The rise of 3D carbon fiber technology has revolutionized modern manufacturing, offering unparalleled advantages in strength, durability, and efficiency. This advanced material combines the lightweight nature of carbon fiber with the precision of 3D printing, enabling the creation of components that are both robust and highly customizable. Industries have embraced this innovation due to its ability to withstand extreme heat and resist chemical degradation.

The global carbon fiber market reflects this growing demand. Valued at $4.8 billion in 2022, it is projected to reach $13.9 billion by 2032, growing at an impressive 11.2% annual rate. This surge highlights the transformative potential of 3D carbon fiber in sectors like aerospace, automotive, and medical devices. As you explore its applications, you’ll see how it continues to redefine manufacturing standards.

Key Takeaways

-

3D carbon fiber is strong and light, perfect for tough tasks.

-

It resists heat and chemicals, lasting in harsh conditions.

-

Using carbon fiber in 3D printing cuts waste and saves money.

-

This method speeds up making things and allows easy changes.

-

Fields like planes, cars, and medicine use 3D carbon fiber a lot.

Key Properties of 3D Carbon Fiber

Strength and Stiffness

3D carbon fiber stands out for its exceptional strength and stiffness. You can rely on this material to handle demanding applications where durability is critical. Carbon fiber composites are known for their ability to maintain structural integrity under heavy loads. Unlike traditional materials, such as ABS or aluminum, carbon fiber filaments provide superior rigidity. This makes them ideal for high-performance carbon fiber materials used in aerospace, automotive, and other industries requiring robust components.

The unique properties of carbon fiber materials stem from their internal structure. The alignment of carbon atoms in a crystalline formation enhances their mechanical performance. This ensures that 3D carbon fiber components can endure stress without deformation, offering unmatched reliability in high-stress environments.

Lightweight and High Strength-to-Weight Ratio

One of the most remarkable properties of 3D carbon fiber is its lightweight nature combined with a high strength-to-weight ratio. This characteristic allows you to replace heavier materials like aluminum without compromising performance. Continuous carbon fiber retains its strength while being only half the weight of aluminum.

|

Material |

Strength-to-Weight Ratio |

Rigidity Comparison |

|---|---|---|

|

3D Printed Carbon Fiber |

50% higher than aluminum |

25x more rigid than ABS |

|

ABS |

Baseline |

Baseline |

|

Aluminum (6061) |

Baseline |

Baseline |

This table highlights how 3D carbon fiber outperforms traditional materials in both strength and rigidity. By leveraging these properties, you can achieve lightweight designs that enhance efficiency and reduce energy consumption in applications like transportation and aerospace.

Heat and Chemical Resistance

3D carbon fiber materials also excel in extreme environments. Their heat resistance makes them suitable for applications exposed to high temperatures, such as engine components or aerospace parts. Additionally, carbon fiber composites resist chemical degradation, ensuring long-term durability even in corrosive environments.

You can trust high-performance carbon fiber materials to maintain their properties under challenging conditions. This makes them a preferred choice for industries requiring materials that combine resilience, performance, and longevity.

Benefits of 3D Printing with Carbon Fiber

Enhanced Mechanical Performance

3D printing with carbon fiber delivers exceptional mechanical performance, making it a preferred choice for high-performance products. The integration of carbon fiber into 3D printing materials enhances stiffness, strength, and dimensional accuracy. These properties allow you to create components that can withstand heavy loads and extreme conditions without compromising structural integrity.

Finite element analysis (FEA) and physical testing validate the superior performance of 3D printed carbon fiber parts. For instance, tensile tests on Onyx and continuous fiber parts revealed that the predicted load was exceeded by 25%. This demonstrates the reliability of carbon fiber 3D printing in producing durable and high-performance filaments. Additionally, the unique texture of carbon fiber adds aesthetic value, making it ideal for applications where appearance matters.

Cost Efficiency and Reduced Material Waste

Additive manufacturing with carbon fiber offers significant cost savings compared to traditional methods. By building objects layer by layer, 3D printing technology minimizes material waste, using only the required amount of 3D printing filaments. This approach reduces waste significantly, making it an environmentally friendly option.

Cost efficiency is another advantage of carbon fiber 3D printing. It eliminates the need for expensive tooling and reduces labor costs, especially for small-batch or customized production. This makes it an ideal solution for industries seeking to optimize production costs while maintaining high-quality standards.

Faster Production and Customization

3D printing technology accelerates production timelines, enabling you to bring products to market faster. Advanced software like ON-RAMP automates the CAD-to-print workflow, reducing manual preparation time from hours to minutes. Similarly, 3D data processing times have dropped from nearly an hour to just five minutes, streamlining the entire process.

Carbon fiber 3D printing also excels in customization. You can easily tailor designs to meet specific requirements, making it suitable for industries like aerospace and medical devices. The CBAM process further enhances efficiency by producing lightweight parts that are 60% lighter than traditional methods. This combination of speed and flexibility ensures that carbon fiber 3D printing meets the demands of modern manufacturing.

