How Titanium Improves Automotive Performance with Lightweight Design

Titanium transforms the automotive industry by offering exceptional properties that enhance vehicle performance. Its lightweight properties reduce the overall weight of vehicles, improving speed and fuel efficiency. Titanium’s strength-to-weight ratio surpasses materials like steel and aluminum. It is 45% lighter than steel yet equally strong, and twice as strong as aluminum alloys while only 60% heavier. These advantages lead to significant fuel savings, ranging from $2.20 to over $8.50 per kilogram of weight saved, depending on the vehicle type. By combining strength with lightweight design, titanium ensures durability without compromising performance.

Key Takeaways

Titanium is light, helping cars go faster and use less fuel.

Lighter cars with titanium speed up quickly and handle better.

Titanium doesn’t rust, so parts last longer and need less fixing.

In electric cars, titanium helps batteries work better and go farther.

Titanium costs more at first but saves money over time by lasting longer and using less fuel.

Why Weight Matters in Automotive Performance

The Role of Weight in Speed and Efficiency

Weight plays a crucial role in determining how efficiently a vehicle performs. Heavier vehicles require more energy to operate, which directly impacts fuel efficiency. For example:

The U.S. Environmental Protection Agency (EPA) analyzed vehicles from model year 2023. It found that lighter cars achieved up to 65 mpg, while heavier SUVs and trucks managed only 12 mpg.

Cutting weight in vehicles improves fuel efficiency, making them more economical to operate.

Reducing weight also affects acceleration and top speed. Lighter vehicles accelerate faster because they face less inertia. However, at high speeds, aerodynamic drag becomes the dominant factor, making weight less significant. By reducing weight, you can enjoy better fuel efficiency and quicker acceleration, enhancing overall performance.

How Lightweight Materials Improve Handling and Safety

Lightweight materials like titanium improve handling by lowering a vehicle’s center of gravity. This makes the car more stable during sharp turns and sudden maneuvers. Safety also benefits from reducing weight. Studies show that lightweight materials save approximately 451 lives per billion miles traveled. Materials like fiber-reinforced composites absorb crash energy better than steel, creating safer vehicle structures.

Using lightweight materials in crumple zones can also prevent injuries during collisions. For example, less stiff materials like plastics absorb impact forces, protecting passengers. By reducing weight with advanced materials, you can achieve both better handling and improved safety.

Weight Reduction and Environmental Impact

Reducing weight in vehicles contributes significantly to environmental sustainability. Lighter vehicles consume less fuel, which lowers greenhouse gas emissions. Titanium, a popular material in the automotive industry, offers additional environmental benefits. Its natural resistance to corrosion eliminates the need for protective coatings, reducing waste. Titanium is also non-toxic and eco-friendly, making it an ideal choice for sustainable automotive manufacturing.

By cutting weight, you not only improve fuel efficiency but also reduce your carbon footprint. This shift toward lightweight materials like titanium supports a greener future for the automotive industry.

The Benefits of Titanium in Automotive Design

High Strength-to-Weight Ratio for Superior Performance

Titanium’s high strength-to-weight ratio makes it a game-changer in the automotive industry. This exceptional property allows you to reduce vehicle weight without compromising strength. Titanium components can endure extreme forces, making them ideal for structural parts that enhance crashworthiness. For example:

Titanium absorbs and distributes impact forces during collisions, improving passenger safety.

Its lightweight nature improves fuel efficiency and overall vehicle performance.

Additionally, titanium enables the creation of sleeker, more aerodynamic designs. These designs reduce drag and improve airflow, resulting in better fuel economy and a smoother driving experience. By using titanium, you can achieve superior performance while maintaining safety and efficiency.

Corrosion Resistance for Longevity

Titanium’s natural corrosion and rust resistance surpasses materials like stainless steel, especially in harsh environments. Unlike steel, which often requires protective coatings, titanium forms a natural oxide layer that acts as a barrier against oxidation. This makes it ideal for automotive components exposed to road salt, moisture, and other corrosive elements.

For example, titanium exhaust systems and fasteners last longer, reducing the need for frequent replacements. This durability not only lowers maintenance costs but also ensures reliability in critical applications. By choosing titanium, you benefit from components that withstand the test of time, even in challenging conditions.

Heat Resistance for High-Temperature Applications

Titanium’s heat resistance makes it invaluable for vehicles operating in extreme conditions. It maintains its strength and structural integrity across a wide temperature range, making it suitable for high-performance applications like racing vehicles. Titanium exhaust wraps, for instance, can endure temperatures up to 1800°F (982°C) without degrading. These wraps:

Reduce heat soak and lower engine bay temperatures.

Protect sensitive components from heat damage, extending their lifespan.

Improve exhaust gas velocity, enhancing engine performance and throttle response.

By incorporating titanium into high-temperature components, you ensure optimal performance and durability, even under the most demanding conditions.

Durability for Reduced Maintenance Costs

Titanium stands out in the automotive industry for its long-lasting durability, which directly reduces maintenance costs. Its ability to withstand daily wear and tear ensures that components remain reliable over time. Unlike traditional materials, titanium resists damage from environmental factors like moisture, road salt, and extreme temperatures. This resistance minimizes the need for frequent repairs or replacements, saving you both time and money.

