A Deep Dive into Carbon Fiber Resin Composites in 2025

You are witnessing a materials revolution in 2025, driven by carbon fiber resin composites. These advanced materials combine carbon fiber’s incredible strength with a resin matrix’s durability. This pairing creates a solution that is both strong and lightweight. Industries now rely on carbon fiber for its ability to resist corrosion and withstand extreme conditions. Its lightweight nature reduces energy consumption, making it a sustainable choice. From aerospace to renewable energy, carbon fiber transforms how you think about performance and efficiency. This material is not just a trend; it is reshaping the future.

Key Takeaways

Carbon fiber resin mixes are strong and very light, perfect for many industries.

New tech like 3D printing and robot fiber placement improve making them faster and better.

Eco-friendly and reusable resins help protect the planet and cut waste.

These composites are tough, with great strength and impact resistance for lasting use.

Scientists are working to make them cheaper, easier to recycle, and more flexible for more uses.

What Are Carbon Fiber Resin Composites?

Composition and Structure

Carbon fibers: Lightweight and high-strength filaments.

Carbon fibers are the backbone of carbon fiber composites. These filaments are incredibly thin, often thinner than a strand of human hair. Despite their size, they offer remarkable mechanical properties, including high tensile strength and stiffness. You’ll find that carbon fibers are not only lightweight but also capable of withstanding significant loads. This makes them ideal for applications where reducing weight without compromising strength is essential.

Resin matrix: Binding agents for durability and performance.

The resin matrix plays a crucial role in carbon fiber composites. It binds the carbon fibers together, forming a cohesive structure. Epoxy resin is the most commonly used matrix due to its excellent mechanical properties and durability. It enhances the composite’s ability to resist environmental factors like moisture and chemicals. The resin also distributes stress across the fibers, ensuring the material performs well under pressure. This combination of carbon fibers and epoxy resin creates a material that excels in both strength and longevity.

Unique Properties

Exceptional strength-to-weight ratio.

Carbon fiber resin composites stand out for their high strength-to-weight ratio. This property allows you to achieve superior performance while keeping structures lightweight. Whether in aerospace or automotive industries, this balance of strength and weight is a game-changer.

Resistance to corrosion, fatigue, and environmental factors.

These composites resist corrosion and fatigue better than traditional materials. You can rely on them in harsh environments, where exposure to moisture, chemicals, or extreme temperatures might degrade other materials. This durability ensures long-term reliability and reduces maintenance needs.

Thermal and electrical conductivity for specialized uses.

Carbon fiber composites also offer unique thermal and electrical properties. While the resin matrix insulates, the carbon fibers can conduct electricity and heat. This makes them suitable for specialized applications like electronics and heat-resistant components.

By combining carbon fibers with epoxy resin, you get a material that redefines performance. The science behind carbon fiber lies in this synergy, which delivers unmatched mechanical properties and versatility.

Advancements in Carbon Fiber Resin Composites in 2025

Innovations in Manufacturing Techniques

3D printing and additive manufacturing for precision.

You are now witnessing a revolution in how carbon fiber composites are made. 3D printing and additive manufacturing have introduced unmatched precision to the manufacturing process. These techniques allow you to create complex shapes and structures with minimal waste. By layering materials with pinpoint accuracy, you can achieve optimal mechanical properties in carbon fiber-reinforced polymer composites. This innovation ensures that every component meets exact specifications, enhancing both performance and efficiency.

Automated fiber placement (AFP) and robotic integration.

Automation has transformed the production of carbon fiber-reinforced epoxy composites. Automated fiber placement (AFP) uses robotic systems to lay carbon fibers with incredible accuracy. This process reduces errors and speeds up production. Robotic integration also ensures consistent quality, which is crucial for applications requiring high tensile strength. With these advancements, you can produce lightweight components faster and more cost-effectively.

New Resin Formulations

Development of bio-based and recyclable resins.

The science behind carbon fiber continues to evolve with the development of bio-based and recyclable epoxy resin. These new formulations reduce environmental impact while maintaining excellent mechanical properties. You can now use carbon fiber-reinforced composites that align with sustainability goals. These resins also make recycling easier, paving the way for a more circular economy in polymer matrix composites.

Enhanced thermal and mechanical properties for demanding applications.

Epoxy resin formulations in 2025 offer enhanced thermal and mechanical performance. These improvements make carbon fiber-reinforced polymer composites suitable for extreme environments. Whether you need materials for aerospace or renewable energy, these resins ensure durability and reliability. Their ability to withstand heat and stress expands the possibilities for carbon fiber-reinforced epoxy composites.

