Carbon fiber comes in different types, with plain and twill weaves being the most common. These types of carbon fiber differ in their weave patterns, structural properties, and visual appeal. Plain carbon fiber offers uniformity and strength, making it ideal for applications requiring stability. Twill carbon fiber, on the other hand, provides flexibility and works well for complex shapes.

-

The carbon fiber fabrics market highlights both plain and twill weaves.

-

Twill weave reduces weight by using less resin, while plain weave may increase laminated weight for intricate designs.

Your choice depends on the application and the desired balance between performance and aesthetics.

Key Takeaways

-

Plain carbon fiber is strong and stable, great for structures.

-

Twill carbon fiber is flexible and looks cool, good for fancy shapes.

-

Think about the finish; shiny ones look nice, but matte ones hide flaws.

-

Your budget matters; plain carbon fiber costs less, twill is for luxury.

-

Pick what fits your project; plain is stable, twill is flexible and pretty.

Structural Differences in Carbon Fiber Patterns

Plain Carbon Fiber: Uniformity and Stability

Plain carbon fiber stands out for its uniformity and exceptional stability. Its tightly packed plain weave carbon fiber pattern creates a checkerboard appearance, offering consistent strength across the material. This uniformity makes it ideal for applications requiring high structural integrity. For example, plain weave carbon fiber pattern materials are often used in flat or slightly curved surfaces where stability is critical.

You’ll find that plain carbon fiber provides a higher specific strength and stiffness compared to traditional materials like aluminum or steel. A comparison shows that plain carbon fiber has a specific strength of 1800 KSI, which is five times greater than aluminum and over four times that of steel. Its specific stiffness is also double that of these metals, making it a superior choice for lightweight yet strong designs. Additionally, its low thermal expansion ensures minimal dimensional changes, even under temperature fluctuations.

|

Material |

Specific Strength (KSI) |

Specific Stiffness (MSI) |

|---|---|---|

|

Plain Carbon Fiber |

1800 |

200 |

|

Aluminum |

350 |

100 |

|

Steel |

417 |

100 |

Twill Carbon Fiber: Flexibility and Adaptability

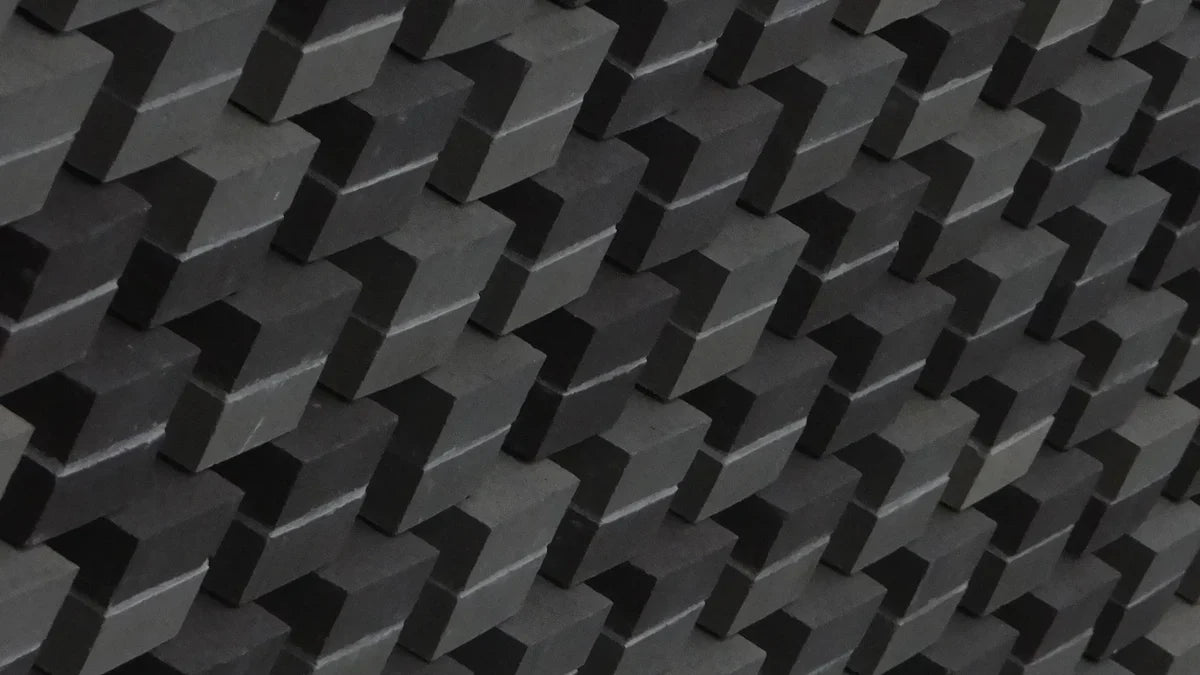

Twill weave carbon fiber offers a diagonal, ribbed pattern that enhances flexibility. This carbon fibre weave is easier to manipulate, making it perfect for complex shapes and curved surfaces. Its stylish appearance also adds a textured, high-end look to finished products.