Corrosion resistance is another key advantage of titanium. Components made from this material maintain their integrity even in harsh conditions. For example, titanium fasteners and exhaust systems last significantly longer than those made from steel. This longevity translates to fewer replacements, reducing overall maintenance expenses. By choosing titanium, you benefit from a material that keeps your vehicle running smoothly for years.

Although titanium has a higher upfront cost, its durability offers long-term savings. The reduced need for maintenance offsets the initial investment, making it a cost-effective choice for manufacturers and consumers alike. Additionally, titanium’s high strength-to-weight ratio allows for lighter components, which improve fuel efficiency. This dual benefit of durability and efficiency makes titanium a valuable asset in the automotive industry.

Key benefits of titanium’s durability include:

Lower maintenance costs due to reduced wear and tear.

Fewer replacements because of excellent corrosion resistance.

Enhanced fuel efficiency from lighter, stronger components.

By incorporating titanium into your vehicle, you gain a reliable material that delivers both performance and savings. Its durability ensures that your car remains efficient and dependable, even under demanding conditions.

Applications of Titanium in Automotive Components

Titanium Fasteners for Lightweight Strength

Titanium fasteners play a vital role in improving vehicle performance. These fasteners are 45% lighter than stainless steel, which significantly reduces the overall weight of a vehicle. This reduction enhances fuel efficiency and acceleration. Titanium fasteners also have one of the highest strength-to-weight ratios, allowing you to use less material without compromising strength. Their excellent fatigue resistance ensures durability, even in high-stress applications like suspension systems or engine components.

Titanium fasteners provide strength comparable to steel while being much lighter, improving fuel efficiency.

Their corrosion resistance makes them ideal for long-term use, reducing maintenance needs.

High-performance vehicles benefit from titanium fasteners through better acceleration and handling.

By incorporating titanium fasteners, you can achieve a balance of strength, durability, and lightweight design, making them indispensable in the automotive industry.

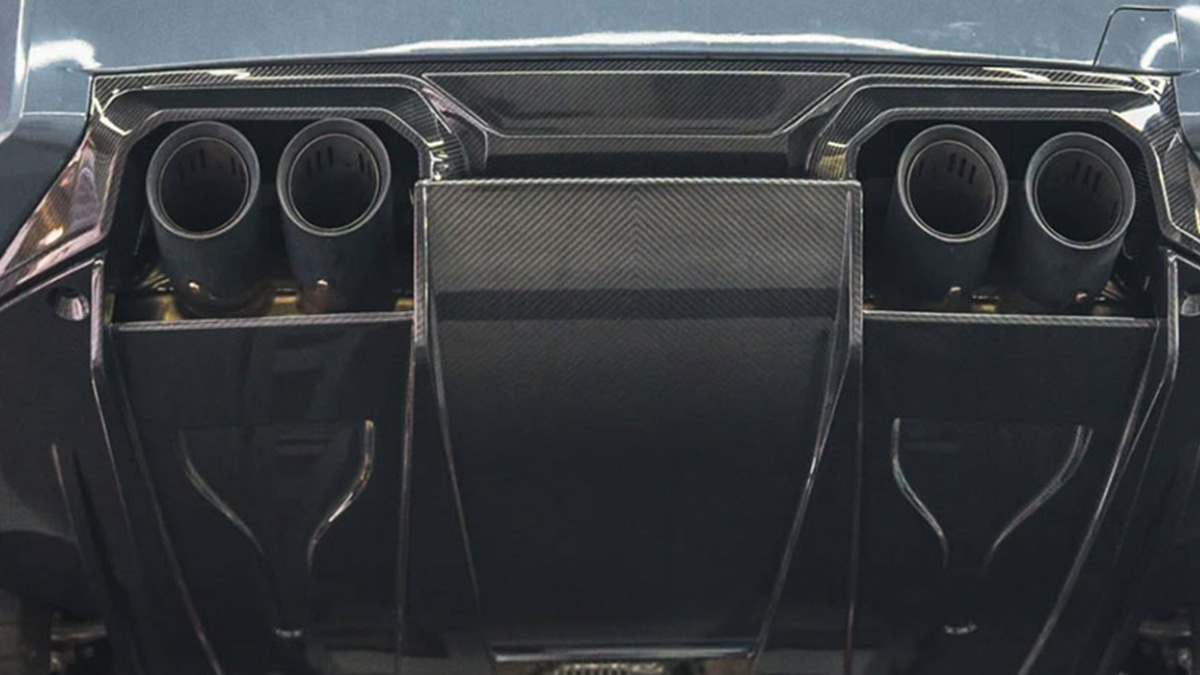

Titanium Exhaust Systems for Performance and Efficiency

Titanium exhaust systems offer unmatched benefits for modern vehicles. These systems are over 60% lighter than stainless steel, which improves both performance and fuel efficiency. Titanium’s corrosion resistance ensures that exhaust components last longer, even in harsh environments. Additionally, the thinner material used in titanium exhausts produces a refined sound, enhancing your driving experience.

