What Makes Carbon Fiber Resin Unique and Highly Versatile

You encounter materials every day, but few match the remarkable qualities of carbon fiber resin. This lightweight material combines exceptional strength with adaptability, making it a game-changer in modern technology. Its unique composition allows it to excel in high-performance applications where durability and efficiency are critical. Carbon fiber stands out because it offers unmatched versatility, meeting the demands of industries ranging from aerospace to sports. Whether you need strength or flexibility, this material delivers solutions that redefine innovation.

Key Takeaways

Carbon fiber resin is strong and lightweight, perfect for industries like aerospace and cars.

Its special makeup gives it heat stability, rust resistance, and durability, lasting a long time.

It allows flexible designs, helping makers create custom parts with less waste and better efficiency.

This material helps the planet by saving energy in transport and making products last longer, cutting pollution.

Carbon fiber resin is used in sports gear, green energy, and medical tools, boosting new ideas and performance.

Understanding Carbon Fiber Resin

What Is Carbon Fiber Resin

Carbon fiber resin is a composite material that combines carbon fibers with a polymer matrix. You might know it as carbon fiber reinforced polymer, or CFRP. This material stands out because it offers high strength and low weight. The resin binds the carbon fibers together, creating a structure that resists stress and deformation. You’ll find it used in applications where performance and durability are essential.

CFRP is not just a single material but a combination of components working together. The carbon fibers provide strength, while the resin ensures flexibility and stability. This synergy makes carbon fiber resin a preferred choice in industries requiring advanced materials.

Composition of Carbon Fiber Composites

Carbon fiber composites consist of two main elements: carbon fibers and a polymer matrix. The carbon fibers are thin strands of carbon atoms arranged in a crystalline structure. These fibers are incredibly strong and lightweight. The polymer matrix, often an epoxy resin, surrounds and supports the fibers. This combination creates a material that is both rigid and adaptable.

You’ll notice that fiber composites like CFRP are designed to maximize performance. The carbon fibers handle tensile forces, while the resin absorbs impacts and distributes stress. This balance ensures that carbon fiber materials perform well under demanding conditions.

How Carbon Fiber Resin Is Manufactured

The production of CFRP involves several steps. First, manufacturers create carbon fibers through a process called carbonization. This process involves heating organic precursors, such as polyacrylonitrile, to remove non-carbon elements. The result is strong, lightweight carbon fibers.

Next, these fibers are combined with a polymer resin. This step, known as carbon fiber manufacturing, involves layering the fibers in specific orientations to achieve desired properties. The resin is then cured, or hardened, to form a solid composite. This method allows you to customize the properties of fiber composites for specific applications.

Carbon fiber resin’s manufacturing process ensures precision and quality. It’s why this material is trusted in industries like aerospace, automotive, and renewable energy.

Key Properties of Carbon Fiber Resin

Strength-to-Weight Ratio

One of the most remarkable properties of carbon fiber resin is its high strength-to-weight ratio. This means it offers exceptional strength while remaining lightweight. You’ll find this property invaluable in applications where reducing weight without compromising durability is critical. For example, in aerospace and automotive industries, using CFRP allows engineers to design structures that are both strong and efficient.

The strength-to-weight ratio of carbon fiber materials surpasses that of metals like steel and aluminum. This advantage makes it ideal for creating components that need to withstand high stress while maintaining low mass. The mechanical properties of carbon fiber ensure that it performs well under tension and compression, making it a reliable choice for demanding environments.

Thermal Stability and Resistance

Carbon fiber resin exhibits excellent thermal stability and resistance. It can endure extreme temperatures without losing its structural integrity. This property makes it suitable for applications in industries like aerospace, where materials face high heat during operation.

You’ll notice that CFRP maintains its rigidity even in fluctuating thermal conditions. Unlike metals, which expand or contract significantly with temperature changes, carbon fiber composites remain stable. This stability ensures consistent performance and reduces the risk of material failure.

