Exploring Carbon Composite Properties in 2025

Carbon composites represent a breakthrough in material science. These materials combine carbon fibers with a matrix to create a lightweight yet strong structure. You encounter their impact in industries like aerospace, automotive, and renewable energy. Their ability to deliver high performance while reducing weight makes them essential for modern engineering. By 2025, carbon composites have become a cornerstone of innovation, driving efficiency and sustainability across various fields. Their adaptability ensures they meet the demands of cutting-edge technologies.

Key Takeaways

Carbon composites are light and strong, great for planes and cars.

Using them in vehicles saves energy and cuts fuel use.

These materials are tough and don’t wear out quickly.

They can be shaped for different uses, helping create new designs.

Making and recycling them in eco-friendly ways helps the planet.

Key Properties of Carbon Composites

Lightweight and Strength

High strength-to-weight ratio

Carbon fiber stands out as a high-performing composite material due to its exceptional strength-to-weight ratio. You get a material that is both incredibly strong and remarkably light. This property makes carbon composites ideal for applications where reducing weight is critical without compromising durability. For example, carbon fiber composites are widely used in aerospace and automotive industries to create lightweight components that can withstand significant stress.

Energy efficiency benefits in transportation

When you use carbon composites in transportation, you achieve greater energy efficiency. Lightweight components reduce the energy required for movement, whether in cars, airplanes, or trains. This translates to lower fuel consumption and reduced emissions. Carbon fiber’s tensile strength ensures that these materials maintain their integrity even under heavy loads, making them a reliable choice for modern transportation systems.

Durability and Resistance

Long-lasting performance with minimal wear

Carbon composites deliver long-lasting performance. Their resistance to wear and tear ensures that you won’t need frequent replacements, saving both time and resources. This durability makes them a preferred choice for industries that demand high-performing materials capable of enduring harsh conditions.

Resistance to extreme temperatures and chemicals

Carbon fiber composites excel in extreme environments. They resist high temperatures and exposure to chemicals, maintaining their structural integrity. Whether you’re designing for aerospace, automotive, or industrial applications, you can rely on these materials to perform consistently under challenging conditions.

Versatility in Design

Customizable for diverse applications

Carbon composites offer unmatched versatility. You can customize them to meet specific design requirements, whether for intricate shapes or unique structural needs. This adaptability makes them suitable for a wide range of industries, from renewable energy to sports equipment.

Compatibility with other materials

Carbon fiber integrates seamlessly with other materials. You can combine it with metals, plastics, or ceramics to create hybrid structures that leverage the strengths of each component. This compatibility expands the possibilities for innovation, allowing you to develop solutions tailored to complex engineering challenges.

Advancements in Carbon Composite Technology by 2025

Innovations in Manufacturing

Faster, cost-effective production methods

By 2025, manufacturing processes for carbon fiber have become faster and more affordable. You now see advanced techniques that reduce production time while maintaining quality. These methods allow industries to scale up production without increasing costs. For example, automated weaving and molding processes ensure consistent results, making carbon composite materials more accessible for various applications.

Integration of AI and automation in fabrication

Artificial intelligence and automation play a significant role in fabricating carbon fiber components. AI-driven systems analyze designs and optimize production steps, reducing waste and improving efficiency. Automated machinery ensures precision during manufacturing, which enhances the performance of the final product. You benefit from these advancements through higher-quality materials and shorter production cycles.

Enhanced Material Properties

Development of stronger, lighter carbon fibers

The development of high-strength carbon fibers has revolutionized material science. These fibers are now lighter and stronger than ever before. You can rely on them to create structures that withstand immense stress while reducing overall weight. This advancement opens new possibilities for industries like aerospace and automotive, where performance and efficiency are critical.

Improved bonding and durability in matrix materials

Matrix materials in carbon composites have also seen significant improvements. Enhanced bonding techniques ensure that the carbon fiber and matrix work together seamlessly. This results in materials with greater durability and resistance to wear. You can trust these composites to perform reliably in demanding environments, from high-speed vehicles to industrial machinery.

Sustainability and Recycling

Eco-friendly production techniques

Sustainability has become a priority in carbon composite production. Manufacturers now use eco-friendly methods that minimize environmental impact. For instance, renewable energy powers many production facilities, and waste materials are repurposed whenever possible. These practices help you contribute to a greener future while benefiting from advanced materials.

Advances in recycling to reduce environmental impact

Recycling technology for carbon fiber has made significant strides. You can now recycle used composites into new materials without compromising quality. This reduces waste and conserves resources, making carbon composites a more sustainable choice. These advancements align with global efforts to create a circular economy and reduce carbon footprints.

Applications of Carbon Composites in Modern Industries

Aerospace and Aviation

Lightweight structures for fuel efficiency

You see carbon fiber revolutionizing aerospace engineering. Its lightweight nature reduces the overall weight of aircraft, leading to significant fuel savings. This efficiency not only lowers operational costs but also minimizes environmental impact. Carbon composites allow engineers to design lighter airframes and components without sacrificing strength or safety. As a result, modern aircraft achieve better performance and longer flight ranges.

Use in spacecraft and satellite components

Carbon fiber plays a critical role in spacecraft and satellite construction. Its high strength-to-weight ratio ensures that these structures can withstand the extreme conditions of space. You benefit from its durability and resistance to temperature fluctuations, which are essential for long-term missions. Carbon composites also help reduce launch weight, making space exploration more cost-effective and sustainable.

