select a weave for high-performance applications, you must consider both the geometry of the part and the direction of the loads it will face.

|

Weave Pattern |

Performance Characteristics |

Recommended Aerospace Applications |

|---|---|---|

|

Plain Weave |

Uniform strength, excellent dimensional stability |

Stability-critical parts, easy handling |

|

Twill Weave |

Improved drapability, flexibility, diagonal pattern |

Complex shapes: fairings, control surfaces |

|

Satin Weave |

Smooth surface, high strength |

Structural panels, interiors needing strength and aesthetics |

|

Specialized Weaves |

Tailored mechanical properties |

Custom components with unique performance needs |

|

Bidirectional |

Balanced strength and stiffness in two directions |

Multi-directional load parts: control surfaces, panels |

|

Multidirectional |

Reinforcement in multiple directions, damage tolerance |

Fuselage, wing spars, critical structures |

You should use unidirectional carbon fiber fabric for parts that require maximum tensile strength and stiffness along a single axis, such as aircraft wings or race car chassis. This weave type allows you to achieve the highest possible performance in targeted directions. For components exposed to multi-directional stresses, bidirectional and multidirectional weaves provide balanced strength and enhanced durability. Twill and satin weaves offer superior drapability, making them ideal for complex aerodynamic surfaces.

Tip: In high-performance carbon fiber applications, always match the weave orientation to the primary load direction for optimal performance and safety.

When you compare carbon fiber fabric to traditional materials like aluminum, you gain significant weight savings—up to 40%. The tensile strength of high-performance carbon fiber can reach up to 500,000 psi, far exceeding aluminum. However, you must account for its brittleness under impact and higher production costs. You can use carbon fiber composites to reduce weight and improve fuel efficiency in aerospace, while motorsports benefit from increased speed and driver protection.

Automotive and Sports

You see carbon cloth fabric used throughout the automotive and sports industries. Manufacturers choose specific weaves to balance performance, appearance, and manufacturability. Industry research shows that plain weave carbon fiber fabric delivers the highest strength for flat or gently curved parts. Twill weave, especially 2×2 twill, provides a blend of strength and flexibility, making it suitable for more complex geometries.

-

Plain weave: Use this for flat panels, dashboards, and interior trim. Its checkerboard pattern offers a refined, subtle look. Ferrari often selects plain weave for both interior and exterior parts to achieve understated elegance.

-

Twill weave: Choose this for exterior body panels, spoilers, and parts with aggressive curves. Lamborghini and McLaren favor twill weave for its dramatic diagonal pattern and superior drapability. Twill weave also appears in high-performance sports equipment, such as bicycle frames and snowboards, where you need both strength and flexibility.

-

Unidirectional weave: Apply this to load-bearing automotive parts like chassis reinforcements and suspension components. You maximize strength along the axis of greatest stress.

-

Spread tow weave: Use this advanced weave for structural parts where you want to reduce crimping and improve load efficiency. Spread tow weaves enhance surface finish and performance in high-end applications.

Note: For visual consistency, match the weave pattern across adjacent parts. Twill weave creates a bold, sporty look for exteriors, while plain weave provides a subtle, technical finish for interiors.

In sports equipment, you benefit from stable carbon cloth fabric weaves that enhance durability and flex. Laminates—multiple layers of carbon fiber fabric cured under heat and pressure—deliver the stiffness and dimensional stability needed for high-performance carbon fiber snowboards, hockey sticks, and racquets.

Hobby and Cosmetic

You can achieve impressive results in hobbyist and decorative projects by selecting the right carbon fiber fabric. Here, you often prioritize ease of molding, flexibility, and visual appeal over maximum structural performance. Looser weaves allow you to wrap carbon cloth fabric around complex shapes, but you may sacrifice some stability. Tighter weaves offer more strength but less flexibility.

-

Plain weave: Choose this for small, flat parts or when you want a classic checkerboard look. It works well for electronics covers, wallets, and jewelry.

-

2×2 twill weave: This is the most popular choice for hobbyists. Its diagonal pattern provides a striking visual effect and greater rigidity, making it ideal for RC car bodies, drone frames, and decorative automotive trim.

-

Satin weave: Use this for projects that require a smooth, glossy finish, such as luxury accessories or interior panels.

-

Forged carbon fiber: Select this for artistic or statement pieces. Its marbled appearance stands out in watches, phone cases, and custom decor.