Additionally, the thermal resistance of carbon fiber resin protects it from damage caused by heat exposure. This feature enhances its durability and extends its lifespan, even in challenging environments.

Electrical Conductivity

Carbon fiber resin also offers unique electrical conductivity properties. While the polymer matrix itself is non-conductive, the carbon fibers within the composite provide a level of conductivity. This characteristic makes CFRP suitable for applications requiring electromagnetic shielding or static dissipation.

You’ll find this property particularly useful in industries like electronics and aerospace. For instance, carbon fiber materials can protect sensitive equipment from electromagnetic interference. The combination of electrical conductivity and other properties of carbon fiber, such as high impact resistance and rigidity, makes it a versatile material for advanced technological applications.

Corrosion and Fatigue Resistance

Carbon fiber resin offers exceptional resistance to corrosion and fatigue. Unlike metals, which often corrode when exposed to moisture or chemicals, fiber composites remain unaffected. This makes them ideal for environments where materials face constant exposure to harsh conditions. For example, you’ll find carbon fiber composites used in marine applications, where saltwater can quickly degrade traditional materials.

Fatigue resistance is another critical property of carbon fiber resin. Over time, repeated stress can weaken many materials, leading to cracks or failure. However, fiber composites maintain their structural integrity even under continuous load cycles. This durability ensures long-term performance, especially in industries like aerospace and automotive, where components endure constant stress.

You can rely on carbon fiber resin to deliver consistent results in challenging environments. Its ability to resist both corrosion and fatigue extends the lifespan of products, reducing maintenance costs and improving reliability. This makes it a preferred choice for engineers designing high-performance systems.

Design Flexibility in Fiber Composites

Fiber composites offer unmatched design flexibility. You can customize their properties by adjusting the orientation of the carbon fibers and the type of polymer matrix used. This allows you to create materials tailored to specific applications. For instance, you can design components with a high strength-to-weight ratio for aerospace or lightweight structures for sports equipment.

The manufacturing process of fiber composites also supports complex shapes and intricate designs. Unlike metals, which often require extensive machining, carbon fiber composites can be molded into precise forms. This reduces material waste and enhances efficiency.

You’ll notice that this flexibility opens up endless possibilities for innovation. Whether you’re developing advanced medical devices or renewable energy solutions, fiber composites provide the adaptability needed to meet unique challenges. Their ability to combine strength, lightweight properties, and customizability makes them a cornerstone of modern engineering.

Applications of Carbon Fiber Resin Across Industries

Aerospace and Aviation

You’ll find carbon fiber resin playing a vital role in aerospace and aviation. Its lightweight nature and exceptional strength make it ideal for building aircraft components. Engineers use carbon fiber composite parts to reduce the weight of airplanes, which improves fuel efficiency and reduces emissions. For example, wings, fuselages, and tail sections often rely on carbon fiber materials to handle the stresses of flight.

The thermal stability of carbon fiber composites ensures they perform well in extreme conditions. Aircraft face significant temperature changes during operation, and fiber composites maintain their integrity under these circumstances. Additionally, the corrosion resistance of CFRP makes it suitable for long-term use in harsh environments. These properties make carbon fiber applications essential for modern aviation.

