Air-fuel ratio targets for performance are crucial for engine efficiency. They indicate how effectively the engine burns fuel to generate power. For standard engines, the optimal air-fuel ratio targets for performance range from 12.8:1 to 13:1. Turbocharged engines, on the other hand, require a richer mixture, typically around 11.5:1, due to their operation under higher pressure. These turbo engines necessitate precise tuning to prevent overheating or potential damage. Understanding these air-fuel ratio targets for performance is essential for maximizing power output and ensuring the engine operates smoothly.

Key Takeaways

-

Learn the best air-fuel ratios for engines. Regular engines work well with ratios of 12.8:1 to 13:1. Turbo engines need richer mixes, around 11.5:1.

-

Change air-fuel ratios for different conditions. High places or different fuels can affect the mix. Adjust it to keep the engine working well.

-

Use tools like wideband O2 sensors to get live data. These tools help set the right air-fuel mix so the engine stays safe and works well.

-

Keep performance and reliability balanced. Tuning for power is good, but the engine must last long and not get damaged.

-

Adjust ignition timing and fuel delivery. These changes can make the engine stronger and more efficient, especially under heavy use.

Understanding Air-Fuel Ratios

Defining Air-Fuel Ratios

The air-fuel ratio (AFR) shows how much air mixes with fuel. For gasoline engines, the perfect AFR is about 14.7:1. This means 14.7 parts of air burn one part of fuel. Think of it as a recipe for good engine performance. A correct AFR helps the engine run well, use fuel efficiently, and reduce pollution.

Different fuels need different AFRs. For example, ethanol’s AFR is 9:1, while propane’s is 15.67:1. These differences depend on the fuel’s chemical makeup. Knowing these numbers is important when tuning an engine for specific fuels.

|

Fuel |

Chemical Formula |

AFR |

|---|---|---|

|

Methanol |

CH3OH |

6.47:1 |

|

Ethanol |

C2H5OH |

9:1 |

|

Gasoline |

C8H18 |

14.7:1 |

|

Propane |

C3H8 |

15.67:1 |

|

Hydrogen |

H2 |

34.3:1 |

The Role of Air-Fuel Ratios in Engine Tuning

Air-fuel ratios are very important for engine tuning. They decide how well the engine burns fuel to make power. A perfect AFR burns all the fuel and air, balancing power, fuel use, and pollution. But tuning often changes this ratio.

For naturally aspirated engines, AFRs between 12.8:1 and 13:1 give the best power. Turbocharged engines need richer AFRs, around 11.5:1, to stay cool. Changing the AFR can improve engine performance for different fuels or driving needs.

Stoichiometric Ratio and Its Variations

The stoichiometric ratio is the best mix of air and fuel for burning. For gasoline, this is 14.7:1. But different fuels change this ratio. For example, E10 (gasoline with 10% ethanol) has a ratio of 14.1:1. E85 (85% ethanol) has a lower ratio of 9.7:1.

These changes affect tuning. A lean mix (AFR > 14.7:1) saves fuel but can harm the engine. A rich mix (AFR < 14.7:1) gives more power but wastes fuel. Adjusting the AFR carefully balances power, safety, and pollution.

Air-Fuel Ratio Targets for Performance

Naturally-Aspirated Engines

Typical Air-Fuel Ratio Targets

Naturally-aspirated engines work best with air-fuel ratios of 12.8:1 to 13:1. This range gives the most power and keeps the engine safe. These engines pull air in using normal air pressure. Tuning them carefully helps balance fuel use and power. Staying in this range makes the engine run smoothly and efficiently.

|

Best Air-Fuel Ratio |

Lambda Range |

|---|---|

|

12.8:1 to 13:1 |

0.83 to 0.85 |

How Air Pressure Affects Engines

Air pressure changes how naturally-aspirated engines perform. At higher places, the air is thinner, which changes the air-fuel mix. You might need to adjust the ratio to fix this. At sea level, thicker air helps the engine burn fuel better. Tuning for the environment helps these engines work their best.

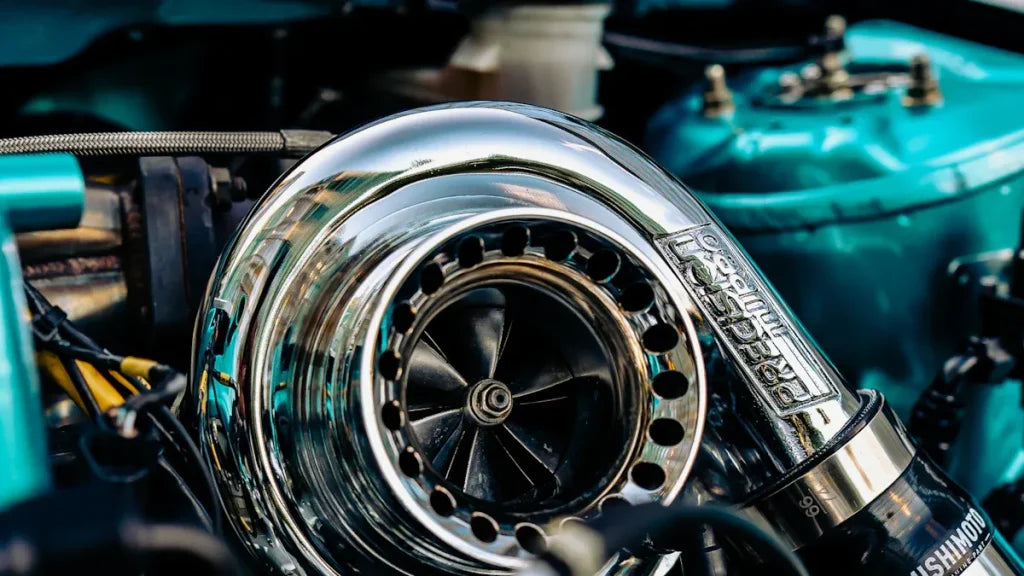

Turbocharged Engines

Richer Mixtures for Turbocharged Engines

Turbocharged engines need richer air-fuel mixes, like 11.5:1, to stay safe. These engines work under high pressure, so they get hotter. The richer mix cools the engine and protects its parts. Turbo engines need exact tuning to handle the extra stress.