You can use carbon fiber fabric in the form of cloths, veneers, or flexible sheets. Veneers are thin and easy to apply as surface finishes, while fabrics and cloths allow you to mold around curves and edges. High-gloss finishes enhance the three-dimensional effect of the weave, increasing the cosmetic appeal of your project.

Tip: For hobby and cosmetic uses, focus on the visual pattern and finish. Choose a weave that matches your design vision and is easy to work with for your skill level.

You can use carbon cloth fabric to create lightweight, durable, and hypoallergenic products. The unique patterns of carbon fiber fabric make it a favorite among designers and hobbyists who want both function and style.

Mistakes to Avoid

Overlooking Needs

You must always match the carbon fiber weave pattern to your project’s specific requirements. Ignoring the unique needs of your application can lead to serious performance and quality issues. For example, using plain weave in a part that demands flexibility or high impact resistance may result in premature failure. Twill weave offers excellent flexibility and conforms well to complex shapes, but using it where not needed can add unnecessary weight and cost. Satin weave provides a glossy, pliable finish, but if you use it in structural parts where strength is critical, you risk compromising durability and overall quality.

|

Weave Pattern |

When to Avoid |

Potential Issues |

|---|---|---|

|

Plain |

High-flex or impact areas |

Reduced performance, possible cracking |

|

Twill |

Simple, flat parts |

Unnecessary weight, higher cost |

|

Satin |

Load-bearing structures |

Lower strength, compromised quality |

Tip: Always assess your project’s geometry, load direction, and desired appearance before choosing a weave. This ensures you achieve the right balance of performance and quality.

Cost Over Performance

You might feel tempted to cut costs by choosing cheaper carbon fiber or lower-grade weaves. However, this approach often leads to reduced quality and shorter lifespan. High-quality materials and advanced manufacturing processes give carbon fiber its superior strength, fatigue resistance, and environmental durability. When you prioritize cost over performance, you risk using materials that lack the necessary strength and quality for demanding applications. Cheaper options may crack under impact or degrade quickly, leading to higher maintenance and replacement costs over time.

-

Lower-cost carbon fiber parts often lack optimized resin systems and precise engineering, which reduces long-term durability.

-

High-quality materials ensure your components maintain their performance and quality throughout their service life.

-

For non-critical or cosmetic projects, budget options may suffice, but you sacrifice the long-term benefits of true carbon fiber quality.

Note: The initial investment in high-quality materials pays off with better performance, less maintenance, and greater overall quality.

Manufacturing Issues

Manufacturing with carbon fiber requires careful planning and attention to detail. Each weave pattern affects how the material behaves during lay-up and machining. If you neglect manufacturing constraints, you risk damaging the fibers, causing delamination, or producing parts with inconsistent quality. Twill and satin weaves, while offering superior drapability, demand precise lay-up orientation to maintain uniform performance. The anisotropic nature of carbon fiber means you must offset layers to achieve balanced stiffness and rigidity.

Common manufacturing challenges include:

-

Brittleness and delamination during machining, which can compromise part integrity.

-

Accelerated tool wear and hazardous dust generation.

-

Heat buildup that softens the resin matrix, leading to dimensional inaccuracies.

-

Difficulty achieving a smooth surface finish, especially with complex weaves.

-

Maintaining dimensional accuracy and preventing deformation requires rigid fixturing and precise control.

Tip: Work with experienced fabricators and follow best practices to ensure your carbon fiber parts deliver the expected performance and quality.

Selecting optimal carbon fiber weave patterns ensures your project meets both performance and visual goals. Use the comparison table below to match weave properties to your needs:

|

Weave Pattern |

Flexibility |

Strength |

Visual Appeal |

Ideal Use Case |

|---|---|---|---|---|

|

Plain Weave |

Low |

High |

Low |

Flat panels, stable parts |

|

Twill Weave |

Medium |

High |

High |

Automotive, visible surfaces |

|

Satin Weave |

High |

Medium |

Medium |

Curved, molded components |

|

Spread Tow |

Medium |

Very High |

Very High |

Aerodynamic, lightweight gear |

You can improve your results by consulting experts. They help you select materials, guide prototyping, and ensure quality. Explore resources like case studies and material samples to make informed decisions for your next project.

Share:

How to Protect Carbon Fiber with the Best UV Resistant Clear Coat

How Does Carbon Fiber Composite Material Deliver Strength and Lightness