Unlike plain weave, twill weave uses less resin, reducing the overall weight of the material. This makes it a popular choice in industries where weight reduction is crucial. However, its slightly looser weave results in less load-bearing capacity compared to plain weave carbon fiber pattern materials. Despite this, twill weave remains strong enough for most applications while providing better impact absorption.

Comparing Strength and Durability

When comparing different carbon fiber patterns, plain weave carbon fiber excels in strength and durability. Its tightly packed structure makes it sturdier and stiffer, ideal for applications where structural integrity is a priority. Twill weave, while slightly less strong, compensates with its flexibility and adaptability.

For flat or slightly curved surfaces, plain weave carbon fiber pattern materials deliver consistent performance. On the other hand, twill weave carbon fiber is better suited for specialized carbon fiber patterns that conform to complex shapes. Both options offer an exceptional strength-to-weight ratio, but your choice depends on the specific requirements of your project.

|

Property |

Plain Carbon Fiber |

Twill Carbon Fiber |

|---|---|---|

|

Appearance |

Uniform, checkerboard pattern |

Diagonal, ribbed pattern |

|

Strength and Durability |

Slightly stronger due to tighter weave |

Slightly less load-bearing capacity |

|

Flexibility |

Stiffer, less flexible |

More flexible, easier to manipulate |

|

Weight |

May require more material for complex shapes |

Can use less resin, reducing total weight |

Aesthetic Appeal of Different Types of Carbon Fiber

Plain Carbon Fiber: Subtle and Minimalistic

Plain carbon fiber offers a clean and understated look. Its checkerboard pattern creates a uniform appearance that appeals to those who prefer simplicity. You might notice this type of carbon fiber in applications where functionality takes precedence over flashy designs. For example, it often appears in industrial equipment or structural components where aesthetics are secondary.

The subtle design of plain carbon fiber complements minimalistic styles. If you value a professional and clean finish, this option works well. Its consistent pattern also ensures a seamless look when used on flat or slightly curved surfaces. While it may lack the visual flair of other types of carbon fiber, its simplicity makes it timeless and versatile.

Twill Carbon Fiber: Stylish and Textured

Twill carbon fiber stands out with its diagonal, ribbed pattern. This weave creates a textured surface that adds depth and sophistication to any product. You’ll often see it in high-end applications like luxury cars, sports equipment, or premium electronics. Its stylish appearance makes it a favorite for those who want to combine performance with aesthetics.

The flexibility of twill carbon fiber allows it to conform to complex shapes without losing its visual appeal. This makes it ideal for curved surfaces or intricate designs. If you’re looking for a material that delivers both strength and a high-end look, twill carbon fiber is an excellent choice.

Popularity of 2×2 and 4×4 Twill Weave Carbon Fiber Patterns

Among twill weaves, the 2×2 twill weave carbon fiber pattern is the most popular. Its balanced design offers a perfect mix of style and functionality. You’ll find this pattern in automotive interiors, bicycle frames, and even consumer electronics. The 2×2 weave provides a sleek, modern look while maintaining the flexibility needed for complex shapes.

The 4×4 twill weave carbon fiber pattern, on the other hand, features a larger and more pronounced texture. This pattern is less common but highly sought after for its bold and striking appearance. If you want a design that truly stands out, the 4×4 weave delivers a unique aesthetic. Both patterns highlight the versatility of twill carbon fiber, making it a top choice for various industries.

Applications of Plain and Twill Carbon Fiber

Automotive Industry

Carbon fiber plays a significant role in the automotive industry, especially in high-performance automotive designs. You’ll find plain carbon fiber used frequently due to its checkerboard appearance and tightly knit structure. This material is the second most popular fabric type in automotive applications. Its uniformity makes it easier to handle without distortions, although it can be challenging to drape over molds.

Twill carbon fiber, on the other hand, is often chosen for its stylish and textured look. Its flexibility allows it to conform to complex shapes, making it ideal for curved surfaces like car interiors or aerodynamic body panels. High-performance products, such as sports cars and luxury vehicles, often incorporate twill carbon fiber for both its aesthetic appeal and lightweight properties.

Aerospace and Aviation

In aerospace, carbon fibre composites have revolutionized the industry. Twill carbon fiber stands out for its unparalleled strength-to-weight ratio, dimensional stability, and lightweight characteristics. These properties make it essential for critical aerospace components. For example, it is used in the construction of space probes like NASA’s Parker Solar Probe and Mars rovers. Its ability to endure high stresses while maintaining structural integrity under extreme conditions makes it indispensable in aircraft design.

|

Property |

Description |

|---|---|

|

Strength-to-weight ratio |

Unparalleled strength-to-weight ratios make it ideal for critical aerospace components. |

|

Dimensional stability |

Maintains structural integrity under extreme conditions, essential for aircraft design. |

|

Lightweight characteristics |

Reduces overall weight, contributing to fuel efficiency and performance in aviation. |

Carbon fiber composites also reduce the weight of spacecraft, which is crucial for cost efficiency. Every kilogram saved can lead to significant fuel savings. For instance, reducing 1 kg of weight can save 500 kg of fuel, lowering launch costs by approximately $20,000.