Sustainability Efforts

Reducing carbon emissions in production processes.

Sustainability is at the forefront of advancements in carbon fiber-reinforced composites. Modern manufacturing processes now focus on reducing carbon emissions. By optimizing energy use and adopting cleaner technologies, you can minimize the environmental footprint of carbon fiber production. These efforts make carbon fiber-reinforced polymer composites a more eco-friendly choice.

Recycling and reuse strategies for composite materials.

Recycling strategies for carbon fiber resin are gaining momentum. Researchers are developing methods to recover carbon fibers and epoxy resin from used composites. These innovations allow you to reuse materials without compromising mechanical performance. This approach not only reduces waste but also supports the long-term sustainability of carbon fiber-reinforced composites.

Properties and Applications of Carbon Fiber Resin Composites

Mechanical Properties

High tensile strength and stiffness for structural integrity.

The mechanical properties of composites like carbon fiber-reinforced polymer are unmatched. Carbon fiber offers high tensile strength, ensuring materials can withstand significant loads without breaking. Its stiffness adds structural integrity, making it ideal for applications requiring precision and reliability. You can trust carbon fiber parts to maintain their shape and performance under stress, whether in aerospace or construction.

Impact resistance and long-term durability.

Carbon fiber composites excel in impact resistance. They absorb and distribute energy effectively, reducing the risk of damage. This durability ensures long-term performance, even in demanding environments. The epoxy resin used in these composites enhances their ability to resist wear and tear, making them a reliable choice for critical applications.

Thermal and Electrical Properties

Heat resistance for extreme environments.

Carbon fiber-reinforced epoxy composites perform well in high-temperature conditions. The epoxy resin matrix provides excellent thermal stability, allowing these materials to endure extreme environments. This makes them suitable for aerospace and industrial applications where heat resistance is essential.

Electrical conductivity for advanced technological applications.

The science behind carbon fiber includes its unique electrical properties. While the epoxy resin insulates, the carbon fibers conduct electricity. This combination supports advanced technological applications, such as electronics and energy storage systems. You can rely on these materials for innovative solutions in modern industries.

Applications Across Industries

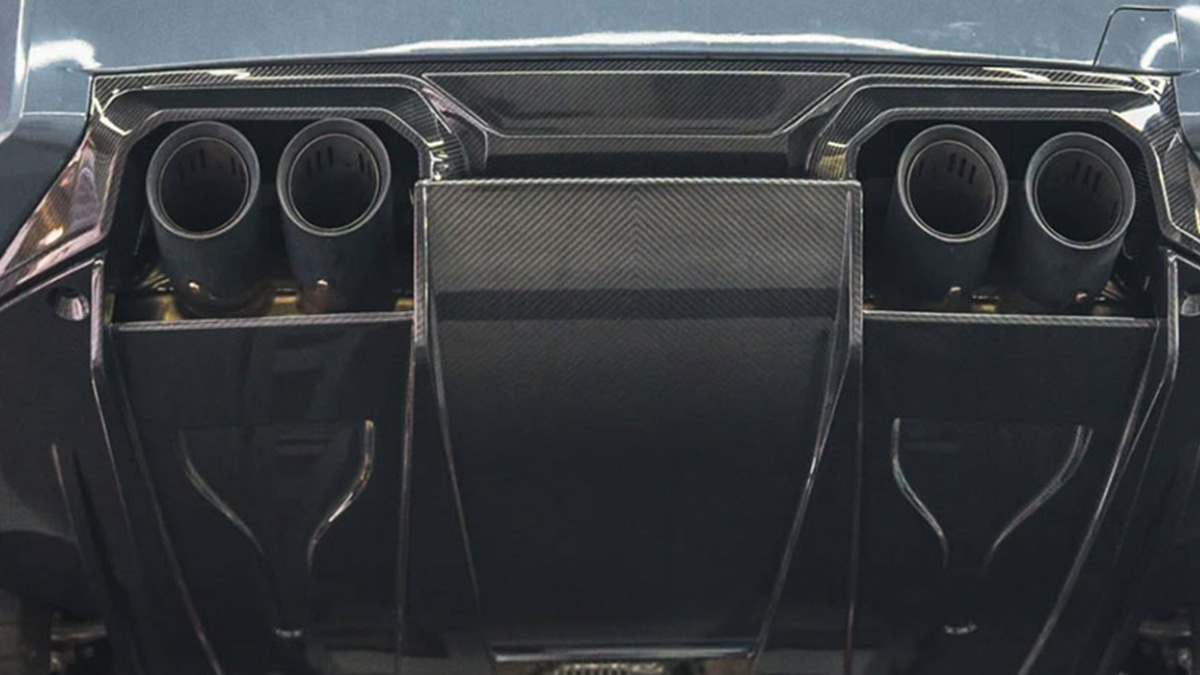

Automotive: Lightweight components for improved fuel efficiency.