Boost Pressure and Adjusting Ratios

Boost pressure affects the air-fuel ratio in turbo engines. More boost means more fuel is needed for safe burning. Adjusting the ratio stops knocking and keeps power high. For high-performance turbo engines, even small mistakes can cause damage.

Why They Differ

Power and Combustion Efficiency

Naturally-aspirated and turbocharged engines make power differently. Naturally-aspirated engines need precise air-fuel ratios for power. Turbo engines use extra air pressure, so they need richer mixes.

Managing Heat and Preventing Damage

Heat is a big issue for turbo engines. They get hotter because of high pressure. Richer mixes cool them and stop damage. Naturally-aspirated engines stay cooler, so they can use leaner mixes safely.

Practical Tuning Strategies

Tuning Naturally-Aspirated Engines

Fuel Delivery Adjustments

To tune naturally-aspirated engines, fuel delivery must be adjusted. Change fuel and ignition settings based on airflow and engine load. This ensures the engine gets enough fuel in different situations. For example, adding more fuel during heavy loads can boost power. This keeps fuel use efficient and prevents engine damage. Correct fuel adjustments also help the engine run smoothly without issues.

Ignition Timing Optimization

Ignition timing is key for tuning naturally-aspirated engines. Changing timing affects how well the engine burns fuel. Adjusting timing improves power and fuel use while avoiding engine knocking. For these engines, timing changes depend on speed and load. This ensures fuel burns at the right time for better performance.

Tuning Turbocharged Engines

Boost Pressure Management

Turbocharged engines need careful boost pressure control for safety. As boost rises, adjust the air-fuel mix to avoid harm. A richer mix, like 11:1, helps cool the engine under pressure. Watch boost levels to prevent overloading and damage.

Turbo engines need richer air-fuel ratios, like 11:1, as boost increases. This avoids overheating and knocking, which can harm parts. Ignition timing should also be delayed to stop detonation under high pressure.

Fuel Management for High-Performance Applications

Fuel management is very important for turbocharged engines. The engine needs enough fuel to match the extra air from the turbo. Adjust the fuel injection system to deliver the right amount. This boosts power, improves efficiency, and protects the engine from overheating.

Essential Tools and Techniques

Wideband O2 Sensors and Data Analysis

Wideband O2 sensors are great for checking air-fuel ratios. They give real-time data to help fine-tune the engine. By studying this data, you can find areas to improve. This keeps the engine running safely and efficiently.

ECU Calibration and Tuning Software

Modern engines use ECUs to control their systems. Tuning software helps adjust the ECU for better fuel and ignition settings. This process, called EFI tuning, customizes engine performance. With the right tools, you can balance power, efficiency, and reliability.

|

Metric |

Before AI Implementation |

After AI Implementation |

|---|---|---|

|

Average Response Time |

200ms |

150ms |

|

Error Rate |

5% |

1% |

|

Resource Utilization |

75% |

50% |

Misconceptions and Challenges in Tuning

Debunking “One-Size-Fits-All” Air-Fuel Ratios

Some think one air-fuel ratio fits all engines. This is not true. Engine performance depends on fuel, altitude, and design. A single ratio cannot handle these differences well.

In 1922, Stanwood Sparrow’s NACA Report #189 showed air-fuel ratios affect engines differently. The report proved that maximum power comes from various ratios, not one fixed number.

For example:

-

Higher altitudes mean thinner air, so the mix needs adjusting.

-

Fuels like E10 and E85 need special tuning for their unique ratios.

-

Even gasoline’s 14.7:1 ratio may not always give the best power.

Tuning should be flexible. Adjust it to fit your engine and environment.

Balancing Performance with Reliability

Tuning for power can reduce engine reliability. Balancing both ensures long-term use. Turbo engines need richer mixes to stay cool, even if it uses more fuel.

Studies show targeted changes work better than random adjustments. For example:

-

Changing specific engine parts improves performance without stressing others.

-

Random tuning in big systems often gives good results too.

Focus on power and durability to avoid engine damage while improving performance.

Environmental Factors and Their Impact on Tuning

Your surroundings affect engine tuning a lot. High altitudes have less oxygen, needing richer mixes. At sea level, denser air allows leaner mixes. Temperature also matters. Cold air has more oxygen, while hot air has less.

Adjusting for these conditions keeps the engine running well. Ignoring them can hurt efficiency or even damage the engine. Always think about your environment when tuning air-fuel ratios.

Knowing air-fuel ratios helps engines work their best. Naturally aspirated engines need exact ratios for good performance. Turbocharged engines use richer mixes to stay cool and avoid harm. Tuning makes sure fuel burns well, balancing power, fuel use, and pollution.

-

Tuning helps by:

-

Burning all fuel with the right mix.

-

Allowing strong power with different ratios.

-

Tools like wideband O2 sensors and ECU software make tuning easier. Focus on balancing power, safety, and durability to keep your engine safe and strong.

Share:

Twin Disc vs Single Disc Clutches for Daily Driving

Why Modern Cars Rely on MAF Sensors Over Speed Density Systems