Emerging Applications of Carbon Fiber Reinforced Polymer in 2025

Carbon fiber reinforced polymer combines carbon fibers with a polymer matrix to create a material that is both lightweight and incredibly strong. You encounter its impact across industries like aerospace, automotive, and renewable energy. Its ability to reduce weight without compromising durability makes it a game-changer. In 2025, market trends show a growing demand for sustainable and high-performance materials. This demand drives innovation in CFRP applications, shaping the future of technology and infrastructure.

Key Takeaways

Carbon fiber reinforced polymers (CFRP) are changing industries. They are light and strong, improving performance and efficiency.

In airplanes, CFRP makes them lighter, saving fuel and flying better. In cars, it helps electric cars go farther and look cooler.

CFRP is important for clean energy. It makes wind turbine blades work better and solar panel supports last longer.

New ideas like self-fixing materials and smart CFRP with sensors make things safer and cheaper to fix.

Eco-friendly CFRP production, like recycling and plant-based materials, helps the planet and meets industry needs.

Emerging Applications of Carbon Fiber Reinforced Polymers

Aerospace and Defense

Lightweight aircraft components

You see carbon fiber composites revolutionizing the aerospace industry. Aircraft manufacturers prioritize reducing weight to improve fuel efficiency and performance. Carbon fiber reinforced polymers offer an ideal solution. These composite materials provide exceptional strength while significantly lowering the weight of aircraft components. Wings, fuselages, and interior parts now rely on these advanced materials. This lightweighting approach enhances flight range and reduces operational costs.

Space exploration and satellite structures

Space exploration demands materials that can withstand extreme conditions. Carbon fiber composites excel in this domain. Their durability and resistance to temperature fluctuations make them perfect for satellite structures and spacecraft. You’ll notice their use in payload supports, antenna systems, and structural panels. These applications ensure reliability during space missions while minimizing launch weight, which is critical for cost efficiency.

Automotive Industry

Electric vehicle lightweighting

Electric vehicles (EVs) benefit greatly from carbon fiber reinforced polymers. Lightweighting is essential for improving battery efficiency and extending driving range. Carbon fiber composites replace heavier materials in EV frames, body panels, and interior parts. This shift not only enhances performance but also supports sustainability by reducing energy consumption.

