Curing time is very important in carbon fiber manufacturing. It affects how fast it’s made and how well it performs. Wet carbon fiber requires more curing time than dry carbon fiber. This is influenced by factors such as resin makeup and weather conditions. For example, curing in high humidity alters the material’s glass transition temperature (Tg). Dry processes cure faster, benefiting industries that demand speed and high quality in carbon fiber manufacturing.

Key Takeaways

-

Curing time is very important in making carbon fiber. Wet carbon fiber takes more time to cure, but dry carbon fiber cures faster. This affects how quickly it’s made and how well it works.

-

Wet carbon fiber works well for detailed designs and cheaper projects. It uses more resin, so it’s heavier and not great for high-performance uses.

-

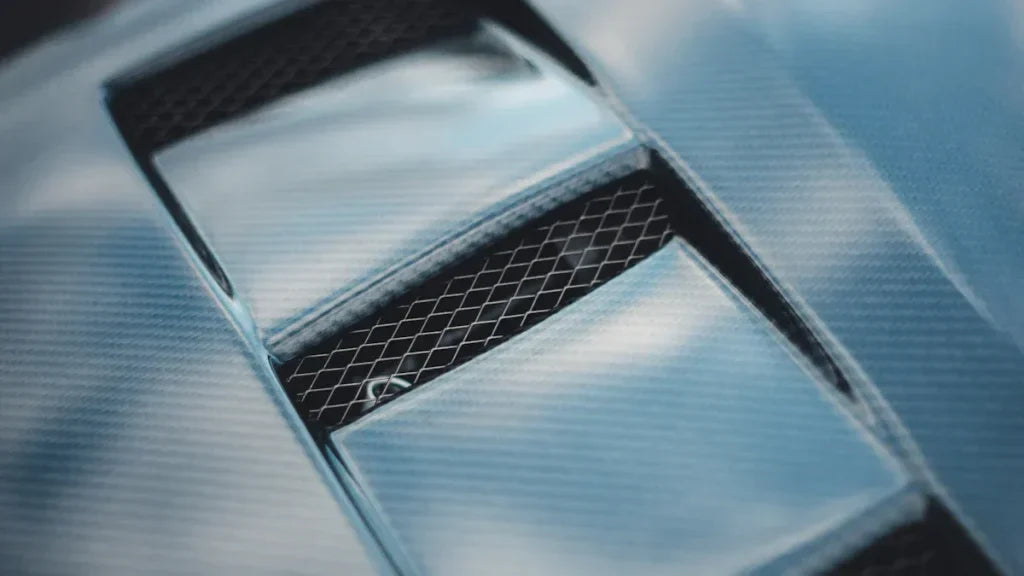

Dry carbon fiber is stronger and lighter. It uses pre-cured resin and controlled settings, making it great for planes and cars.

-

Humidity changes curing quality. High humidity can make the material weaker by lowering the glass transition temperature (Tg). Keeping the environment controlled helps get better results.

-

Picking the right curing method depends on the project. Wet curing is cheaper for simple designs, but dry curing is better for strong, light parts.

Understanding Carbon Fiber Manufacturing Processes

Wet Carbon Fiber Manufacturing

Wet carbon fiber is made by adding resin during production. This lets the material be shaped into complex designs. It works well for projects needing flexible shapes. But, things like air humidity can change the product’s quality. For example, high humidity can affect the material’s glass transition temperature (Tg). To keep quality steady, you must check temperature, humidity, and resin mix amounts.

This process often uses more resin than fiber, making it heavier. Because of this, it’s not great for high-performance uses. Still, wet carbon fiber is a cheaper option for everyday products.

Dry Carbon Fiber Manufacturing

Dry carbon fiber, or pre-preg, has resin added before production. This method controls the resin-to-fiber ratio better. It makes parts that are lighter and stronger. The resin is partly cured, which reduces extra resin and boosts strength.

This method is perfect for industries like cars and planes. These industries need strong and lightweight materials. But, it needs special tools and skills, which cost more. Even with higher costs, dry carbon fiber is very strong and stiff.