Automotive and Transportation

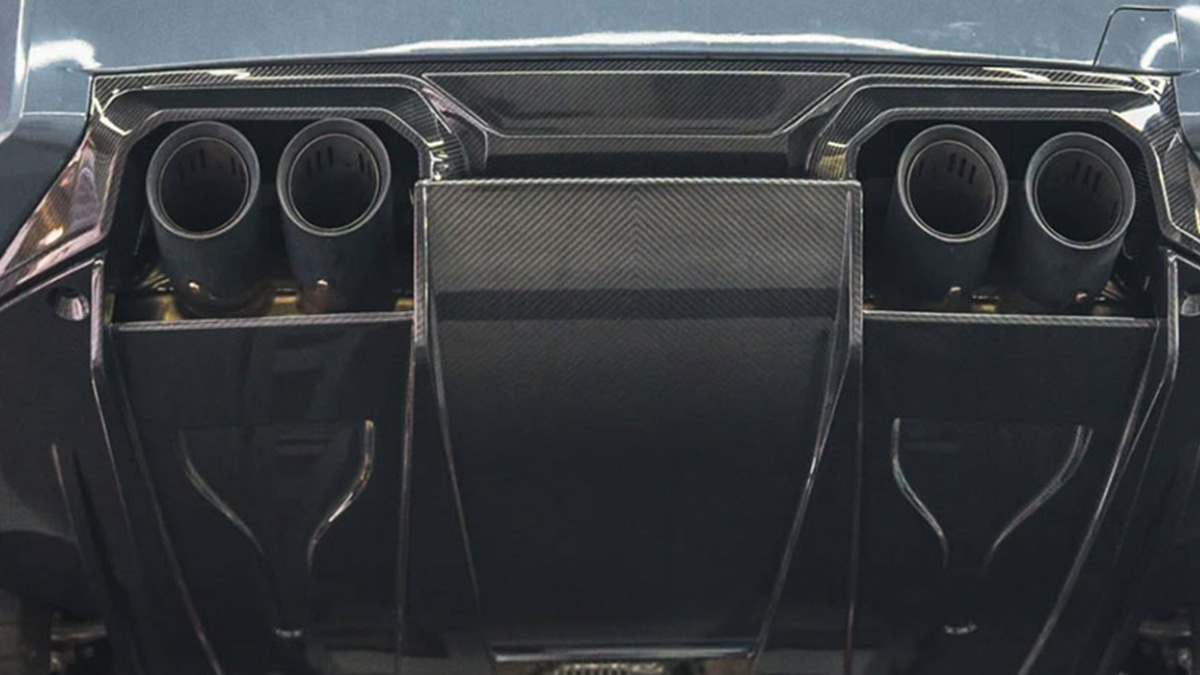

In the automotive industry, carbon fiber resin has revolutionized vehicle design. You’ll notice that manufacturers use carbon fiber composite parts to create lightweight yet durable structures. This reduces the overall weight of vehicles, enhancing fuel efficiency and performance. High-performance applications, such as sports cars and electric vehicles, benefit greatly from this material.

Carbon fiber composites also improve safety. Their high strength-to-weight ratio allows for the creation of impact-resistant components. For instance, crash structures and body panels made from CFRP can absorb energy effectively during collisions. This ensures better protection for passengers. The versatility of carbon fiber materials makes them a preferred choice for automotive innovation.

Sports and Recreation Equipment

Carbon fiber resin has transformed the world of sports and recreation. You’ll see it used in equipment like bicycles, tennis rackets, and golf clubs. Athletes prefer these products because they combine lightweight properties with exceptional strength. This allows for better performance and reduced fatigue during use.

Fiber composites also enable the creation of custom designs. Manufacturers can tailor the orientation of carbon fibers to meet specific performance needs. For example, a tennis racket can be designed to maximize power and control. The durability of carbon fiber composites ensures that sports equipment withstands rigorous use, making it a reliable choice for professionals and enthusiasts alike.

Renewable Energy Solutions

Carbon fiber plays a crucial role in advancing renewable energy technologies. You’ll see it used in wind turbines, where lightweight and strong materials are essential. The blades of wind turbines must endure high stress and harsh weather conditions. Carbon fiber ensures they remain durable while maintaining efficiency. Its high strength-to-weight ratio allows for longer blades, which capture more wind energy and improve power generation.

In solar energy, carbon fiber applications enhance the performance of photovoltaic systems. Lightweight carbon fiber structures support solar panels, making them easier to install and transport. This reduces costs and increases the accessibility of solar energy solutions. Additionally, the material’s corrosion resistance ensures long-term reliability, even in challenging outdoor environments.

Hydrogen storage tanks also benefit from carbon fiber. These tanks store hydrogen at high pressures, requiring materials that can handle extreme conditions. Carbon fiber composites provide the necessary strength while keeping the tanks lightweight. This makes hydrogen fuel cells more practical for transportation and energy storage.