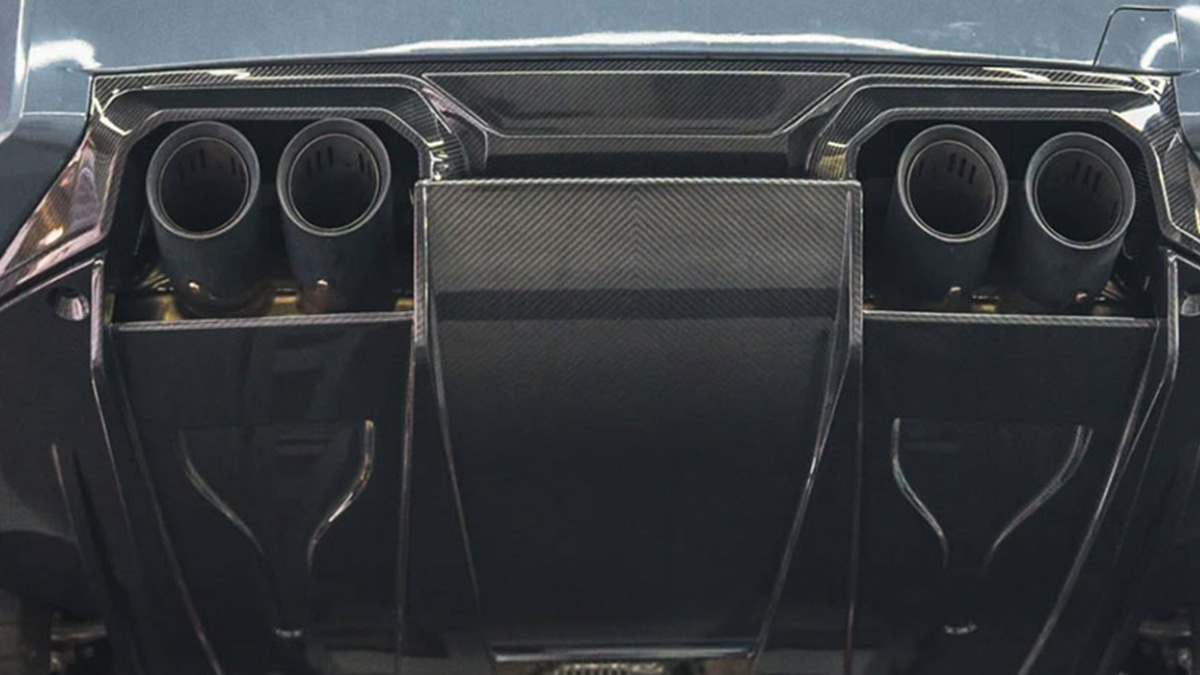

High-performance sports cars

High-performance applications in the automotive sector often involve sports cars. Carbon fiber composites dominate this space due to their unmatched strength-to-weight ratio. You’ll find these materials in chassis, spoilers, and other structural components. They improve speed, handling, and safety, making them indispensable for cutting-edge automotive designs.

Renewable Energy

Wind turbine blades

Wind energy relies on efficient turbine designs. Carbon fiber composites play a vital role in manufacturing wind turbine blades. These composite materials provide the necessary stiffness and strength to withstand high wind speeds. Their lightweight nature also allows for longer blades, increasing energy output and efficiency.

Solar panel support structures

Solar energy systems require durable and lightweight support structures. Carbon fiber reinforced polymers meet these requirements perfectly. They ensure stability while reducing the overall weight of solar installations. This makes transportation and installation easier, promoting wider adoption of renewable energy solutions.

Healthcare and Medical Devices

Prosthetics and orthotics

You see carbon fiber composites transforming the healthcare industry, especially in prosthetics and orthotics. These composite materials provide unmatched strength and lightweight properties, making them ideal for creating artificial limbs and braces. They allow for better mobility and comfort, enabling users to lead more active lives. The adaptability of carbon fiber composites ensures that each prosthetic or orthotic device can be customized to meet individual needs. This innovation improves both functionality and user satisfaction.

Advanced medical imaging equipment

Carbon fiber reinforced polymer plays a crucial role in advanced medical imaging equipment. Its lightweight and durable nature makes it perfect for components in X-ray machines, CT scanners, and MRI systems. These applications benefit from the material’s ability to reduce weight while maintaining structural integrity. You’ll notice that carbon fiber composites also minimize interference with imaging technologies, ensuring clearer and more accurate results. This advancement enhances diagnostic capabilities and patient care.

Construction and Infrastructure

Reinforced bridges and buildings

In construction, composite materials like carbon fiber reinforced polymer are revolutionizing how you build bridges and buildings. These materials strengthen structures while reducing overall weight. Engineers use them to reinforce concrete and steel, increasing durability and resistance to wear. This application extends the lifespan of infrastructure, reducing maintenance costs and improving safety.

Seismic-resistant structures

Carbon fiber composites are essential in creating seismic-resistant structures. Their flexibility and strength allow buildings to withstand earthquakes more effectively. You’ll find these materials used in retrofitting older buildings and designing new ones in earthquake-prone areas. This application ensures greater protection for people and property during natural disasters.

Emerging Sectors

Energy storage systems

Carbon fiber reinforced polymer is making strides in energy storage systems. Its lightweight and durable properties improve the efficiency of battery casings and other components. These applications enhance energy density and safety, paving the way for more reliable and sustainable energy solutions.

Water and wastewater management

In water and wastewater management, composite materials offer innovative solutions. Their resistance to corrosion and chemicals makes them ideal for pipes, tanks, and filtration systems. These applications ensure long-lasting performance and reduced maintenance, contributing to cleaner and more efficient water systems.

Technological Advancements in Carbon Fiber Reinforced Polymers

Lightweighting Innovations

Enhanced strength-to-weight ratios

You’ll notice that carbon fiber composites continue to push the boundaries of lightweighting. These composite materials offer an exceptional strength to weight ratio, making them ideal for industries like aerospace, automotive, and renewable energy. Engineers now design components that are lighter yet stronger than ever before. This advancement reduces energy consumption and enhances performance across various applications. For example, in electric vehicles, lightweighting improves battery efficiency and extends driving range.

Integration with other advanced materials

The integration of carbon fiber composites with advanced materials like nanomaterials has opened new possibilities. By combining these materials, you achieve even higher strength to weight ratios and improved durability. This innovation allows for the creation of hybrid composite materials tailored to specific applications. For instance, in construction, these materials enhance the resilience of seismic-resistant structures. This integration also supports the development of multifunctional components, such as those used in smart infrastructure.

