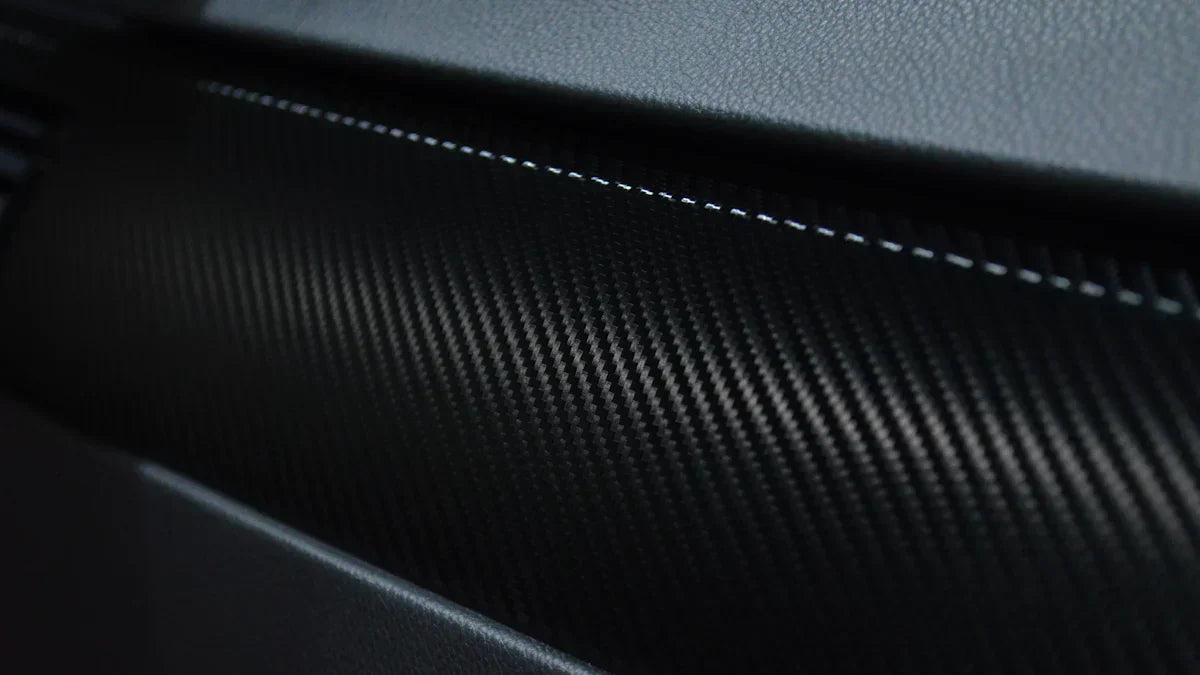

You might wonder why a 4mm carbon fiber sheet stands out in modern materials. Its high strength-to-weight ratio makes it incredibly efficient for applications requiring both strength and lightweight properties. This material resists wear and environmental damage, ensuring exceptional durability. Unlike metals, it does not corrode, even in harsh conditions. Its lightweight properties also make it easy to handle without compromising strength. Industries rely on carbon fiber for its unmatched quality and performance. Whether in aerospace, automotive, or sports equipment, the lightweight properties of carbon fiber sheets deliver reliability and long-lasting results.

Key Takeaways

-

4mm carbon fiber sheets are light but very strong. They are great for planes, cars, and sports gear.

-

These sheets do not rust or get damaged easily. They last a long time even in tough weather.

-

Carbon fiber is made to be very strong and stiff. It can hold heavy weight without bending or breaking.

-

Taking care of it is simple; just wipe it clean. It almost never needs fixing because it is so tough.

-

Carbon fiber can be shaped in many ways. This makes it useful for many jobs and industries.

What Makes 4mm Carbon Fiber Sheets Durable?

