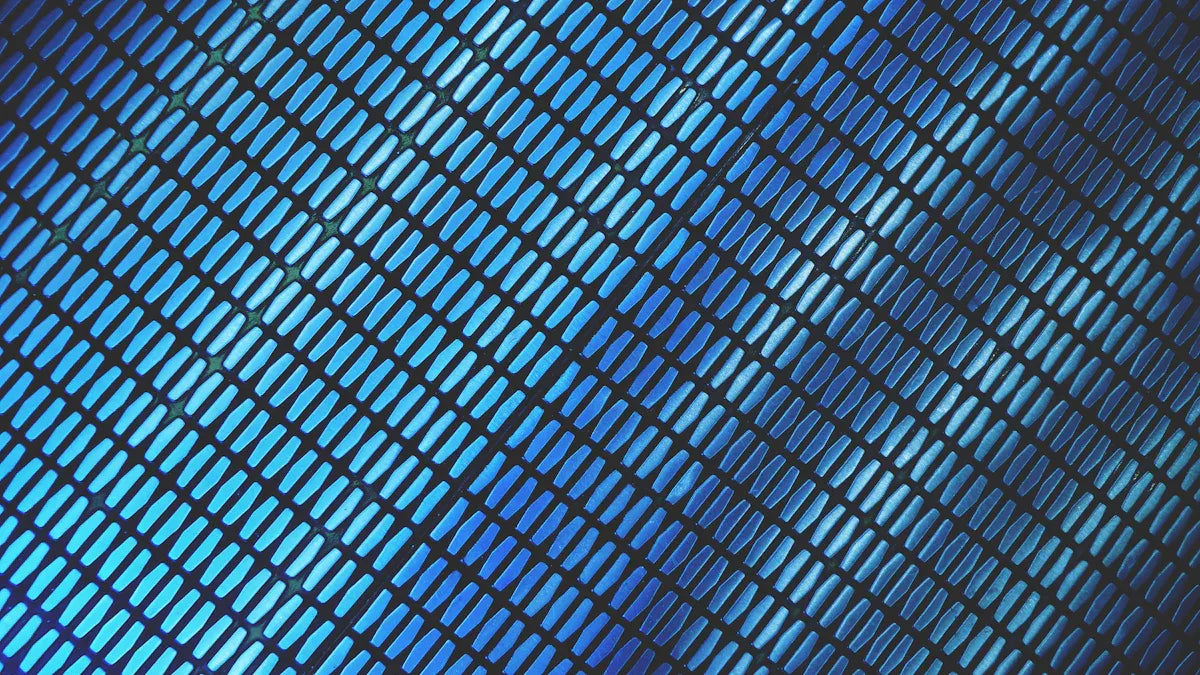

When you need materials that combine strength and lightweight design, 2mm carbon fiber sheets deliver unmatched performance. These sheets offer an exceptional strength-to-weight ratio, making them indispensable for applications requiring high strength without added bulk. Their durability ensures they withstand wear and tear, even in demanding environments. You’ll find them resistant to corrosion and environmental factors, which extends their lifespan significantly. Industries like aerospace, automotive, and sports equipment rely on 2mm carbon fiber sheets to create innovative, high-performance solutions that push the boundaries of design and functionality.

Key Takeaways

-

2mm carbon fiber sheets are very strong but lightweight. They are great for projects needing both strength and lightness.

-

These sheets last a long time and don’t wear out easily. This means fewer replacements and saving money over time.

-

They don’t rust, so they work well in tough conditions. This makes them useful for many industries.

-

The 2mm thickness is strong yet bendable, perfect for creative designs. It’s used in planes, cars, and sports gear.

-

Using 2mm carbon fiber sheets improves projects and makes them last longer. They are better than materials like aluminum or steel.

