The Benefits of High-Revs in Performance Cars

High-revving engines captivate you with their ability to deliver thrilling power and unmatched acceleration. These engines excel by operating at higher revolutions per minute (RPM), allowing them to generate more power in a compact design. You experience smoother power delivery and precise control, making every drive exhilarating. High-revs are not just about speed; they embody the essence of performance, offering a dynamic connection between you and the car. Whether on the road or the racetrack, high-revving engines redefine what it means to enjoy driving.

Key Takeaways

High-revving engines deliver exceptional power and acceleration, making them ideal for performance driving and racing.

Operating at higher RPMs allows these engines to complete more combustion cycles, resulting in increased horsepower and smoother power delivery.

The design of high-revving engines, including features like oversquare configurations and advanced valvetrain systems, enhances responsiveness and driving dynamics.

While high-revving engines provide thrilling performance, they require more maintenance and can be less fuel-efficient compared to low-revving engines.

Understanding the trade-offs of high-revving engines helps you make informed decisions about your driving style and vehicle choice.

The emotional connection and excitement of driving a high-revving engine create a unique experience that resonates with automotive enthusiasts.

For those who prioritize performance, the benefits of high-revving engines far outweigh the challenges, making them a favorite among driving aficionados.

How High-Revs Work in High-Revving Engines

The Role of RPM in Power Generation

Revolutions per minute (RPM) play a critical role in how engines generate power. When you increase the RPM, the engine completes more combustion cycles in a given time. This means more energy gets released, resulting in higher power output. High-revving engines excel in this area by operating at an extended rev range, allowing them to produce significant horsepower.

Unlike engines designed for low RPMs, high-revving engines maintain their power delivery at the upper end of the rev range. This characteristic makes them ideal for performance cars, where maintaining speed and acceleration is essential. For example, racing engines often operate at extremely high RPMs to maximize power and torque during competitions. By keeping the engine in its optimal rev range, you can experience smoother acceleration and better control.

Key Differences Between High-Revs and Low-Revs in Engine Design

High-revving engines differ significantly from low-revving engines in their design and functionality. One of the most notable differences lies in the engine’s bore and stroke ratio. High-revving engines often use an oversquare design, where the bore (cylinder width) is larger than the stroke (piston movement). This design reduces piston speed, minimizing stress on engine components and enabling the engine to achieve higher RPMs. Wider bores also allow for larger intake and exhaust valves, improving airflow and efficiency at high speeds.

In contrast, low-revving engines prioritize torque at lower RPMs. These engines deliver power more efficiently at slower speeds, making them better suited for everyday driving. They require fewer gear shifts and less clutch slip, offering smoother drivability in stop-and-go traffic. However, they lack the exhilarating performance and responsiveness that high-revving engines provide.

High-revving engines also demand advanced materials and engineering to withstand the intense stress of operating at high RPMs. Components like the valvetrain and crankshaft must endure extreme forces without compromising durability. This level of precision engineering ensures that the engine performs reliably even under demanding conditions.

The Benefit of a High Revving Engine in Performance Cars

Increased Power and Horsepower

High-revving engines excel at delivering exceptional power. By operating at higher revolutions per minute (RPM), these engines complete more combustion cycles in less time. This rapid cycle increases the energy output, resulting in greater horsepower. You experience this as a surge of power when you push the engine to its upper limits.

The benefit of a high revving engine becomes evident when you compare it to low-revving engines. While low-revving engines focus on producing torque at lower speeds, high-revving engines shine in high-speed scenarios. They provide the top-end power needed for thrilling performance, especially during a fast launch or when maintaining speed in a drag race performance. This makes high-revving engines ideal for those who crave excitement and precision in their driving experience.

Enhanced Acceleration and Speed

Acceleration is where high-revving engines truly stand out. The ability to rev higher allows the engine to generate more power quickly, giving you a noticeable boost in speed. This is particularly beneficial during a launch, where rapid acceleration can make all the difference. Whether you’re merging onto a highway or competing in a drag race, the quick response of a high-revving engine ensures you stay ahead.

High-revs also contribute to maintaining speed without losing momentum. When you keep the engine in its optimal RPM range, you achieve smoother and more consistent acceleration. This characteristic is invaluable in racing scenarios, where every fraction of a second counts. The benefit of a high revving engine lies in its ability to combine speed with control, offering you an unparalleled driving experience.

