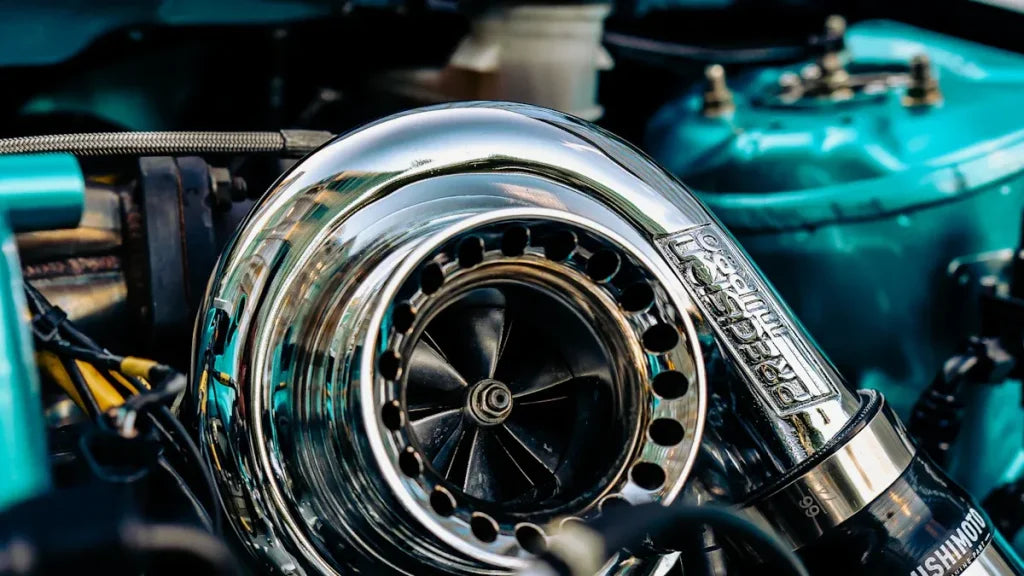

Turbocharger spool time explained refers to how quickly the turbocharger can start delivering power. A faster spool time results in quicker power delivery to the engine, enhancing the driving experience. Conversely, if the spool time is slow, you may experience a delay known as turbo lag. Addressing turbo lag can significantly improve your car’s responsiveness and make it feel more energetic. Understanding turbocharger spool time explained can lead to improvements in your vehicle, making your driving smoother and more efficient.

Key Takeaways

-

Turbo spool time decides how fast your car gets power. Faster spool means better response and more fun while driving.

-

Switching to lighter turbo parts and better exhausts can cut turbo lag. These upgrades help exhaust gases move quicker, boosting performance.

-

New tech like variable geometry turbos and electric assist systems stop turbo lag. They give instant power and make the car work better.

-

Taking care of your turbo, like cleaning air filters and checking oil flow, is very important. Good care makes your turbo last longer.

-

Adjusting your engine’s ECU can improve boost and fuel use. This change gives more power and makes your car respond faster.

Turbocharger Spool Time Explained

What Is Turbocharger Spool Time?

Turbocharger spool time is how long it takes for the turbo to create enough pressure for full power. This starts when exhaust gases spin the turbine and ends when the turbo reaches top speed. Faster spool times mean quicker power, improving turbo response. Slow spool times cause turbo lag, which delays power and affects driving. Knowing spool time helps improve a turbocharged engine’s performance.

Causes of Turbocharger Lag

Turbo Size and Design

The size and shape of a turbo affect turbo lag. Small turbos spool faster but may lack strong power at high speeds. Big turbos take longer to spool but give more power at high RPMs. Newer designs with better airflow reduce lag and improve spool time. Lightweight parts also help the turbo spin faster by lowering resistance.

Exhaust Gas Dynamics

How exhaust gases flow affects turbo spool speed. Smooth gas flow makes the turbine spin faster, while blockages or turbulence slow it down. A shorter distance between the exhaust manifold and turbo helps gases reach the turbine quicker, reducing lag. At low RPMs, less exhaust pressure slows the turbo, making it harder to perform well.

