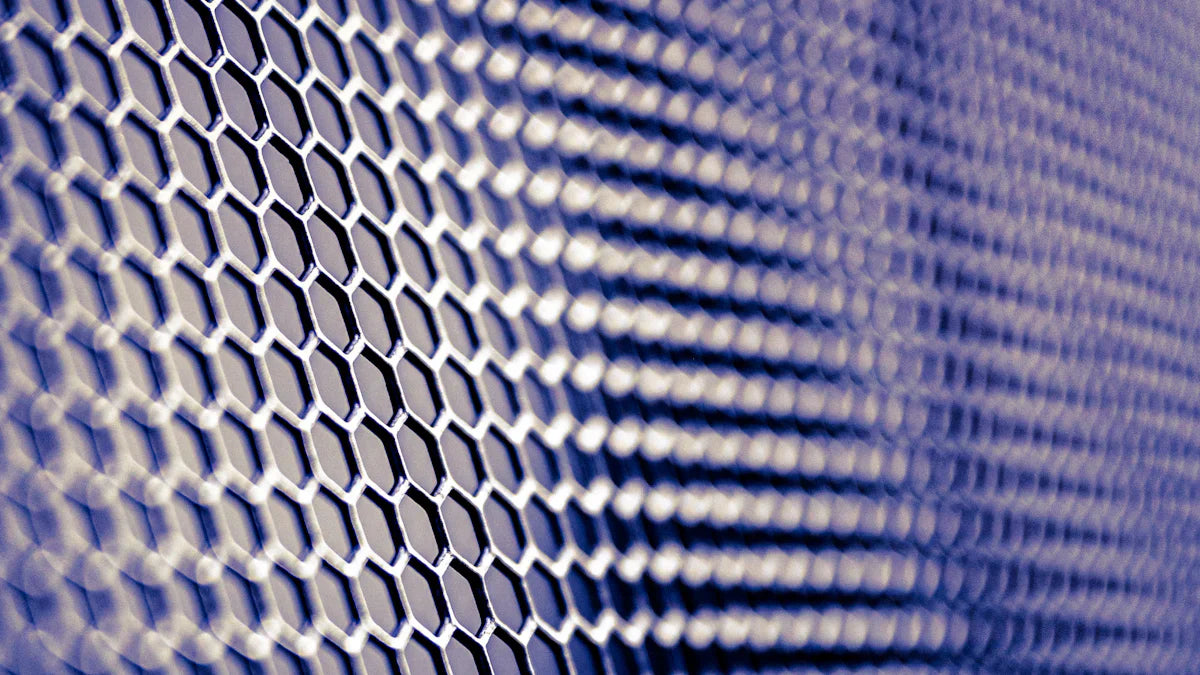

Honeycomb carbon fiber is transforming how you think about materials in the automotive industry. Its lightweight structure reduces vehicle weight without compromising strength, making it a game-changer in automotive design. This material resists environmental wear and tear, ensuring durability over time. Its unique honeycomb structure provides exceptional strength-to-weight performance, which improves fuel efficiency and safety. By addressing these critical challenges, honeycomb carbon fiber has become an essential component in creating high-performance vehicles.

Key Takeaways

-

Honeycomb carbon fiber is light but very strong. It is great for fast cars and helps them use less fuel.

-

This material makes cars lighter, so they handle better and pollute less. This helps protect the environment.

-

The honeycomb design of carbon fiber does not rust or wear out easily. It lasts long and stays safe in tough conditions.

-

Honeycomb carbon fiber keeps people safe in crashes by soaking up the crash energy.

-

New ways to make honeycomb carbon fiber are lowering its cost. This means more types of cars can use it.