Key Process Differences Between Wet and Dry Carbon Fiber

The main difference is how resin is added. Wet carbon fiber adds resin during production, which can cause uneven results. Dry carbon fiber uses pre-added resin, making it more precise.

|

Comparison Aspect |

Wet Carbon Fiber |

Dry Carbon Fiber |

|---|---|---|

|

Manufacturing Process |

Resin added during production, may cause uneven results. |

Pre-added resin ensures even and precise material properties. |

|

Weight |

Heavier because of extra resin. |

Lighter due to better resin control. |

|

Applications |

Good for simple uses but not high-performance tasks. |

Best for high-performance needs like strength and lightness. |

Dry carbon fiber has more fiber compared to resin, making it stronger. Wet carbon fiber is cheaper and easier to make, so it’s good for simpler projects.

Curing Time Differences in Wet and Dry Carbon Fiber

Factors Affecting Curing Times

Resin Type and Composition

The resin type affects how long curing takes. Wet carbon fiber uses liquid resin added during making. This resin needs more time to fully harden after shaping. Dry carbon fiber uses pre-cured resin, which is partly hardened before use. This step shortens the final curing time. The resin’s makeup also matters. Some resins harden quickly at low heat, while others need high heat for strength.

Temperature and Pressure Requirements

Curing depends a lot on heat and pressure. Wet carbon fiber often cures at room temperature. This can take hours or even days. Humidity can make it slower. Dry carbon fiber cures in ovens or autoclaves. These use high heat and pressure to speed up curing. They also make the product more even. But, large parts may need longer curing, raising energy costs.

Automation and Equipment Used

Machines and tools can change curing times. Wet carbon fiber is often made by hand. This can cause uneven results and longer curing. Dry carbon fiber uses special machines like ovens and autoclaves. These tools control curing better, making it faster and more even. Though these machines cost more, they save time and improve production.

Curing Times for Wet Carbon Fiber

Wet carbon fiber takes longer to cure because of weather. Humidity can lower the material’s glass transition temperature (Tg). This can cause uneven curing. For example, high humidity can trap water in the resin. This slows curing and weakens the material. Curing can take hours or days, depending on the resin and weather. Wet carbon fiber is cheaper but slows down production.

Curing Times for Dry Carbon Fiber

Dry carbon fiber cures faster due to pre-cured resin and controlled settings. Ovens or autoclaves are used for curing, taking a few hours. New methods, like electromagnetic induction, heat faster and shorten curing time. These methods depend on the resin and fiber properties. Dry carbon fiber uses more energy but cures quickly. This makes it great for industries needing strong materials fast.

Comparing Wet and Dry Carbon Fiber Curing Processes

Advantages of Wet Carbon Fiber Curing

Wet carbon fiber curing has benefits for certain uses. It spreads resin evenly, giving steady strength to the material. This method allows shaping into detailed designs, perfect for cars and planes. For example, a study of 203 laminates showed how air moisture changes glass transition temperature (Tg). This highlights why controlling the environment is important during production.

This process is also cheaper to use. It needs simple tools and less energy than dry carbon fiber curing. This makes it a good option for projects where cost matters more than performance.

Disadvantages of Wet Carbon Fiber Curing

Wet carbon fiber curing has some downsides. It often makes heavier parts because of extra resin. Too much resin lowers strength, making it less ideal for high-performance needs. For instance, sunlight can damage wet carbon fiber, causing it to fade or turn yellow.

It also takes longer to cure. Wet carbon fiber curing may need hours or days, slowing work. Its higher weight compared to strength limits its use in industries needing light materials.

|

Drawback |

Description |

|---|---|

|

Heavier Than Dry Carbon |

Extra resin adds more weight. |

|

Weaker Structural Integrity |

Too much resin lowers material strength. |

|

Higher Risk of Yellowing & Fading |

Sunlight can damage and fade the material. |

Advantages of Dry Carbon Fiber Curing

Dry carbon fiber curing makes light and strong materials. It removes extra resin, giving a better strength-to-weight ratio. This method is great for industries like racing and aerospace, where weight matters a lot.