The Unique Properties of 2mm Carbon Fiber Sheets

Exceptional Strength-to-Weight Ratio

You’ll find that 2mm carbon fiber sheets excel in applications where both strength and lightweight design are critical. These sheets offer an ultimate strength of 4.9 GPa, which is significantly higher than many traditional materials like aluminum or steel. Despite their impressive strength, they maintain a low density of just 1.86 g/cm³, making them ideal for projects where reducing weight is essential. This unique combination of rigidity and strength allows you to achieve high performance without compromising on efficiency.

The advantages of carbon fiber composites become even more apparent when you consider their high stiffness. This property ensures that the material resists deformation under stress, making it suitable for demanding environments like aerospace and automotive industries. Whether you’re designing lightweight aircraft components or high-performance car parts, the exceptional strength-to-weight ratio of 2mm carbon fiber sheets provides a clear advantage.

High Durability and Resistance to Wear

Durability is one of the standout features of carbon fiber composites. These sheets resist wear and tear even in the most challenging conditions. Their rigidity ensures that they maintain structural integrity over time, reducing the need for frequent replacements. This durability translates to long-term cost savings, especially in industries where reliability is paramount.

The high stiffness of 2mm carbon fiber sheets also contributes to their resistance to mechanical wear. Unlike traditional materials, they don’t easily succumb to scratches, dents, or other forms of damage. This makes them an excellent choice for applications requiring both strength and longevity.

Corrosion Resistance and Longevity

One of the unique properties of 2mm carbon fiber sheets is their exceptional resistance to corrosion. Unlike metals, which can rust or degrade when exposed to moisture or chemicals, carbon fiber composites remain unaffected. This makes them ideal for use in environments where exposure to harsh conditions is unavoidable.

Long-term studies have confirmed the durability of carbon fiber composites. For example, research on fiber-reinforced polymer (FRP) materials highlights their ability to withstand environmental factors without significant degradation. The table below summarizes key findings from these studies:

|

Study Title |

Key Findings |

|---|---|

|

Durability and long-term performance of fiber reinforced polymer (FRP) composites |

Minimal effects of environmental conditions on mechanical properties, supporting longevity claims. |

|

Environment-Assisted Degradation of Bond between Steel and Carbon Fiber Reinforced Polymer |

Highlights resilience of CFRP under harsh environments. |

|

Durability of fibre reinforced polymers used in concrete structures |

Extensive tests show minimal degradation, emphasizing long-term performance. |

By choosing 2mm carbon fiber sheets, you gain a material that combines ultimate strength, rigidity, and long-lasting performance. These advantages of carbon fiber make it a superior choice for projects requiring reliability and durability.

Why 2mm Thickness is Optimal for Carbon Fiber Sheets

Balancing Strength and Flexibility

The 2mm thickness strikes the perfect balance between strength and flexibility. You’ll notice that this thickness provides enough structural integrity to handle significant loads while maintaining the adaptability needed for complex designs. This balance makes it ideal for applications requiring both durability and slight flexibility, such as drone frames or sports equipment.

Tip: When working with carbon fiber composites, choosing the right thickness ensures your project achieves optimal performance without unnecessary material waste.

The inherent rigidity of carbon fiber composites ensures that even at 2mm, the material resists deformation under stress. This property allows you to create components that can endure high-pressure environments without compromising their structural integrity.

Lightweight Design Without Compromising Performance

A 2mm carbon fiber sheet offers an excellent lightweight solution without sacrificing performance. You’ll find that its low density, combined with high strength, makes it a superior choice for weight-sensitive projects. For example, in aerospace applications, reducing weight directly improves fuel efficiency and overall performance.

The rigidity of these sheets ensures that their lightweight nature does not come at the cost of durability. Unlike heavier materials like steel or aluminum, carbon fiber composites maintain their structural properties while significantly reducing the overall weight of your design. This makes them indispensable for industries where every gram matters.

Versatility Across Different Applications

The 2mm thickness enhances the versatility of carbon fiber composites, allowing you to use them across a wide range of applications. Whether you’re designing automotive parts, robotics components, or even custom furniture, this thickness adapts seamlessly to your needs.

