5 Hauptverwendungszwecke von nichtrostenden Stählen heute

Stainless steels play a vital role in shaping modern life. Their corrosion resistance, strength, and recyclability make them indispensable across industries. You encounter stainless steel daily, from the cutlery in your kitchen to the skyscrapers in your city. Its smooth surface ensures hygiene in hospitals and food processing, while its durability supports heavy loads in construction. The Asia Pacific region leads global production, driven by industrial growth. With its versatile properties, stainless continues to meet the demands of evolving technologies and sustainable practices, proving its value in countless applications.

Wichtigste Erkenntnisse

Stainless steel is strong and rust-proof, perfect for bridges and tall buildings.

In food work, it keeps things clean and safe, great for tools and cookware.

Doctors use stainless steel for tools because it lasts and handles cleaning well.

Cars use stainless steel to be lighter, save fuel, and stay tough.

For energy, stainless steel resists rust and heat, helping in green energy and oil work.

Applications of Stainless Steels in Construction and Architecture

Stainless steel has transformed the architecture and construction industries with its strength, versatility, and aesthetic appeal. Its applications range from structural components to decorative elements, making it a cornerstone of modern design.

Strukturelle Komponenten

Bridges and Skyscrapers

You see stainless steel in iconic structures like bridges and skyscrapers. Its high strength and durability ensure these structures can withstand heavy loads and extreme weather. For example, the One World Trade Center in New York uses stainless steel to symbolize resilience and provide structural integrity. This material also resists corrosion, reducing maintenance needs and extending the lifespan of these massive projects.

Reinforcement in Concrete

Stainless steel plays a crucial role in reinforcing concrete. It prevents corrosion in environments exposed to moisture or chemicals, ensuring the longevity of buildings and infrastructure. This makes it an ideal choice for projects like coastal constructions or industrial facilities.

Aesthetic Applications

Facades and Cladding

Stainless steel enhances the visual appeal of buildings with its sleek, modern look. It offers design flexibility, allowing architects to create intricate forms and finishes. Iconic examples include the Museum of Contemporary Art Cleveland, with its reflective black exterior, and the Fondation Louis Vuitton, which resembles sails.

Vorteil | Beschreibung |

|---|---|

Visuelle Attraktivität | Stainless steel has a sleek, modern look that enhances architectural aesthetics. |

Flexibilität bei der Gestaltung | It allows for intricate and innovative structures, accommodating complex forms and various finishes. |

Oberflächenbehandlungen | Available in brushed, mirrored, and textured options, enhancing aesthetic appeal and durability. |

Interior Design and Fixtures

You’ll find stainless steel in interior design elements like railings, countertops, and fixtures. Its polished surface adds elegance while being easy to clean and maintain. This makes it a popular choice for both residential and commercial spaces.

Benefits in Construction

Korrosionsbeständigkeit

Stainless steel’s corrosion resistance ensures structures remain intact even in harsh environments. This property reduces the need for frequent repairs, saving time and resources.

Longevity and Low Maintenance

Although stainless steel may have a higher initial cost, its durability and low maintenance needs result in significant long-term savings. Structures made with stainless steel require fewer replacements, making it a cost-effective choice for sustainable projects.

Stainless steel combines functionality and beauty, making it indispensable in architecture and construction. Its ability to endure harsh conditions while maintaining its aesthetic appeal ensures its continued use in modern designs.

Most Common Uses of Stainless Steel in the Food and Beverage Industry

Stainless steel plays a vital role in the food and catering industry, ensuring safety, durability, and efficiency. Its unique properties make it indispensable in food processing and culinary uses.

Food Processing Equipment

Tanks and Vats

Stainless steel tanks and vats are essential for storing and processing liquids like milk, beer, and juices. These containers maintain the purity of the contents due to their non-reactive nature. Grade 304 stainless steel is commonly used for dairy and brewing applications, offering excellent corrosion resistance and durability. Its smooth surface ensures easy cleaning, which is critical for maintaining hygiene in food production.

Conveyors and Mixers

You’ll find stainless steel in conveyors and mixers used in large-scale food production. These machines handle everything from dough mixing to transporting packaged goods. Stainless steel’s strength and resistance to wear make it ideal for such high-demand tasks. Additionally, its ability to withstand rigorous cleaning ensures compliance with food safety standards.