Self-Healing Composites

Damage detection and repair mechanisms

Self-healing composites represent a groundbreaking advancement in material science. These composite materials can detect damage, such as cracks or fractures, and initiate repair processes. You’ll find this technology particularly useful in aerospace and defense applications, where safety and reliability are critical. By embedding nanomaterials into carbon fiber composites, engineers create systems capable of identifying and addressing structural issues in real time. This reduces maintenance costs and improves operational efficiency.

Prolonged material lifespan

The ability of self-healing composites to repair themselves extends their lifespan significantly. This feature ensures that composite materials remain functional for longer periods, even under harsh conditions. In renewable energy applications, such as wind turbine blades, this advancement minimizes downtime and enhances energy production. You benefit from more sustainable and cost-effective solutions, as these materials require fewer replacements over time.

Additive Manufacturing

3D printing of CFRP components

Additive manufacturing has revolutionized how you produce carbon fiber reinforced polymer components. With 3D printing, you can create complex shapes and structures that were previously impossible. This method reduces material waste and speeds up production. In industries like healthcare, 3D-printed carbon fiber composites enable the creation of customized prosthetics and orthotics. These applications improve patient outcomes and provide greater accessibility to advanced medical devices.

Customization and rapid prototyping

The flexibility of additive manufacturing allows for rapid prototyping and customization. You can quickly design and test new components, accelerating innovation across various applications. For example, in the automotive industry, this technology supports the development of high-performance sports cars by enabling precise adjustments to designs. Additive manufacturing also facilitates the production of lightweight and durable parts, enhancing the overall efficiency of composite materials.

Smart CFRP

Embedded sensors for real-time monitoring

Smart carbon fiber reinforced polymers (CFRP) are transforming how you monitor structures and systems. By embedding sensors directly into the material, you gain the ability to track performance in real time. These sensors measure factors like stress, temperature, and vibrations. This data helps you identify potential issues before they become critical. For example, in aerospace applications, embedded sensors can detect stress points on aircraft components. This ensures safety and reduces the need for frequent inspections.

You’ll also find these sensors useful in renewable energy systems. Wind turbine blades made from CFRP can include sensors to monitor wear and tear. This allows you to schedule maintenance only when necessary, saving time and resources. The integration of sensors into CFRP materials enhances their functionality without adding extra weight. This makes them ideal for applications where lightweighting is essential.

Internet of Things (IoT) integration

The Internet of Things (IoT) takes smart CFRP to the next level. By connecting embedded sensors to IoT networks, you can access real-time data from anywhere. This connectivity allows you to monitor and control systems remotely. In construction, IoT-enabled CFRP materials can provide updates on the structural health of bridges and buildings. This helps you ensure safety and plan repairs proactively.

IoT integration also benefits industries like automotive and healthcare. In electric vehicles, CFRP components with IoT capabilities can track performance and optimize energy use. In medical devices, IoT-connected CFRP prosthetics can provide feedback to improve user experience. The combination of advanced materials and IoT technology opens up endless possibilities for innovation.

Smart CFRP represents a significant leap forward in material science. Its ability to combine lightweighting with real-time monitoring and IoT connectivity makes it a cornerstone of future technologies.

Sustainability Trends in Carbon Fiber Reinforced Polymer Production

Recycling and Reuse

Advances in CFRP recycling technologies

You’ll notice significant progress in recycling technologies for carbon fiber reinforced polymer. Engineers now use advanced methods to separate fibers from the polymer matrix without compromising their quality. These techniques allow you to recover and reuse composite materials in new applications. For example, recycled fibers can reinforce automotive parts or construction materials. This innovation reduces waste and supports sustainability by extending the lifecycle of composites.

Circular economy principles in CFRP applications

The adoption of circular economy principles is transforming how you approach carbon fiber composites. Instead of discarding materials after use, industries focus on designing products for reuse and recycling. This approach minimizes waste and conserves resources. You’ll see these principles applied in sectors like aerospace and automotive, where manufacturers repurpose components to create sustainable solutions. By embracing a circular mindset, you contribute to a more sustainable future.

Low-Carbon Manufacturing

Renewable energy-powered production processes

Manufacturers are shifting to renewable energy sources to produce composite materials. Solar, wind, and hydropower now fuel production facilities, reducing reliance on fossil fuels. This transition lowers the carbon footprint of carbon fiber composites. You’ll find this approach particularly impactful in industries aiming to meet strict environmental standards. Renewable energy-powered processes align with global efforts to combat climate change.