Engine Load and RPM

Engine load and RPM levels impact turbo lag. Higher RPMs create more exhaust gases, helping the turbo spin faster and reducing lag. At low engine loads or idle, less exhaust pressure slows the turbo’s response. Keeping the engine in the right RPM range improves turbo response and reduces delays.

Why Reducing Turbo Lag Is Important

Enhanced Throttle Response

Reducing turbo lag makes throttle response quicker, so your car feels faster and more responsive. A fast turbo response gives power when you need it, like during acceleration or passing other cars.

Improved Driving Experience

Turbo lag can make a car feel slow, especially at low speeds. Fixing turbo lag makes driving smoother and more fun. Quick power delivery gives you more control and confidence while driving.

Potential Fuel Efficiency Benefits

A well-tuned turbo engine can save fuel. Faster spool times mean you don’t need to press the gas pedal as hard, which uses less fuel. While turbos are made for power, reducing lag can also make driving more efficient.

Technological Solutions to Reduce Turbo Lag

Variable Geometry Turbochargers (VGT)

How VGTs Work

Variable geometry turbochargers have adjustable vanes inside the turbine. These vanes control how exhaust gases flow through the turbo. At low speeds, the vanes make the passage smaller. This increases gas speed and helps the turbo spin faster. At high speeds, the vanes open wider for better gas flow. This design gives both quick response and strong power at all speeds.

Benefits for Reducing Turbo Lag

VGTs help reduce turbo lag by boosting low-speed power. They improve throttle response and make driving smoother. Studies show VGTs can increase torque by up to 45%. They also improve peak torque by over 30%. Faster spinning at low speeds ensures power is ready when needed. This makes your car feel more responsive and fun to drive.

Twin-Scroll Turbochargers

Design Advantages

Twin-scroll turbos have a divided turbine and exhaust manifold. This design separates exhaust pulses from different cylinders. It reduces interference and improves how the turbo works. Twin-scroll turbos spool faster than single-scroll ones. This makes them more efficient and better for performance.

Improved Exhaust Gas Flow

Twin-scroll turbos improve how exhaust gases move. The divided paths reduce turbulence and keep gas flow steady. This setup helps the turbo respond quicker, especially at mid-range speeds. It also reduces turbo lag and boosts engine efficiency. Many modern cars use twin-scroll turbos for these benefits.

Electric Assist Turbochargers

Overview of Electric Assist Systems

Electric assist turbos use a motor to spin the turbine. This gives instant power without waiting for exhaust gases. Hybrid systems combine electric motors with regular turbos. These systems provide smooth power at all engine speeds.

Eliminating Turbocharger Lag

Electric assist turbos remove turbo lag completely. They don’t rely on exhaust pressure to work. The motor keeps the turbo ready to deliver power anytime. This improves throttle response and saves fuel. It also makes driving more efficient and enjoyable.

Anti-Lag Systems (ALS)

How ALS Works

Anti-lag systems (ALS) keep the turbo spinning even when you stop pressing the gas. This happens by keeping exhaust gases flowing to the turbo, so it stays ready to give power. Here’s how it works:

-

Fuel Injection Timing: Fuel is added after the exhaust valves close. This causes small explosions in the exhaust, keeping the turbo spinning.

-

Retarding Ignition Timing: Ignition happens later, making exhaust gases move faster and keeping the turbo active.

-

Bypass Valves: These valves let out extra pressure when you stop pressing the gas. This stops the turbo from slowing down too much.

These methods help the turbo stay ready, especially during quick gas pedal changes.

Pros and Cons of ALS

Anti-lag systems have good points but also some downsides.

Advantages:

-

Power is ready as soon as you press the gas.

-

Less turbo lag makes the car respond faster.

-

Great for racing or fast driving.

Disadvantages:

-

The turbo and exhaust parts wear out faster because of heat.

-

More fuel is used since extra fuel is burned in the exhaust.

-

Not the best for everyday driving, as it focuses on speed over saving fuel.

ALS helps reduce turbo lag but can shorten turbo life and use more fuel. Think about these trade-offs before using it.