Stainless Steel Type | Composition | Common Uses |

|---|---|---|

304 | 18% chromium, 8% nickel | Dairy, beer processing, sanitation |

316 | Higher nickel content | Commercial food production, better corrosion resistance |

430 | Less nickel | General food processing, requires drying after moisture exposure |

Kitchenware and Utensils

Cutlery and Cookware

Stainless steel products like cutlery and cookware are staples in every kitchen. Their durability and resistance to rust make them perfect for daily use. Whether it’s a chef’s knife or a frying pan, stainless steel ensures long-lasting performance. Its non-reactive surface preserves the taste and quality of food, making it a favorite for culinary uses.

Commercial Kitchen Equipment

In commercial kitchens, stainless steel equipment like countertops, ovens, and sinks dominate. These items endure heavy use while maintaining cleanliness. The non-porous surface prevents stains and microbial growth, ensuring a hygienic environment. Stainless steel’s ability to withstand extreme temperatures also makes it ideal for busy kitchens.

Nutzen Sie | Beschreibung |

|---|---|

Easy to Clean | Non-porous surface prevents stains and ensures easy maintenance. |

Highly Durable | Withstands extreme temperatures and heavy use in commercial settings. |

Protected Against Rust | Oxide layer prevents rust, ensuring longevity even in harsh conditions. |

Benefits in Food Safety

Hygiene and Cleanability

Stainless steel ensures hygiene in food processing environments. Its smooth, non-porous surface resists bacteria and allows for thorough cleaning. You can sanitize it using high-pressure washing or steam cleaning without damaging the material. This makes it a reliable choice for maintaining food safety.

Resistance to Contamination

Stainless steel’s non-reactive properties prevent it from leaching substances into food. This preserves the taste and quality of the products. Its durability also reduces the need for frequent replacements, ensuring long-term safety. Compliance with FDA and USDA standards further highlights its importance in the food and catering industry.

Stainless steel’s role in the food and beverage industry cannot be overstated. From processing equipment to kitchenware, it ensures safety, efficiency, and durability, making it one of the most common stainless steel uses today.

Stainless Steels in the Medical and Healthcare Sector

Stainless steel plays a critical role in the medical and dental industries, offering unmatched hygiene, durability, and reliability. Its unique properties make it indispensable for surgical tools, medical equipment, and healthcare advancements.