Improved Responsiveness and Driving Dynamics

High-revving engines enhance your connection to the car by improving responsiveness. These engines react instantly to throttle inputs, allowing you to control acceleration and speed with precision. This responsiveness is crucial for performance driving, where quick adjustments can make or break your experience on the road or track.

The dynamic nature of high-revving engines also improves overall driving dynamics. By operating at higher RPMs, the engine delivers smoother power transitions, reducing drag and ensuring a seamless flow of energy. This creates a more engaging and enjoyable driving experience, whether you’re navigating tight corners or accelerating on a straightaway. The benefit of a high revving engine extends beyond raw power—it transforms how you interact with your vehicle.

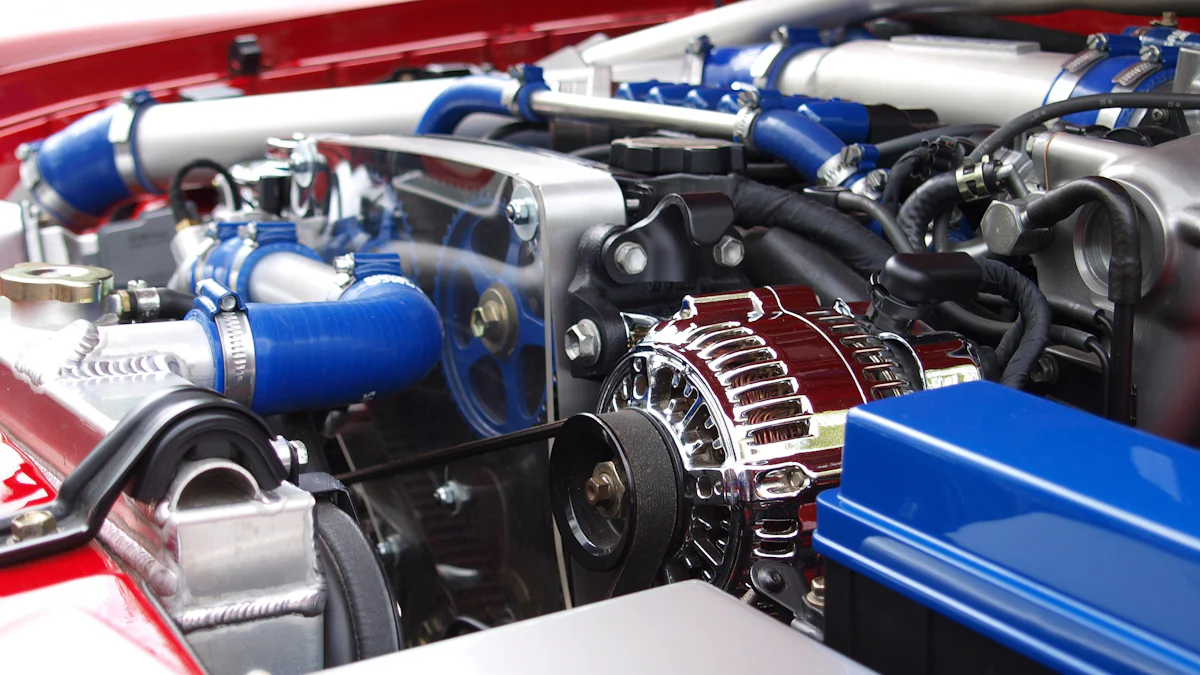

Engineering Behind High RPM Motors

Advanced Valvetrain Design for High-Revs

The valvetrain plays a critical role in enabling high-revving engines to achieve their impressive performance. In high rpm motors, the valvetrain must operate with precision and durability to handle the extreme speeds at which the engine components move. Engineers design these systems to minimize valve float, a condition where valves fail to close properly at high speeds. This is achieved by using lightweight materials like titanium for valves and retainers, reducing inertia and allowing the system to function seamlessly at elevated RPMs.

High-revving engines often incorporate advanced technologies such as variable valve timing (VVT). This system adjusts the timing of valve openings and closings to optimize airflow and combustion efficiency across a wide range of engine speeds. For example, systems like Honda’s VTEC switch between camshaft profiles to deliver both low-end torque and high-end power. This innovation ensures that high rpm motors maintain a balance between performance and reliability, even under demanding conditions.

Another key feature is the use of dual overhead camshafts (DOHC). This configuration allows for more precise control over valve operation, enabling higher airflow and better combustion at high RPMs. By optimizing the valvetrain design, engineers ensure that high-revving engines deliver consistent power and responsiveness, making them ideal for performance applications.