Ball Bearing Turbochargers

Faster Spool Times with Ball Bearing Designs

Ball bearing turbos spin faster because they have less friction. Unlike regular bearings, ball bearings let the turbo move more easily. This means it needs less energy to reach top speed. The result is quicker power and better response. If you want faster acceleration and less turbo lag, ball bearing turbos are a great option.

Comparison with Journal Bearing Turbos

Ball bearing and journal bearing turbos work differently. Here’s a simple comparison:

|

Bearing Type |

Spool Time Difference |

|---|---|

|

Ball Bearing |

150-200 rpm faster response |

|

Journal Bearing |

Slower response overall |

Ball bearing turbos are best for racing or when quick response matters. Journal bearings are better if you care more about cost and durability than speed.

Practical Ways to Reduce Turbo Lag

Driving Tips

Keeping the Right RPM Range

Stay in the correct RPM range to keep the turbocharger ready. Low RPMs create less exhaust gas, slowing the turbo down. Staying in mid-to-high RPMs helps the turbo respond faster. For example, downshifting during acceleration keeps the turbo active and reduces delays.

Using Smooth Throttle Control

Pressing the gas pedal too hard can hurt the turbo’s performance. Gently pressing it helps the turbo spool steadily, giving smoother power. This method also protects the turbocharger from wearing out quickly. Race drivers use this trick for better control and speed.

Upgrades for Better Performance

Lighter Turbo Parts

Switching to lighter turbine and compressor wheels makes the turbo spin faster. Lighter parts need less energy to move, improving spool time. Many car enthusiasts notice quicker acceleration after upgrading to lightweight materials.

Better Exhaust Systems

High-flow exhaust systems reduce backpressure, helping exhaust gases reach the turbo faster. This upgrade improves spool time and cuts turbo lag. Reviews show these systems make a big difference, especially during quick accelerations.

|

Upgrade Type |

Benefit Description |

|---|---|

|

Lightweight Components |

Faster spool-up due to reduced rotational inertia. |

|

Performance Exhaust Systems |

Improved exhaust flow, reducing backpressure and enhancing turbocharger response. |

Regular Care

Clean Air Filters and Good Oil Flow

Dirty air filters block airflow, making the turbo work harder. Replacing them often ensures better airflow and turbo performance. Proper oil flow is also key to keeping turbo parts cool and moving smoothly.

Keeping Exhaust Systems Clear

A clogged exhaust system slows down gas flow, increasing turbo lag. Regular checks and fixes keep the exhaust system working well. Studies show poor maintenance can damage turbos, proving why care is important.

Tip: Taking care of your turbo saves money and makes it last longer.

Engine and Turbo Placement

Putting the Turbo Near the Exhaust Manifold

Placing the turbocharger close to the exhaust manifold helps it work better. Shorter paths let exhaust gases reach the turbine faster. This makes the turbo spool quicker and improves throttle response. Long exhaust paths lose energy, slowing the turbo down. Keeping the distance short transfers more energy to the turbine.

The exhaust manifold’s design is also very important. A smooth manifold allows gases to flow easily. Blockages or sharp turns can slow the flow and delay spool time. The wastegate should be placed to avoid disrupting gas flow. Adjusting exhaust gas temperatures (EGTs) can also boost the turbo’s efficiency and speed.

Improving Intake Runners for Faster Spool

Intake runners guide air into the engine and affect turbo speed. Short, straight runners reduce air resistance, helping the turbo spool faster. This design delivers compressed air to the engine quickly, improving response. Long or bent runners slow airflow and increase turbo lag.

The turbo compressor’s design also matters. A good compressor improves airflow and reduces spool time. Using lightweight materials in the intake system lowers the energy needed to move air. These changes make driving smoother and more responsive.

Tip: When upgrading your turbocharger, focus on both exhaust and intake designs. Small adjustments can greatly reduce turbo lag and improve performance.