Sports and Recreation

Plain carbon fiber is a popular choice in sports equipment due to its superior strength and lightweight nature. You’ll see it in applications like tennis rackets, golf clubs, and bicycles. Its versatility allows for faster swings and improved performance in sports that demand precision and speed.

Twill carbon fiber is equally valuable in high-performance products for sports. Its flexibility and textured appearance make it ideal for equipment like racing helmets, skis, and surfboards. Whether you’re looking for durability or a sleek design, carbon fiber enhances the performance and appeal of sports gear.

Consumer Electronics

Carbon fiber has become a game-changer in the world of consumer electronics. Its lightweight and durable properties make it a preferred material for many modern devices. You’ll often find carbon fibre composites in products like laptops, smartphones, and wearable gadgets. These materials not only enhance the performance of your devices but also improve their overall design.

Twill carbon fiber, in particular, offers unique advantages for electronic applications. Its flexibility allows it to conform to three-dimensional shapes, making it ideal for sleek and ergonomic designs. For example, manufacturers use twill fabric to create curved smartphone cases or lightweight laptop shells. The material’s impact resistance also ensures better protection for your devices, reducing the risk of damage from accidental drops.

|

Benefit |

Description |

|---|---|

|

Drapability |

Twill fabric can conform to three-dimensional shapes due to its weaving. |

|

Impact Protection |

The weave resists impact and deformation better than unidirectional fibers. |

The stylish appearance of twill carbon fiber adds another layer of appeal. Its textured, high-end look makes it a popular choice for premium electronics. You might notice this material in luxury headphones or high-performance gaming accessories. These products not only perform well but also stand out visually.

When choosing materials for consumer electronics, manufacturers prioritize durability, aesthetics, and functionality. Carbon fiber meets all these requirements, making it a versatile option for various applications. Whether it’s a lightweight smartwatch or a durable tablet case, carbon fiber continues to revolutionize the way electronic devices are designed and used.

Choosing the Right Carbon Fiber for Your Needs

Performance vs. Aesthetics

When choosing between different types of carbon fiber, you must balance performance and aesthetics based on your application. Plain carbon fiber offers superior strength and stability, making it ideal for structural applications. Twill carbon fiber, however, provides flexibility and a stylish appearance, which suits intricate designs or high-end products.

The finish also plays a significant role in your decision. A glossy finish highlights the weave pattern and adds UV protection, while a matte finish reduces glare and hides imperfections. If durability is a priority, a clear coat enhances the depth of the weave and protects against scratches.

|

Type of Finish |

Description |

Advantages |

|---|---|---|

|

Glossy Finish |

A smooth, reflective finish that provides an elegant, high-end look. |

Highlights the weave pattern and provides excellent UV protection. |

|

Matte Finish |

A non-reflective finish that provides a clean, subtle look. |

Reduces glare, hides surface imperfections, and provides a better grip surface. |

|

Clear Coat |

A transparent, protective layer added to the surface of the cloth to protect it from scratches and damage. |

Provides excellent durability and enhances the depth of the weave pattern. |

Budget Considerations

Your budget significantly influences your choice of carbon fiber. Plain carbon fiber is often more cost-effective due to its simpler weave and production process. It works well for applications where performance matters more than appearance. Twill carbon fiber, with its intricate weave and stylish look, tends to cost more. This makes it a better fit for luxury or high-end applications.

You should also consider the material’s weight. Twill carbon fiber uses less resin, which can reduce overall weight and potentially lower costs in weight-sensitive industries like aerospace. However, plain carbon fiber may require more material for complex shapes, increasing expenses.

Industry-Specific Recommendations

Different industries have unique requirements for carbon fiber. In structural applications, plain weave carbon fiber provides high stability and strength. Its uniform checkerboard pattern ensures consistent performance. For intricate designs, twill weave carbon fiber offers flexibility and a visually appealing diagonal pattern.

-

Plain Weave: High stability, subtle appearance, ease of use, but limited flexibility and potential weak points.

-

Twill Weave: Good balance of flexibility and stability, visually appealing, suitable for a wide range of applications.

When considering weight, twill weave can cover complex shapes with less resin, making it ideal for lightweight applications. Plain weave, while stronger, may require more material for the same shapes. Your choice should align with the specific needs of your industry and project.

Both plain carbon fiber and twill carbon fiber excel in different areas, making them suitable for various applications. You’ll find plain carbon fiber ideal for lightweight and cost-effective designs. It’s commonly used in furniture, sporting goods like bicycles and tennis rackets, and industrial automation for its durability and structural stiffness.

Twill carbon fiber, with its stylish and textured appearance, shines in high-end applications. It’s a preferred choice for luxury items, trade shows, and interior design. Whether you prioritize performance or aesthetics, your choice depends on the specific needs of your project.

Share:

Steps to Join a Car Track Racing Event in 2025

Ever Wondered How Lignin Becomes Carbon Fiber?