Methods of 3D Carbon Fiber Printing

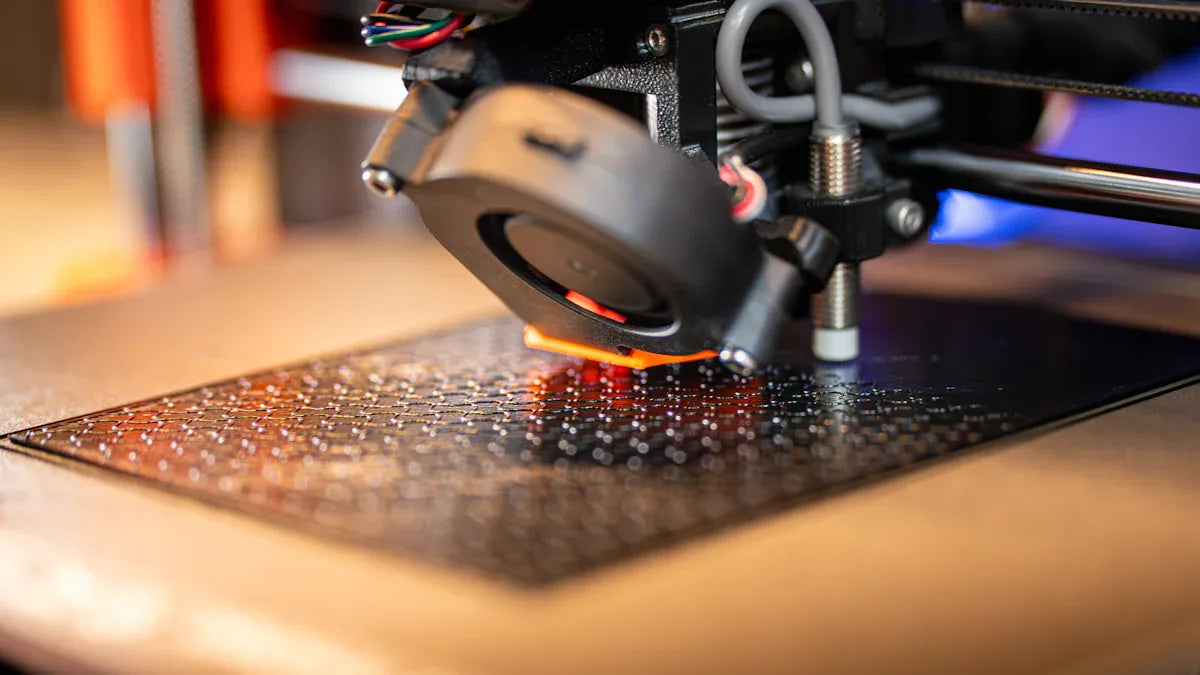

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is one of the most accessible methods for 3D carbon fiber printing. This process uses thermoplastic filaments mixed with short carbon fiber strands, known as chopped carbon fiber filaments. These filaments are compatible with standard FDM printers, making this method cost-effective and widely available. However, the strength improvements are limited compared to other techniques.

To optimize mechanical properties, you should carefully adjust printing parameters. For example:

-

Increasing infill density enhances tensile strength.

-

Decreasing raster angle improves tensile strength.

-

Using a 45-degree raster angle at 50% infill density prolongs fatigue life, while a 0-degree raster angle at 75% infill density maximizes it.

The table below highlights optimal settings for FDM with carbon fiber:

|

Parameter |

Optimal Setting |

Effect on Mechanical Properties |

|---|---|---|

|

Raster Angle |

0° |

Enhanced tensile and flexural strength |

|

Layer Thickness |

0.2 mm |

Improved material bonding |

|

Printing Speed |

40 mm/s |

Further improved mechanical properties |

|

Composite Material |

CF with recycled PET |

30% increase in tensile strength observed |

By fine-tuning these parameters, you can achieve better results in FDM-based carbon fiber printing.

Continuous Fiber Fabrication (CFF)

Continuous Fiber Fabrication (CFF) takes carbon fiber 3D printing to the next level. Unlike FDM, this method uses advanced systems equipped with dual extruders and specialized mechanisms. These systems lay down continuous carbon fiber strands within a thermoplastic matrix, resulting in significantly stronger and stiffer parts.

This method is ideal for applications requiring high-performance components. You can use CFF to produce parts with superior strength-to-weight ratios, making it a preferred choice in industries like aerospace and automotive. While the initial investment in CFF technology is higher, the long-term benefits in terms of performance and durability often outweigh the costs.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is another advanced method for 3D carbon fiber printing. This process uses a laser to sinter powdered materials, including carbon fiber-filled nylon, layer by layer. Materials like Windform XT are commonly used in SLS, offering excellent mechanical properties and durability.

One of the key advantages of SLS is its ability to produce complex geometries without the need for support structures. This makes it ideal for creating functional prototypes and intricate designs. Additionally, SLS parts exhibit high strength and precision, making them suitable for demanding applications in industries such as aerospace and medical devices.

