Understanding Chopped Carbon Fiber and Its Applications

Chopped carbon fiber consists of short, cut fibers made from carbon. These fibers combine exceptional strength with a lightweight structure, making them a game-changer in material science. You can find it in products where durability and performance matter most. Its unique properties allow engineers to create innovative solutions for challenges in industries like aerospace, automotive, and construction. By using chopped carbon fiber, manufacturers achieve stronger, lighter, and more efficient designs, paving the way for groundbreaking advancements.

Principales conclusiones

Chopped carbon fiber is light but strong and bendable, perfect for many uses.

It makes products last longer and work better, especially in cars, planes, and buildings.

This material is cheap and simple to use, helping companies make good parts without costly tools.

Its special features, like resisting chemicals and handling heat, help create new ideas in electronics and tech.

Using chopped carbon fiber helps the planet by recycling and saving energy during production.

¿Qué es la fibra de carbono cortada?

Definición y características

Chopped carbon fiber refers to short, cut strands of carbon fiber. These strands, also known as carbon fiber chopped strands, are typically a few millimeters long. They retain the strength and lightweight properties of continuous carbon fibers but offer greater flexibility in manufacturing. You’ll find that this material is often used in composites to enhance strength, durability, and performance.

One key characteristic of carbon fiber chopped short is its ability to blend seamlessly with other materials. This makes it ideal for creating carbon fiber composite materials. These composites are lightweight yet strong, making them suitable for demanding applications. Additionally, chopped carbon fiber material provides excellent resistance to wear, heat, and chemicals, ensuring long-lasting performance.

Consejo: Chopped carbon fiber is perfect for applications where you need strength and versatility without the complexity of continuous fibers.

Carbon Fiber Chopped Short vs. Continuous Carbon Fiber

When comparing carbon fiber chopped short to continuous carbon fiber, the differences lie in their structure and applications. Continuous carbon fibers are long, unbroken strands that provide maximum strength in one direction. They are often used in aerospace and high-performance sports equipment.

In contrast, carbon fiber chopped strands are shorter and more versatile. They can be mixed into resins, plastics, or other materials to create composites. This allows you to mold them into complex shapes or use them in areas where continuous fibers might not fit. While continuous fibers excel in specific, high-strength applications, chopped carbon fiber material offers a balance of strength, flexibility, and cost-effectiveness.

How Chopped Carbon Fiber is Made

The chopped carbon fiber manufacturing process begins with continuous carbon fibers. These fibers undergo cutting into short lengths, typically ranging from 3 to 50 millimeters. The process ensures that the carbon fiber chopped strands maintain their structural integrity.

Manufacturers often use specialized machines to cut the fibers precisely. The chopped carbon fiber manufacturing process may also involve coating the strands with a resin or binder. This step improves their compatibility with other materials during composite production. The result is a versatile material that can be used in various industries, from automotive to construction.

Nota: The carbon fiber manufacturing process for chopped fibers is efficient and scalable, making it accessible for a wide range of applications.

Propiedades únicas de la fibra de carbono cortada

Relación resistencia/peso

One of the most remarkable features of chopped carbon fiber is its strength-to-weight ratio. This material combines high tensile strength with a lightweight structure, making it ideal for applications where reducing weight is critical. For example, you can use it to create lightweight automotive parts that improve fuel efficiency without compromising durability. The strength-to-weight ratio of chopped carbon fiber allows you to design products that are both strong and easy to handle. This property makes it a preferred choice in industries like aerospace, where every ounce matters.

Durability and Wear Resistance

Chopped carbon fiber offers excellent durability and wear resistance. Its structure resists damage from repeated use, making it suitable for high-stress environments. You’ll find this material in products that need to withstand harsh conditions, such as construction tools or industrial components. Unlike traditional materials, chopped carbon fiber maintains its integrity over time, even when exposed to friction or impact. This durability ensures that your products last longer and perform better, reducing the need for frequent replacements.