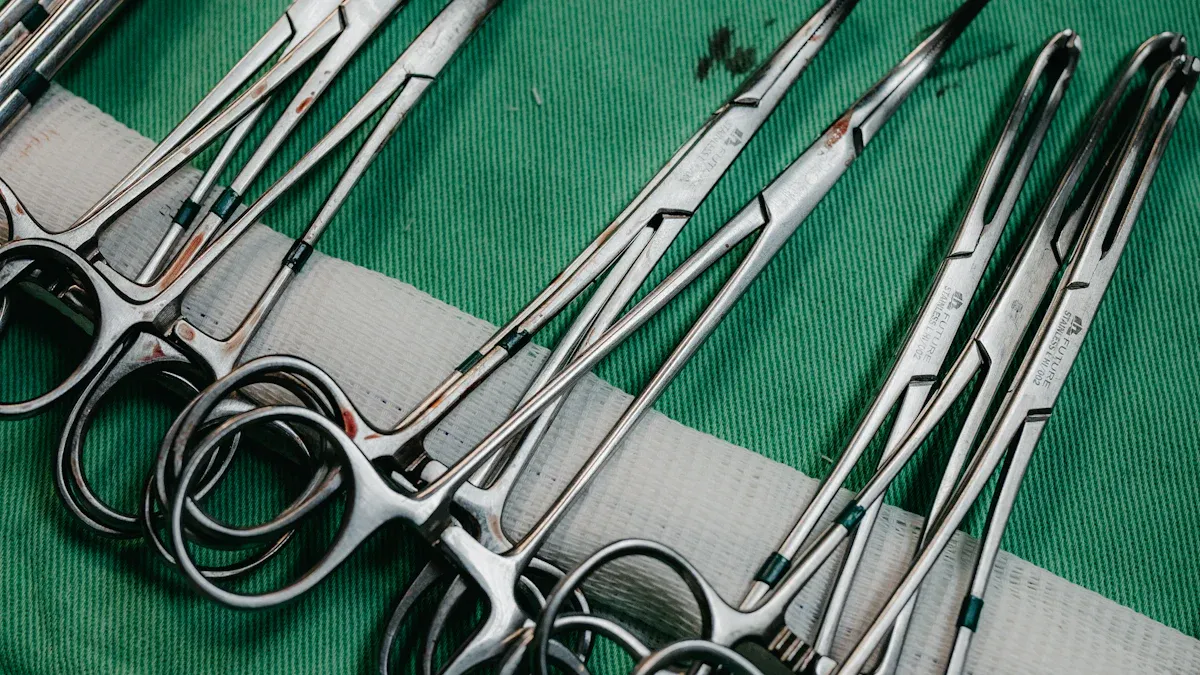

Surgical Instruments

Scalpels and Forceps

Stainless steel is the material of choice for surgical tools like scalpels and forceps. Its corrosion resistance ensures these instruments remain effective even after repeated exposure to alkaline solutions, chlorine, and sterilization processes. The high-temperature resistance of stainless steel allows it to endure autoclaving without losing integrity. Additionally, its smooth surface makes cleaning easy, ensuring compliance with strict hygiene standards in hospitals and clinics. These qualities make stainless steel both cost-effective and environmentally friendly, as it is 100% recyclable.

Implantable Devices

Stainless steel is vital for implantable medical devices due to its structural strength and biocompatibility. It resists corrosion from organic chemicals and harsh environments, ensuring patient safety. For example, Type 316 stainless steel, with its increased nickel and molybdenum content, performs well in severe conditions. Its hard metallic surface prevents bacteria and microorganisms from adhering, while seamless manufacturing techniques eliminate debris traps. These features enhance hygiene and durability, making stainless steel a reliable choice for implants.

Stainless Steel Type | Corrosion Resistance Characteristics |

|---|---|

Type 304 | Resists organic chemicals and dyestuffs |

Type 316 | Increased nickel and molybdenum for severe conditions |

Medical Equipment

Hospital Beds and Trolleys

Stainless steel is widely used in hospital beds and trolleys due to its strength and resistance to wear. It can withstand impacts and thermal extremes, making it ideal for demanding healthcare environments. Its non-porous surface prevents bacteria from adhering, ensuring a hygienic and safe environment for patients.

Diagnostic Machines

Diagnostic machines often feature stainless steel components because of their durability and ease of maintenance. Stainless steel surfaces require lower concentrations of disinfectants, reducing the risk of disease transmission. Its strength-to-weight advantage also ensures long-term reliability, minimizing maintenance costs for healthcare facilities.

Benefits in Healthcare

Biocompatibility

Stainless steel’s biocompatibility makes it suitable for use in surgical tools and implantable devices. It does not react with bodily tissues, ensuring patient safety. This property is essential for maintaining the integrity of medical procedures and devices.

Sterilization and Durability

Stainless steel’s ability to withstand repeated sterilization processes ensures its longevity in healthcare settings. Its durability reduces the need for frequent replacements, making it a cost-effective choice for hospitals and clinics. Studies confirm that stainless steel maintains its disinfecting efficiency over time, supporting its widespread use in medical and dental industries.

Stainless steel continues to drive advancements in healthcare. Its unmatched hygiene, strength, and reliability make it a cornerstone material in medical technology.

Applications of Stainless Steel in Automotive and Transportation

Stainless steel plays a vital role in the automotive and transportation industries, offering durability, efficiency, and sustainability. Its unique properties make it indispensable for various components and systems.

