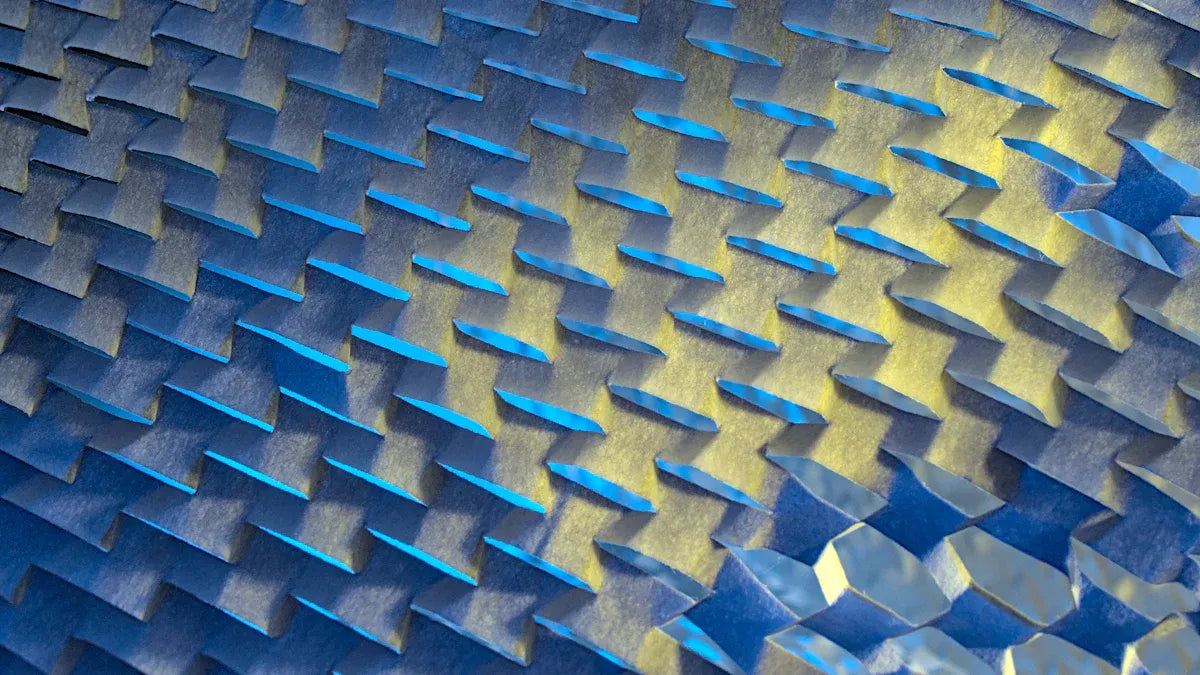

Aligning carbon fiber weave pattern matching tips is crucial for both aesthetics and structural integrity. If the patterns don’t match, the repair can appear messy and may compromise the material’s strength and durability. Proper alignment ensures that the carbon fiber remains strong and smooth.

To achieve this, careful preparation is essential. Start by cleaning and sanding the surface to create a smooth finish. Utilize tools such as rollers or brushes to evenly spread the resin. Employing vacuum bagging techniques helps eliminate air bubbles, resulting in a superior finish. By following these carbon fiber weave pattern matching tips, you can achieve excellent results every time.

Key Takeaways

-

Getting the surface ready is very important. Clean and sand it well to make sure the carbon fiber sticks and lines up correctly.

-

Use the best tools for cutting and lining up carbon fiber. Sharp scissors, rulers, and tape help make clean cuts and keep the pattern neat.

-

Take your time to match the patterns. Line up the weave slowly and check often to keep it strong and looking good.

-

Spread resin evenly and let it dry fully. This step is key for a smooth look and a strong repair.

-

Don’t rush or use the wrong tools. Careful work and good materials make carbon fiber repairs stronger and better.

Tools and Materials for Carbon Fiber Weave Pattern Matching

Important Tools for Accuracy

To match carbon fiber patterns well, use proper tools. Start with sharp scissors or a rotary cutter. These cut fabric neatly without messy edges. A ruler helps you measure straight lines for plain weave patterns. Masking tape holds the fabric steady while you work. A small roller smooths the fabric and removes air bubbles. For harder projects, try a laser guide. It aligns patterns perfectly with great precision.

Necessary Materials for Carbon Fiber Fixes

The materials you pick are key to a good repair. Always use high-quality carbon fiber fabric. Choose from 2×2 or 4×4 twill weave patterns based on your needs. For stronger repairs, unidirectional carbon fiber adds strength in one direction. Resin is very important too. Epoxy resin sticks well and dries smooth. If using vacuum bagging, include release film and breather fabric. These help create a perfect finish.

Extra Tools for Complex Carbon Fiber Patterns

For tricky patterns or detailed designs, advanced tools help. Templates copy hard shapes easily. Heat guns bend fabric around curves without stretching it too much. For small items like insoles, a precision knife makes tiny cuts. Layering tools stack fabric layers neatly for depth and texture. These tools aren’t always needed but make your work look professional.