Conductividad térmica y eléctrica

Another unique property of chopped carbon fiber is its ability to conduct heat and electricity. This makes it a valuable material in electronics and technology. You can use it to dissipate heat in devices, preventing overheating and improving performance. Additionally, its electrical conductivity allows it to function as a component in advanced circuits. These properties open up opportunities for innovation in fields like renewable energy and smart devices. By incorporating chopped carbon fiber, you can create efficient, high-performing solutions for modern challenges.

Consejo: Understanding the unique properties of chopped carbon fiber helps you choose the right material for your project, ensuring optimal performance and longevity.

Chemical Resistance and Versatility

Chopped carbon fiber stands out for its impressive chemical resistance. This property makes it an excellent choice for environments where materials face exposure to harsh chemicals or corrosive substances. You can rely on it to maintain its structural integrity even when used in challenging conditions. Unlike traditional materials that may degrade or weaken over time, chopped carbon fiber resists chemical reactions, ensuring long-lasting performance.

This chemical resistance opens up a wide range of applications. For example, you can use it in construction projects where materials often encounter moisture, salt, or industrial chemicals. It also works well in manufacturing equipment that handles corrosive substances, such as chemical tanks or pipelines. By choosing chopped carbon fiber, you ensure that your products remain durable and reliable, even in extreme environments.

Versatility is another key advantage of chopped carbon fiber. Its ability to blend with various materials allows you to create customized composites for specific needs. Whether you need lightweight components for aerospace or durable reinforcements for construction, this material adapts to your requirements. You can mold it into complex shapes or combine it with resins, plastics, or metals to enhance performance. This flexibility makes it a go-to material across multiple industries.

Consejo: When selecting materials for projects involving harsh environments, consider chopped carbon fiber for its unmatched chemical resistance and adaptability. It offers a practical solution for creating durable, high-performing products.

By understanding the chemical resistance and versatility of chopped carbon fiber, you can make informed decisions for your projects. This material not only withstands tough conditions but also provides the flexibility to innovate and meet diverse challenges.