-

Aerospace: Lightweight yet strong components for aircraft.

-

Automotive: High-performance parts that improve speed and efficiency.

-

Sports Equipment: Durable and lightweight designs for better performance.

The rigidity and strength of 2mm carbon fiber sheets make them suitable for both structural and aesthetic purposes. Their sleek, modern appearance adds a professional touch to any project, while their performance characteristics ensure long-term reliability.

Applications of 2mm Carbon Fiber Sheets

Aerospace: Lightweight Components for Aircraft

In aerospace, reducing weight is critical for improving fuel efficiency and overall performance. 2mm carbon fiber sheets excel in this sector due to their high strength-to-weight ratio and resistance to extreme temperatures. These properties make them ideal for structural components like wings and fuselages. For instance, a project utilizing carbon fiber sheets achieved a 25% reduction in launch weight, resulting in significant cost savings.

The following table highlights the performance metrics of 2mm carbon fiber sheets in aerospace applications:

|

Sector |

Application |

Performance Metric |

|---|---|---|

|

Aerospace |

Structural components (wings, fuselages) |

High strength, low density, high temperature resistance |

Compared to traditional materials like aluminum, carbon fiber composites offer superior stiffness and strength while maintaining a lower density. This combination ensures that aircraft components remain lightweight without compromising structural integrity.

Automotive: High-Performance and Fuel-Efficient Designs

In the automotive industry, 2mm carbon fiber sheets play a pivotal role in creating high-performance vehicles. Their lightweight nature contributes to weight reduction, which enhances speed and fuel efficiency. These sheets are commonly used in body panels, chassis, and engine components, where strength and durability are essential.

By replacing heavier materials like steel, carbon fiber composites improve safety and handling while reducing emissions. For example, vehicles incorporating carbon fiber components often achieve better acceleration and braking performance due to the reduced weight. This makes them a preferred choice for manufacturers aiming to meet stringent environmental standards and deliver cutting-edge designs.

Sports Equipment: Enhancing Performance and Durability

Athletes and sports enthusiasts benefit greatly from the use of 2mm carbon fiber sheets in equipment design. These sheets provide the perfect balance of strength and lightweight properties, enabling manufacturers to create gear that enhances performance. Whether it’s a tennis racket, bicycle frame, or hockey stick, carbon fiber composites ensure durability and precision.

The rigidity of these sheets allows for better energy transfer, giving athletes a competitive edge. Additionally, their resistance to wear and environmental factors ensures that sports equipment maintains its quality over time. This durability makes carbon fiber an excellent investment for both professional and recreational users.

Note: The versatility of 2mm carbon fiber sheets extends beyond these industries, making them a valuable material for countless applications.

Industrial Uses: Robotics, Drones, and Structural Components

In industrial applications, 2mm carbon fiber sheets have become a game-changer. Their unique properties make them an ideal material for robotics, drones, and structural components. You’ll find that their lightweight nature and exceptional strength allow engineers to design innovative solutions that were previously unattainable with traditional materials.

Robotics: Precision and Efficiency

Robotics demands materials that combine precision, durability, and efficiency. 2mm carbon fiber sheets meet these requirements perfectly. Their high stiffness ensures that robotic arms and frames maintain accuracy during operation, even under heavy loads. Additionally, their lightweight design reduces the energy required for movement, improving overall efficiency.

Did you know? Carbon fiber’s resistance to wear ensures that robotic components last longer, reducing maintenance costs and downtime.

Drones: Lightweight and High-Performance

Drones rely on lightweight materials to achieve optimal flight performance. By using 2mm carbon fiber sheets, you can reduce the weight of drone frames without compromising their structural integrity. This results in longer flight times and improved maneuverability. The material’s strength also ensures that drones can withstand impacts and harsh environmental conditions, making them suitable for both recreational and industrial use.