The process uses heat and pressure to improve material quality. For example, curing under pressure makes lighter and stronger parts. The exact resin application also gives better strength and a smoother finish.

|

Benefit |

Description |

|---|---|

|

Weight Savings |

Dry carbon fiber parts are lighter with less resin. |

|

Increased Strength |

Exact resin use improves strength and structure. |

|

Superior Finish |

The process creates a smooth surface with fewer flaws. |

Dry carbon fiber curing also speeds up production. New methods like electromagnetic heating make curing faster. This is helpful for industries needing quick and strong materials.

Disadvantages of Dry Carbon Fiber Curing

Dry carbon fiber curing has many benefits but also some problems. One big issue is the high cost. Making it needs special tools like ovens and autoclaves. These tools are expensive and use a lot of energy. This makes the process costly for projects with small budgets.

Another problem is the time it takes. Even though it cures faster than wet carbon fiber, the steps are more complex. For example, using an autoclave gives better results but takes longer. This can slow down work, especially for big projects.

Dry carbon fiber is also sensitive to its environment. It needs to be stored in the right conditions. If not, the resin can go bad, causing quality problems. This means manufacturers must monitor storage closely and use special facilities.

Here’s a summary of the downsides:

|

Disadvantage |

Description |

|---|---|

|

Higher Costs |

Special tools and energy use make it expensive. |

|

Slower Production |

Complex steps like autoclaving take more time. |

Quality issues can also happen. Uneven heat or poor handling may cause defects. These defects can weaken the final product.

-

Making it costs more due to complex tools.

-

It is sensitive to storage conditions, affecting quality.

Even with these issues, dry carbon fiber is still popular. Knowing its limits helps you decide if it fits your needs.

Industry Applications and Considerations

Impact of Curing Time on Production Timelines

Curing time affects how fast carbon fiber parts are made. Longer curing times, especially with medium heat (90–100 °C), increase energy use. This slows production and raises costs.

Medium-heat curing (~90–100 °C) ensures even temperatures but uses more energy and reduces production speed.

To save time, resin transfer molding (RTM) is a better option. RTM shortens curing cycles and costs less than autoclave curing.

RTM is faster and cheaper than autoclave curing, needing less money for tools and equipment.

Humidity can cause curing problems. High humidity lowers the glass transition temperature (Tg), weakening the material.

High humidity during curing lowers Tg, reducing the quality of carbon fiber parts.

Material Properties and Performance Implications

Curing time changes how strong carbon fiber parts are. For example, high humidity during curing lowers the Tg of carbon fiber reinforced polymer (CFRP). This happens because water gets trapped, reducing curing quality.

|

Finding |

Description |

|---|---|

|

Effect of Humidity |

High humidity during curing lowers the glass transition temperature (Tg). |

|

Mechanism |

Water pockets in the uncured material reduce curing quality and Tg. |

Controlling curing conditions improves strength and durability. This is key for industries needing strong carbon fiber materials.

Selecting the Right Method for Applications

Aerospace and Automotive Industries

Aerospace and car industries need light but strong materials. Dry carbon fiber curing works best here. It makes strong parts quickly, meeting tight deadlines.

Sports Equipment and Consumer Goods

For sports gear and consumer items, wet carbon fiber curing is better. It allows detailed designs at a lower cost. Though slower, it’s affordable for these uses.

Construction and Industrial Applications

In construction and industry, durability is most important. Wet curing is cheaper for big projects. Dry curing is stronger for critical parts.

Curing time is important in making carbon fiber. Wet carbon fiber cures slower, so it’s good for cheaper projects. Dry carbon fiber cures faster and is stronger for tough tasks. Picking the right curing time helps balance speed and quality.

The glass transition temperature (Tg) shows material quality. It changes with resin type and curing settings. Watching these factors keeps results steady. Dry curing is best for fast, strong production. Wet curing is better for detailed, low-cost designs. Pick the method that fits your project.

Share:

Car Model Comparison 2025 – Which One Fits You?

Dry vs Wet Carbon Fiber Strength and Stiffness in 2025