Aplicaciones de la fibra de carbono cortada

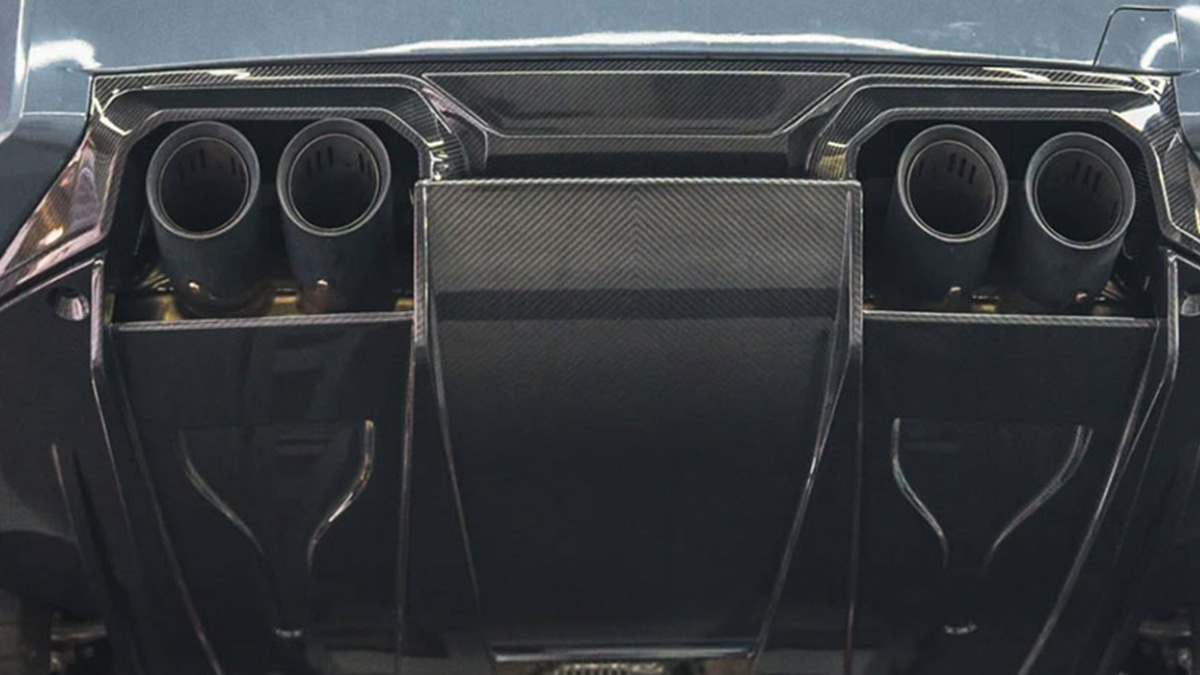

Chopped Carbon Fiber in Automotive

Lightweight Components for Fuel Efficiency

Chopped carbon fiber in automotive manufacturing plays a crucial role in creating lightweight body parts. You can find it in components like panels, hoods, and doors. These parts reduce the overall weight of the automobile, leading to better fuel efficiency. By using chopped carbon fiber reinforced plastics, manufacturers achieve a balance between strength and weight. This high-performance material ensures that vehicles remain durable while consuming less fuel. Lightweight designs also improve handling and acceleration, enhancing the driving experience.

High-Performance and Durable Parts

Automobile manufacturing benefits greatly from the durability of chopped carbon fiber reinforced plastics. You’ll see it used in engine components, brake systems, and structural reinforcements. These parts withstand high stress and extreme conditions, ensuring long-lasting performance. The material’s wear resistance makes it ideal for automotive applications where reliability is critical. By incorporating chopped carbon fiber, manufacturers achieve significant performance improvement in both safety and durability.

Chopped Carbon Fiber in Aerospace

Reinforcement in Flight Control Surfaces

The aerospace industry relies on chopped carbon fiber reinforcement for critical components. You can find it in flight control surfaces like ailerons and rudders. These parts require exceptional strength to handle aerodynamic forces. Chopped carbon fiber reinforced plastics provide the necessary rigidity while keeping the weight low. This ensures that aircraft maintain stability and control during flight.

Weight Reduction for Aircraft Efficiency

Weight reduction is a top priority in the construction of airplanes. Chopped carbon fiber offers a solution by replacing heavier materials in non-structural components. You’ll see it used in interior panels, seat frames, and other lightweight parts. This material reduces the overall weight of the aircraft, improving fuel efficiency and reducing emissions. Its versatility makes it a valuable asset in aerospace engineering.

Chopped Carbon Fiber in Construction

Reinforcement in Concrete and Composites

Chopped carbon fiber in construction enhances the strength of concrete and composite materials. You can use it to reinforce concrete structures, increasing their load-bearing capacity. This application is particularly useful in bridges, buildings, and other infrastructure projects. The material’s ability to blend with resins and other binders allows for customized solutions in the construction industry.

Resistencia a la corrosión en entornos agresivos

Chopped carbon fiber reinforced plastics offer excellent corrosion resistance, making them ideal for harsh environments. You’ll find them used in pipelines, chemical tanks, and marine structures. Unlike traditional materials, they resist degradation from moisture, salt, and chemicals. This ensures long-lasting performance and reduces maintenance costs in challenging conditions.

Deportes y ocio

High-Performance Equipment and Gear

Chopped carbon fiber in sporting goods has revolutionized the way you experience sports. This material enhances the performance of equipment like tennis rackets, bicycles, and golf clubs. Its lightweight nature allows you to handle gear with ease, while its strength ensures durability during intense use. For example, a tennis racket reinforced with chopped carbon fiber offers better control and power, giving you an edge on the court. Similarly, bicycles made with this material provide a smoother ride and improved speed.

You’ll also find chopped carbon fiber in protective gear such as helmets and pads. These items need to withstand high impacts while remaining comfortable to wear. The material’s wear resistance ensures that your gear lasts longer, even under tough conditions. By choosing equipment made with chopped carbon fiber, you gain high-performance tools that help you excel in your sport.

Lightweight and Durable Solutions for Athletes

Athletes benefit greatly from the lightweight and durable properties of chopped carbon fiber. This material reduces the weight of sports gear, allowing you to move faster and perform better. For instance, running shoes with carbon fiber components feel lighter on your feet, helping you conserve energy during long races. At the same time, the material’s strength ensures that your gear remains reliable, even after repeated use.