Structural Components: Durability and Versatility

In construction and manufacturing, 2mm carbon fiber sheets excel as structural components. Their high strength-to-weight ratio allows you to create durable yet lightweight frameworks. Whether it’s for load-bearing structures or intricate designs, these sheets provide the reliability needed for long-term performance.

The versatility of 2mm carbon fiber sheets ensures they adapt to various industrial needs. From enhancing robotic precision to improving drone efficiency, their applications continue to expand as industries seek stronger and lighter materials.

Comparing 2mm Carbon Fiber Sheets to Alternative Materials

Aluminum: Strength and Weight Differences

When comparing 2mm carbon fiber sheets to aluminum, you’ll notice significant differences in both strength and weight. Aluminum is known for its lightweight properties, but carbon fiber composites outperform it in terms of strength-to-weight ratio. While aluminum offers decent rigidity, carbon fiber composites provide superior stiffness, ensuring better resistance to deformation under stress.

In applications where weight reduction is critical, such as aerospace or automotive design, carbon fiber sheets excel. They weigh less than aluminum while delivering higher tensile strength. This combination allows you to create components that are not only lighter but also more durable. Additionally, carbon fiber’s resistance to environmental factors, such as corrosion, gives it a clear advantage over aluminum in long-term performance.

Steel: Why Carbon Fiber is Superior for Lightweight Needs

Steel has long been a go-to material for its strength, but it falls short when weight becomes a concern. 2mm carbon fiber sheets offer a density that is only 20% of steel, making them significantly lighter. Despite their low weight, these sheets maintain exceptional strength, making them ideal for lightweight structures.

-

Light Weight: Carbon fiber sheets drastically reduce the overall weight of your design.

-

High Strength: They provide the strength needed for demanding applications.

-

Corrosion Resistance: Unlike steel, carbon fiber does not rust or degrade over time.

-

Dimensional Stability: These sheets maintain their shape and size under varying conditions.

-

Ease of Fabrication: Carbon fiber sheets are easier to fabricate and install compared to steel.

By choosing carbon fiber composites, you gain a material that combines rigidity, strength, and long-term reliability, making it a superior alternative to steel for lightweight needs.

Plastics: Durability and Performance Advantages

Plastics are often used for their affordability and ease of manufacturing, but they lack the durability and performance of 2mm carbon fiber sheets. The following table highlights key differences between these materials:

|

Property |

Carbon Fiber Sheets |

Plastics |

|---|---|---|

|

Strength-to-Weight Ratio |

More than five times that of steel |

Generally lower than carbon fiber |

|

Corrosion Resistance |

Resistant to most chemicals |

Varies widely, often less resistant |

|

Thermal Stability |

Maintains properties at high temperatures |

May soften or deform at high temperatures |

|

Design Flexibility |

Can be fabricated into complex shapes |

Limited in complex designs |

You’ll find that carbon fiber composites outperform plastics in nearly every category. Their rigidity ensures better structural integrity, while their resistance to high temperatures and chemicals makes them suitable for demanding environments. For projects requiring both durability and precision, carbon fiber sheets are the superior choice.

2mm carbon fiber sheets offer unmatched benefits, combining lightweight design, exceptional strength, and remarkable versatility. Their abrasion resistance, waterproof nature, and heat insulation make them ideal for diverse applications, from aerospace to sports equipment.

|

Key Attribute |

Description |

|---|---|

|

Material |

100% Carbon Fiber |

|

Feature |

Abrasion-Resistant, Waterproof, Anti-static, Heat-Insulation, High Performance |

|

Applications |

Aerospace, Automotive, Marine, Sports Equipment, Industrial |

With a projected market growth rate exceeding 15% through 2030, investing in these sheets ensures you stay ahead in industries like electric vehicles and robotics. Explore the potential of 2mm carbon fiber sheets to elevate your projects today.

Share:

From Stock to Stunning: Audi Owners Share Carbon Fiber Transformations

Debunking Myths About Mercedes W463 Carbon Fiber Spoilers