Vacuum valves play a crucial role in your car’s engine by managing the flow of air and fuel. These small yet powerful components use vacuum pressure to regulate how much air enters the system, ensuring the engine runs smoothly. Without them, your engine could lose efficiency or even face damage. By maintaining the right balance of air and fuel, vacuum valves help improve performance and reduce harmful emissions. Their precision ensures your vehicle operates at its best, keeping both power and efficiency in check.

Key Takeaways

-

Vacuum valves control air and fuel in car engines for better performance.

-

They have parts like the body, diaphragm, spring, and ports. Each part helps manage airflow.

-

Taking care of vacuum valves stops problems like leaks and pressure issues. This avoids expensive repairs.

-

These valves help systems like brakes, emissions, and air conditioning. They make driving safer and more comfortable.

-

Knowing how vacuum valves work shows why they are important. They keep engines running well and cut down pollution.

What Are Vacuum Valves in Automotive Engines?

Definition and Purpose of Vacuum Valves

Vacuum valves are essential components in automotive engines. They regulate the flow of air and fuel to ensure optimal engine performance. These valves, such as the butterfly valve, control the air-fuel mixture entering the engine. They rely on the vacuum system created by the engine’s manifold to function effectively. For example, under light load and low throttle, the manifold generates high vacuum pressure. This pressure helps the valves manage airflow efficiently. On the other hand, minimal vacuum occurs during heavy loads, altering how the valves operate.

The primary purpose of vacuum valves is to maintain engine efficiency and support various systems. They enhance fuel efficiency by regulating airflow and creating necessary restrictions. Additionally, they power components like exhaust gas recirculation solenoids and fuel pressure regulators. Without these valves, your engine would struggle to maintain smooth operation and meet modern emission standards.

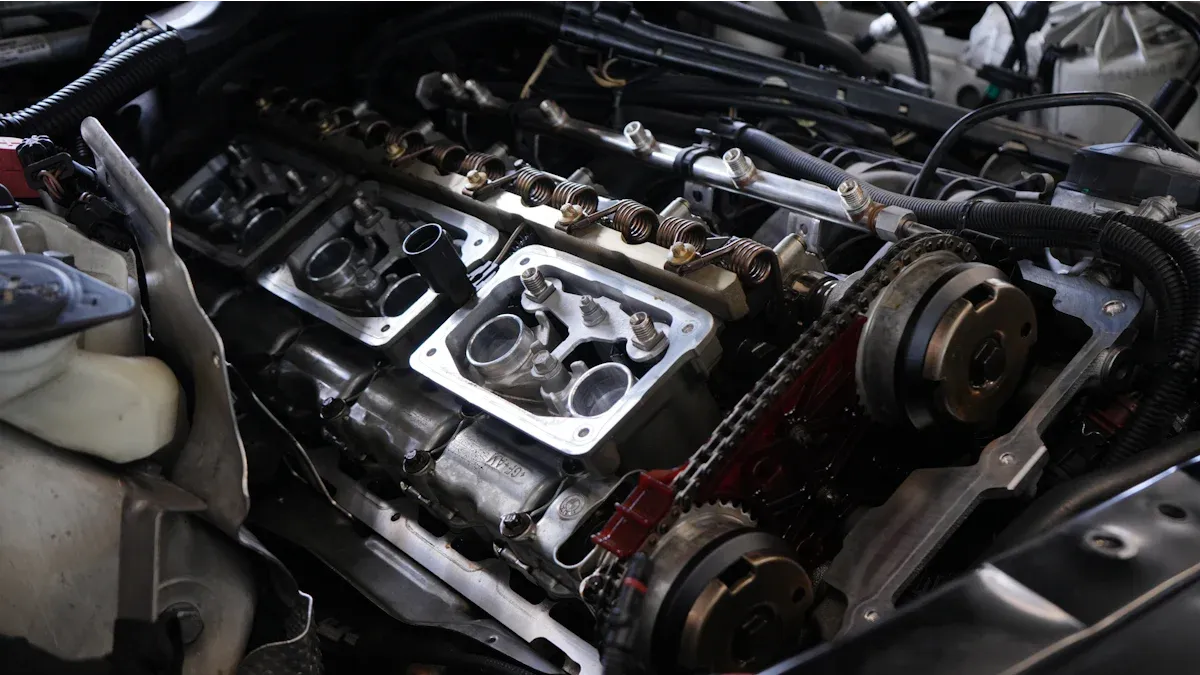

Key Components of Vacuum Valves

Vacuum valves consist of several key components that work together to regulate airflow. These include:

-

Valve Body: The main structure that houses the internal mechanisms.