Challenges in the Automotive Industry and Aerospace Sector

The Demand for Lightweight Materials

In the automotive industry, reducing weight is one of the most pressing challenges. You’ve likely noticed how modern vehicles aim to be faster, more efficient, and environmentally friendly. Achieving these goals requires lightweight materials that don’t compromise on strength. Traditional metals like steel and aluminum often add unnecessary bulk, limiting performance. This is where advanced solutions like carbon fiber reinforced plastic come into play. By using these materials, manufacturers achieve significant weight reduction, which directly improves fuel efficiency and handling. For high-performance vehicles, every pound saved can make a noticeable difference in speed and agility.

Strength and Durability Requirements

Vehicles in the automotive industry and aerospace sector face extreme conditions. Whether it’s the high speeds of a race car or the intense pressure changes experienced by an aircraft, materials must withstand immense stress. You need components that won’t crack, warp, or degrade over time. Carbon fiber reinforced plastic excels in this area. Its honeycomb structure provides exceptional durability while keeping weight to a minimum. This combination ensures that vehicles remain reliable and safe, even under the harshest conditions. For manufacturers, this means fewer repairs and longer-lasting performance.

Environmental and Fuel Efficiency Challenges

Fuel efficiency is no longer just a selling point—it’s a necessity. As you know, stricter environmental regulations push manufacturers to create vehicles that consume less fuel and produce fewer emissions. Significant weight reduction plays a critical role here. Lighter vehicles require less energy to move, which translates to better mileage and lower emissions. Additionally, materials like carbon fiber reinforced plastic are more sustainable than traditional metals. They resist corrosion, reducing waste over time. By adopting lightweight materials, the automotive industry takes a big step toward meeting environmental goals while delivering high-performance vehicles.

Advantages of Honeycomb Carbon Fiber Over Traditional Materials

Steel vs. Honeycomb Carbon Fiber

Steel has been a go-to material for decades due to its strength and availability. However, it adds significant weight to vehicles. You may notice that heavier vehicles consume more fuel and are harder to maneuver. Honeycomb carbon fiber offers a better alternative. It provides high strength-to-weight ratios, making vehicles lighter without sacrificing durability. This material also resists corrosion, unlike steel, which rusts over time. By switching to honeycomb carbon fiber, manufacturers can create vehicles that are both efficient and long-lasting.

Aluminum vs. Honeycomb Carbon Fiber

Aluminum is lighter than steel, but it still falls short in certain areas. It lacks the structural integrity needed for high-performance applications. Honeycomb carbon fiber outperforms aluminum by offering superior strength and stiffness. You’ll find that it also handles stress and fatigue better, ensuring reliability under extreme conditions. Additionally, carbon fiber reinforced plastic, a key component of honeycomb carbon fiber, provides better thermal insulation. This makes it ideal for applications where temperature control is critical.

Key Properties of Honeycomb Carbon Fiber

Superior Strength-to-Weight Ratio

Honeycomb carbon fiber stands out for its high strength-to-weight ratios. This property allows you to achieve lightweight designs without compromising on strength. Vehicles made with this material accelerate faster, handle better, and consume less fuel.

Resistance to Corrosion and Fatigue

Unlike traditional metals, honeycomb carbon fiber resists corrosion and fatigue. You won’t have to worry about rust or material degradation over time. This ensures that vehicles remain safe and reliable for years.

Thermal and Acoustic Insulation Benefits

Honeycomb carbon fiber also excels in thermal and acoustic insulation. It helps maintain cabin temperatures and reduces noise levels. This improves comfort and efficiency, especially in high-performance vehicles.

Applications of Honeycomb Carbon Fiber in High-Performance Vehicles

Aerospace Applications

Aircraft Fuselage and Wings

You’ll find honeycomb carbon fiber widely used in aircraft fuselage and wings. Its lightweight nature reduces the overall weight of the aircraft, improving fuel efficiency and range. The material’s strength ensures that the fuselage can withstand high-pressure changes during flight. It also resists fatigue, which is critical for maintaining structural integrity over time. By using honeycomb carbon fiber, aerospace engineers create safer and more efficient aircraft designs.