Carbon fiber car parts are revolutionizing the automotive industry. Their lightweight properties reduce vehicle weight, improving fuel efficiency and performance. Applications in automotive parts include body panels, chassis components, and interior elements for performance vehicles.

Aerospace: Structural integrity and weight reduction for aircraft.

In aerospace, carbon fiber composites provide the perfect balance of strength and weight reduction. Aircraft benefit from enhanced structural integrity and reduced fuel consumption, making flights more efficient and sustainable.

Renewable Energy: Wind turbine blades and solar panel supports.

Carbon fiber-reinforced polymer composites play a vital role in renewable energy. Wind turbine blades made from these materials are lightweight yet strong, improving energy generation. Solar panel supports also benefit from their mechanical performance and durability.

Sporting Goods: High-performance equipment like bicycles and tennis rackets.

Sporting goods manufacturers use carbon fiber for its lightweight properties and mechanical performance. Bicycles, tennis rackets, and other equipment gain enhanced strength and reduced weight, improving user experience and performance.

Construction: Reinforced materials for bridges and buildings.

In construction, carbon fiber-reinforced polymer matrix composites provide reinforcement for bridges and buildings. Their mechanical properties ensure long-lasting structures that can withstand environmental challenges.

Challenges and Potential Solutions

Cost and Scalability

High production costs and limited scalability in manufacturing.

You may notice that carbon fiber remains expensive to produce. The manufacturing process involves energy-intensive steps, such as creating carbon fibers and curing epoxy resin. These steps contribute to high costs, making it difficult to scale production for widespread use. Industries like automotive and aerospace face challenges in adopting carbon fiber parts for mass production due to these limitations.

Innovations to streamline production and reduce expenses.

Efforts to lower costs focus on improving efficiency in the manufacturing process. Advanced automation, such as robotic systems, reduces labor costs and minimizes waste. Researchers are also exploring faster curing methods for epoxy resin, which could shorten production times. These innovations aim to make carbon fiber-reinforced polymer composites more accessible for industries like construction and performance vehicles.

Recyclability and Environmental Impact

Challenges in recycling carbon fiber resin composites.

Recycling carbon fiber resin composites presents unique difficulties. The strong bond between carbon fibers and epoxy resin makes separation challenging. Traditional recycling methods often degrade the mechanical properties of recovered materials, limiting their reuse. This creates a barrier to achieving a circular economy for polymer matrix composites.

Research into eco-friendly alternatives and advanced recycling methods.

Scientists are developing new techniques to address these challenges. Thermal and chemical processes show promise in separating carbon fibers from epoxy resin without compromising mechanical performance. Additionally, bio-based resins offer an eco-friendly alternative, reducing the environmental impact of carbon fiber-reinforced polymer composites. These advancements could pave the way for more sustainable solutions in industries like renewable energy and automotive.

Technical Limitations

Constraints in flexibility and certain applications.

While carbon fiber excels in strength and stiffness, it lacks flexibility. This limitation restricts its use in applications requiring materials that can bend or stretch. For example, some construction projects may require more adaptable materials than carbon fiber-reinforced polymer can provide.

Ongoing research to expand material capabilities and versatility.

Researchers are working to overcome these constraints by modifying epoxy resin formulations. These efforts aim to enhance the mechanical properties of carbon fiber composites, making them suitable for a broader range of applications. Innovations in hybrid materials, which combine carbon fiber with other substances, also show potential for improving flexibility without sacrificing strength.

Carbon fiber resin composites have redefined material science in 2025. You’ve seen how advancements in manufacturing, resin formulations, and sustainability efforts have expanded their capabilities. These composites now play a critical role in industries like aerospace, automotive, and renewable energy. Their lightweight strength and durability make them indispensable for innovation and efficiency. Challenges like cost and recyclability remain, but ongoing research promises solutions. As you look ahead, expect breakthroughs that will further enhance the versatility and sustainability of carbon fiber composites, shaping a more efficient and eco-friendly future.