CarbonXtreme Post

The Ultimate Guide to BMW M4 Rear Diffusers in 2025

Upgrading your 2025 BMW M4 with a redesigned rear diffuser boosts both performance and style. By optimizing airflow, a quality diffuser reduces drag, improves stability, and increases downforce for better handling—especially at high speeds or on track days. Popular materials like carbon fiber offer lightweight strength, while ABS plastic provides durability at a lower cost. In 2025, bold, angular designs and exposed carbon finishes dominate the style trends, perfectly complementing the M4’s aggressive stance. Choosing the right diffuser means balancing performance, aesthetics, compatibility, and budget to get a component that transforms your driving experience.

Best Carbon Fiber Front Lips for Mercedes W463 and W464 Models

Upgrading your 2025 Mercedes G63, G500, W463, or W464 with a carbon fiber front lip enhances both appearance and performance. These lightweight yet durable components improve aerodynamics by reducing lift and drag, boosting stability and handling at high speeds. Precision-fit designs ensure seamless integration with the G-Class body, while various styles—from glossy UV-protected finishes to dry carbon matte options—allow for customization. Easy-to-install and low-maintenance, a quality front lip delivers a striking, aggressive look without sacrificing practicality or long-term durability.

Why 2025 Mercedes G63 G500 W463 W464 Need Carbon Fiber Spoilers

Carbon fiber rear spoilers for the 2025 Mercedes G63, G500, W463, and W464 offer a perfect blend of performance and style. They enhance aerodynamics by reducing drag, increase downforce for sharper handling and better traction, and improve fuel efficiency through lightweight construction. With rugged yet luxurious aesthetics, multiple finishes, and precise model-specific fitment, these spoilers seamlessly upgrade both the look and driving dynamics of the G-Class. Durable and low-maintenance, they are built to withstand extreme conditions while delivering long-term value.