Materials and Cooling Systems for High-Stress Performance

High rpm motors operate under intense stress, requiring materials and cooling systems that can withstand extreme conditions. Lightweight yet strong materials like forged aluminum and carbon composites are commonly used for engine components. These materials reduce the overall weight of the engine while maintaining structural integrity, allowing the engine to rev higher without compromising durability.

The crankshaft and connecting rods in high-revving engines are often made from forged steel or titanium. These materials provide the strength needed to endure the immense forces generated at high RPMs. Additionally, pistons are designed with shorter skirts and coated with friction-reducing materials to minimize wear and improve efficiency.

Cooling systems in high rpm motors are equally critical. High-revving engines generate significant heat due to the rapid combustion cycles. To manage this, engineers use advanced cooling techniques such as liquid cooling systems with high-capacity radiators and oil coolers. These systems ensure that the engine maintains optimal operating temperatures, preventing overheating and preserving performance.

Some engines also feature sodium-filled exhaust valves, which dissipate heat more effectively. This innovation helps maintain the reliability of high-revving engines during prolonged periods of high-stress operation. By combining advanced materials with efficient cooling systems, engineers create high rpm motors that deliver exceptional power and longevity.

Trade-Offs and Challenges of High-Revs

Increased Wear and Maintenance Requirements

High-revving engines operate at extreme speeds, which places significant stress on their components. When you push an engine to higher revolutions per minute (RPM), the internal parts, such as pistons, crankshafts, and valves, move at incredible velocities. This rapid movement increases friction and heat, leading to accelerated wear. Over time, the constant strain can reduce the lifespan of these components, requiring more frequent maintenance and part replacements.

Running high rpm motors close to their redline for extended periods amplifies this issue. The intense forces generated during high-speed operation can cause parts to degrade faster than in low-revving engines. For example, the valvetrain must endure immense pressure to maintain precise timing at high RPMs. If not properly maintained, this can result in valve float or even catastrophic engine failure.

To keep high-revving engines performing at their best, you must adhere to strict maintenance schedules. Regular oil changes, inspections, and part replacements become essential. Neglecting these tasks can lead to costly repairs or a complete engine rebuild. While the thrill of high-revs is undeniable, the increased wear demands a higher level of care and attention from you as an owner.

Fuel Efficiency and Practicality Concerns

High-revving engines prioritize performance over fuel efficiency. The rapid combustion cycles required to achieve high RPMs consume more fuel in less time. As a result, these engines often deliver lower miles per gallon compared to their low-revving counterparts. If you value fuel economy, this trade-off may pose a challenge.

The design of high rpm motors further contributes to their reduced efficiency. To generate more power at higher speeds, these engines rely on a narrow power band. This means they perform optimally within a specific RPM range, often at the expense of fuel consumption. For daily driving, where you frequently operate outside this range, the practicality of high-revving engines diminishes.

Additionally, the increased drag caused by the rapid movement of internal components impacts efficiency. The energy required to overcome this drag results in higher fuel consumption. While this trade-off is acceptable in racing scenarios, it may not align with the needs of everyday drivers seeking a balance between performance and practicality.

Despite these challenges, high-revving engines remain a favorite among enthusiasts. Their ability to deliver exhilarating power and speed outweighs the drawbacks for those who prioritize performance. However, understanding these trade-offs helps you make informed decisions about whether a high-revving engine suits your driving style and needs.

Why High-Revs Are Essential for Racing Vehicles

Maximizing Performance and Speed on the Track

High-revving engines dominate the world of racing because they deliver unmatched performance and speed. These engines operate at high rpm motors, allowing them to generate more power in less time. On the track, every second matters. High-revs ensure that your vehicle stays in its optimal power band, providing the acceleration and top-end speed needed to outperform competitors.

In drag racing, where rapid acceleration is critical, high-revving engines shine. They complete more combustion cycles per minute, producing the horsepower required to launch off the line and maintain speed down the strip. This ability to sustain high speeds makes them indispensable for competitive racing. For example, Formula 1 cars rely on high rpm motors to achieve blistering lap times, showcasing the importance of high-revs in maximizing performance.

The design of high-revving engines also plays a crucial role in their racing success. Engineers optimize these engines to handle extreme stress and maintain reliability under demanding conditions. Lightweight materials and advanced cooling systems ensure that the engine performs consistently, even during prolonged high-speed runs. By combining durability with peak performance, high-revving engines become the backbone of racing vehicles.