By leveraging these carbon fiber 3D printing processes, you can select the method that best suits your specific requirements, balancing cost, performance, and complexity.

Applications of 3D Carbon Fiber Materials

Aerospace and Aviation

The aerospace industry has embraced 3D carbon fiber for its ability to reduce weight while maintaining strength. Aircraft manufacturers prioritize lightweight materials to enhance fuel efficiency and lower emissions. Carbon fiber composites excel in this regard, offering significant weight reduction compared to traditional metals.

|

Evidence Type |

Description |

|---|---|

|

Weight Reduction |

Carbon fiber composites significantly reduce aircraft weight, enhancing fuel efficiency and reducing emissions. |

|

Market Growth |

The UK civil aerospace turnover reached approximately $34.5 billion in 2022, indicating a growing market for carbon fiber in aviation. |

|

Passenger Traffic Increase |

International passenger traffic increased by 152.7% in 2022 compared to 2021, driving demand for lightweight materials like carbon fiber. |

You can see how these advancements directly impact the aviation sector. By integrating carbon fiber into aircraft components, manufacturers achieve better performance and meet the growing demand for sustainable aviation solutions.

Automotive and Transportation

In the automotive sector, carbon fiber applications are transforming vehicle design and performance. The material’s high strength-to-weight ratio allows you to create lighter vehicles without compromising safety or durability. This results in improved fuel efficiency and reduced emissions, aligning with global sustainability goals.

Electric vehicles (EVs) particularly benefit from 3D printed carbon fiber applications. Lightweight components extend battery life and enhance overall efficiency. Additionally, carbon fiber’s ability to withstand extreme conditions makes it ideal for high-performance applications, such as racing cars and luxury vehicles.

Tip: By adopting 3D printing with carbon fiber, automotive manufacturers can produce customized parts faster and with less material waste, reducing costs and environmental impact.

Medical Devices and Prosthetics

The medical field has seen remarkable advancements through the use of 3D carbon fiber. Its lightweight and durable properties make it an excellent choice for prosthetics and medical devices. You can design custom prosthetics tailored to individual patients, ensuring a perfect fit and improved comfort.

3D printing technology further enhances these applications by enabling rapid prototyping and production. For example, carbon fiber prosthetics offer superior strength and flexibility, allowing patients to regain mobility with confidence. The material’s biocompatibility and resistance to wear ensure long-lasting performance, even under demanding conditions.

Unsurprisingly, carbon fiber is also being explored for surgical tools and implants, where precision and durability are critical. These innovations highlight the transformative potential of 3D carbon fiber in improving healthcare outcomes.

Sports Equipment and Consumer Goods

The use of 3D carbon fiber in sports equipment and consumer goods has transformed these industries. Its lightweight and high-strength properties make it an ideal material for creating durable and performance-enhancing products. You can find carbon fiber in everything from tennis rackets and bicycles to golf clubs and helmets. These applications not only improve functionality but also provide a competitive edge for athletes.

The global market for carbon fiber in sports is growing rapidly. This surge is driven by the increasing demand for high-performance gear and the rising participation in competitive sports. Manufacturers are leveraging advancements in material engineering and 3D printing to produce equipment that is both efficient and sustainable. For example, carbon fiber’s ability to withstand stress without adding weight makes it perfect for creating aerodynamic bicycles and lightweight protective gear.

In addition to sports, consumer goods are also benefiting from this innovative material. Carbon fiber is now used in products like luggage, watches, and even smartphone cases. Its sleek appearance and durability appeal to consumers looking for premium-quality items. Emerging economies are contributing to this growth as fitness awareness and sports participation increase globally. Furthermore, government policies promoting sustainable materials and advancements in recycling are encouraging the adoption of carbon fiber in these sectors.

Note: By incorporating 3D printing technology, manufacturers can customize designs and reduce production waste. This approach not only enhances product quality but also aligns with the growing focus on sustainability.

The applications of 3D carbon fiber in sports and consumer goods demonstrate its versatility and potential to revolutionize these markets. Whether you’re an athlete seeking better performance or a consumer looking for durable products, carbon fiber offers unmatched benefits.

3D carbon fiber technology offers a unique combination of strength, lightweight properties, and heat resistance. These attributes make it a game-changer for industries requiring high-performance materials. By integrating this technology, you can achieve faster production, reduce waste, and create highly customized designs.

Key Takeaway: 3D carbon fiber is not just a material; it’s a tool for innovation. Its ability to enhance efficiency and performance positions it as a cornerstone of modern manufacturing.

As industries continue to evolve, adopting advanced materials like 3D carbon fiber will help you stay ahead of the curve. This technology has the potential to redefine what’s possible in aerospace, automotive, healthcare, and beyond.

Share:

From Stock to Stunning: Audi Owners Share Carbon Fiber Transformations

Debunking Myths About Mercedes W463 Carbon Fiber Spoilers