Step-by-Step Carbon Fiber Weave Pattern Matching Tips

Step 1: Getting the Surface Ready

Preparing the surface is key for matching carbon fiber patterns. A clean, smooth surface helps the material stick and align better. Follow these steps to get it ready:

-

Take off old coatings, sealants, or dirt. This makes a clean base.

-

Fix any cracks or damage. A perfect surface bonds better and lasts longer.

-

Sand the area well to make it smooth. This helps the carbon fiber stick properly.

-

Use a clean, lint-free cloth to wipe away dust or particles.

Spending time on this step makes aligning carbon fiber patterns much easier.

Step 2: Cutting Carbon Fiber Fabric Precisely

Cutting the fabric correctly is important for neat pattern matching. The right tools make a big difference. Try these:

-

Blue laser heads cut cleanly and waste less material.

-

CNC mills are great for tricky shapes, cutting with high accuracy.

-

CNC router bits are flexible and cut within 0.05 mm precision.

-

For simple cuts, sharp scissors or rotary cutters work well.

Don’t use hacksaws for detailed work. They aren’t precise enough. Whether it’s a 2×2 twill or unidirectional pattern, accurate cuts give a professional look.

Step 3: Matching the Carbon Fiber Patterns

Aligning patterns takes patience and care. Lay the fabric on the prepared surface. Adjust it until the weave matches perfectly. For plain weaves, keep the lines straight. For 4×4 twill weaves, match the diagonal lines carefully.

Use masking tape to hold the fabric in place while working. A small roller smooths the fabric and removes air bubbles. For tricky shapes, templates help you align patterns correctly. Taking your time here ensures a perfect repair or project.

Step 4: Securing the Weave Alignment

Keeping the carbon fiber pattern in place is very important. After matching the weave, make sure it doesn’t move. If it shifts, the repair may look bad or lose strength.

Here’s how to keep the weave steady:

-

Use masking tape: Stick small pieces of tape on the fabric edges. This keeps it still without harming the fibers.

-

Press lightly: Roll over the fabric gently with a small roller. This flattens it and removes air bubbles.

-

Work in parts: For big repairs, secure one section at a time. This avoids mistakes and keeps the pattern aligned.

-

Check often: Step back and look at the pattern from different sides. Make sure the plain weave or 2×2 twill weave stays even.

For tricky shapes, use templates to hold unidirectional carbon fiber patterns in place. Taking your time here makes the repair look neat and work well.

Step 5: Applying Resin and Achieving a Smooth Finish

Adding resin is the last step to finish your repair. The right resin and method give a smooth, strong result. Pick a good epoxy resin. Look for features like UV protection and scratch resistance.

Follow these steps to apply resin:

-

Clean the surface: Wipe and sand the area so the resin sticks well.

-

Spread resin evenly: Use a brush or roller to apply thin layers. Don’t use too much, or it might puddle.

-

Let it cure: Depending on your project, let it dry at room temperature, use heat, or try vacuum bagging. These methods make the repair stronger and better-looking.

After curing, check for any flaws. Look closely for surface problems. Use tools like ultrasound to find hidden issues. For strong repairs, test the material’s bending or pulling strength.

A shiny, smooth finish makes the carbon fiber look great and protects it from damage. By following these steps, your repair will look professional and last a long time.

Common Mistakes to Avoid When Aligning Carbon Fiber Patterns

Misaligned Weave Patterns

If carbon fiber patterns don’t line up, they lose strength. Misaligned fibers make the material weaker and less durable. For example, a 0° alignment has a strength of 107 N/mm². But at 30°, the strength drops to 26 N/mm². The material also becomes brittle with more misalignment. At 0°, strain at break is 0.8%, but at 40°, it’s only 0.1%.

To fix this, always match the weave to the load direction. Use masking tape or templates to keep the fabric steady. Step back often to check the alignment from all sides. These steps help keep the carbon fiber strong and aligned.

Using Inappropriate Tools or Materials

Wrong tools or materials can ruin your repair. Problems like fiber misalignment, cracks, or air bubbles may appear. For example, bad tools can break fibers, lowering strength. Cheap materials can add dirt or debris, causing weak spots.

|

Problem |

What Happens |

Why It Happens |

|---|---|---|

|

Fiber Misalignment |

Fibers don’t line up, making it weaker. |

Bad tools or poor handling. |

|

Voids and Porosity |

Air bubbles weaken the layers. |

Dirty tools or bad processing. |

|

Delaminations |

Layers separate, reducing strength. |

Wrong curing or handling. |

|

Matrix Cracks |

Cracks in the material make it less stiff. |

Poor cutting or handling. |

|

Fiber Breakage |

Broken fibers lower the material’s strength. |

Cheap tools or materials. |

|

Inclusions and Foreign Debris |

Dirt or other materials cause weak spots. |

Dirty work area or bad materials. |

To avoid these problems, use good-quality fabric and resin. Cut carefully with sharp scissors or rotary cutters. Don’t use tools that might damage the fibers. Good tools and materials make repairs stronger and last longer.