Automobilkomponenten

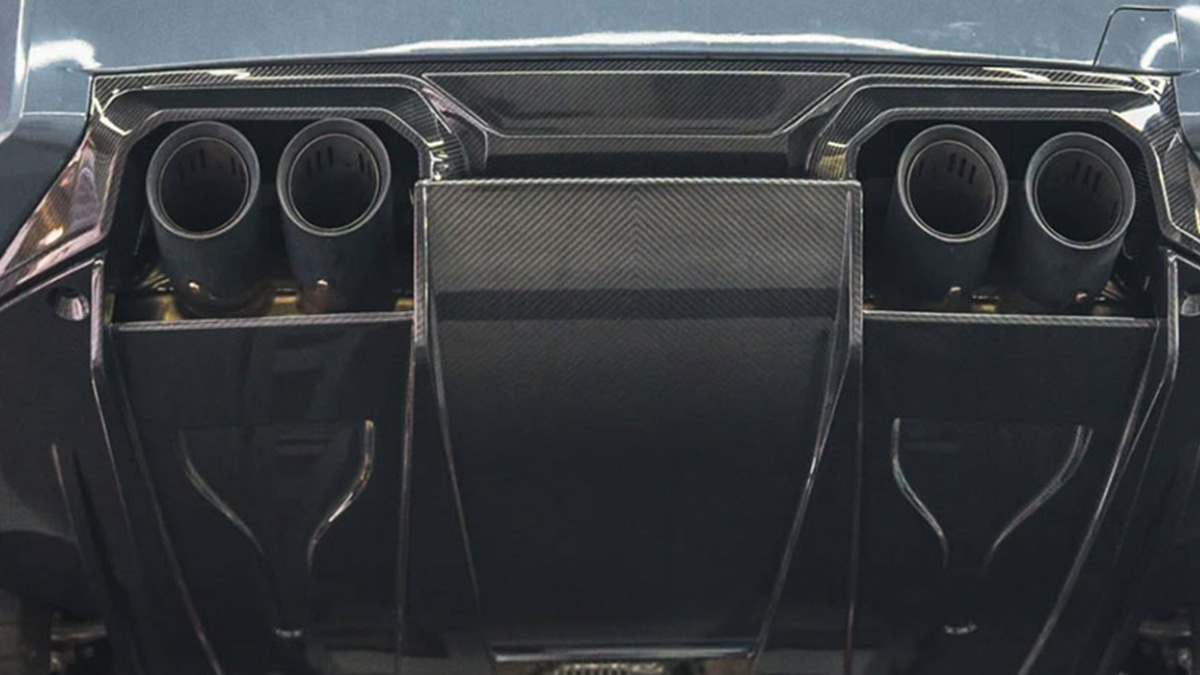

Exhaust Systems

You’ll find stainless steel in automotive exhaust systems due to its exceptional durability and resistance to corrosion. These systems face constant exposure to heat, moisture, and road salt. Stainless steel ensures they remain functional and long-lasting. Its heat resistance prevents warping, even under extreme temperatures generated by performance engines. With proper maintenance, stainless steel exhausts often last the lifetime of the vehicle, reducing replacement costs and waste.

Dauerhaftigkeit: Withstands rust and corrosion.

Langlebigkeit: Performs reliably over the vehicle’s lifespan.

Hitzebeständigkeit: Handles high temperatures without degrading.

Chassis and Frames

Stainless steel provides strength and lightweight properties for vehicle chassis and frames. Its high strength-to-weight ratio enhances structural integrity while reducing overall weight. This improves fuel efficiency and reduces greenhouse gas emissions. In electric vehicles (EVs), stainless steel also aids in thermal management, ensuring optimal battery performance and longevity.

Public Transportation

Train Carriages

Stainless steel is a popular choice for train carriages. Its corrosion resistance ensures durability in varying weather conditions. The material’s strength supports heavy loads, while its smooth surface simplifies cleaning, maintaining hygiene for passengers. Stainless steel also contributes to the sleek, modern designs of high-speed trains.

Bus and Truck Bodies

You’ll notice stainless steel in bus and truck bodies, where it provides both strength and aesthetic appeal. Its resistance to wear and tear ensures these vehicles withstand daily use and harsh environments. Additionally, stainless steel’s recyclability aligns with the growing focus on sustainability in public transportation.

Benefits in Transportation

Weight Reduction and Fuel Efficiency

Stainless steel’s lightweight nature reduces vehicle weight, improving fuel efficiency and lowering emissions. This is especially critical in EVs, where lighter structures enhance battery range and performance. By using stainless steel, manufacturers contribute to a more sustainable future.

Widerstandsfähigkeit gegen Abnutzung und Verschleiß

Stainless steel resists wear and tear, even in demanding conditions. This reduces maintenance costs and extends the lifespan of vehicles. Its corrosion resistance ensures components remain functional, even after years of exposure to harsh environments.

Stainless steel continues to revolutionize the automotive and transportation industries. Its applications improve vehicle performance, enhance sustainability, and reduce costs, making it a cornerstone material in modern transportation.