Reduction of carbon emissions in supply chains

Efforts to reduce carbon emissions extend beyond production. You’ll see companies optimizing supply chains to minimize transportation-related emissions. Local sourcing of raw materials and efficient logistics play a key role. These strategies ensure that the entire lifecycle of composite materials aligns with sustainability goals. By supporting low-carbon supply chains, you help create a greener manufacturing ecosystem.

Bio-Based Composites

Use of natural fibers and resins

Bio-based composites are gaining traction as eco-friendly alternatives to traditional materials. You’ll find natural fibers like flax, hemp, and jute replacing synthetic ones in some applications. These fibers, combined with bio-based resins, create durable and lightweight composite materials. This innovation reduces dependence on petroleum-based resources and promotes sustainability in industries like construction and automotive.

Biodegradable composites

Biodegradable composites represent a breakthrough in material science. These materials decompose naturally, leaving minimal environmental impact. You’ll see their use in short-term applications like packaging and temporary structures. By choosing biodegradable options, you support sustainable solutions that reduce long-term waste. This advancement highlights the potential of composite materials to align with environmental priorities.

Sustainability in carbon fiber reinforced polymer production is no longer optional. By adopting recycling technologies, low-carbon processes, and bio-based composites, you contribute to a future where innovation and environmental responsibility go hand in hand.

Challenges in Carbon Fiber Reinforced Polymer Adoption

High Costs

Expensive raw materials

You’ll find that one of the biggest challenges with carbon fiber reinforced polymer is the high cost of raw materials. Carbon fibers require energy-intensive production processes, which drive up their price. The polymer matrix, often made from advanced resins, adds to the expense. These costs make CFRP less accessible for industries with tight budgets. For example, while aerospace and automotive sectors can afford these materials, smaller industries struggle to justify the investment.

Cost barriers for small-scale industries

Small-scale industries face significant hurdles when adopting CFRP. The initial investment in equipment and materials often exceeds their financial capacity. You’ll notice that these industries also lack the economies of scale that larger companies enjoy. This makes it harder for them to compete in markets where composites are becoming the standard. As a result, the high cost limits the widespread adoption of CFRP across diverse sectors.

Scalability Issues

Limitations in mass production

Scaling up the production of CFRP presents another challenge. The manufacturing process involves precise layering and curing, which require specialized equipment and skilled labor. You’ll see that these factors slow down production and increase costs. This makes it difficult to meet the growing demand for CFRP in industries like renewable energy and construction. The lack of efficient mass production methods restricts the material’s potential applications.

Supply chain constraints

Supply chain issues further complicate the scalability of CFRP. The production of carbon fibers depends on limited raw materials, which creates bottlenecks. You’ll find that disruptions in the supply chain can delay projects and increase costs. Additionally, the global nature of CFRP production means that transportation and logistics add another layer of complexity. These challenges make it harder for industries to adopt CFRP on a large scale.

Recyclability Concerns

Difficulty in separating fibers and resins

Recycling CFRP poses a significant challenge due to the difficulty of separating carbon fibers from the polymer matrix. You’ll notice that traditional recycling methods often degrade the quality of the fibers, limiting their reuse. This makes it hard to create a sustainable lifecycle for CFRP products. Industries must invest in advanced recycling technologies to overcome this issue, but these solutions remain costly and underdeveloped.

Limited infrastructure for recycling

The lack of recycling infrastructure further hinders the adoption of CFRP. You’ll find that most regions lack facilities capable of processing composite materials. This results in a reliance on landfills or incineration, which are not environmentally friendly. Without a robust recycling network, industries struggle to manage the end-of-life phase of CFRP products. This creates a barrier to the material’s widespread use, especially in sectors prioritizing sustainability.

The future trends of CFRP reveal its transformative potential across industries. You see its applications expanding in aerospace, automotive, healthcare, and renewable energy, driven by the demand for lightweight and durable materials. Technological advancements like self-healing composites and smart CFRP enhance performance and reliability. Sustainability efforts, including recycling and bio-based composites, ensure a greener future. As you explore the future trends of CFRP, its role in shaping innovative and eco-friendly solutions becomes clear. This material will continue to redefine possibilities in technology and infrastructure.