The Emotional Appeal of High-Revs for Enthusiasts

For enthusiasts, high-revs are more than just a technical feature—they evoke pure excitement. The sound of high rpm motors screaming at full throttle creates an emotional connection between you and the car. Whether you’re watching a drag racing event or driving on a track, the roar of a high-revving engine amplifies the thrill of the experience. As one automotive expert noted, “An engine that sounds awesome at 6,000 rpm will sound even better at 1,000 more revs.” This auditory sensation is a key reason why high-revs captivate racing fans and drivers alike.

High-revving engines also offer a unique driving experience. The responsiveness and precision they provide make you feel in control, enhancing your confidence behind the wheel. When you push the engine to its limits, you tap into its full potential, creating a sense of accomplishment and exhilaration. This emotional appeal sets high-revs apart, making them a favorite among those who value performance and passion in equal measure.

The connection between high-revs and racing culture runs deep. From the screaming engines of Formula 1 cars to the high-pitched wail of superbikes, high-revving engines symbolize speed and power. They represent the pursuit of excellence and the desire to push boundaries. For enthusiasts, this connection transforms high-revs into more than just a mechanical feature—it becomes a celebration of the art and science of performance driving.

Comparing High-Revs to Other Engine Types

High-Revs vs. Turbocharged Engines

High-revving engines and turbocharged engines both aim to deliver exceptional performance, but they achieve this in very different ways. High-revving engines rely on their ability to operate at extremely high revolutions per minute (RPM). This design allows them to produce power through rapid combustion cycles, offering immediate torque and a thrilling driving experience. Turbocharged engines, on the other hand, use forced induction to compress air into the engine, increasing power output without requiring higher RPMs.

One key difference lies in cost and complexity. High-revving engines demand advanced engineering and lightweight materials to handle the stress of high RPMs. This makes them more expensive to build and maintain. Turbocharged engines, however, achieve similar power levels with less intricate designs, making them more cost-effective. For example, a turbocharger can boost power by increasing air pressure, which requires fewer modifications to the engine’s core structure.

Another distinction is how these engines deliver power. High-revving engines excel in providing immediate responsiveness. You feel the power surge as soon as you push the throttle, making them ideal for racing and performance driving. Turbocharged engines, however, often experience a delay known as “turbo lag.” This occurs because the turbocharger needs time to spool up before delivering its full boost. While modern turbocharged engines have minimized this lag, the instantaneous nature of high-revs remains unmatched.

In terms of energy efficiency, turbocharged engines often have the upper hand. They generate power by utilizing exhaust gases, which would otherwise go to waste. High-revving engines, by contrast, consume more fuel due to their rapid combustion cycles. If you prioritize fuel economy alongside performance, turbocharged engines may offer a better balance.

High-Revs vs. Electric Motors

High-revving engines and electric motors represent two distinct approaches to performance. High-revving engines focus on maximizing power through high RPMs, creating an engaging and visceral driving experience. Electric motors, however, deliver instant torque from a standstill, offering seamless acceleration without the need for high RPMs.

One of the most noticeable differences is the sound and feel. High-revving engines produce a symphony of mechanical noise as they climb through the rev range. This auditory feedback enhances the emotional connection between you and the car. Electric motors, in contrast, operate almost silently. While this quietness appeals to some drivers, others may miss the raw excitement that comes with the roar of a high-revving engine.

Electric motors also excel in efficiency and simplicity. They convert energy into motion with minimal losses, making them more environmentally friendly. High-revving engines, while thrilling, consume more fuel and produce higher emissions. If sustainability matters to you, electric motors provide a clear advantage.

Performance-wise, electric motors shine in delivering consistent torque across all speeds. High-revving engines, however, require you to keep the engine within a specific RPM range to access peak power. This characteristic makes electric motors more user-friendly for everyday driving, while high-revving engines cater to enthusiasts who enjoy mastering the art of gear changes and throttle control.

In terms of maintenance, electric motors have fewer moving parts, reducing the likelihood of wear and tear. High-revving engines, with their complex designs and high-stress operation, demand regular upkeep to maintain peak performance. If you prefer a low-maintenance option, electric motors stand out as the more practical choice.

Both engine types offer unique benefits. High-revving engines captivate you with their sound, responsiveness, and connection to traditional performance driving. Electric motors impress with their efficiency, instant torque, and modern appeal. Your choice depends on whether you value the thrill of high-revs or the innovation of electric power.