-

Diaphragm: A flexible membrane that responds to changes in vacuum pressure.

-

Spring: Provides resistance and helps the valve return to its default position.

-

Ports: Openings that allow air to flow in and out of the valve.

Each component plays a critical role in ensuring the valve operates correctly. For instance, the diaphragm adjusts based on vacuum pressure, allowing precise control of airflow. This precision is vital for maintaining engine performance and efficiency.

Engine Systems That Depend on Vacuum Valves

Many engine systems rely on vacuum valves to function properly. These include:

-

Brake Assist Systems: Vacuum-assist brake servos use manifold vacuum to enhance braking power.

-

Emission Control Systems: Components like exhaust gas recirculation solenoids depend on vacuum valves to reduce harmful emissions.

-

Fuel Systems: Fuel pressure regulators use vacuum to maintain the correct fuel delivery.

-

HVAC Systems: Vacuum valves control airflow and temperature in heating and cooling systems.

Historically, vacuum systems in vehicles have powered various features, such as transmission shift controls, hidden headlamp doors, and power door locks. These advancements highlight the versatility and importance of vacuum valves in automotive technology.

How Do Vacuum Valves Function in an Engine?

The Role of Vacuum Pressure in Engine Operation

Vacuum pressure plays a vital role in the operation of your engine. During the intake stroke of a four-stroke engine, the piston moves downward, creating low pressure in the cylinder. This pressure difference allows atmospheric pressure to push air through the manifold and into the combustion chamber. This process ensures a consistent air-fuel mixture, which is essential for the internal combustion process.

Many systems in your vehicle rely on vacuum pressure to function effectively. For example:

-

The EGR valve uses vacuum pressure to recirculate exhaust gases, reducing emissions.

-

The PCV valve regulates harmful gases from the crankcase, maintaining engine performance.

-

The power brake booster enhances braking force by utilizing vacuum pressure.

-

The HVAC system uses vacuum control to switch between air distribution modes, improving comfort.

Without vacuum pressure, these systems would fail to operate, leading to reduced efficiency and performance.

Interaction Between Vacuum Valves and Other Engine Components

Vacuum valves work closely with other components to ensure your engine runs smoothly. The EGR valve, for instance, depends on vacuum control to redirect exhaust gases into the combustion chamber. This process reduces harmful emissions and improves efficiency. Similarly, the PCV valve uses vacuum pressure to remove gases from the crankcase, preventing buildup and maintaining proper valve timing.

The power brake booster also relies on vacuum pressure to amplify the force applied to the brake pedal. This interaction ensures effective braking. Additionally, the HVAC system uses vacuum valves to control airflow and temperature, enhancing your driving experience. These interactions highlight the importance of vacuum valves in supporting various engine systems.

Step-by-Step Process of Vacuum Valve Operation

Understanding how vacuum valves operate can help you appreciate their role in your engine. Here’s a simplified step-by-step process:

-

The engine generates vacuum pressure during the intake stroke.

-

This pressure activates the diaphragm inside the vacuum valve.

-

The diaphragm moves, allowing air to flow through the valve.

-

The spring inside the valve provides resistance, ensuring precise control.

-

The valve adjusts airflow based on the engine’s needs, maintaining efficiency.

This process ensures that the air-fuel mixture remains balanced, supporting the internal combustion process and overall engine performance.

Types of Vacuum Valves in Automotive Engines

PCV (Positive Crankcase Ventilation) Valves

The PCV valve plays a crucial role in maintaining your engine’s efficiency. It manages crankcase gases by controlling the flow of blow-by gases into the intake system. This process prevents excessive pressure buildup in the crankcase, which could damage seals or gaskets. At idle, the PCV valve restricts gas flow to avoid making the engine run too lean. When the engine operates under load or at higher RPM, the valve opens wider, allowing more gases to flow into the intake system. This adjustment ensures optimal performance.