Material Composition and Properties

The durability of 4mm carbon fiber sheets begins with their unique composition. These sheets are made from carbon fiber composites, which combine carbon fibers with a polymer resin. This combination creates a material with exceptional strength and stiffness. The fibers provide rigidity, while the resin binds them together, ensuring structural stability. You’ll notice that the properties of carbon fiber make it stand out. It offers high tensile strength, meaning it can withstand significant force without breaking. Its lightweight nature adds to its appeal, making it easier to handle and install without sacrificing performance. The stiffness of carbon fiber ensures that it resists bending or deformation under pressure, making it ideal for demanding applications.

Resistance to Environmental Factors

Carbon fiber sheets excel in resisting environmental challenges. Unlike metals, they do not corrode when exposed to moisture or chemicals. This makes them perfect for outdoor use or in harsh environments. You’ll find that their durability extends to resisting UV radiation, which prevents degradation over time. Their lightweight structure does not compromise their ability to handle extreme temperatures. Whether in freezing cold or intense heat, these sheets maintain their strength and rigidity. This resistance ensures long-lasting performance, even in the most challenging conditions.

Structural Integrity and Dimensional Stability

The structural integrity of 4mm carbon fiber sheets is unmatched. They maintain their shape and size under stress, thanks to their high stiffness and rigidity. You can rely on them to provide consistent performance without warping or cracking. Their lightweight design does not affect their ability to support heavy loads. This dimensional stability ensures that they remain reliable over time, even in applications requiring precision. The strength of carbon fiber composites ensures that these sheets deliver consistent results, making them a trusted choice across industries.

How Strong Are 4mm Carbon Fiber Sheets?

Tensile Strength and Load-Bearing Capacity

You might be surprised by the tensile strength of 4mm carbon fiber sheets. These sheets can withstand immense force without breaking. The carbon fiber material combines stiffness and strength, allowing it to handle heavy loads while maintaining its lightweight nature. This makes it ideal for applications where both durability and efficiency are critical. For example, in aerospace and automotive industries, engineers rely on the load-bearing capacity of carbon fiber to create structures that are both strong and lightweight. The stiffness of the material ensures that it resists deformation, even under significant pressure. You can trust these sheets to deliver consistent performance in demanding environments.

Impact and Flexural Strength

The impact strength of carbon fiber sheets is equally impressive. When subjected to sudden forces, these sheets absorb energy without cracking or breaking. Their rigidity plays a key role in this, as it prevents the material from bending excessively. Flexural strength, which measures the ability to resist bending under load, further highlights the reliability of carbon fiber. You’ll find that the stiffness and strength of these sheets make them perfect for applications requiring resistance to both impact and bending. Whether in sports equipment or industrial machinery, carbon fiber ensures durability and long-lasting performance.

Real-World Examples of Strength

Real-world applications showcase the unmatched strength of 4mm carbon fiber sheets. In the aerospace industry, they form the backbone of lightweight yet strong aircraft components. In the automotive world, manufacturers use them to create durable car parts that enhance performance without adding weight. Even in sports, carbon fiber is a game-changer. From bicycles to tennis rackets, its strength and rigidity provide athletes with reliable equipment. These examples prove that carbon fiber sheets excel in both strength and versatility, making them a trusted choice across various fields.

Longevity and Quality of 4mm Carbon Fiber Sheets

Lifespan and Maintenance

You can expect 4mm carbon fiber sheets to last for decades. Their exceptional strength and durability ensure they remain reliable over time. Unlike traditional materials, carbon fiber does not degrade quickly. Its lightweight nature reduces stress on structures, which helps extend its lifespan. You won’t need frequent replacements, saving both time and money.

Maintaining carbon fiber sheets is straightforward. They resist dirt and grime, so cleaning requires minimal effort. A simple wipe with a damp cloth keeps them in excellent condition. Their stiffness and rigidity prevent warping, so you don’t have to worry about structural changes. Regular inspections ensure optimal performance, but these sheets rarely need repairs.

