Why Carbon Reinforced Nylon is a Game-Changer for Industry

You need strong, reliable materials to create durable and precise prototypes. Carbon reinforced nylon offers unmatched strength and thermal stability. This advanced material combines the versatility of nylon with the performance of carbon fibers. It delivers lightweight yet robust solutions for industrial applications. You can rely on its dimensional stability to maintain accuracy during functional testing. Its unique properties make it a superior choice for industries seeking innovative prototyping solutions.

Principales conclusiones

Carbon reinforced nylon mixes strong carbon fibers with flexible nylon. It is great for tough and accurate prototypes.

This material is strong but light, helping industries like aerospace and cars make lighter parts without losing strength.

Carbon reinforced nylon works well in tough conditions. It resists heat and chemicals, making it dependable for hard jobs.

Using carbon reinforced nylon with SLS 3D printing saves material and money. It makes prototyping cheaper and easier.

The material stays stable and doesn’t warp much. This helps create detailed shapes with great accuracy, improving design options.

Understanding Carbon Reinforced Nylon

Composición y estructura

Nylon as a versatile base material

Nylon serves as the foundation for carbon-fiber-reinforced nylon. You may already know nylon as a lightweight, flexible, and durable material. It offers excellent wear resistance and high impact resistance, making it ideal for industrial applications. Its adaptability allows it to combine with other materials, such as carbon fibers, to create high-performance filament solutions. This combination enhances its properties, making it suitable for demanding environments.

Carbon fibers for enhanced performance

Carbon fibers are the key to transforming standard nylon into carbon-fiber-reinforced nylon. These fibers provide high stiffness and high tensile strength, which significantly improve the material’s mechanical properties. By integrating carbon fiber filament into nylon, you get a composite material with superior strength and stiffness. This makes it perfect for applications requiring high performance and durability. Carbon fibers also contribute to the material’s lightweight nature, ensuring it remains easy to handle and process.

Propiedades clave

Elevada relación resistencia/peso

Carbon-fiber-reinforced nylon offers a remarkable high strength-to-weight ratio. This means you can achieve the same or greater strength as metals while reducing the overall weight of your prototypes. This property is especially valuable in industries like aerospace and automotive, where weight reduction is critical.

Resistencia térmica y química

This material excels in extreme environments. It resists high temperatures and exposure to chemicals, ensuring consistent performance. You can rely on it for applications that demand thermal stability and resistance to corrosive substances.

Dimensional stability and low warping

Carbon-fiber-reinforced nylon maintains its shape under stress. Its high stiffness ensures dimensional stability, even during functional testing. Additionally, it exhibits low warping, making it an excellent choice for 3D printing complex geometries with precision.

Benefits of Carbon Reinforced Nylon in Industrial Prototyping

Mechanical Strength and Durability

Withstanding stress and heavy loads

You need materials that can handle stress and heavy loads during prototyping. Carbon reinforced nylon offers high strength, making it ideal for creating functional prototypes that endure demanding conditions. Its carbon fiber filament enhances the material’s ability to resist deformation under pressure. This ensures your prototypes maintain their structural integrity, even when subjected to significant impact or weight.

Long-lasting prototypes for functional testing

Durability is essential when testing functional prototypes. Carbon reinforced nylon delivers long-lasting performance, allowing you to conduct repeated tests without compromising the quality of your parts. This durability ensures you can rely on your prototypes for accurate results, saving time and resources in the development process.

Estabilidad térmica y química

Performance in extreme environments

Carbon reinforced nylon excels in extreme environments. Its high strength and thermal resistance make it suitable for applications exposed to high temperatures. You can use it to create functional parts that maintain their performance even in challenging conditions.

Resistance to moisture and corrosive substances

Moisture and corrosive substances can degrade many materials, but carbon reinforced nylon resists these elements effectively. This property ensures your carbon fiber 3D printed parts remain durable and reliable, even in environments with high humidity or exposure to chemicals.

Flexibilidad de diseño

Compatibility with 3D printing methods like SLS 3D printing

SLS 3D printing is a popular method for creating precise and complex geometries. Carbon reinforced nylon works seamlessly with SLS, enabling you to produce functional prototypes with intricate designs. Its compatibility with this technology reduces material waste and enhances efficiency.

Precision in creating complex geometries

You can achieve exceptional precision when designing with carbon reinforced nylon. Its dimensional stability and low warping allow you to create detailed parts with high accuracy. This makes it an excellent choice for industries requiring functional parts with complex shapes and tight tolerances.

Eficiencia de costes

Reduced material waste and labor costs

You can achieve significant cost savings by using carbon reinforced nylon in your prototyping process. This material works seamlessly with sls 3d printing, a method that minimizes waste by using only the exact amount of material needed for each part. Unlike traditional manufacturing methods, sls does not require cutting or machining, which often leads to excess material being discarded. This efficiency reduces waste and helps you save on material expenses.

Sls also streamlines the production process, reducing the need for extensive manual labor. You can automate much of the work, which lowers labor costs and speeds up production. The durability of carbon reinforced nylon ensures that your prototypes last longer, reducing the need for frequent replacements. This durability translates to fewer resources spent on reprinting or repairing parts, further enhancing cost efficiency.