You’ll notice that carbon fiber contributes to the efficiency and sustainability of renewable energy systems. Its unique properties make it indispensable for creating innovative solutions that address global energy challenges.

Medical and Industrial Applications

In the medical field, carbon fiber offers unmatched benefits. You’ll find it used in prosthetics, where its lightweight nature improves comfort and mobility for patients. Carbon fiber prosthetics are strong enough to support daily activities while remaining easy to wear. This enhances the quality of life for individuals relying on these devices.

Diagnostic imaging equipment also incorporates carbon fiber. Its radiolucent property allows X-rays to pass through without interference, producing clearer images. This improves the accuracy of medical diagnoses and treatments. Additionally, carbon fiber’s durability ensures that medical devices withstand repeated use, reducing maintenance costs.

In industrial applications, carbon fiber materials improve the performance of machinery and tools. You’ll see it used in robotic arms, where its lightweight and rigid structure enhances precision and speed. Carbon fiber also resists wear and tear, making it ideal for demanding environments. Its ability to handle stress and fatigue ensures long-lasting performance in industrial settings.

Whether in healthcare or manufacturing, carbon fiber applications deliver reliable and efficient solutions. Its versatility and strength make it a valuable material for advancing technology in these fields.

Advantages of Carbon Fiber Resin Over Other Materials

Comparison with Metals

When you compare carbon fiber resin to metals like steel or aluminum, the advantages become clear. Carbon fiber resin offers a high strength-to-weight ratio, which means it provides exceptional strength while remaining lightweight. This property makes it ideal for applications where reducing weight is critical, such as in aerospace or automotive industries.

Metals, while strong, often add unnecessary weight to structures. Carbon fiber resin allows you to achieve the same or greater strength without the bulk. Additionally, metals are prone to corrosion over time, especially in harsh environments. Carbon fiber resin resists corrosion, ensuring long-term durability and reliability.

You’ll also notice that carbon fiber composites offer greater design flexibility than metals. While metals require extensive machining to achieve complex shapes, carbon fiber can be molded into intricate designs with ease. This reduces waste and enhances efficiency in manufacturing processes.

Comparison with Plastics

Plastics are lightweight and versatile, but they lack the strength and durability of carbon fiber resin. When you need materials that can handle high stress or extreme conditions, carbon fiber resin outperforms traditional plastics. Its ability to combine lightweight properties with exceptional strength makes it a superior choice for demanding applications.

Plastics often degrade when exposed to heat, chemicals, or UV radiation. Carbon fiber resin, on the other hand, maintains its structural integrity in challenging environments. This makes it suitable for applications in industries like aerospace, renewable energy, and medical technology.

You’ll find that carbon fiber resin also offers better thermal stability than plastics. It can endure extreme temperatures without warping or breaking down. This ensures consistent performance and extends the lifespan of products made from this material.

Environmental and Sustainability Benefits

Carbon fiber resin contributes to sustainability in several ways. Its lightweight nature reduces energy consumption in transportation applications, such as vehicles and aircraft. By lowering fuel usage, it helps decrease greenhouse gas emissions.

The durability of carbon fiber resin also minimizes waste. Products made from this material last longer, reducing the need for frequent replacements. This extends the lifecycle of components and lowers the environmental impact of manufacturing.

You’ll see carbon fiber resin playing a role in renewable energy solutions as well. Its use in wind turbines and solar panel supports enhances the efficiency of these systems. By enabling cleaner energy production, carbon fiber resin supports global efforts to combat climate change.

Carbon fiber resin stands out as a material that combines strength, lightweight properties, and adaptability. You see its impact across industries, from aerospace to renewable energy, where it solves complex challenges with ease. Its ability to deliver high performance while remaining versatile highlights its importance in modern technology. As innovation advances, you can expect carbon fiber resin to play a key role in shaping the future of materials science. This material continues to redefine what’s possible, offering solutions that push the boundaries of engineering and design.