Stainless Steels in Energy and Power Generation

Stainless steel plays a pivotal role in the energy and power generation industries. Its unique properties, such as corrosion resistance and high durability, make it indispensable in renewable energy systems and traditional oil and gas applications.

Renewable Energy Systems

Wind Turbine Components

You’ll find stainless steel in critical wind turbine components like blades, towers, and fasteners. Its corrosion resistance ensures these parts withstand harsh environments, especially in offshore wind farms. The material’s high tensile strength and fatigue resistance enhance the reliability of turbines, reducing maintenance needs and operational costs.

Eigentum | Explanation |

|---|---|

Korrosionsbeständigkeit | Protects turbine components from rust and degradation in marine and coastal environments. |

Enduring Strength | Ensures structural integrity under constant mechanical stress and extreme weather conditions. |

Minimal Maintenance | Lowers downtime and operational expenses, improving overall efficiency. |

Solar Panel Frames

Stainless steel provides structural support for solar panel frames, ensuring long-term functionality even in extreme conditions. Its superior strength compared to aluminum allows it to resist impacts from heavy snow or strong winds. Additionally, its corrosion resistance makes it ideal for installations in coastal or high-humidity areas. By maintaining its integrity over time, stainless steel reduces the need for frequent replacements, lowering maintenance costs and enhancing the efficiency of photovoltaic systems.

Withstands drastic temperature changes without degrading.

Enhances sunlight absorption, improving solar panel performance.

Offers a sustainable solution due to its recyclability and long lifespan.

Oil and Gas Industry

Pipelines and Storage Tanks

Stainless steel is a preferred material for pipelines and storage tanks in the oil and gas sector. Its resistance to corrosion ensures safe transportation and storage of crude oil, natural gas, and other chemicals. This property minimizes the risk of leaks and contamination, making it a reliable choice for both onshore and offshore operations. The material’s strength also allows it to handle high-pressure environments, ensuring durability and safety.

Offshore Platforms

Offshore oil and gas platforms rely heavily on stainless steel for their structural components. The material’s corrosion resistance protects against the harsh marine environment, reducing maintenance costs and extending the platform’s lifespan. While the initial cost of stainless steel may be higher, its lower life cycle costs make it a cost-effective solution in the long run.

Vorteile | Challenges |

|---|---|

Corrosion resistance | Higher initial cost |

Lower life cycle costs | Need for proper material selection |

Weight reduction | K.A. |

Benefits in Energy Sector

High-Temperature Resistance

Stainless steel performs exceptionally well in high-temperature environments. This makes it ideal for applications like hydrogen production, where electrolyzers must handle extreme heat. Its ability to maintain structural integrity under such conditions ensures efficiency and safety in energy systems.

Korrosionsbeständigkeit in rauen Umgebungen

The energy sector often operates in challenging environments, from offshore wind farms to desert solar installations. Stainless steel’s corrosion resistance ensures long-lasting performance, reducing the need for frequent repairs or replacements. This durability supports sustainable energy production by lowering resource consumption and operational costs.

Stainless steel continues to drive innovation in energy and power generation. Its unmatched properties make it a cornerstone material for renewable energy systems and traditional oil and gas applications.

Stainless steel remains a cornerstone material across industries, offering unmatched durability, versatility, and sustainability. Its applications in construction, healthcare, food processing, transportation, and energy highlight its critical role in modern innovation. You benefit from its long lifespan, energy efficiency, and corrosion resistance, which reduce environmental impact and maintenance costs.

Nutzen Sie | Beschreibung |

|---|---|

Dauerhaftigkeit | Stainless steel has a long lifespan, reducing the frequency of replacements compared to other materials. |

Energie-Effizienz | It helps reduce energy consumption and lowers carbon footprint in industrial applications. |

Korrosionsbeständigkeit | This property minimizes the need for maintenance and specialized cleaning supplies, reducing environmental impact. |

Looking ahead, stainless steel will continue driving progress. Urbanization and sustainability projects will increase demand in construction. The shift to electric vehicles and advancements in healthcare and aerospace technologies will further expand its applications. With a projected market growth of 6.7% CAGR from 2024 to 2030, stainless steel will remain vital to industrial innovation and sustainability.