Weight reduction improves vehicle dynamics and fuel efficiency.

Corrosion resistance ensures durability and reduces maintenance costs.

High strength-to-weight ratio allows for lightweight yet robust components.

Titanium’s heat resistance enhances safety and reliability in high-performance parts.

By choosing titanium exhaust systems, you gain a durable, efficient, and high-performing solution that elevates your vehicle’s capabilities.

Structural Components for Safety and Rigidity

Titanium’s exceptional strength and durability make it ideal for structural automotive components. Its high tensile strength allows parts to withstand extreme forces without deforming, enhancing crashworthiness. Titanium components absorb and distribute impact forces, improving safety for passengers. The material’s corrosion resistance ensures that safety features remain effective over time, while its heat resistance maintains structural integrity under extreme conditions.

Titanium’s strength contributes to the rigidity of automotive components.

Structural parts made from titanium enhance crash safety by absorbing impact forces.

Durability reduces maintenance costs and increases reliability.

By using titanium in structural components, you ensure a safer and more reliable vehicle, capable of withstanding demanding conditions.

Emerging Uses in Electric Vehicles (EVs)

Titanium is becoming a cornerstone material in the evolution of electric vehicles (EVs). Its unique properties, such as lightweight strength, heat resistance, and corrosion resistance, make it indispensable for improving EV performance and safety.

One of the most exciting applications of titanium is in EV batteries. Lithium-titanium anodes enable faster charging and discharging, addressing one of the biggest challenges in EV adoption—charging time. This innovation not only enhances convenience but also improves battery efficiency and lifespan. Additionally, titanium is used in battery enclosures, providing impact protection while reducing overall vehicle weight. This weight reduction translates to better energy efficiency and extended driving range.

🚗 Did you know? Tesla vehicles feature a titanium underbody shield. This component enhances safety by protecting the battery pack from potential damage and reducing the risk of fires.

Titanium also plays a role in electric motors. Lightweight titanium components improve motor performance by reducing rotational inertia, which leads to quicker acceleration and smoother operation. Its heat resistance ensures that motors and other high-temperature components remain efficient and safe under demanding conditions.

As the automotive industry shifts toward sustainable solutions, the demand for titanium continues to grow. Its corrosion resistance extends the lifespan of EV components, reducing waste and environmental impact. By incorporating titanium, manufacturers can create lighter, more aerodynamic vehicles that meet stringent environmental regulations while delivering superior performance.

The future of EVs relies on materials that balance strength, weight, and sustainability. Titanium stands out as a material that meets these demands, paving the way for safer, more efficient, and environmentally friendly electric vehicles.

Challenges of Using Titanium in Automotive Design

High Costs of Material and Manufacturing

Titanium’s high cost remains one of the biggest challenges in automotive design. As a raw material, titanium is significantly more expensive than alternatives like steel or aluminum. Manufacturing titanium components also requires specialized equipment and expertise, which adds to the expense. For example:

Controlled atmospheres are necessary during welding and heat treatment to maintain titanium’s properties.

The complexity of the manufacturing process increases production costs.

Repairs and maintenance can be more challenging compared to traditional materials.

These factors make titanium a costly choice, limiting its use to high-performance or luxury vehicles. However, advancements in technology, such as additive manufacturing, are helping reduce waste and improve production efficiency, making titanium more accessible over time.

Limited Availability and Sourcing Issues

The limited availability of titanium further complicates its adoption in the automotive industry. In 2018, the production cost of titanium was approximately $4,800 USD per metric ton, making it a premium material. This high cost restricts its use primarily to racing cars and high-end models, where performance benefits outweigh economic concerns.

Note: Despite its lightweight strength and durability, titanium’s expense prevents widespread use in mass-market vehicles.

Manufacturers face additional challenges in sourcing titanium due to its limited supply chain. These constraints highlight the need for innovation in production methods to make titanium more affordable and widely available.

Balancing Cost with Performance Benefits

To balance titanium’s cost with its performance advantages, manufacturers are exploring innovative strategies. These include:

Using titanium composite plates to combine titanium with other metals, reducing costs while maintaining strength.

Optimizing designs to minimize material usage without sacrificing durability.

Adopting additive manufacturing to create complex parts with less waste.

Other approaches involve developing lower-cost titanium alloys and improving wear resistance through advanced treatments. These innovations aim to make titanium a viable option for a broader range of vehicles. By reducing costs and enhancing efficiency, manufacturers can unlock titanium’s full potential in automotive design.

Titanium has revolutionized automotive design with its lightweight and durable properties. By reducing weight, it enhances vehicle performance, including speed, fuel efficiency, and safety. Its corrosion resistance and eco-friendly characteristics align with global sustainability goals. Over the next decade, the demand for titanium will grow due to its role in creating sleeker, more aerodynamic vehicles and improving safety standards. The shift toward electric and hybrid vehicles further highlights titanium’s importance in lightweight design. Despite challenges like cost, advancements in technology will make titanium more accessible, ensuring its pivotal role in the future of high-performance automotive innovation.