Rushing Through the Process

Rushing causes mistakes that are hard to fix later. Misaligned patterns, stretched fabric, or uneven resin can ruin the repair. If fibers aren’t aligned, the material becomes weak and brittle.

Take your time to clean the surface and cut fabric neatly. Align the weave slowly and carefully. For tricky shapes, use templates to guide you. Work on one section at a time and check often. A slow, careful process makes the repair look great and stay strong.

Overstretching or Distorting the Fabric

Pulling carbon fiber fabric too much can make it weaker. It also changes how it looks. Stretching the fabric too far moves the weave pattern. This creates uneven tension and lowers its strength. The material may fail if it’s misaligned. Forcing the fabric to fit tricky shapes can also cause distortion.

To stop these issues, handle the fabric gently. Use rollers to smooth it without pulling too hard. For curved areas, use a heat gun lightly. This helps the fabric bend without stretching. Work on small sections to keep the weave pattern in place.

Tip: Keep the fabric tight but don’t stretch it. Balanced tension keeps the weave straight and strong.

Watch the fabric closely while working. Tools like Structural Health Monitoring (SHM) can find damage early. Non-Destructive Testing (NDT) checks for stretching or distortion without harming the material. These methods help you see if the fabric stays strong.

Changing the material can also help avoid stretching. Adding nano-modifiers to the polymer makes it tougher. This change makes the fabric harder to damage during repairs.

By using these tips, you can stop stretching and distortion. Careful handling and smart tools make your carbon fiber repairs strong and neat.

Advanced Carbon Fiber Weave Pattern Matching Tips for Custom Projects

Designing Unique Carbon Fiber Patterns

Making custom carbon fiber designs can be both useful and stylish. You can pick from patterns like twill, herringbone, or basket weave. These patterns can match your project’s needs. You can also add colors using pigments or color infusion. This helps create unique carbon fiber designs that stand out.

For a bold look, try fatcarbon®. It mixes carbon fiber with bright colors and cool designs. Layers of carbon fiber and colored materials are pressed and heated together. This makes a strong and colorful material, great for custom projects.

|

Type of Carbon Fiber |

Description |

|---|---|

|

Weaves |

Different weaves, braids, and formats like tow and unidirectional. |

|

Composites |

Mixed with resins to form various shapes and patterns. |

Techniques for Complex Shapes and Curves

Shaping carbon fiber for curves needs care and the right tools. Carbon fiber mixed with resin makes it strong, light, and rust-proof. This is perfect for repairs or custom designs with tricky shapes.

For curved surfaces, use heat guns to shape the fabric gently. Don’t pull too hard to avoid damage. Advanced checks, like Matrix Array Ultrasonic Testing (MAUT), make sure curved panels stay strong. These methods prove carbon fiber works well for tough designs.

Using Templates for Precise Alignment

Templates help you align carbon fiber patterns perfectly. They let you copy shapes and patterns easily. To make a template, draw the shape on cardboard or plastic. Use it to cut and place the carbon fiber fabric correctly.

Templates stop mistakes when aligning patterns. They keep designs like 4×4 twill or herringbone even across the surface. Using templates saves time and gives your project a professional finish.

Layering Carbon Fiber for Depth and Texture

Adding layers of carbon fiber makes projects look better and stronger. Stacking fabric layers creates cool designs and adds durability. This method is great for repairs or custom designs needing special patterns.

First, pick the right carbon fiber fabric. Use patterns like plain weave or twill for different looks. To add depth, switch between contrasting patterns. For example, a 2×2 twill layer with a unidirectional layer looks amazing.

Here’s how to layer carbon fiber:

-

Start with the base: Place the first fabric layer on a clean surface. Smooth it with a roller to remove air bubbles.

-

Add resin: Spread a thin, even layer of resin over the fabric. This helps layers stick together.

-

Layer more fabric: Add another fabric layer on top. Align the weave carefully to keep the pattern neat. Apply resin again for each new layer.

-

Press the layers: Use vacuum bagging or weights to press the layers. This removes extra resin and makes a strong bond.

Tip: Templates help align patterns across layers. They keep designs neat and professional.

After drying, check for any mistakes. Sand the surface lightly for a smooth finish. Layering improves both the look and strength of your project. With practice, you can create amazing results!

Getting carbon fiber patterns to match needs care and focus. Good preparation, accuracy, and patience are key for strong repairs. For instance, taking time to prepare well can make carbon fiber parts, like insoles, last longer and stay strong. Checking your work carefully helps you find and fix mistakes for a neat finish.

By using these methods, you can fix or design carbon fiber projects easily. With practice and effort, your work will look great and stay durable.

Share:

Discover Why 1 8 Carbon Fiber Sheets Are Ideal for Strength and Weight Reduction

How to Optimize Your Brakes for Maximum Track Day Performance