Additionally, the PCV valve acts as a flame arrester, preventing potential explosions caused by backfires. It also stops positive pressure from the intake system from entering the crankcase, protecting vital components. By efficiently recycling crankcase gases, the PCV valve reduces emissions and supports the overall health of your engine.

EGR (Exhaust Gas Recirculation) Valves

The EGR valve helps your vehicle meet modern emission standards by reducing harmful nitrogen oxides (NOx). It recirculates a portion of the exhaust gases back into the engine’s intake system. This process dilutes the air-fuel mixture, lowering combustion temperatures by approximately 150°C. Lower temperatures reduce NOx formation, which is a significant contributor to air pollution.

Efficient operation of the EGR valve is essential for maintaining clean exhaust emissions. Without it, your engine would produce higher levels of pollutants. By controlling the flow of exhaust gases, the EGR valve ensures your vehicle remains environmentally friendly while maintaining performance.

Brake Booster Vacuum Valves

Brake booster vacuum valves are vital for your vehicle’s safety. These one-way valves ensure that air only flows out of the vacuum booster, preventing air from entering if the engine stops or a vacuum hose leaks. This design allows the vacuum booster to store enough pressure for several brake applications, even if the engine is off.

The vacuum booster amplifies the force you apply to the brake pedal, making it easier to stop your car. By utilizing vacuum pressure, this system ensures reliable braking performance. Whether you’re driving in traffic or on the highway, the brake booster vacuum valve provides peace of mind by enhancing your vehicle’s stopping power.

HVAC System Vacuum Valves

HVAC system vacuum valves play a key role in maintaining comfort inside your vehicle. These valves control the airflow within the cabin, ensuring you can adjust the temperature and ventilation to your liking. By using vacuum pressure, they regulate how air moves through the system, directing it to specific areas like the windshield, floor, or dashboard vents.

You might notice how your car’s HVAC system switches between different airflow modes. This happens because of vacuum control. The vacuum valves allow the system to alternate between defrost, floor, and dash vents. This mechanism ensures effective temperature regulation, keeping the cabin comfortable in all weather conditions. For example, during winter, the defrost mode clears your windshield by directing warm air to it. In summer, the dash vents provide cool air to keep you refreshed.

These valves work in harmony with the engine’s vacuum system. When you adjust the HVAC settings, the vacuum pressure changes, prompting the valves to open or close. This process ensures precise airflow control, enhancing your driving experience. Without these valves, the HVAC system would struggle to maintain consistent airflow, making it harder to achieve the desired cabin temperature.

Regular maintenance of the HVAC system, including its vacuum valves, ensures optimal performance. If you notice issues like inconsistent airflow or difficulty switching modes, the vacuum valves might need inspection. Addressing these problems promptly can prevent further complications and keep your vehicle’s HVAC system running smoothly.

Why Are Vacuum Valves Important for Engine Performance?

Enhancing Fuel Efficiency

Vacuum valves play a key role in improving your vehicle’s fuel efficiency. They regulate airflow and ensure the engine maintains an optimal air-fuel mixture. For example, the PCV valve removes harmful gases from the crankcase, while the vacuum system controls the flow of these gases. This process prevents energy loss and keeps the engine running efficiently. Similarly, the EGR valve recirculates a portion of the exhaust gases back into the combustion chamber. By doing so, it reduces the need for additional fuel during combustion, saving fuel and enhancing efficiency.

When these valves function correctly, they minimize wasted energy and ensure the engine operates at peak performance. Regular maintenance of the vacuum system ensures these components continue to support fuel efficiency effectively.

Supporting Emission Control Systems

Vacuum valves also contribute significantly to reducing harmful emissions. The EGR valve, for instance, lowers nitrogen oxide (NOx) emissions by recirculating exhaust gases into the intake system. This process reduces combustion temperatures, which helps decrease the formation of pollutants. The PCV valve also plays a vital role in emission control. It eliminates harmful gases from the crankcase and redirects them into the intake manifold for combustion.

By supporting these emission control systems, vacuum valves help your vehicle meet environmental standards. They ensure cleaner exhaust output, making your car more eco-friendly. Properly functioning valves not only protect the environment but also prevent potential fines for failing emissions tests.