Elimination of expensive molds

Traditional manufacturing often requires molds, which can be costly and time-consuming to produce. With sls 3d printing and carbon reinforced nylon, you can eliminate the need for molds entirely. This approach allows you to create prototypes directly from digital designs, saving you both time and money.

The flexibility of sls enables you to make design changes without incurring additional mold costs. You can quickly iterate and refine your prototypes without worrying about the financial burden of creating new molds. This adaptability makes carbon reinforced nylon an excellent choice for industries that require rapid prototyping and frequent design updates.

By reducing material waste, lowering labor costs, and eliminating expensive molds, you can significantly cut expenses while maintaining high-quality results. Carbon reinforced nylon, combined with sls 3d printing, offers a cost-effective solution for creating durable and precise prototypes.

Comparing Carbon Reinforced Nylon to Other Materials

Carbon Reinforced Nylon vs. Standard Nylon

Enhanced strength and stiffness

When you compare carbon reinforced nylon to standard nylon, the difference in strength and stiffness becomes clear. Carbon fibers significantly enhance the mechanical properties of the material. This improvement allows you to create parts that can handle higher loads and resist deformation. Standard nylon, while versatile, lacks the high strength and stiffness needed for demanding applications. By choosing carbon reinforced nylon, you gain a material that performs better under stress.

Applications requiring superior performance

For applications requiring superior performance, carbon reinforced nylon stands out. You can use it to produce functional prototypes or end-use parts that need to endure heavy use. Industries like aerospace and automotive benefit from its ability to maintain structural integrity under challenging conditions. Standard nylon may work for less demanding tasks, but carbon reinforced nylon excels when durability and reliability are critical.

Carbon Reinforced Nylon vs. Metals

Lightweight alternative with comparable strength

Carbon reinforced nylon offers a lightweight alternative to metals without compromising strength. You can achieve comparable high strength while reducing the weight of your parts. This makes it ideal for industries like aerospace, where weight reduction improves efficiency. Unlike metals, this material is easier to handle and process, especially with sls 3d printing.

Corrosion resistance and ease of manufacturing

Metals often face issues like corrosion, which can shorten the lifespan of parts. Carbon reinforced nylon resists moisture and corrosive substances, ensuring long-lasting performance. Additionally, you can manufacture complex geometries more easily with sls. Metals require extensive machining, but sls simplifies the process, saving you time and resources.

Carbon Reinforced Nylon vs. Other Composites

Cost-effectiveness and accessibility

Compared to other composites, carbon reinforced nylon offers better cost-effectiveness. You can use sls 3d printing to minimize material waste and reduce production costs. Other composites may require specialized manufacturing processes, making them less accessible. Carbon reinforced nylon provides a balance of affordability and high performance.

Superior performance in industrial settings

In industrial settings, carbon reinforced nylon delivers superior performance. Its combination of high strength, stiffness, and thermal stability makes it a reliable choice for creating durable parts. Other composites may excel in specific areas, but carbon reinforced nylon offers a well-rounded solution for various applications. You can rely on it for consistent results in demanding environments.