In addition, chopped carbon fiber adapts to various sports applications. Whether you’re a cyclist, runner, or skier, you’ll find that this material enhances your performance. Its versatility makes it a favorite among athletes seeking durable and efficient solutions.

Electrónica y tecnología

Heat Dissipation in Devices

Chopped carbon fiber plays a crucial role in managing heat in electronic devices. Its thermal conductivity helps dissipate heat efficiently, preventing your gadgets from overheating. You’ll find this material in components like heat sinks and cooling systems. For example, laptops and smartphones use chopped carbon fiber to maintain optimal temperatures during operation. This ensures that your devices perform better and last longer.

By incorporating chopped carbon fiber, manufacturers create electronics that handle high-performance tasks without compromising reliability. This innovation benefits you by providing gadgets that stay cool and function smoothly.

Conductive Components in Advanced Circuits

The electrical conductivity of chopped carbon fiber makes it ideal for advanced circuits. You’ll see it used in components like circuit boards and connectors. Its ability to conduct electricity ensures efficient energy transfer, improving the performance of your devices. For instance, renewable energy systems often rely on chopped carbon fiber for its conductive properties.

This material also supports innovation in emerging technologies. From smart devices to electric vehicles, chopped carbon fiber enables the development of efficient and reliable solutions. By using this material, manufacturers meet the growing demand for high-performing electronics.

Benefits of Using Chopped Carbon Fiber

Cost-Effectiveness and Accessibility

Chopped carbon fiber offers a cost-effective solution for industries seeking high-performance materials. Its production process is more affordable compared to continuous carbon fibers, making it accessible for a wider range of applications. You can use it to create durable and lightweight components without exceeding your budget. This affordability allows small and medium-sized businesses to adopt advanced materials that were once limited to high-end industries.

Another advantage is its compatibility with existing manufacturing processes. You don’t need expensive equipment or specialized tools to work with chopped carbon fiber. It blends easily with resins, plastics, and other materials, simplifying production. This accessibility ensures that you can integrate it into your projects without significant changes to your workflow.

Consejo: If you’re looking for a material that balances performance and cost, chopped carbon fiber is an excellent choice.

Versatility Across Multiple Industries

The versatility of chopped carbon fiber makes it a valuable resource across various industries. You can find it in automotive, aerospace, construction, sports, and electronics. Its ability to adapt to different applications allows you to create customized solutions for specific needs. For example, you can use it to reinforce concrete in construction or improve heat dissipation in electronic devices.

This material also works well in both large-scale manufacturing and small, specialized projects. Whether you’re designing lightweight car parts or high-performance sports gear, chopped carbon fiber delivers consistent results. Its adaptability ensures that you can meet the unique demands of your industry while maintaining quality and efficiency.

Sustainability and Recycling Potential

Chopped carbon fiber contributes to sustainability by reducing waste and promoting recycling. Many manufacturers use recycled carbon fibers to produce chopped strands, minimizing the environmental impact. You can choose this material to support eco-friendly practices in your projects.

Its lightweight nature also helps reduce energy consumption in industries like automotive and aerospace. Vehicles and aircraft made with chopped carbon fiber require less fuel, lowering emissions. This makes it a sustainable option for businesses aiming to reduce their carbon footprint.

Recycling potential is another key benefit. You can recover and reuse chopped carbon fiber from old composites, extending its lifecycle. This reduces the need for raw materials and supports a circular economy. By incorporating this material, you contribute to a more sustainable future.

Chopped carbon fiber offers a unique combination of strength, durability, and lightweight properties. You can use it across industries like automotive, aerospace, and construction to create innovative solutions. Its versatility allows you to mold it into various forms, making it suitable for countless applications. This material plays a key role in addressing modern challenges by enabling the production of efficient, high-performing products. Whether you aim to reduce weight, improve durability, or enhance sustainability, chopped carbon fiber provides a reliable and adaptable option.