Ensuring Smooth Engine Operation

Vacuum valves ensure your engine operates smoothly by maintaining the right balance of air and fuel. They regulate airflow into the intake manifold, which directly impacts combustion efficiency. For instance, the brake booster vacuum valve uses the vacuum system to amplify braking force, ensuring safe and reliable braking. Similarly, HVAC system vacuum valves control airflow within the cabin, enhancing your driving comfort.

When these valves malfunction, you may notice issues like rough idling, reduced power, or increased fuel consumption. Regular inspections and maintenance of the vacuum system can prevent these problems. Keeping the valves in good condition ensures your engine runs smoothly and delivers consistent performance.

Preventing Engine Damage Through Pressure Regulation

Vacuum valves play a critical role in protecting your engine from damage by regulating pressure. When pressure levels inside the engine become unbalanced, it can lead to serious problems like gasket failure, oil leaks, or even internal component damage. Vacuum valves help maintain the correct pressure, ensuring the engine operates safely and efficiently.

One of the key ways vacuum valves prevent damage is by controlling crankcase pressure. For example, the PCV valve removes excess gases from the crankcase, preventing pressure buildup that could harm seals and gaskets. This process not only protects the engine but also ensures smoother operation.

Tip: Regularly inspect your vacuum valves to catch potential issues early. A faulty valve can disrupt pressure regulation, leading to costly repairs.

Another important function of vacuum valves is to manage pressure in systems like the brake booster and EGR. The brake booster vacuum valve ensures consistent braking performance by maintaining the right pressure levels. Similarly, the EGR valve prevents excessive pressure in the exhaust system, reducing the risk of overheating or damage to exhaust components.

You can think of vacuum valves as the guardians of your engine’s pressure balance. Without them, the engine would struggle to handle the stresses of daily operation. By keeping these valves in good condition, you ensure your engine stays protected and performs at its best.

Common Issues and Maintenance Tips for Vacuum Valves

Identifying Signs of a Faulty Vacuum Valve

Faulty vacuum valves can cause several noticeable issues in your vehicle. You might experience a stiff or unresponsive brake pedal, which indicates a loss of brake power assist. Poor HVAC performance, such as inconsistent airflow or temperature control, is another common sign. Engine performance may also suffer, leading to rough idling or reduced power. Listen for unusual hissing sounds, as these often signal vacuum leaks. Additionally, a check engine light on your dashboard could point to a problem with the vacuum system.

Tip: Pay attention to these symptoms early. Addressing them promptly can prevent further damage to your engine and related systems.

Common Causes of Vacuum Valve Malfunction

Several factors can lead to vacuum valve malfunctions. Continuous exposure to heat, pressure, and vibration often causes wear and tear on internal components. Over time, this can compromise the valve’s functionality. Clogging and contamination are also frequent culprits. Dirt, debris, or moisture can obstruct the flow of vacuum or prevent the valve from closing properly. These issues reduce the efficiency of the intake and exhaust systems, affecting overall engine performance.

Note: Regular maintenance can help you avoid these common problems and keep your valves functioning effectively.

Maintenance Practices for Longevity and Performance

Proper maintenance ensures your vacuum valves perform well and last longer. Start by conducting regular inspections to check for signs of wear or damage. Functional tests can help you confirm that the valves operate correctly. Cleaning and lubricating the components, as recommended by the manufacturer, prevents debris buildup and ensures smooth operation.

For optimal performance, follow these additional steps:

-

Change the vacuum pump oil regularly to avoid contamination.

-

Monitor oil levels and quality to maintain efficiency.

-

Install a filtration system to keep the oil clean.

By following these practices, you can protect your engine and ensure the intake and exhaust systems work seamlessly.

Vacuum valves are vital for your engine’s performance and efficiency. They regulate airflow, ensuring the right air-fuel mixture for smooth operation. These valves also support emission control systems like the EGR and PCV valves, which reduce harmful gases and protect the environment. Additionally, they enhance braking power and improve climate control, making your driving experience safer and more comfortable.

Regular maintenance keeps these components functioning effectively. Inspecting and cleaning them prevents issues like vacuum leaks or pressure imbalances. By taking care of your vacuum valves, you ensure your engine runs efficiently and avoids costly repairs.

Share:

BMW M4 GT4 Compared to BMW M3 and M5 in 2025

Specifications and Features of the BMW S58B30T0 Engine