Interior Panels and Components

Inside the aircraft, honeycomb carbon fiber enhances both functionality and comfort. Manufacturers use it for interior panels, flooring, and seating components. Its thermal insulation properties help regulate cabin temperature, while its acoustic insulation reduces noise levels. This improves the passenger experience. Additionally, its durability ensures that these components last longer, reducing maintenance costs.

Automotive Applications

Chassis and Body Panels

In the automotive industry, honeycomb carbon fiber is transforming chassis and body panel design. Its lightweight structure improves vehicle handling and acceleration. The material’s strength ensures that these components can endure the stresses of high-speed driving. By incorporating honeycomb carbon fiber, manufacturers achieve better performance without compromising safety.

Crash Structures and Safety Features

Safety is a top priority in the automotive industry. Honeycomb carbon fiber plays a crucial role in crash structures and safety features. Its ability to absorb impact energy helps protect passengers during collisions. This material also resists deformation, maintaining the integrity of the vehicle’s structure. By using honeycomb carbon fiber, you can ensure that vehicles meet the highest safety standards.

Real-World Examples and Case Studies

Several high-performance vehicles and aircraft already showcase the benefits of honeycomb carbon fiber. For example, modern commercial aircraft like the Boeing 787 Dreamliner use this material extensively in their fuselage and wings. In the automotive industry, sports cars such as the McLaren P1 utilize honeycomb carbon fiber for their chassis and body panels. These examples highlight how this material enhances performance, safety, and efficiency in real-world applications.

The Future of Honeycomb Carbon Fiber in Vehicle Design

Advancing Fuel Efficiency and Sustainability

Honeycomb carbon fiber is paving the way for enhanced fuel efficiency in the automotive industry. Its lightweight structure reduces the energy required to move vehicles, which directly improves fuel consumption. You’ll notice that this material not only helps vehicles go farther on less fuel but also reduces harmful emissions. This makes it a key player in meeting global sustainability goals. Additionally, carbon fiber reinforced plastic, a core component of honeycomb carbon fiber, is more environmentally friendly than traditional metals. It resists wear and tear, reducing waste over time. By adopting this material, you contribute to a greener future while enjoying better vehicle performance.

Enhancing Safety and Crashworthiness

Safety remains a top priority in automotive design. Honeycomb carbon fiber offers unmatched crashworthiness by absorbing impact energy during collisions. This feature protects passengers and minimizes damage to the vehicle. You’ll find that its strength and durability ensure the structural integrity of vehicles even under extreme conditions. Unlike traditional materials, carbon fiber reinforced plastic doesn’t deform easily, making it ideal for safety-critical components. By integrating honeycomb carbon fiber into crash structures, manufacturers can meet and exceed modern safety standards. This material gives you peace of mind, knowing that safety isn’t compromised for performance.

Innovations in Manufacturing and Cost Efficiency

Advancements in manufacturing are making honeycomb carbon fiber more accessible to the automotive industry. New production techniques reduce costs and improve scalability. You’ll see that these innovations allow manufacturers to use this material in a wider range of vehicles, not just high-performance models. Automated processes and improved resin systems make carbon fiber reinforced plastic easier to produce. This lowers production time and costs, making it a viable option for mass-market automotive design. As these technologies evolve, honeycomb carbon fiber will become an even more cost-effective solution for creating efficient, safe, and sustainable vehicles.

Honeycomb carbon fiber has revolutionized the automotive industry with its lightweight and durable properties. You can see how it solves critical challenges like fuel efficiency and safety while promoting sustainability. Its unmatched strength and versatility make it the ideal material for high-performance vehicles. As the automotive industry evolves, this material will continue to shape the future of vehicle design. By adopting honeycomb carbon fiber, you contribute to a safer, more efficient, and environmentally friendly world of transportation.

Share:

Carbon Kevlar Fabric vs Fiberglass Pros and Cons You Should Know

What Are Carbon Fiber Mats and How Do They Perform