High-revving engines define the essence of performance cars. They deliver exceptional power and speed, making them indispensable for those who crave thrilling driving experiences. These engines excel in maintaining top-end horsepower, ensuring you can sustain high speeds on roads or tracks. While they demand more maintenance and fuel, their benefits far outweigh the challenges for enthusiasts. The precision and responsiveness they offer create a unique connection between you and the car. Whether for racing or personal enjoyment, high-revving engines elevate driving to an art form.

FAQ

What are the advantages of revving so high?

High-revving engines offer several advantages that enhance performance. By operating at higher revolutions per minute (RPM), these engines complete more combustion cycles in less time. This results in greater power output and improved acceleration. You experience quicker throttle response and smoother power delivery, which makes driving more engaging. High-revs also allow you to maintain speed and control during high-performance scenarios, such as racing or spirited driving.

Is acceleration quicker when revving high compared to lower RPMs?

Yes, acceleration is generally quicker when you rev higher. High-revving engines generate more power at elevated RPMs, which translates to faster acceleration. When you rev to the engine’s optimal range, it produces maximum horsepower and torque, giving you a noticeable boost in speed. In contrast, revving at lower RPMs limits the engine’s power output, resulting in slower acceleration.

What’s the benefit of a high-revving engine with the same power as a low-revving one?

A high-revving engine with the same power as a low-revving engine offers better responsiveness and control. High-revs allow you to access power more quickly, making the engine feel more dynamic. You also benefit from smoother transitions between gears, which enhances the overall driving experience. Additionally, high-revving engines often provide a more exhilarating sound and feel, adding to the excitement of driving.

Does revving high every day shorten the engine’s lifespan?

Revving high daily can increase wear on engine components, but consistent maintenance can mitigate this. High-revving engines operate under greater stress, which accelerates wear on parts like pistons, valves, and crankshafts. However, if you follow a strict maintenance schedule, including regular oil changes and inspections, you can preserve the engine’s longevity. Proper care ensures that the engine remains reliable even with frequent high-revving use.

“The engine is revolving 2-3x as much when you rev high, but with consistent maintenance, the extra wear can be managed effectively.”

How bad is the extra wear caused by high-revving?

The extra wear caused by high-revving depends on how often and how long you push the engine to its limits. High RPMs generate more heat and friction, which can lead to faster degradation of components. However, modern high-revving engines are designed with advanced materials and engineering to handle these stresses. If you maintain the engine properly and avoid prolonged redline operation, the wear remains manageable.

Are high-revving engines less fuel-efficient?

Yes, high-revving engines consume more fuel compared to low-revving ones. The rapid combustion cycles required to achieve high RPMs burn more fuel in less time. This trade-off prioritizes performance over efficiency. If fuel economy is a concern, you may find high-revving engines less practical for daily driving. However, for enthusiasts, the thrill of high-revs often outweighs the reduced efficiency.

Why do racing vehicles rely on high-revving engines?

Racing vehicles rely on high-revving engines because they deliver maximum power and speed. These engines operate in their optimal RPM range, ensuring peak performance during competitions. High-revs allow racers to accelerate quickly, maintain high speeds, and respond instantly to throttle inputs. This level of precision and control is essential for achieving competitive lap times and dominating on the track.

Do high-revving engines require special materials?

Yes, high-revving engines use specialized materials to withstand extreme conditions. Lightweight yet durable materials like titanium and forged aluminum reduce stress on components while maintaining structural integrity. Advanced cooling systems and friction-reducing coatings also play a crucial role in managing the heat and wear generated at high RPMs. These innovations ensure that the engine performs reliably even under demanding conditions.

How do high-revving engines compare to turbocharged engines?

High-revving engines and turbocharged engines achieve performance differently. High-revving engines rely on rapid combustion cycles at elevated RPMs, offering immediate throttle response and a thrilling driving experience. Turbocharged engines use forced induction to compress air, increasing power without requiring high RPMs. While turbocharged engines are more fuel-efficient and cost-effective, high-revving engines excel in delivering raw, responsive power.

Are high-revving engines suitable for everyday driving?

High-revving engines can be used for everyday driving, but they may not be the most practical choice. Their design prioritizes performance over fuel efficiency and comfort. You may find them less efficient in stop-and-go traffic, where low-revving engines perform better. However, if you value excitement and precision in your daily commute, a high-revving engine can make driving more enjoyable.