Automotive Sector

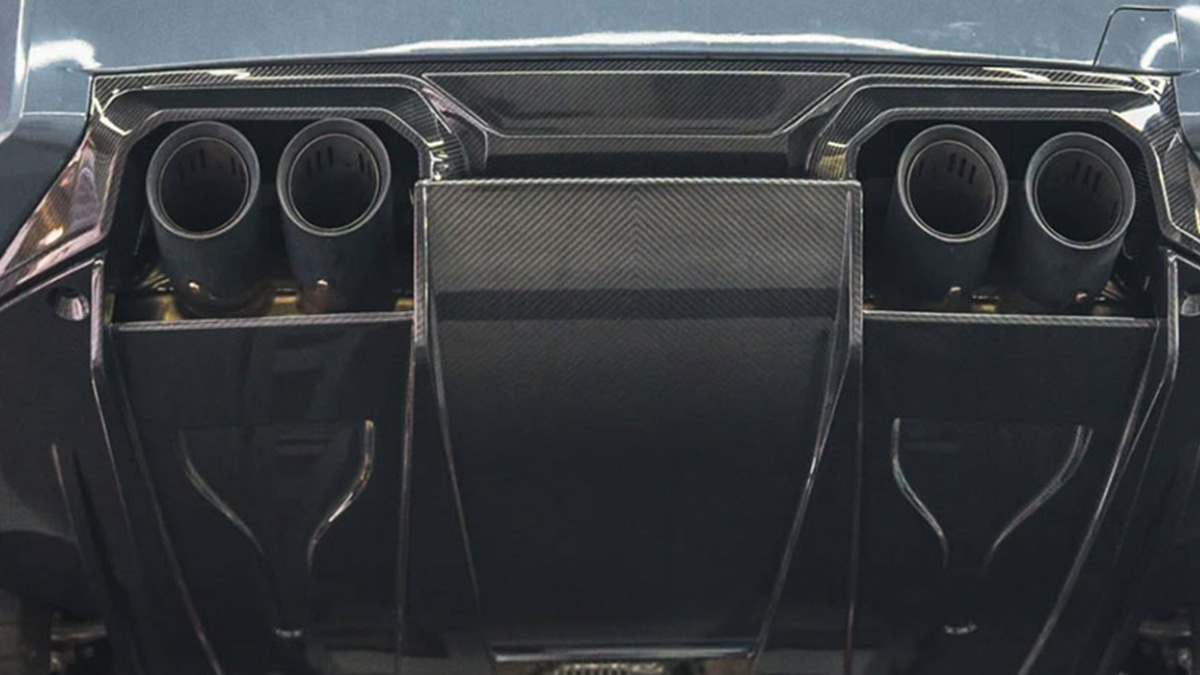

Materials for electric and hybrid vehicles

In automotive design, carbon fiber has become a game-changer. It helps reduce the weight of electric and hybrid vehicles, improving energy efficiency and extending battery life. You can see its application in body panels, chassis, and other structural components. This innovation supports the growing demand for eco-friendly transportation solutions.

Enhanced safety and performance in high-end cars

Carbon composites enhance both safety and performance in high-performance vehicles. Their strength absorbs impact energy during collisions, protecting passengers. At the same time, their lightweight properties improve acceleration, handling, and fuel efficiency. You find these materials in sports cars and luxury vehicles, where precision and reliability are paramount.

Defense and Military

Lightweight armor and protective gear

In aerospace and defense, carbon fiber is essential for creating lightweight armor and protective gear. Soldiers benefit from its ability to provide high levels of protection without adding unnecessary weight. Helmets, vests, and shields made from carbon composites offer durability and comfort in demanding environments.

Applications in drones and advanced weaponry

Carbon composites are integral to modern military technology. You see them in drones, where their lightweight properties enhance flight performance and maneuverability. They are also used in advanced weaponry, offering strength and precision. These materials ensure that military equipment remains reliable and effective in critical situations.

Emerging Applications

Renewable energy, such as wind turbine blades

You see carbon fiber transforming renewable energy systems, especially in wind turbines. Wind turbine blades made from carbon fiber are lighter and stronger than traditional materials. This allows turbines to capture more wind energy while reducing mechanical stress. The lightweight nature of carbon fiber also makes transportation and installation easier, saving time and resources.

Tip: Lighter blades mean less wear on turbine components, leading to lower maintenance costs and longer operational lifespans.

In offshore wind farms, carbon fiber blades withstand harsh marine environments. Their resistance to corrosion and fatigue ensures reliable performance even under extreme conditions. By using these advanced materials, you contribute to a cleaner and more sustainable energy future.

Use in sports equipment and medical devices

Carbon fiber has revolutionized sports equipment. You find it in bicycles, tennis rackets, and golf clubs, where its lightweight and durable properties enhance performance. Athletes benefit from gear that is easier to handle and more resistant to wear. For example, carbon fiber bicycles provide better speed and control, giving you a competitive edge.

In the medical field, carbon fiber plays a critical role in creating advanced devices. Prosthetics made from this material are lightweight and strong, offering greater comfort and mobility. Surgical instruments and imaging equipment also use carbon fiber for its precision and non-magnetic properties. These innovations improve patient outcomes and make medical procedures more efficient.

Note: Carbon fiber’s versatility ensures its continued growth in both sports and healthcare applications.

By 2025, you witness carbon composites redefining material science. Their lightweight strength, durability, and design flexibility make them indispensable across industries. Advancements in manufacturing, material properties, and sustainability further enhance their appeal. These innovations drive efficiency, reduce environmental impact, and open doors to groundbreaking applications.

Looking ahead, you can expect even greater possibilities. Emerging technologies will likely refine these materials, unlocking new uses in fields like renewable energy and healthcare. As industries evolve, carbon composites will continue to shape a future of innovation and sustainability.