Applications of Carbon Reinforced Nylon Across Industries

Industria del automóvil

Lightweight components for improved fuel efficiency

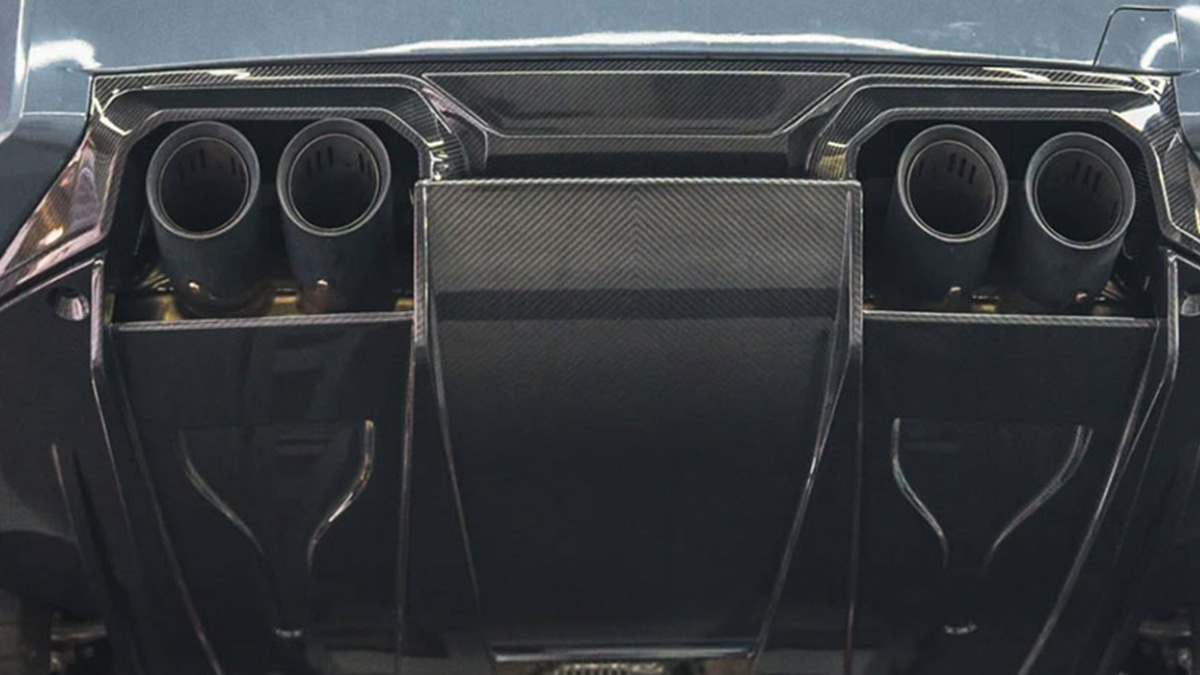

You can use carbon reinforced nylon to create lightweight components that enhance fuel efficiency. Its high strength-to-weight ratio allows you to replace heavier materials without sacrificing durability. For example, you can design engine covers, brackets, or housings that reduce vehicle weight. This weight reduction improves fuel economy and contributes to lower emissions. SLS 3D printing makes it easy to produce these components with precision, ensuring they meet the demanding standards of automotive engineering.

Durable prototypes for rigorous testing

Prototypes play a critical role in the automotive industry. Carbon reinforced nylon enables you to produce durable prototypes that withstand rigorous testing. These prototypes can endure stress, impact, and high temperatures, making them ideal for functional evaluations. SLS 3D printing allows you to create detailed and accurate prototypes quickly, helping you refine designs and accelerate the development process.

Industria aeroespacial

High-performance parts for extreme conditions

In aerospace, you need materials that perform reliably under extreme conditions. Carbon reinforced nylon excels in this area. You can use it to manufacture high-performance parts that resist high temperatures, pressure, and chemical exposure. These parts, such as brackets or structural components, maintain their integrity during flight, ensuring safety and efficiency. SLS technology simplifies the production of these complex parts, reducing lead times and costs.

Prototyping for aerodynamic and structural testing

Aerodynamic and structural testing requires precise prototypes. Carbon reinforced nylon offers the dimensional stability and strength needed for accurate testing. You can create prototypes that replicate the performance of final parts, allowing you to evaluate designs effectively. SLS 3D printing ensures these prototypes meet the exact specifications required for aerospace applications.

Manufacturing and Robotics

Custom tooling and fixtures

In manufacturing, custom tooling and fixtures are essential for efficient operations. Carbon reinforced nylon provides the strength and durability needed for industrial tooling. You can use it to produce jigs, clamps, and other fixtures that withstand repeated use. SLS 3D printing allows you to customize these tools to fit specific requirements, improving productivity and reducing downtime.

Durable components for robotic systems

Robotic systems demand durable components that can handle continuous operation. Carbon reinforced nylon is an excellent choice for creating these parts. Its high strength and resistance to wear ensure long-lasting performance. You can use SLS to produce intricate components, such as robotic arms or gears, with precision. This capability makes carbon reinforced nylon a valuable material for industrial applications in robotics.

Challenges and Solutions in Using Carbon Reinforced Nylon

Retos comunes

Mayores costes iniciales de material

When you start using carbon reinforced nylon, you may notice its higher initial cost compared to standard materials. This is due to the advanced manufacturing processes required to combine nylon with carbon fiber filament. The added strength, durability, and thermal resistance come at a premium. For small-scale projects or businesses, this upfront expense might seem like a barrier. However, the long-term benefits often outweigh the initial investment.

Need for specialized equipment

Producing parts with carbon reinforced nylon often requires specialized equipment. For example, sls 3d printing is one of the most effective methods for working with this material. However, not all facilities have access to the necessary printers or expertise. This can limit your ability to fully utilize the material’s potential. Additionally, maintaining and operating such equipment may require additional training or resources.

Soluciones prácticas

Long-term cost savings through durability

Although the initial cost of carbon reinforced nylon is higher, its durability can save you money over time. Parts made from this material last longer and perform better under stress. You won’t need to replace prototypes or components as frequently, reducing overall expenses. Its resistance to wear, moisture, and chemicals ensures reliable performance, even in demanding environments. By focusing on the long-term benefits, you can justify the upfront investment.

Advances in carbon fiber filament and 3D printing technology

Recent advancements in carbon fiber filament and sls 3d printing technology have made it easier to work with carbon reinforced nylon. Modern printers are more accessible and efficient, reducing production costs. Improved filament formulations enhance material performance, making it suitable for a wider range of applications. These innovations allow you to overcome challenges like equipment limitations and high costs, enabling you to take full advantage of this versatile material.

Carbon reinforced nylon is revolutionizing how you approach industrial prototyping. Its exceptional strength and stiffness allow you to create durable prototypes that perform reliably under stress. You can replace traditional materials like metals or standard nylon with this advanced composite, opening doors to innovative applications. The material’s durability ensures your parts last longer, even in demanding environments. As technology advances, you will see carbon reinforced nylon driving progress in manufacturing. Its ability to produce precise prototypes with complex geometries makes it a cornerstone for future industrial solutions.