Resistance to Corrosion and Degradation

Carbon fiber sheets excel in resisting corrosion. Unlike metals, they do not rust when exposed to moisture. This makes them ideal for outdoor applications or environments with high humidity. Their rigidity ensures they maintain their shape, even in challenging conditions.

Chemical resistance adds another layer of durability. Carbon fiber does not react with most chemicals, so it remains unaffected in industrial settings. Its stiffness prevents cracking, even when exposed to harsh substances. You can rely on its quality to withstand wear and tear without losing strength.

Performance Over Time in Harsh Conditions

Harsh conditions do not compromise the performance of carbon fiber sheets. Extreme temperatures, whether hot or cold, do not affect their rigidity. They maintain their stiffness and strength, ensuring consistent results.

UV resistance prevents degradation from prolonged sun exposure. This makes carbon fiber suitable for outdoor use. Its lightweight design does not reduce its ability to handle heavy loads. You can trust these sheets to perform reliably, even in the most demanding environments.

The combination of strength, durability, and lightweight properties ensures long-term performance. Carbon fiber sheets deliver unmatched quality, making them a preferred choice across industries.

Applications and Benefits of Carbon Fiber Sheets

Industries Using 4mm Carbon Fiber Sheets

You’ll find carbon fiber used across a wide range of industries due to its unique properties. In aerospace, it plays a critical role in creating lightweight yet durable components for aircraft. This reduces fuel consumption and enhances overall performance. The automotive industry also relies on carbon fiber composites to manufacture high-performance vehicles. These materials improve speed and efficiency without adding unnecessary weight.

In the sports industry, carbon fiber sheets are essential for crafting equipment like bicycles, tennis rackets, and golf clubs. These products benefit from the material’s lightweight nature and exceptional strength. Industrial machinery and robotics also use carbon fiber composites for parts that require precision and durability. Even in the medical field, carbon fiber is used to create prosthetics and imaging equipment, showcasing its versatility across diverse applications.

Advantages Over Other Materials

Carbon fiber offers several advantages over traditional materials like steel or aluminum. Its lightweight nature makes it easier to handle and install, reducing labor costs and effort. Despite being light, it delivers unmatched strength, making it ideal for demanding applications. Unlike metals, carbon fiber does not corrode, ensuring long-term reliability in harsh environments.

The stiffness of carbon fiber composites ensures that they resist bending or deformation under pressure. This makes them a better choice for applications requiring precision and stability. Additionally, their resistance to chemicals and UV radiation adds to their durability. You’ll notice that carbon fiber outperforms other materials in terms of both longevity and performance.

Customization and Versatility

Carbon fiber sheets offer incredible customization options. You can cut, shape, or mold them to fit specific applications. This flexibility allows industries to create tailored solutions for unique challenges. Whether you need a lightweight panel for aerospace or a durable part for industrial machinery, carbon fiber composites can meet your requirements.

Their versatility extends to their appearance as well. You can choose from various finishes, including matte or glossy, to match aesthetic preferences. This makes carbon fiber suitable for both functional and decorative purposes. Its ability to adapt to different needs ensures that it remains a top choice for innovative applications across industries.

4mm carbon fiber sheets offer unmatched strength, durability, and longevity. Their ability to resist wear, corrosion, and environmental challenges ensures they perform reliably for years. You’ll find their lightweight nature combined with exceptional stiffness makes them a superior choice for demanding applications.

Why choose carbon fiber?

Its versatility spans industries like aerospace, automotive, and sports, proving its reliability in diverse fields.

If you’re looking for a material that delivers high performance and long-term value, carbon fiber sheets are the ideal solution. Explore their potential for your next project and experience their remarkable benefits firsthand.

Share:

Learn the Manufacturing Process of 5mm Carbon Fiber Sheets

A Guide to Choosing the Right Carbon Fiber Profile for Your Industry