Tuning and Customization for Better Spool Time

ECU Remapping

Adjusting Boost Pressure and Timing

ECU remapping helps improve how your turbo engine works. It changes boost pressure and ignition timing for better performance. Advanced systems ensure the turbo gives power at all RPM levels. Adjusting the air-fuel ratio can increase horsepower and torque. This tuning makes your car accelerate faster and reduces turbo lag. It also makes driving smoother and more responsive.

Optimizing Fuel Delivery

Fuel delivery is key to making the turbo work well. ECU remapping adjusts fuel injection to match turbo boost levels. This ensures the engine gets the right fuel at the right time. Better combustion improves power and efficiency. Tuning balances performance with fuel economy. With proper fuel delivery, you get smoother power and quicker throttle response.

Anti-Lag Systems (ALS)

Reducing Turbo Lag During Gear Shifts

Anti-lag systems keep the turbo spinning when you let off the gas. This helps during gear shifts by keeping the turbo ready. It ensures power is available as soon as you press the gas again. ALS is popular in racing for quick response and better control.

Balancing Performance and Wear

ALS boosts performance but can wear out turbo parts faster. High heat and stress can damage components over time. Combining ALS with other methods can reduce wear while cutting turbo lag. Regular care is important to keep the turbo working well.

Heat Management and Turbo Blankets

Retaining Heat for Faster Spool

Managing heat helps the turbo work better. Turbo blankets keep heat inside the turbo, improving efficiency. Studies show that keeping heat in helps the turbo spool faster. This means quicker power delivery and less turbo lag.

Benefits of Proper Heat Management

Good heat management protects engine parts and improves turbo performance. Turbo blankets and shields reduce heat transfer to other parts.

|

Finding |

Explanation |

|---|---|

|

Heat Loss Reduction |

Turbo blankets keep heat from escaping the turbo. |

|

Improved Efficiency |

Retained heat makes exhaust gases work better. |

|

Faster Spool-Up |

Less heat loss means quicker turbo response. |

|

Thermal Energy Transfer |

Insulation keeps energy focused on the turbo. |

|

Reduced Turbo Lag |

Insulated turbos deliver power faster with less delay. |

Managing heat well improves turbo performance and helps it last longer.

Advanced Techniques

Delaying Spark Timing

Delaying spark timing helps reduce turbo lag by improving exhaust flow. When the spark plug fires later, the engine burns fuel later too. This makes hotter and higher-pressure exhaust gases, spinning the turbo faster. The turbo then delivers power more quickly.

This method is common in performance tuning to boost turbo response. Special ignition maps adjust timing based on engine needs, like knocking. These changes help the engine run well and increase torque. The table below shows how timing and fuel ratios improve spool time:

|

Evidence Type |

Description |

|---|---|

|

Ignition Timing |

Special ignition maps improve torque and fuel use with real-time changes. |

|

Air-Fuel Ratio |

A richer air-fuel mix boosts torque better than a balanced mix. |

Delaying spark timing works well for turbo performance but needs careful tuning. Without care, it can cause overheating or engine problems.

Using More Fuel for Faster Turbo Spin

Adding more fuel than air helps the turbo spin faster. This method raises heat in the exhaust, making the turbo spool quicker. A richer fuel mix is great for faster turbo response, especially at low speeds.

Racers often use this trick to keep the turbo ready for instant power. While regular cars use less fuel for efficiency, more fuel works better for performance. But using extra fuel can raise costs and pollution, so balance is key.

Both methods—delaying spark timing and adding more fuel—need precise tuning. Done right, they make turbo engines respond faster without harming the engine.

Making your turbocharger spool faster improves your car’s performance. Quick spool times mean better throttle response and a more fun drive. It might also save fuel. Try advanced tools like variable geometry or twin-scroll turbos. Simple fixes, like clean air filters and lighter parts, help too. Tuning, such as ECU remapping and managing heat, can make it even better.

Check what your car needs and pick the right methods. With smart choices, your turbocharger will work its best, giving you a smoother and faster ride.

Share:

Parallel twin-turbo setups vs sequential: What to choose now

Roots Blowers vs Twin-Screw Superchargers Explained in 2025