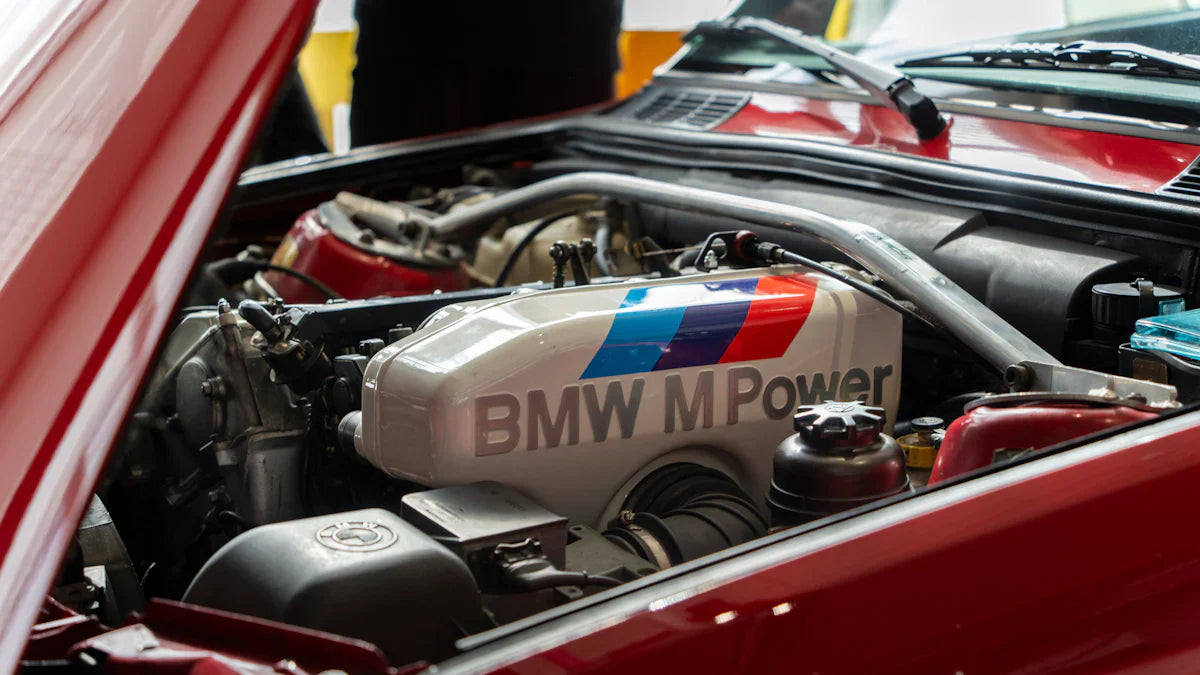

BMW F10 Engine Options and Driving Modes

The BMW F10, part of the 5 Series lineup, blends executive luxury with versatile performance. Offering gasoline, diesel, and hybrid engines, it caters to drivers seeking power, efficiency, or sustainability. Four driving modes—Comfort, Sport, Eco Pro, and Adaptive—allow tailored experiences, from smooth commuting to dynamic handling or fuel-saving drives. With refined design, advanced technology, and customizable performance, the F10 remains a benchmark in the premium sedan segment.

How to Manufacture Carbon Fiber Products and Explore Their Advantages

Carbon fiber products combine extremely strong yet lightweight fibers into versatile composites used in aerospace, automotive, sports, renewable energy, and more. They offer exceptional strength-to-weight ratios, resistance to heat, chemicals, and corrosion, and design flexibility. Manufacturing involves multiple precision stages—material preparation, stabilization, carbonization, surface treatment, and shaping—using methods like wet lay-up, prepreg lamination, RTM, filament winding, and pultrusion. While costs and recycling challenges remain, innovations such as bio-based precursors, advanced curing, and improved recycling methods are enhancing sustainability. The global market, valued at $7.1B in 2023, is projected to grow to $23.2B by 2030 (CAGR 12.6%), driven by performance demands and eco-friendly trends.

What is Carbon Fiber Nylon and Its Key Properties

Carbon fiber nylon is a composite that combines carbon fibers’ high strength and stiffness with nylon’s flexibility and durability, resulting in a lightweight, heat- and chemical-resistant material. It offers a high strength-to-weight ratio, superior wear and fatigue resistance, and design versatility, making it valuable in aerospace, automotive, manufacturing, 3D printing, sports equipment, consumer goods, robotics, and medical devices. While it delivers exceptional performance and long lifespan, challenges include high production costs, limited recycling options, and specialized manufacturing requirements.

Why Carbon Fiber Injection Molding Is Replacing Metal

Carbon fiber injection molding offers a lightweight yet high-strength alternative to metals like steel and aluminum, delivering superior tensile strength, corrosion resistance, and design flexibility. The process enables complex shapes, reduces material waste, and supports large-scale, cost-efficient production. Applications span automotive, aerospace, defense, consumer electronics, medical devices, and sports equipment, where weight reduction enhances performance and efficiency. Advances in hybrid composites, automated fiber placement, and recycled carbon fiber are expanding its use while reducing environmental impact, making it a key technology for sustainable, high-performance manufacturing.

Why Carbon Fiber Rolls Are Vital for Lightweight and Durable Designs

Carbon fiber rolls offer an exceptional strength-to-weight ratio, making them essential for industries like aerospace, automotive, construction, sports, and renewable energy. They combine durability, corrosion resistance, thermal stability, and adaptability to complex shapes, enabling innovative, high-performance designs. Their use reduces weight, improves efficiency, lowers long-term costs, and supports sustainability through energy savings and recyclability. Real-world applications include aircraft components, EV structures, sports equipment, building reinforcement, wind turbine blades, and solar panel frames, where they enhance performance, reliability, and eco-friendliness.

How to Find the Best Carbon Fiber Weave for Your Application

Selecting the right carbon fiber weave is critical to achieving the desired balance of strength, flexibility, aesthetics, and cost for your project. Common weaves include plain weave (stable and ideal for flat surfaces), twill weave (flexible and suited for complex shapes), satin weave (luxurious finish with high formability), and unidirectional weave (maximum strength in one direction). Hybrid weaves blend carbon fiber with other materials like Kevlar for specialized performance. Choosing involves considering factors such as strength/stiffness needs, weight, environmental durability, visual appeal, and budget. Applications range from aerospace and automotive to sports, marine, industrial, and DIY projects, with each weave excelling in specific conditions. Testing samples and consulting experts are recommended to ensure the best fit.